Device for increasing recovery rate of aromatic hydrocarbons of oxidized tail gas of hydrogen peroxide

A technology for oxidizing tail gas and recovery rate, which is applied in the direction of combined devices, steam condensation, chemical instruments and methods, etc., can solve problems such as running loss, environmental pollution, and strong volatility of aromatics, so as to prolong service life, reduce environmental pollution, reduce Effect of Aromatics Concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

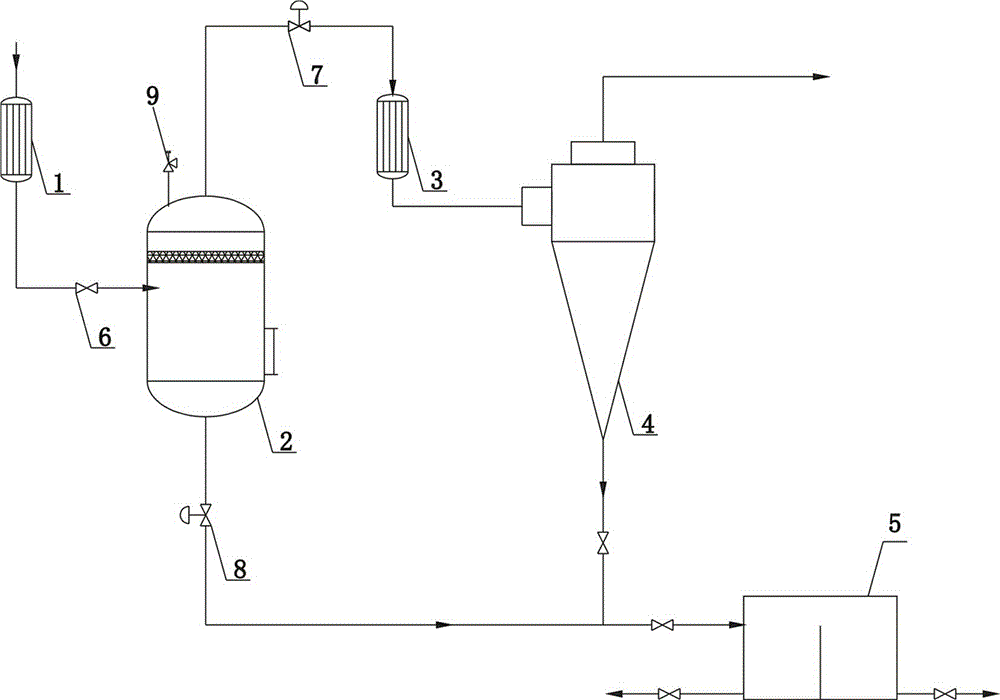

[0017] Such as figure 1 As shown, a device for improving the recovery rate of aromatics in hydrogen peroxide oxidation tail gas includes a primary condenser 1, an intermediate separation tank 2, a secondary condenser 3, a cyclone separator 4 and an oil-water separator 5. The primary condenser 1 is connected to the intermediate separation tank 2 through a pipeline, the top gas phase outlet of the intermediate separation tank 2 is connected to the top of the secondary condenser 3 through a pipeline, and the bottom liquid phase outlet is connected to the oil-water separator 5 through a pipeline; the secondary condenser The outlet of 3 is connected with the inlet of cyclone separator 4; the outlet of liquid phase at the bottom of cyclone separator 4 is connected to oil-water separator 5 through pipelines. The lower part of the intermediate separation tank 2 is provided with a liquid level gauge, and a wire mesh demister and an eddy current prevention baffle are arranged inside. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com