Patents

Literature

53results about How to "Extended one-way service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

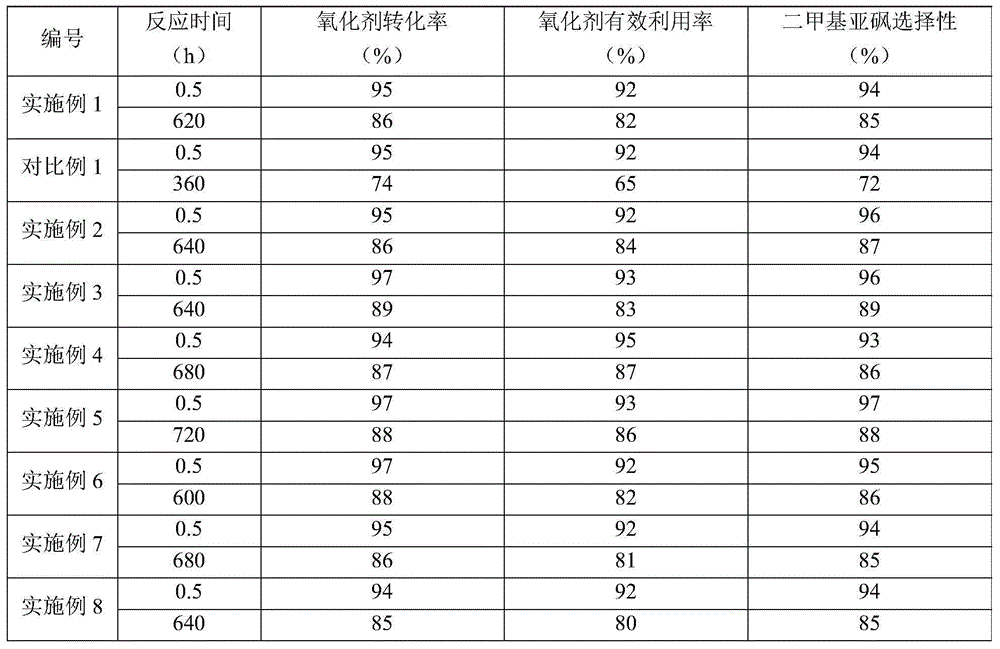

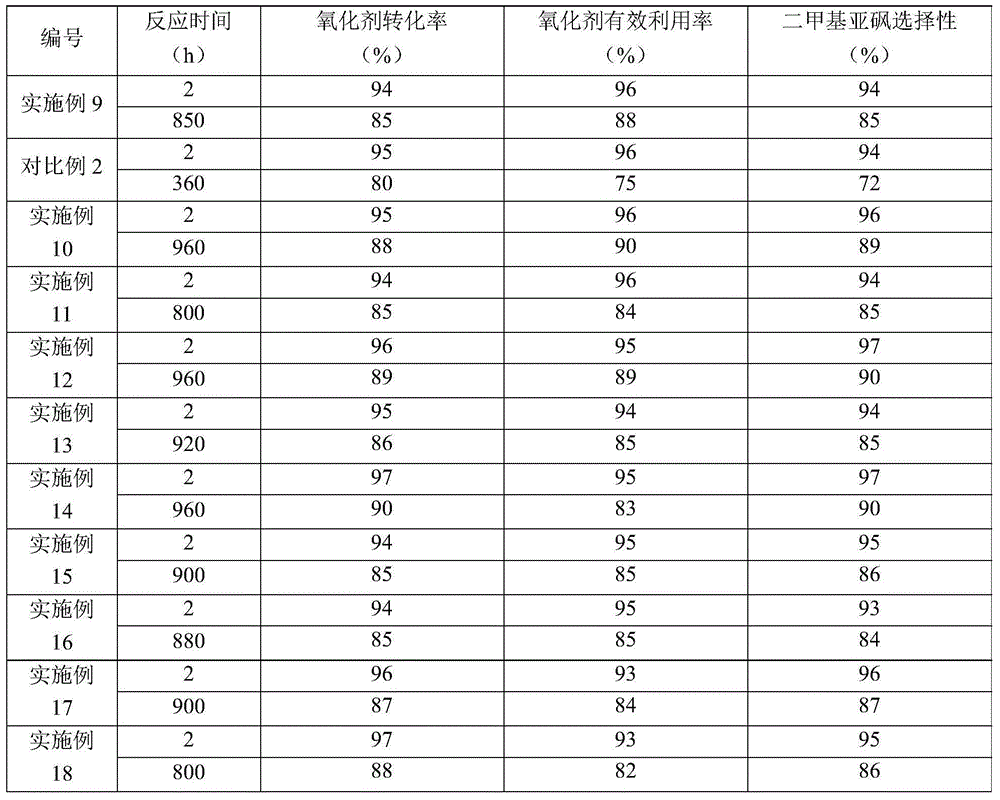

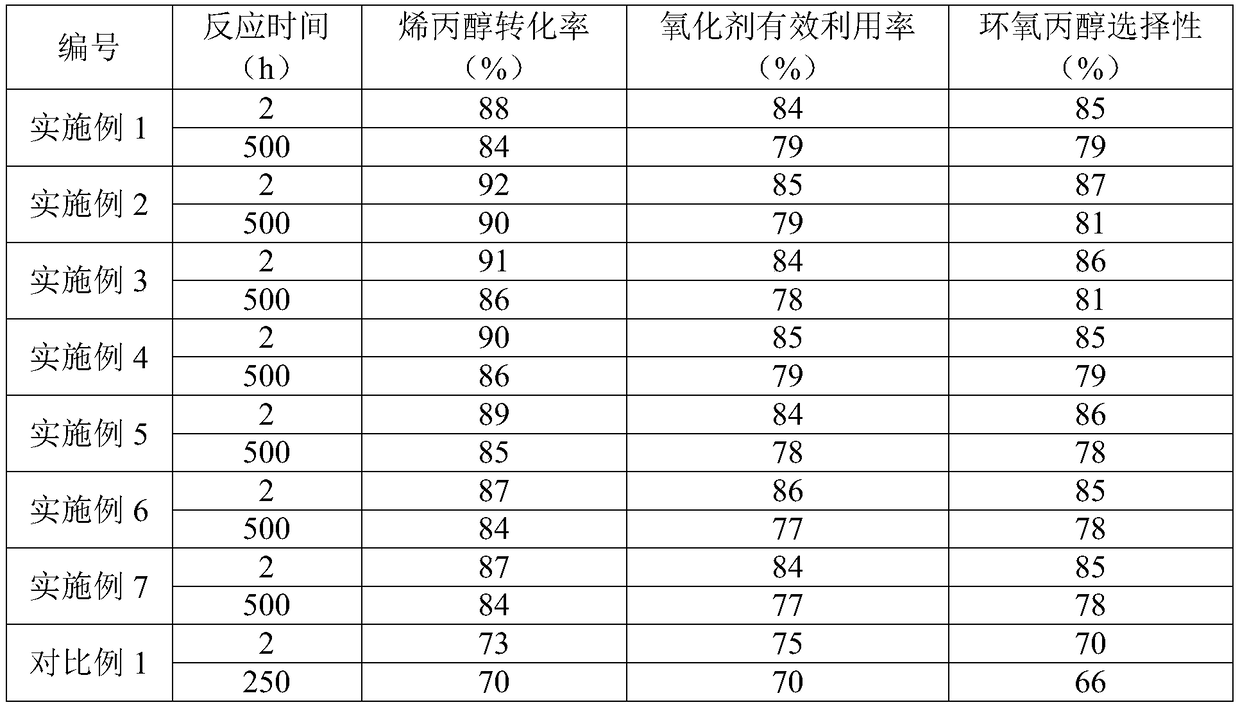

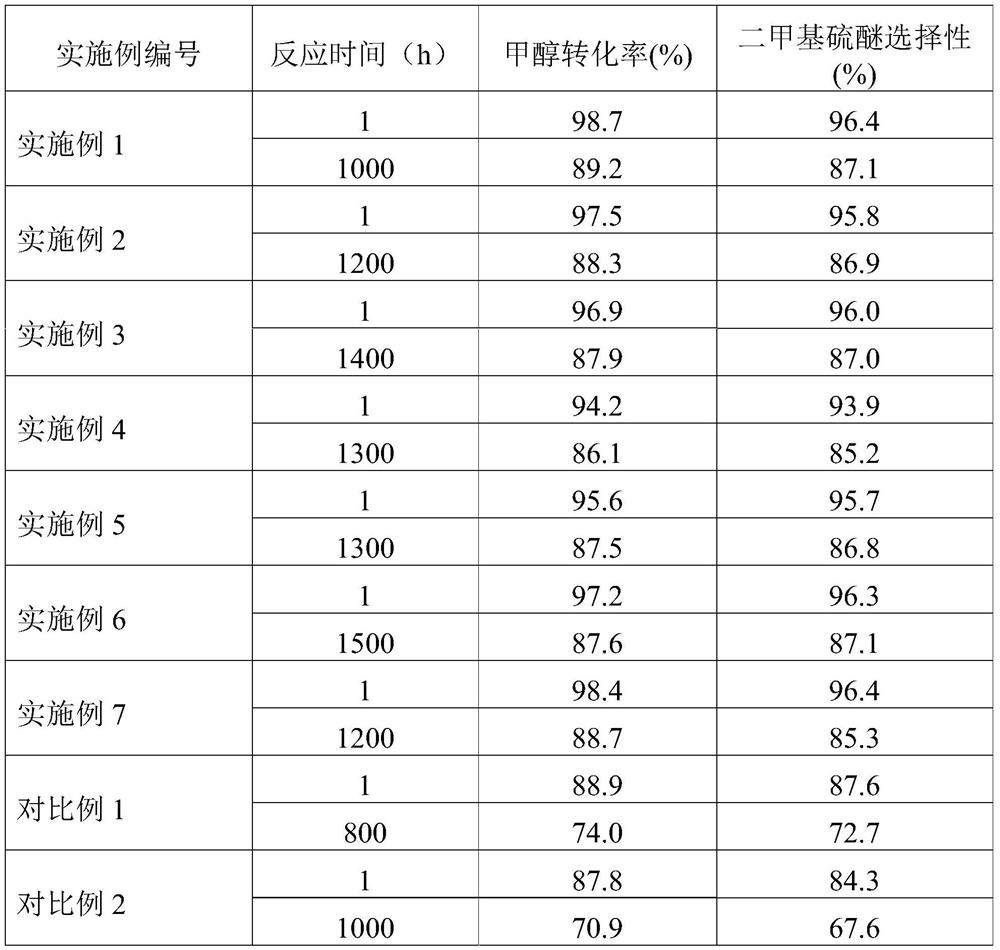

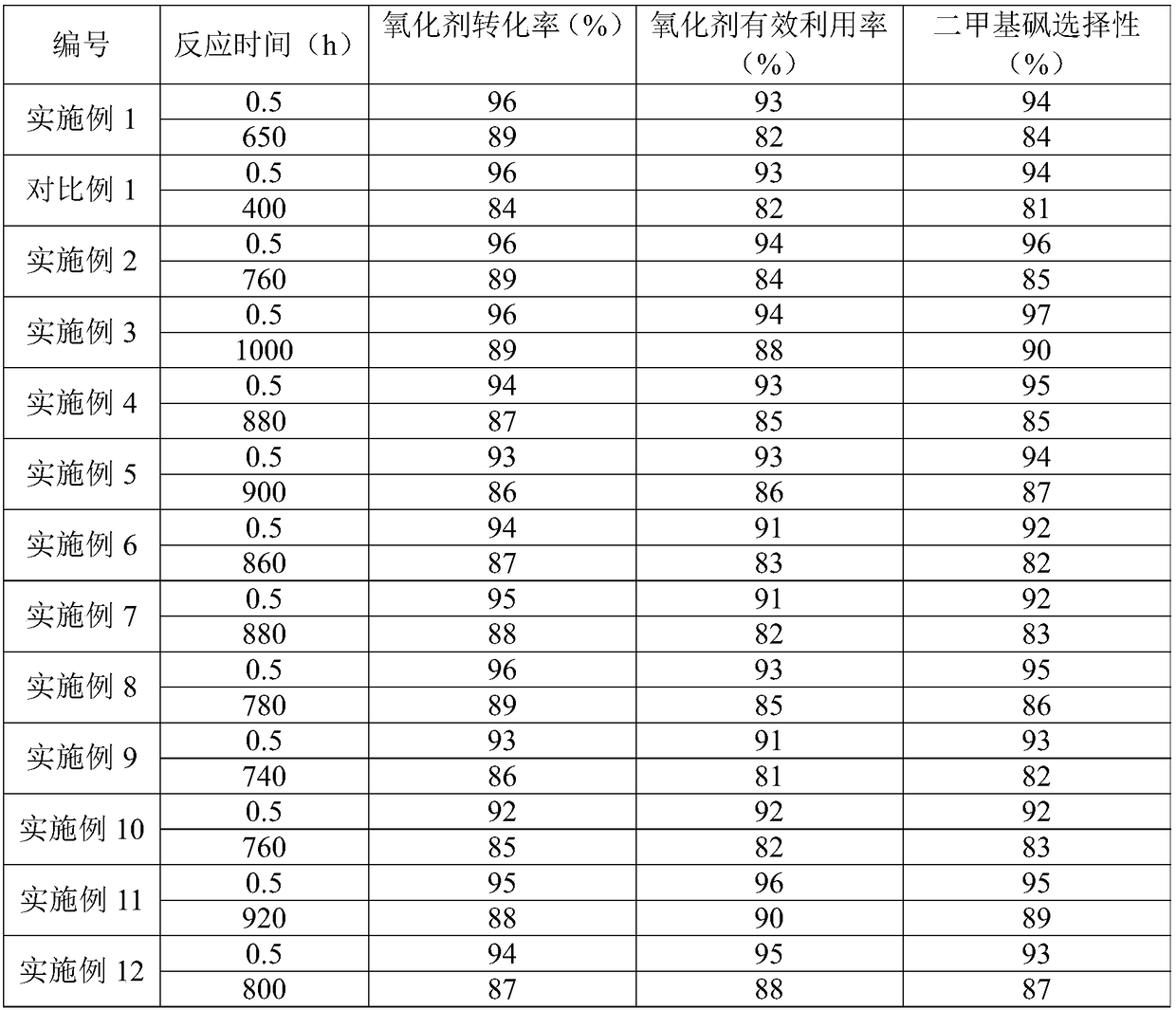

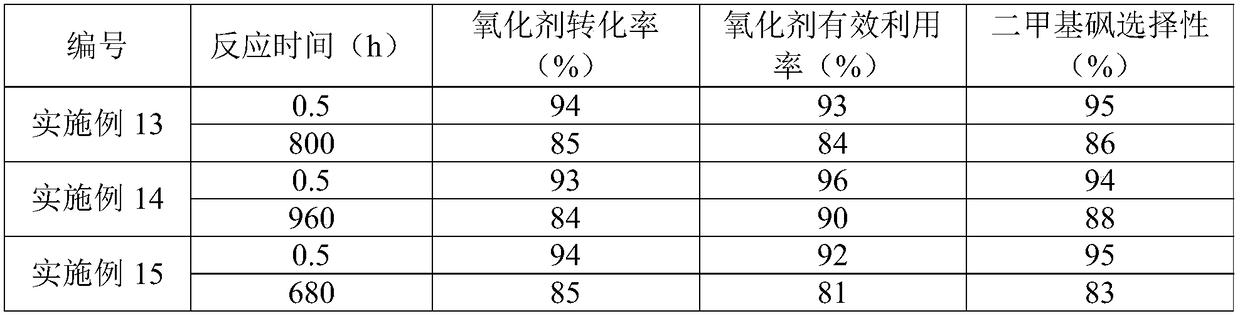

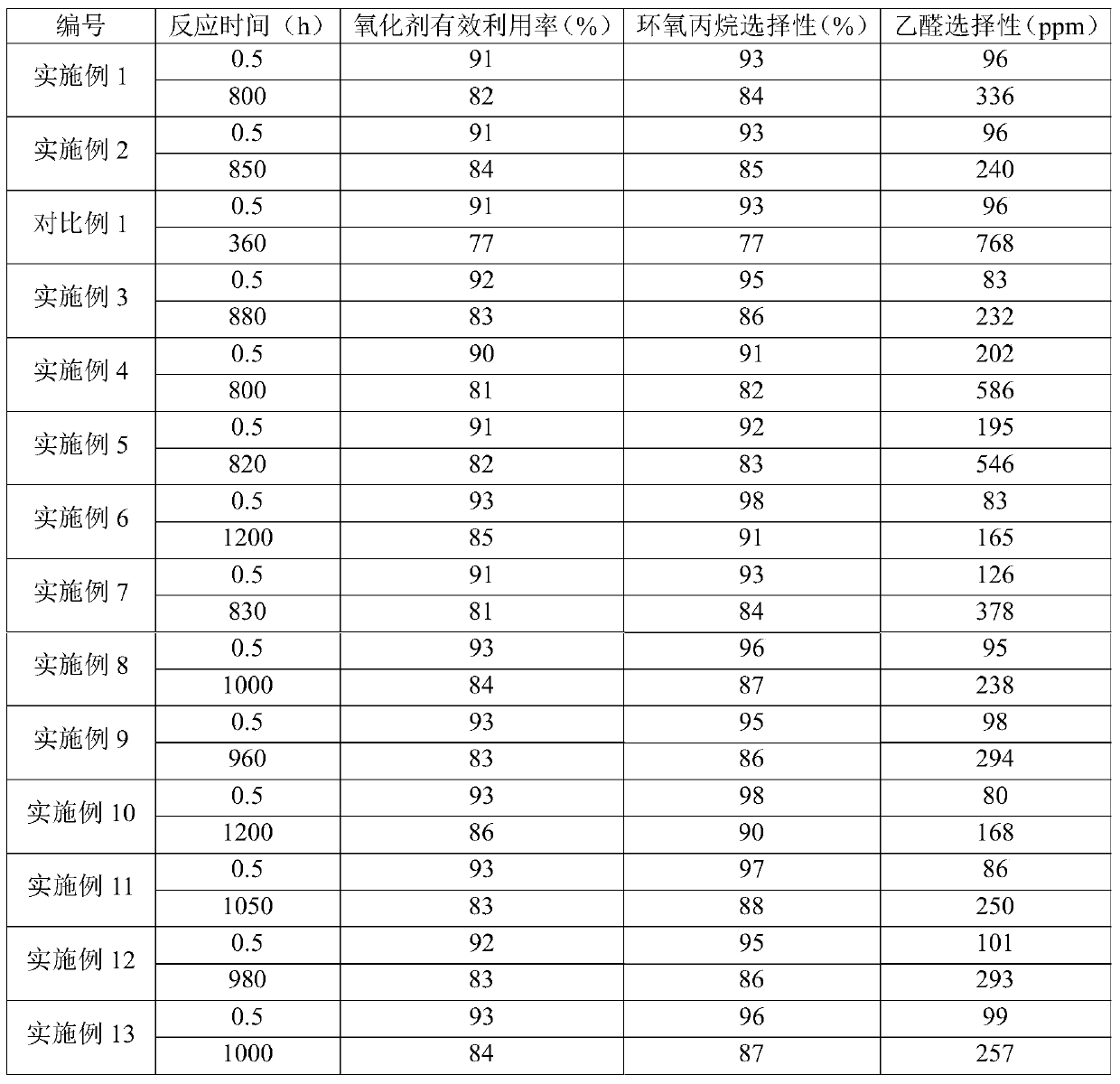

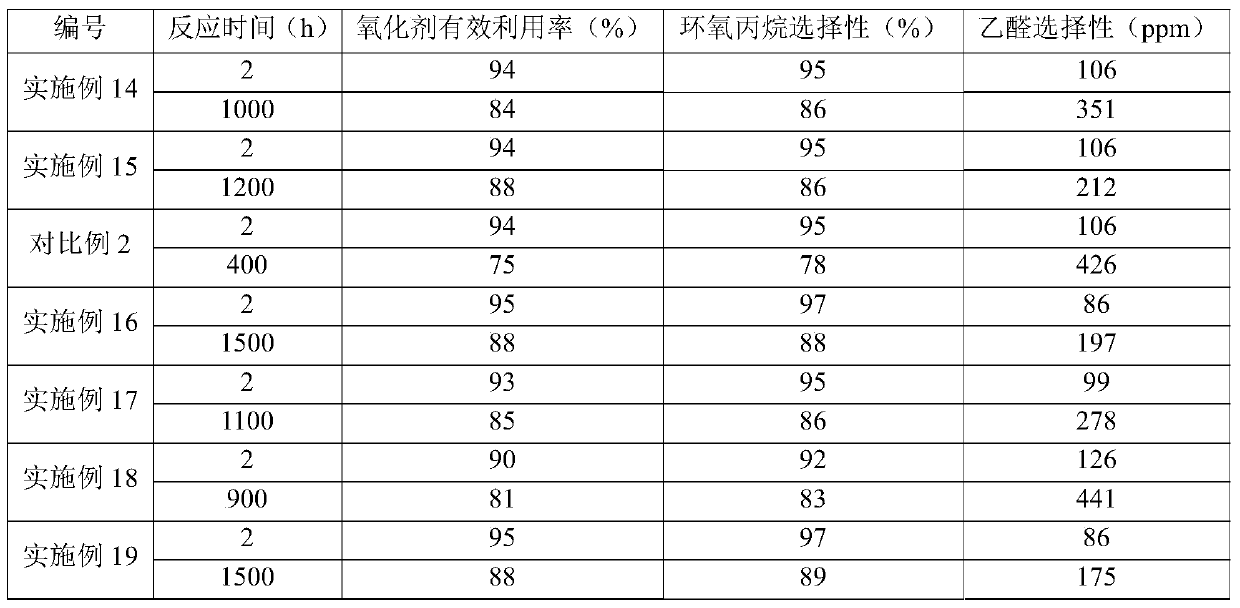

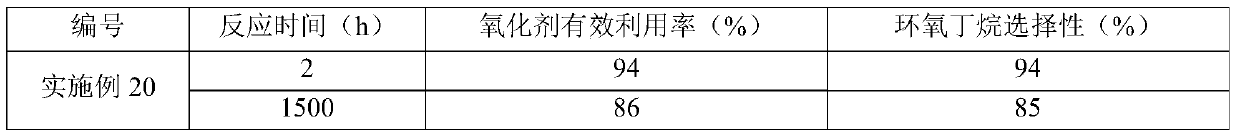

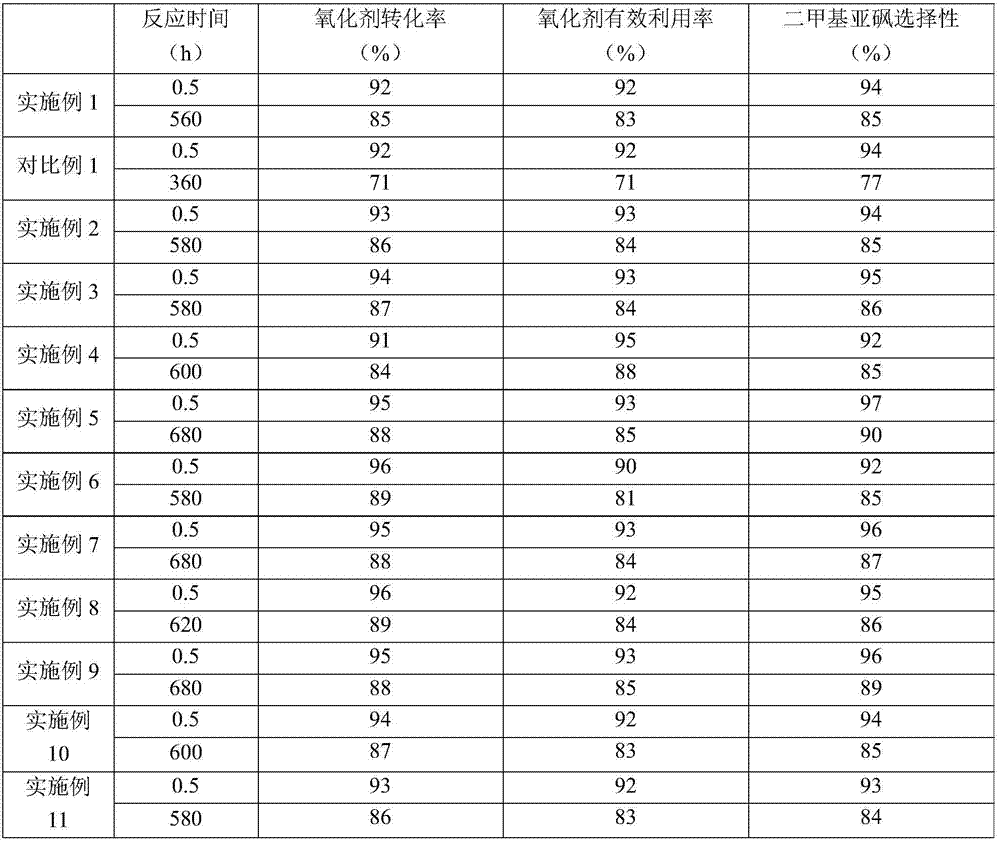

Thioether oxidation method

ActiveCN105384666AExtended one-way service lifeExtended service lifeOrganic chemistryOrganic compound preparationMolecular sieveFixed bed

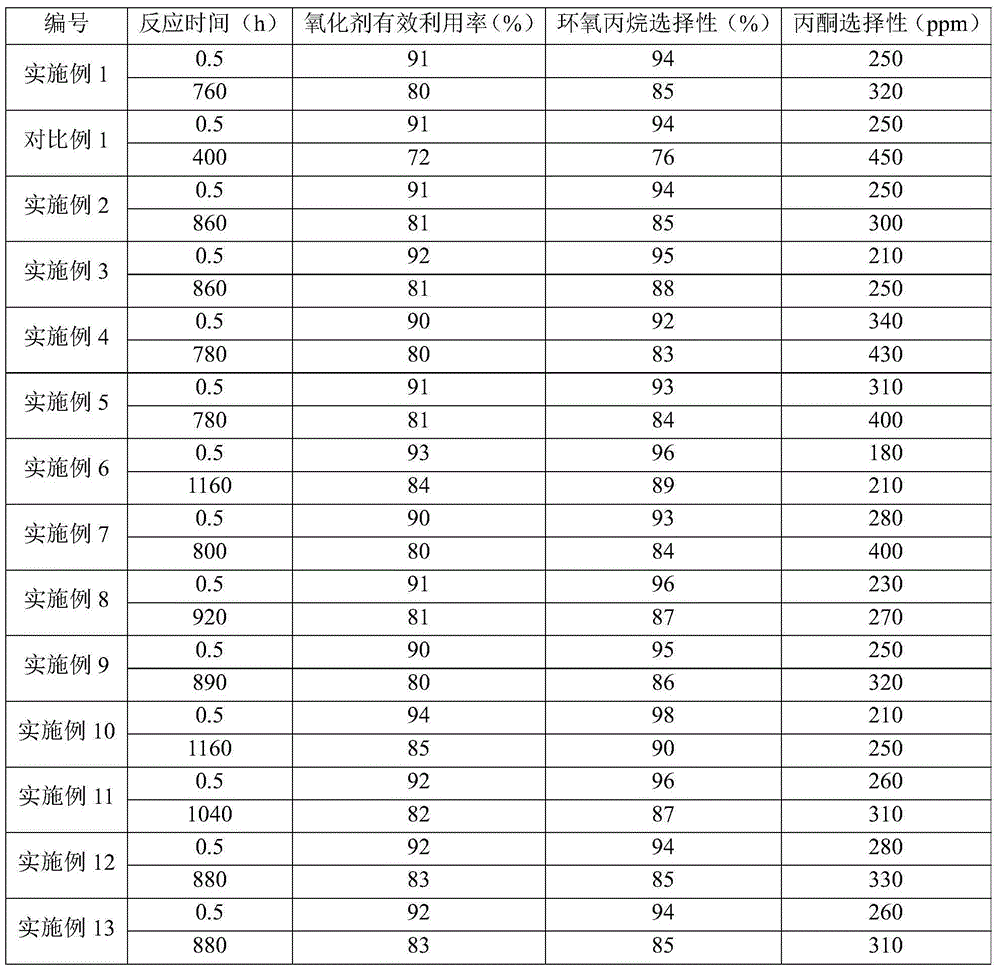

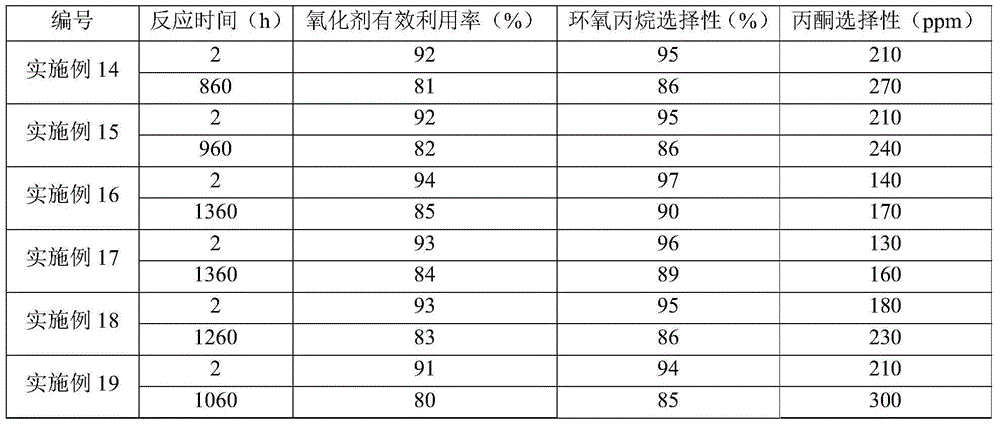

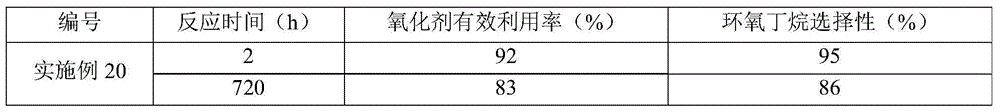

The present invention discloses a thioether oxidation method, which comprises: continuously conveying a liquid mixture into a fixed-bed reactor to make the liquid mixture contact a titanium silicon molecular sieve loaded in the fixed-bed reactor under an oxidation reaction condition, wherein the liquid mixture contains thioether, at least an oxidizing agent and at least a solvent, and the method further comprises that: when the oxidizing agent conversion rate or the target oxidation product selectivity is reduced to a certain degree, the weight hourly space velocity of the solvent is improved until the oxidizing agent conversion rate and / or the target oxidation product selectivity meets the requirement. With the method of the present invention, the one way service life of the titanium silicon molecular sieve adopted as the catalyst can be effectively prolonged, the regeneration frequency of the catalyst can be reduced, the production efficiency can be improved, the operation stability can be improved, and the total service life of the catalyst can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

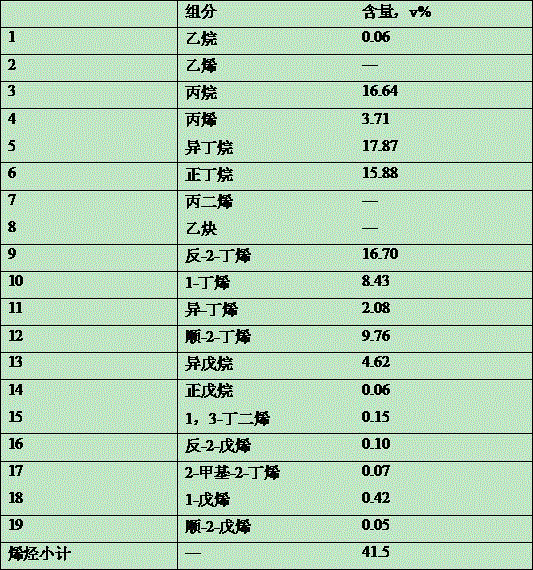

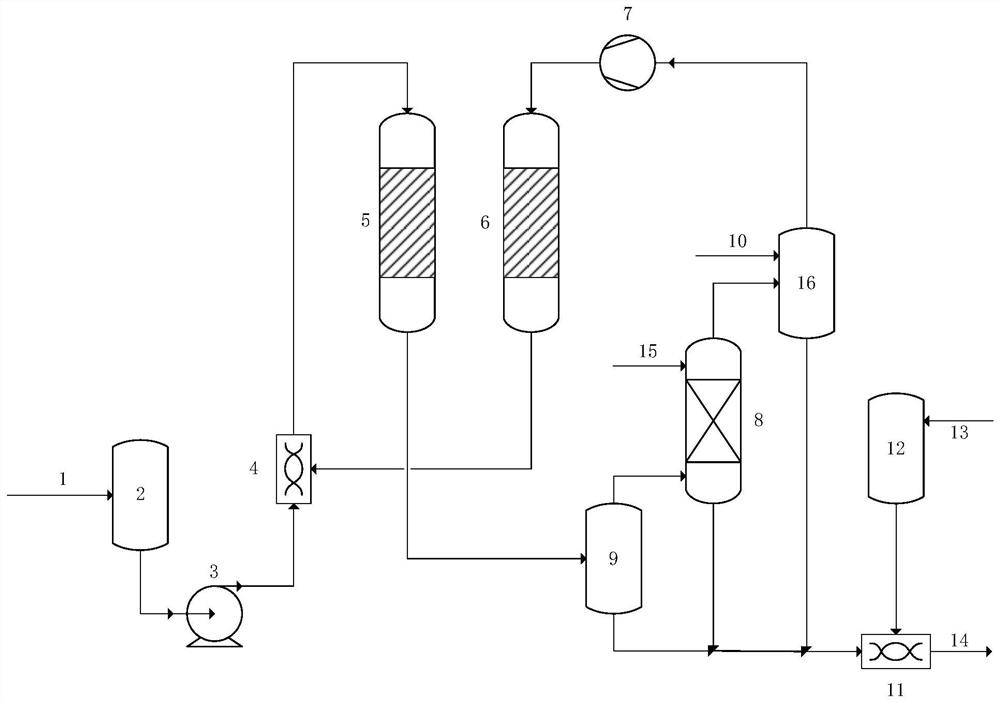

Method for preparing ethylene cracking feed by hydrogenation of liquefied gas

ActiveCN106753561AReduce reaction temperature rise"warm bag" gentleGaseous mixture working upHydrocarbon oils treatment productsHydrogenation reactionReaction temperature

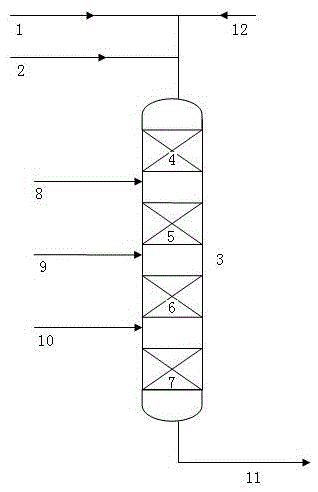

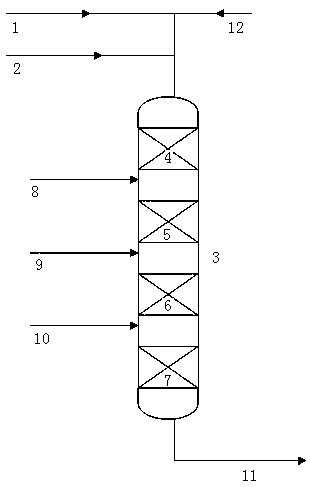

The invention discloses a method for preparing ethylene cracking feed by hydrogenation of liquefied gas. Liquefied gas and hydrogen pass through a hydrogenation reactor in a parallel flow manner and is in contact with hydrogenation catalysts for reaction; two or more hydrogenation catalyst bed layers are arranged in the hydrogenation reactor; the hydrogen enters the two or more hydrogenation catalyst bed layers from different feeding openings respectively; the amounts of the hydrogen entering all the hydrogenation catalyst bed layers are 5 to 95 volume percent of chemical hydrogen consumption required by reaction separately; except the last hydrogenation catalyst bed layer, the sum of total amounts of the hydrogen entering other hydrogenation catalyst bed layers is smaller than the required chemical hydrogen consumption. According to the method disclosed by the invention, by controlling partial pressures of the hydrogen entering different catalyst bed layers, the reaction speed is effectively controlled, and accurate control over the conversion rate is realized, so that reaction temperature rise of all sections of catalyst bed layers in the reactor is reduced, further the carbon deposit speed of the catalyst is retarded, and the single-pass service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

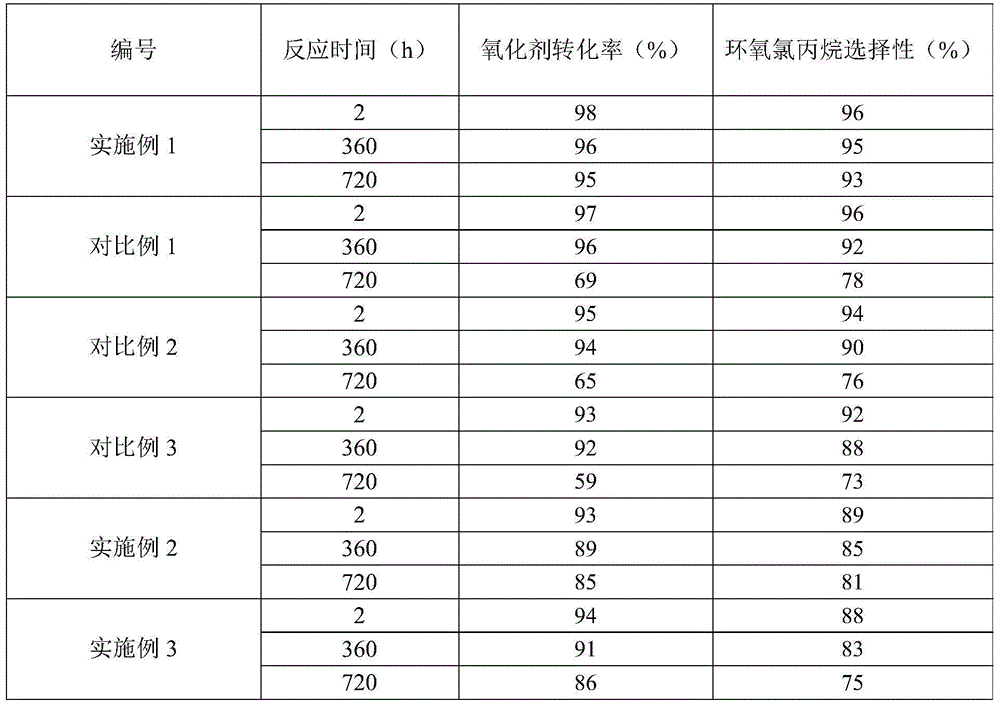

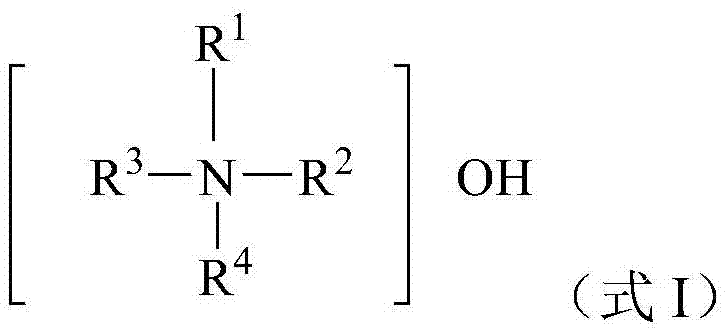

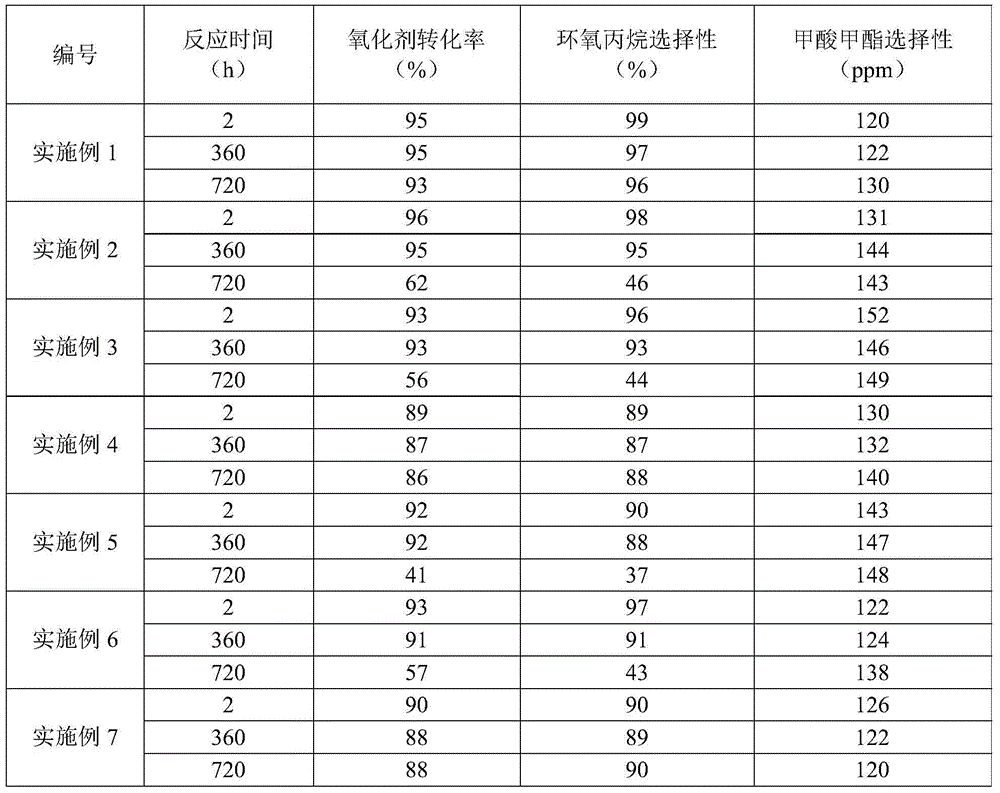

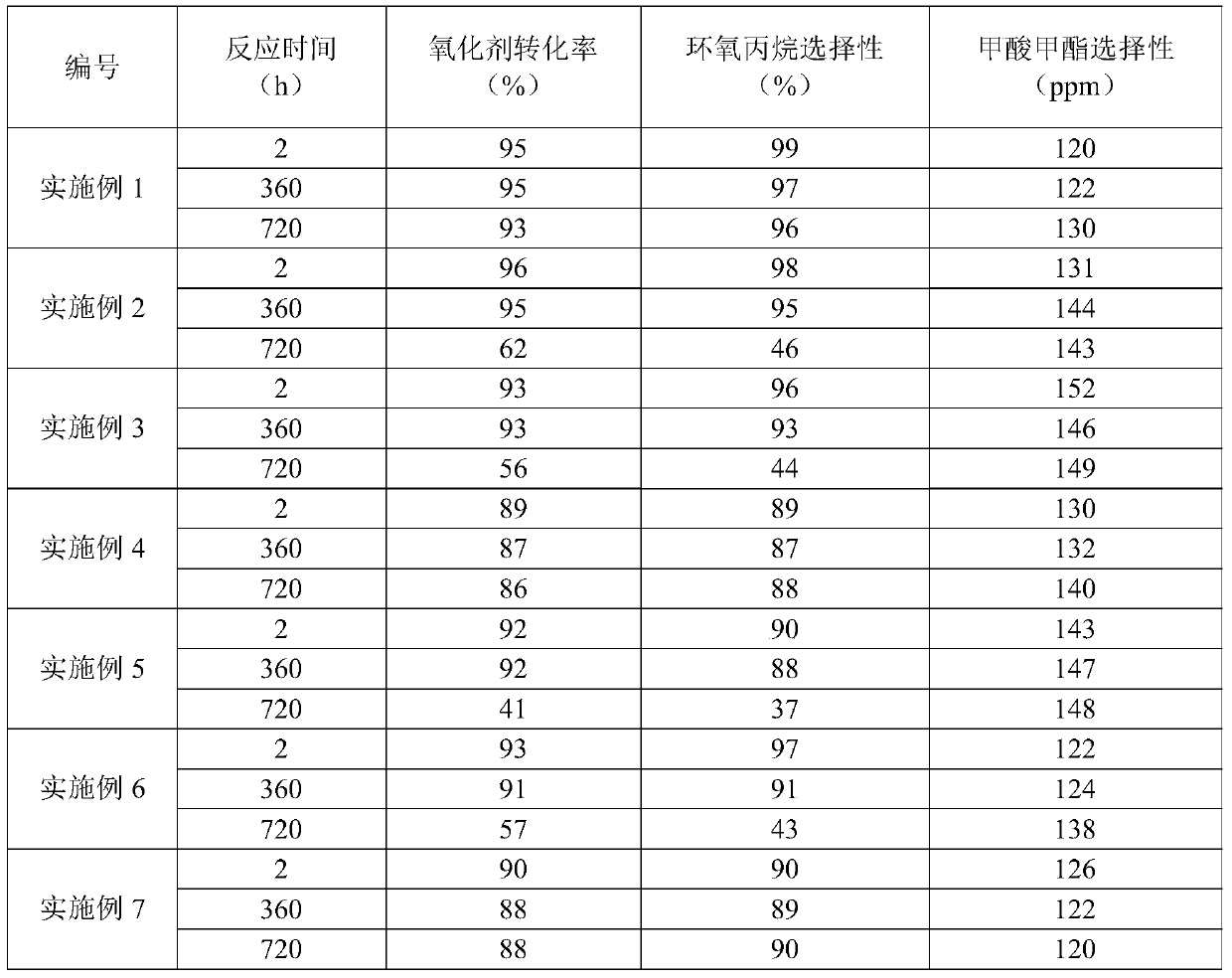

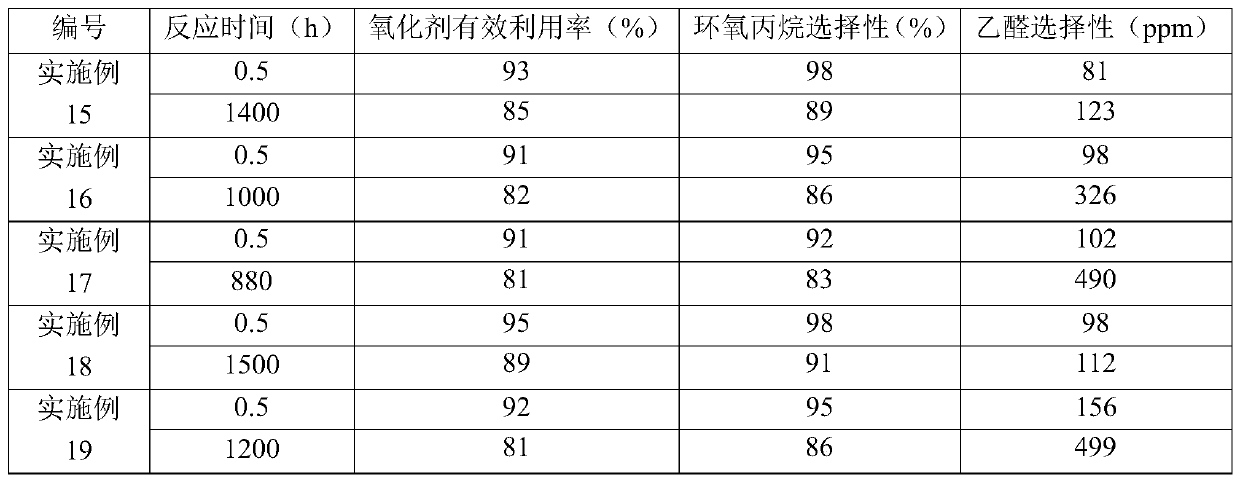

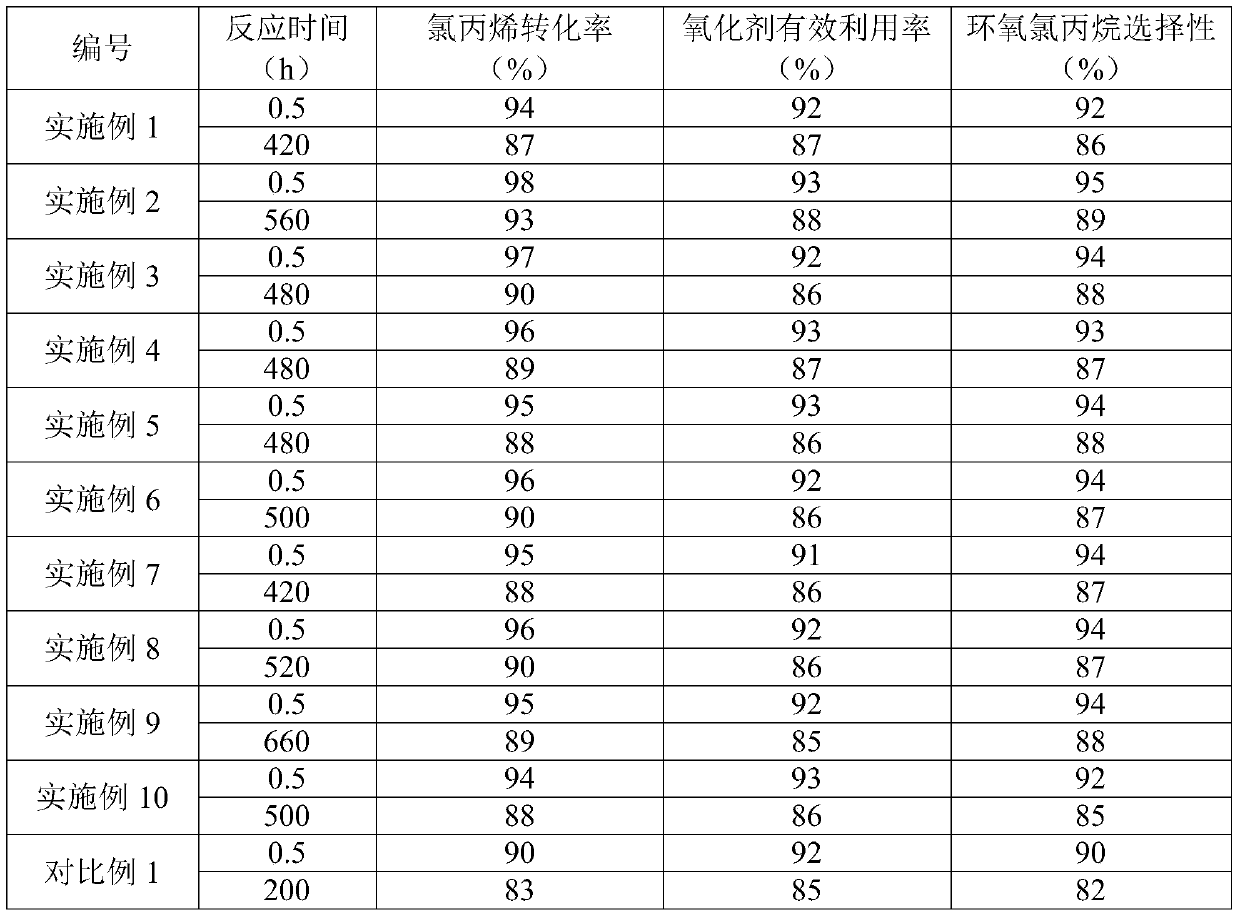

Chloropropene oxidation method

ActiveCN105524028AExtended one-way service lifeReduce regeneration frequencyOrganic chemistryEpoxideMolecular sieve

The invention provides a chloropropene oxidation method. The method comprises the following steps: under oxidation reaction conditions, a liquid mixture comprising chloropropene and an oxidant flows through a catalyst bed layer. The catalyst bed layer comprises a first catalyst bed layer and a second catalyst bed layer. With the flow direction of the liquid mixture as a standard, the first catalyst bed layer is positioned upstream of the second catalyst bed layer. The titanium silicalite molecular sieve loaded in the first catalyst bed layer is hollow titanium silicalite molecular sieve. The titanium silicalite molecular sieve loaded in the second catalyst bed layer is a titanium silicalite molecular sieve different from the hollow titanium silicalite molecular sieve. When the method provided by the invention is used for oxidizing chloropropene, during a long-time continuous running process, a relatively stable oxidant conversion rate and a relatively high target oxidation product selectivity can be obtained. Especially, with the method provided by the invention, epoxide selectivity is high, such that subsequent separation purification difficulty is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

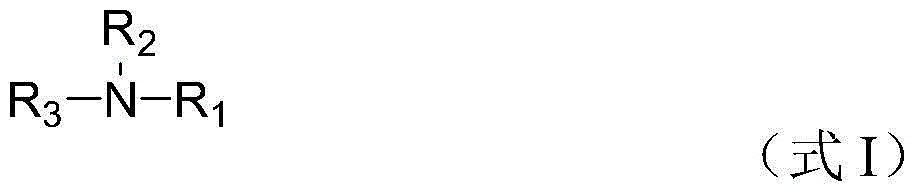

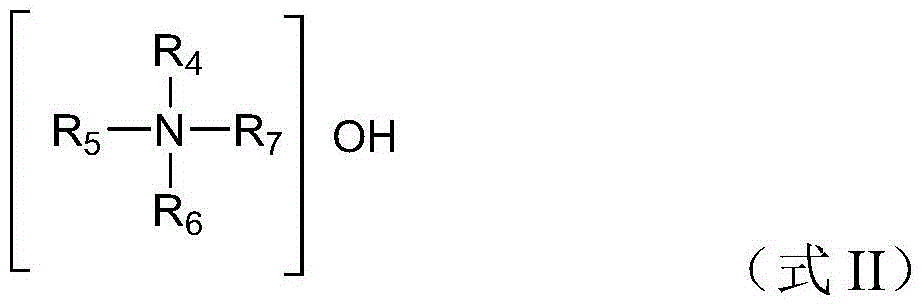

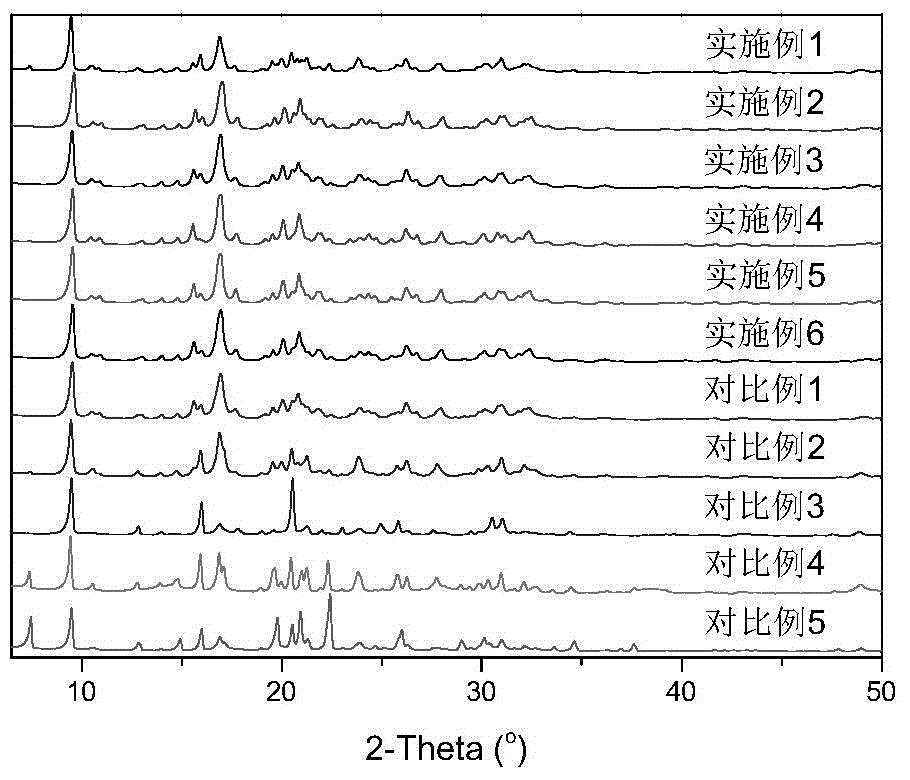

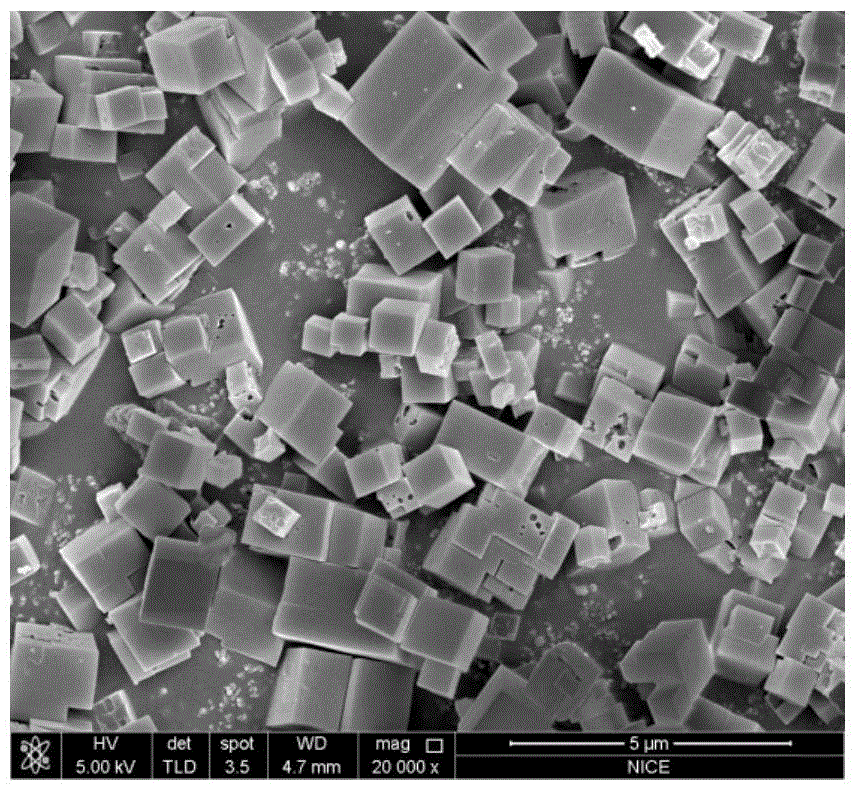

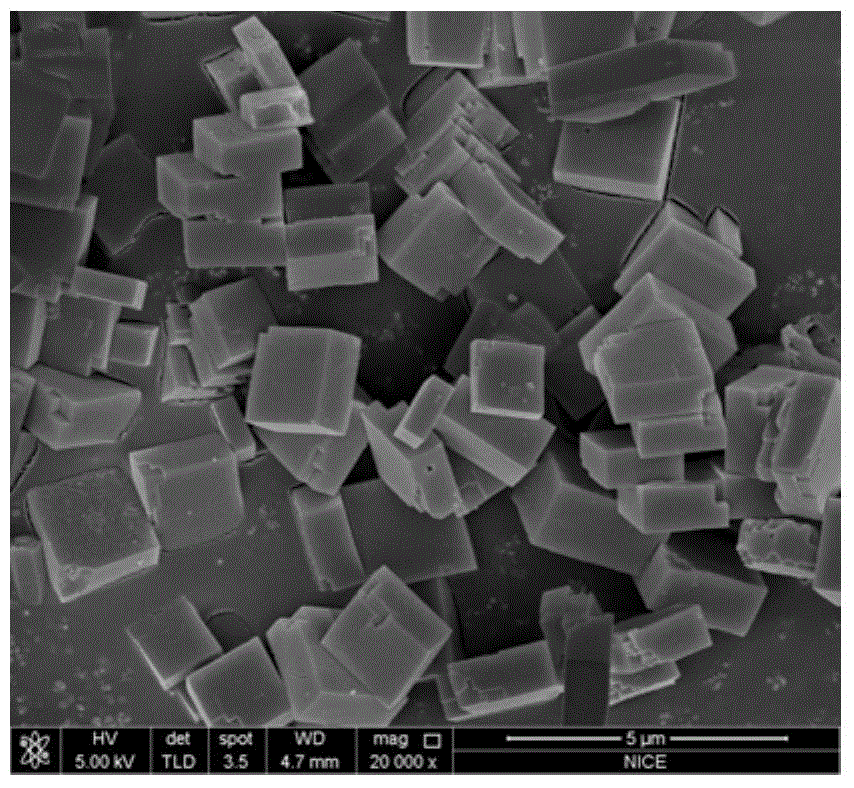

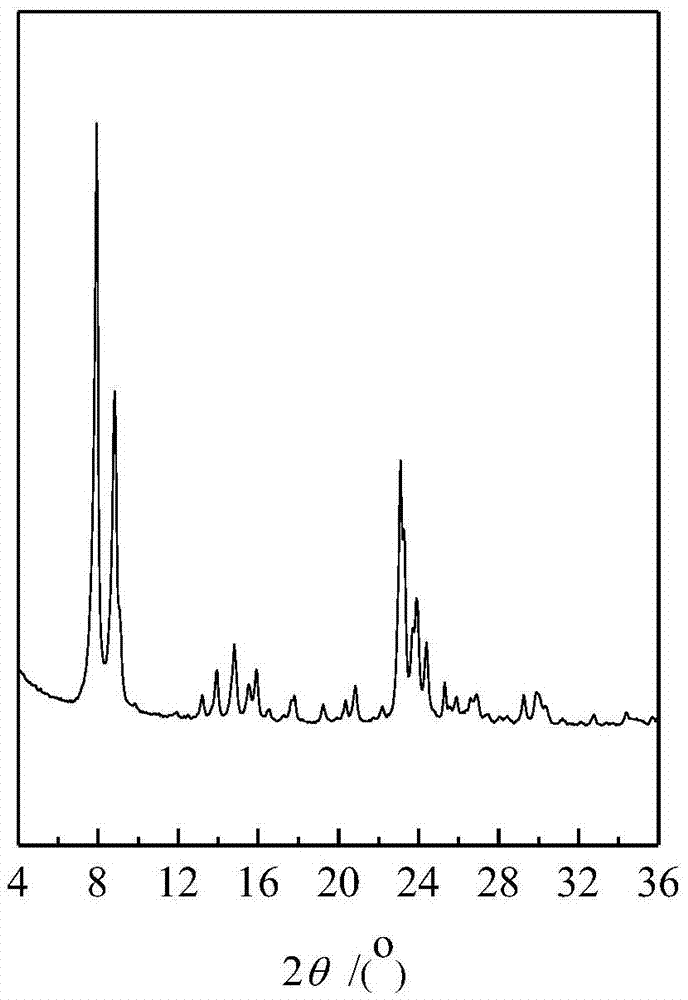

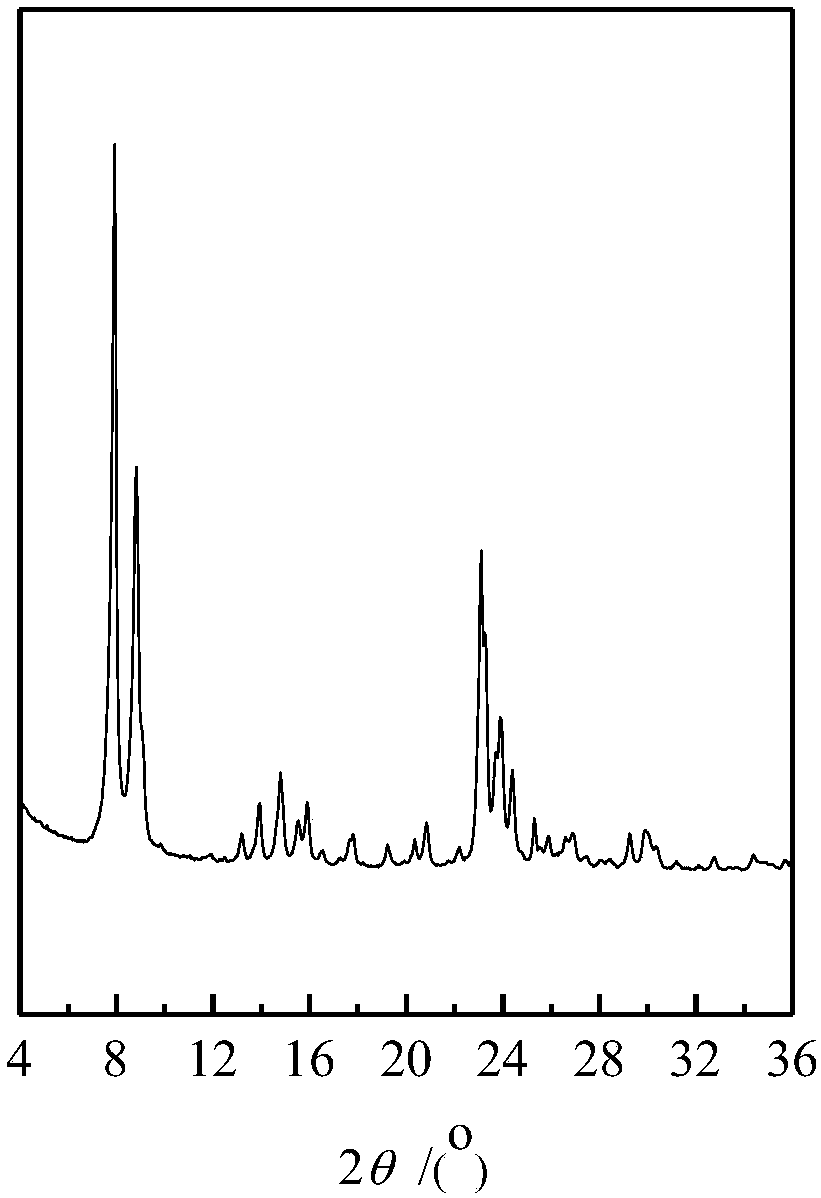

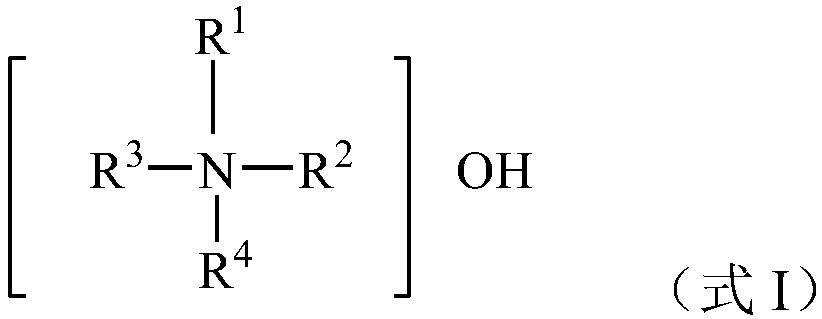

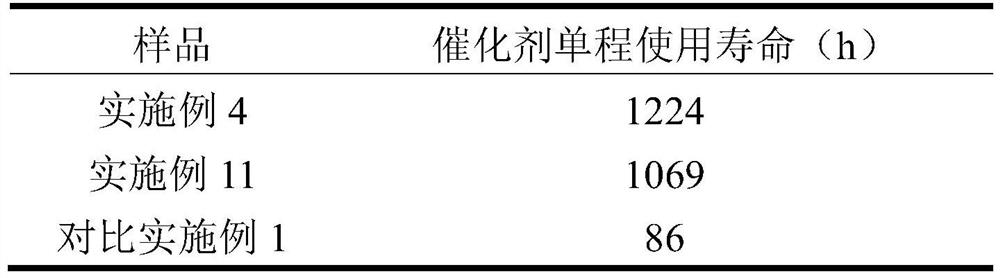

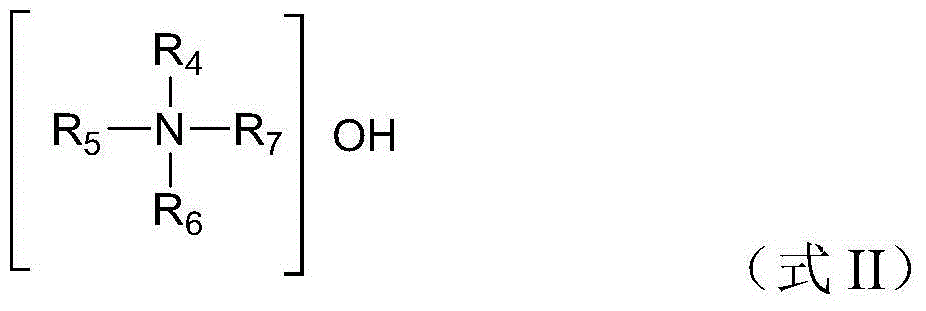

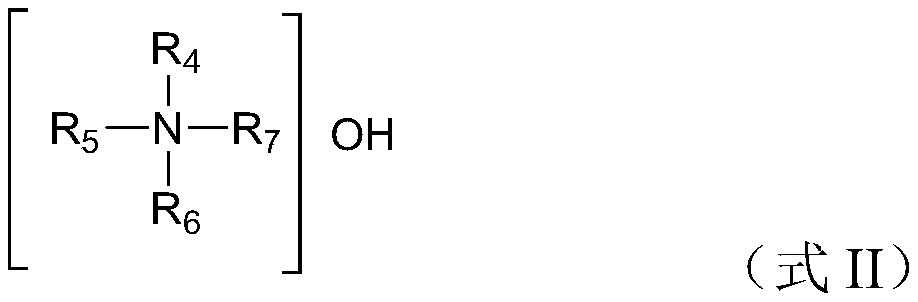

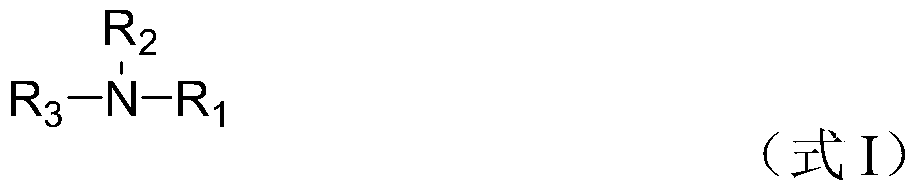

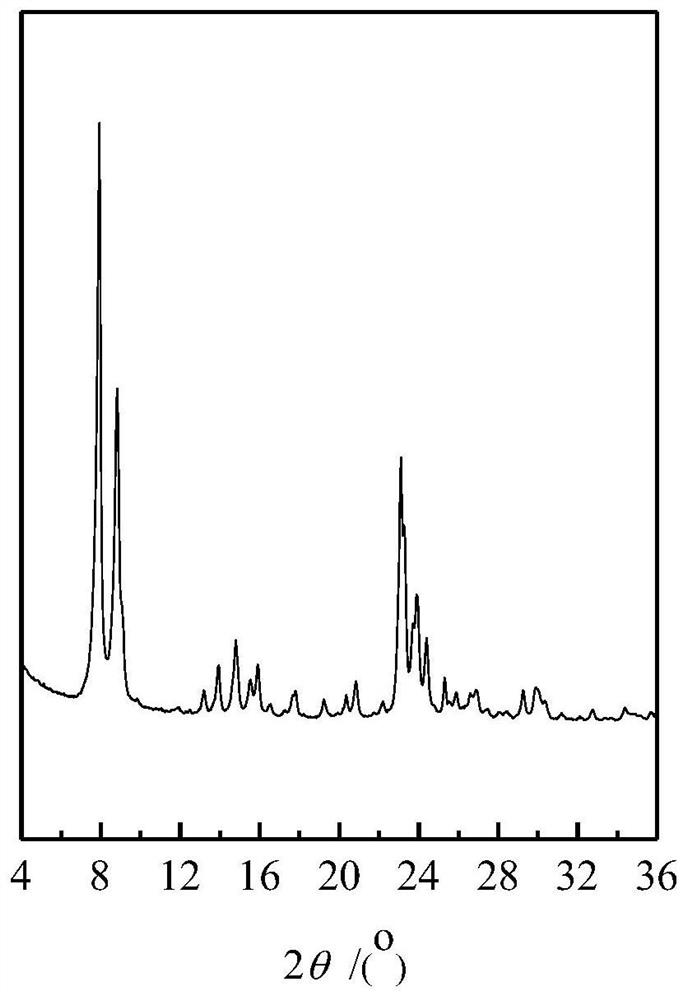

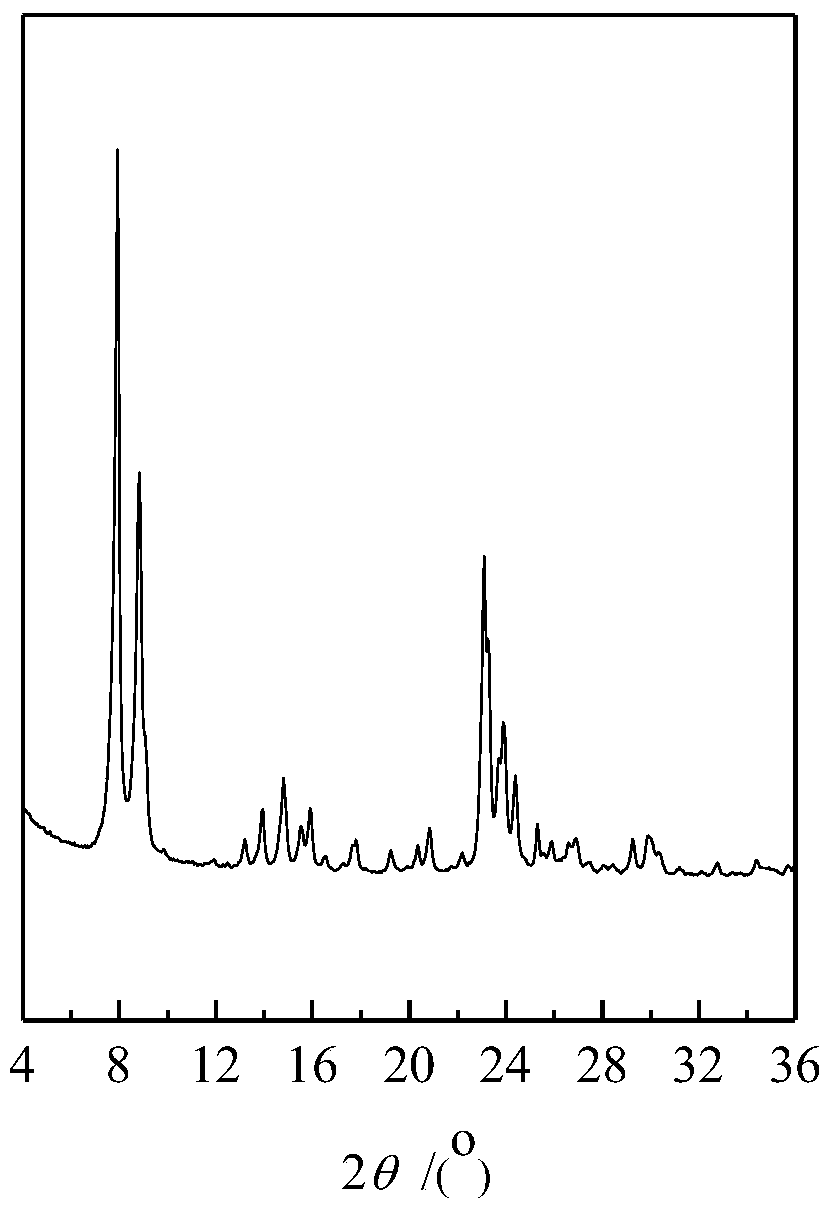

SAPO-18 molecular sieve, method for synthesizing SAPO-18 molecular sieve and method for preparing olefin from methanol

ActiveCN105271302AHigh yieldHigh crystallinityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveIsopropylamine

The invention discloses a method for synthesizing a SAPO-18 molecular sieve. According to the method, a composite template agent is adopted, and N,N-diisopropylethylamine is combined with at least one template agent of triethylamine, diethylamine and isopropylamine for use, so that the time of hydrothermal crystallization is shortened, and the yield of the molecular sieve is increased. The SAPO-18 molecular sieve has a regular appearance and a relatively high crystallinity. The invention further provides a method for preparing olefin from methanol. In the method, the SAPO-18 molecular sieve serving as a catalyst has a high selectivity of light olefins, and has a long single-pass service life.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

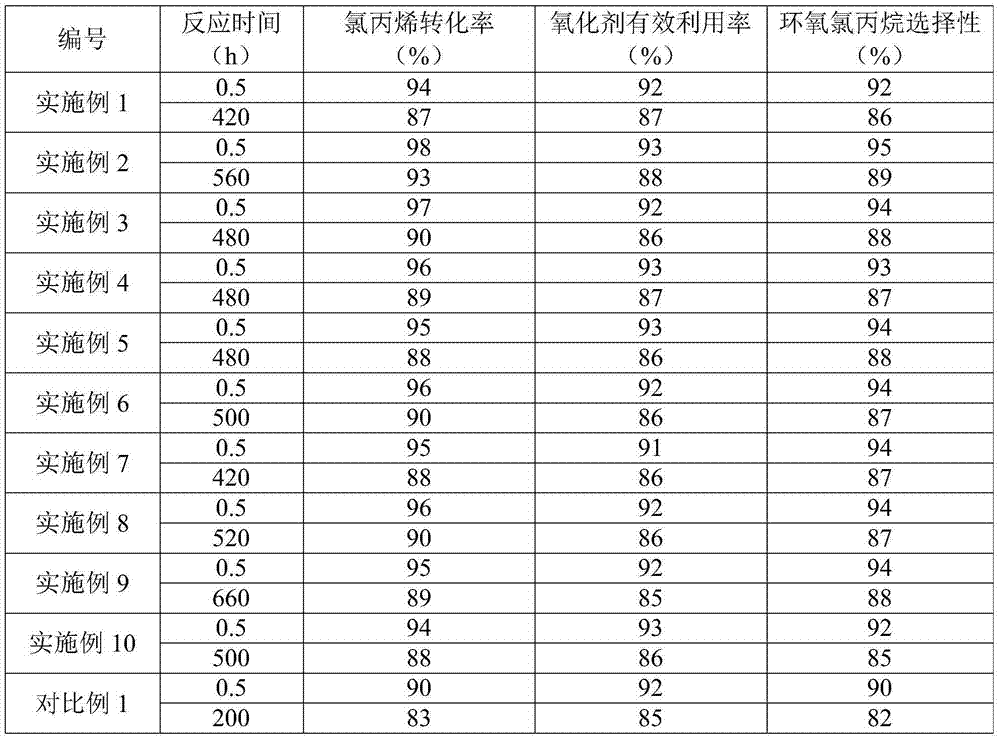

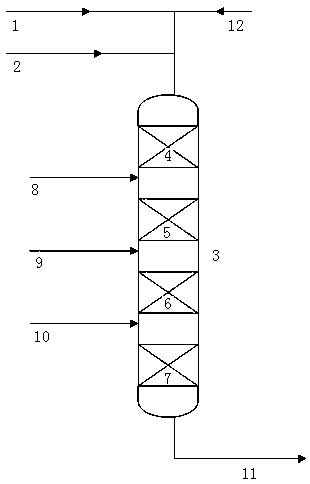

Allyl chloride oxidation method

ActiveCN106967010AExtended one-way service lifeExtended service lifeOrganic chemistryMolecular sieve catalystsMolecular sieveApparent velocity

The present invention discloses an allyl chloride oxidation method, which comprises that a reaction material containing allyl chloride, an oxidizing agent and a solvent sequentially flows through catalyst bed layers from 1 to n under an oxidation reaction condition, wherein n is an integer of more than 2, and the catalyst bed layer is filled with at least a titanium-silicon molecular sieve; and when the reaction material passes through the catalyst bed layers from 1 to n, at least a flow carrier is introduced into the position between at least a pair of the adjacent catalyst bed layers among the catalyst bed layers from 1 to n, such that the apparent velocity of the reaction stream positioned in the downstream catalyst bed layer is higher than the apparent velocity of the reaction stream positioned in the upstream catalyst bed layer in the pair of the adjacent catalyst bed layers by adopting the flowing direction of the reaction material as the reference. With the method of the present invention, the one-way service life of the titanium-silicon molecular sieve can be effectively prolonged, the effective utilization rate of the oxidizing agent can be improved, and the target product selectivity can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ethylene cracking material through liquefied gas hydrogenation

ActiveCN108085061AControl reaction speedAchieve conversion rateGaseous mixture working upHydrocarbon oils treatment productsReaction speedHydrogenation reaction

The invention discloses a method for producing an ethylene cracking material through liquefied gas hydrogenation. The method is characterized in that liquefied gas and hydrogen pass through a hydrogenation reactor through a cocurrent flowing mode, then are contacted with a hydrogenation catalyst under hydrogenation technical condition and subjected to a reaction; the hydrogenation reactor comprises more than two reaction segments, and according to a contact sequence with a reaction material, the activity of the catalyst in a downstream reaction segment is higher than the activity of the catalyst in an upstream reaction segment. The method reduces the relative average reaction speed at an entrance of a catalyst bed layer, changes problem of large relative average reaction speed at the entrance of the catalyst bed layer, a difference of the average reaction speed of each segment of the catalyst bed layer is greatly reduced, and the relative average reaction speed of each segment of the catalyst bed layer is more uniform.

Owner:CHINA PETROLEUM & CHEM CORP +1

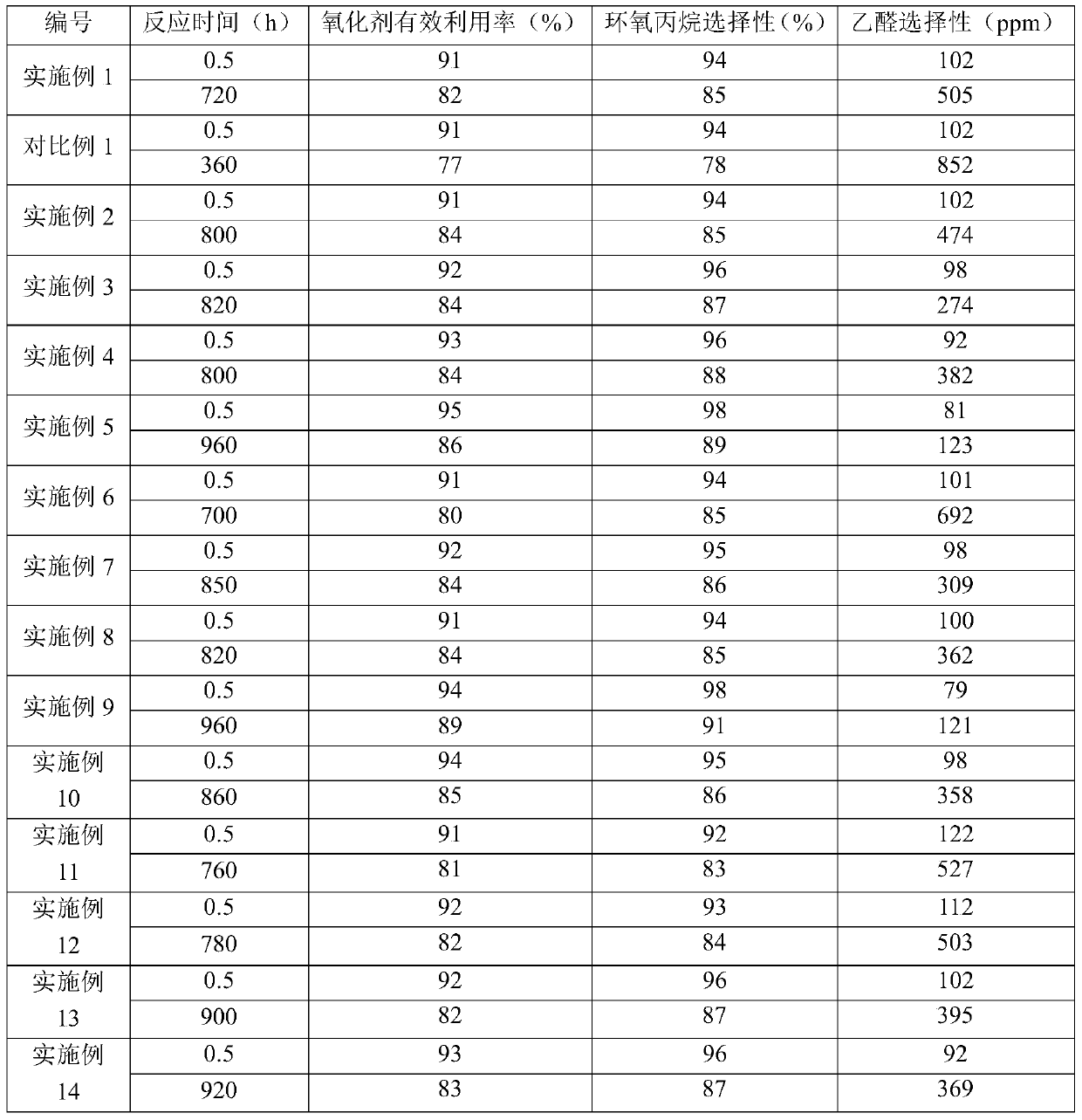

Oxidation method for allyl alcohol

ActiveCN108250161AExtended one-way service lifeExtended service lifeOrganic chemistryMolecular sieve catalystsSolventPeroxide

The invention relates to an oxidation method for allyl alcohol. The oxidation method comprises a step of, under oxidation reaction conditions, allowing a reaction feed containing allyl alcohol, an oxidizing agent and at least one optional solvent to sequentially flow through a first catalyst bed to an n last catalyst bed, wherein each catalyst bed is filled with at least one titanium silicon molecular sieve; the titanium silicon molecular sieve is at least partially modified; and the modified titanium silicon molecular sieve has undergone modification treatment, and the modification treatment comprises a step of contacting the raw material titanium silicon molecular sieve with a modification solution containing nitric acid and peroxide. The method can prolong the single-pass service life of a catalyst, and can stabilize the conversion rate of raw materials, the effective utilization rate of the oxidizing agent and the selectivity of a target oxidation product at high levels even inthe case of long-period continuous operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

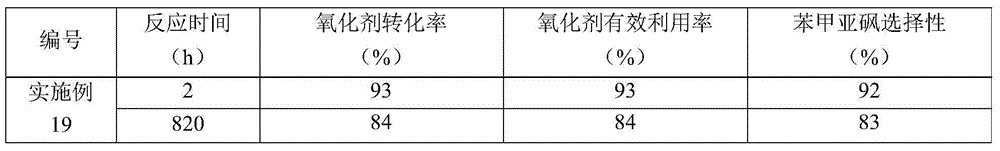

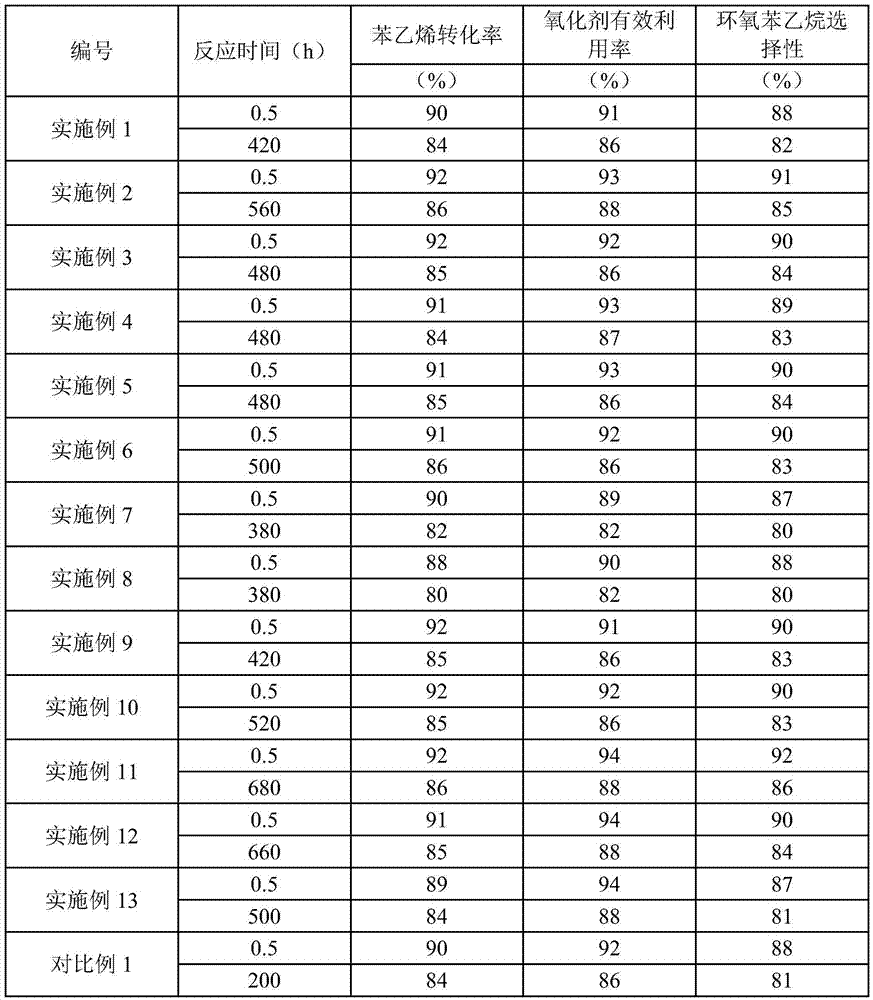

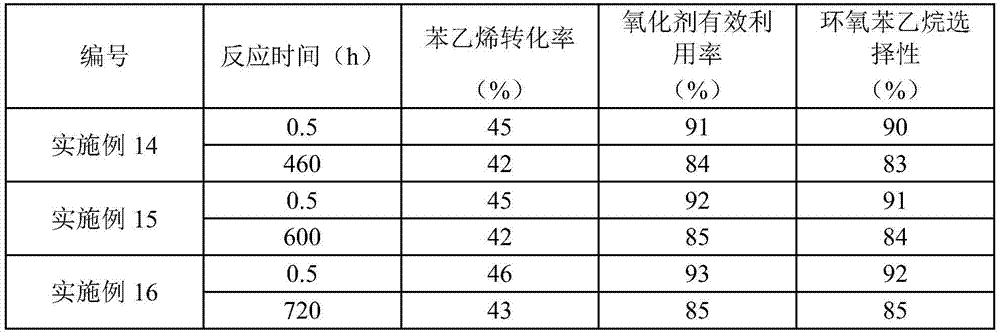

Styrene oxidation method

ActiveCN106967012AExtended one-way service lifeExtended service lifeOrganic chemistryMolecular sieve catalystsMolecular sieveStyrene oxide

The present invention relates to the field of fine chemical industry, and specifically discloses a styrene oxidation method, which comprises that a reaction material containing styrene, an oxidizing agent and an optional solvent sequentially flows through catalyst bed layers from 1 to n under an oxidation reaction condition, wherein n is an integer of more than 2, and the catalyst bed layer is filled with at least a titanium-silicon molecular sieve; and when the reaction material passes through the catalyst bed layers from 1 to n, at least a flow carrier is introduced into the position between at least a pair of the adjacent catalyst bed layers among the catalyst bed layers from 1 to n, such that the apparent velocity of the reaction stream positioned in the downstream catalyst bed layer is higher than the apparent velocity of the reaction stream positioned in the upstream catalyst bed layer in the pair of the adjacent catalyst bed layers by adopting the flowing direction of the reaction material as the reference. With the method of the present invention, the one-way service life of the titanium-silicon molecular sieve can be effectively prolonged, the effective utilization rate of the oxidizing agent can be improved, and the target product selectivity such as styrene oxide selectivity can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

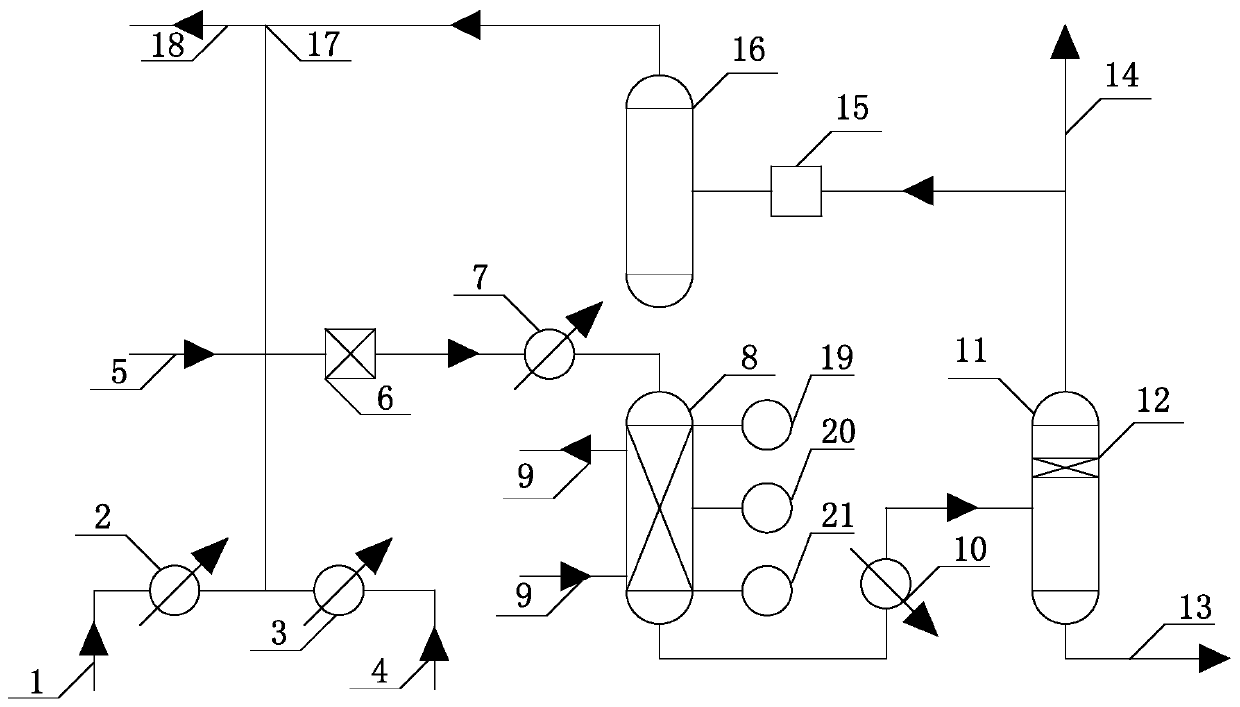

Activation method and reaction device for preparing methyl ethyl ketone catalyst through sec-butyl alcohol dehydrogenation

PendingCN110639623AExtended one-way service lifeReduce energy consumptionOrganic compound preparationPreparation by dehydrogenationNitrogen gasSec-butyl alcohol

The invention belongs to the technical field of sec-butyl alcohol dehydrogenation catalyst activation, and particularly relates to an activation method and a reaction device for preparing a methyl ethyl ketone catalyst through sec-butyl alcohol dehydrogenation. Firstly, catalyst physically adsorbed water is removed, then nitrogen-water vapor is adopted as diluent gas, sec-butyl alcohol is fed at alow air speed to activate the catalyst, and finally, the catalyst is subjected to enhanced reduction through sec-butyl alcohol feeding. According to the activation method for preparing the methyl ethyl ketone catalyst through sec-butyl alcohol dehydrogenation, different reduction methods are adopted in different stages of the activation process of the catalyst, the problems that a traditional alcohol reduction method is large in bed layer temperature rise and prone to carbon deposition can be effectively solved, the one-way service life of the activated catalyst can be effectively prolonged,and use energy consumption is reduced; the sec-butyl alcohol dehydrogenation catalyst reaction device is easy to implement, simple in process and reasonable in design, and the operation process is easy to control.

Owner:ZIBO QIXIANG TENGDA CHEM

Purification method and equipment, mixture flow treatment method and device, method for preparing epoxide and epoxidation reaction system

PendingCN113968772AReduce carbon monoxideExtended one-way service lifeCatalyst carriersGas treatmentPtru catalystAlcohol

The invention discloses a purification method and equipment, a mixture flow treatment method and device, a method for preparing epoxide and an epoxidation reaction system. The purification method comprises bringing alcohol containing impurities and hydrogen into contact with a catalyst with a hydrogenation catalysis function to obtain a hydrogenation product stream with the impurity content reduced, and separating the product stream to obtain a gas-phase material stream containing hydrogen; treating the gas-phase material stream to obtain a treated material stream with a reduced carbon monoxide content; recycling at least a portion of the treated stream for use as at least a portion of the hydrogen. According to the purification method and the purification equipment provided by the invention, the content of carbon monoxide in the gas-phase material flow separated from the hydrogenation reaction product material stream is reduced, and then the gas-phase material stream is used as recycle hydrogen for hydrogenation reaction, so that the one-way service lifetime of a hydrogenation catalyst can be effectively prolonged, and the impurity content in alcohol is kept at a lower level for a long time; and the quality of the epoxypropane product is maintained at a relatively high level for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aldol condensation catalyst composition, preparation method thereof, and method for preparing methyl methacrylate by using aldol condensation catalyst composition

PendingCN113751011AImprove the ability to resist coking and carbon depositionExtended one-way service lifeOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention relates to an aldol condensation catalyst composition, a preparation method thereof and a method for preparing methyl methacrylate by using the aldol condensation catalyst composition. The aldol condensation catalyst composition comprises an active component, an auxiliary agent, a polymerization inhibitor and a carrier, the carrier is SiO2, the active component is silicate of Cs, the auxiliary agent is oxide of Ce, and the polymerization inhibitor is selected from one or more of oxides of Bi, Zr, La, Cu, Mn and Fe, preferably copper oxide. According to the aldol condensation catalyst composition disclosed by the invention, polymerization of double-bond substances in a reaction system is inhibited, and the coking and carbonization rate of the surface of the catalyst is obviously reduced, so that the coking and carbon deposition resistance of the catalyst is improved, and the one-way service life of the catalyst is prolonged.

Owner:BEIJING RISUN TECH CO LTD

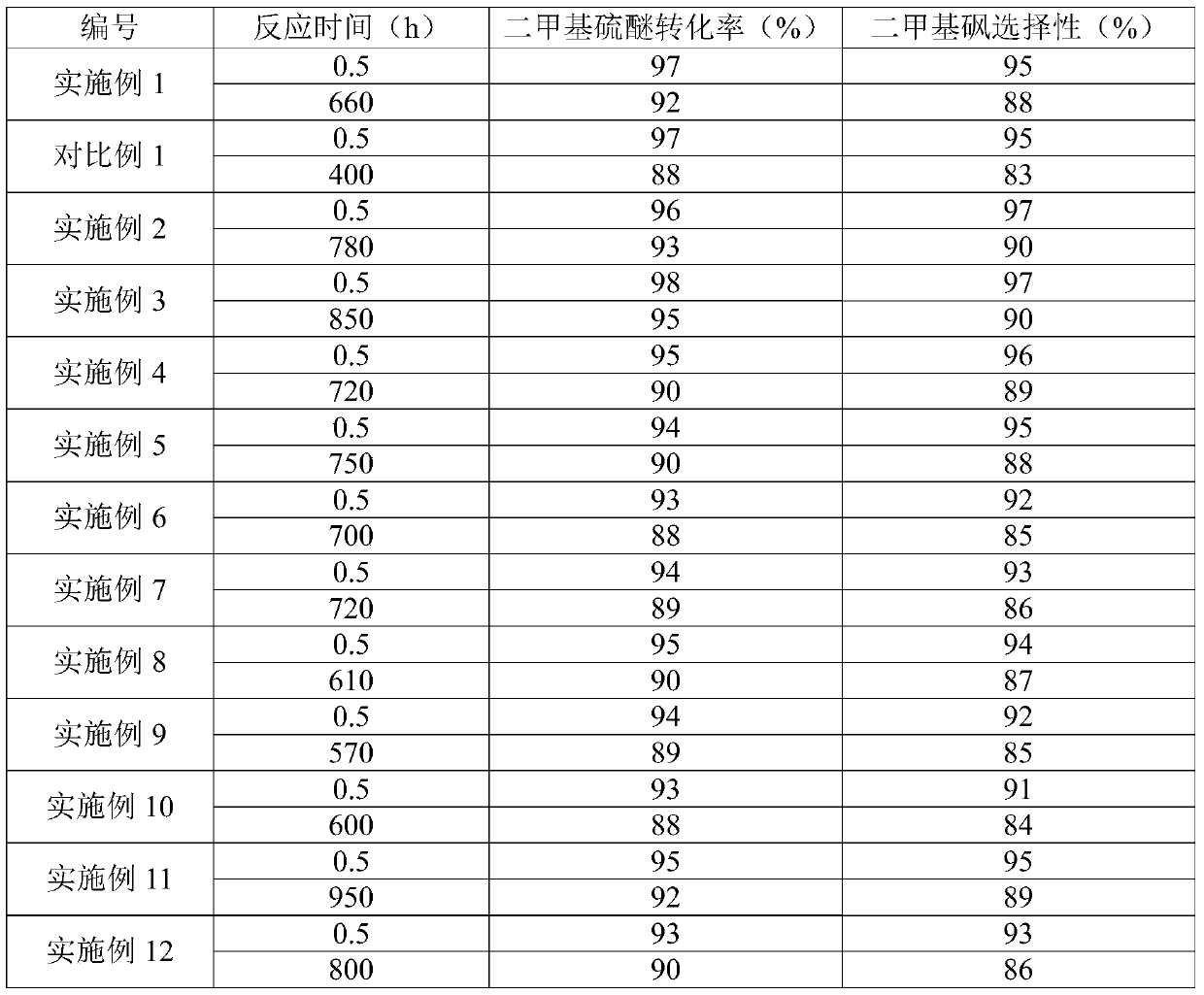

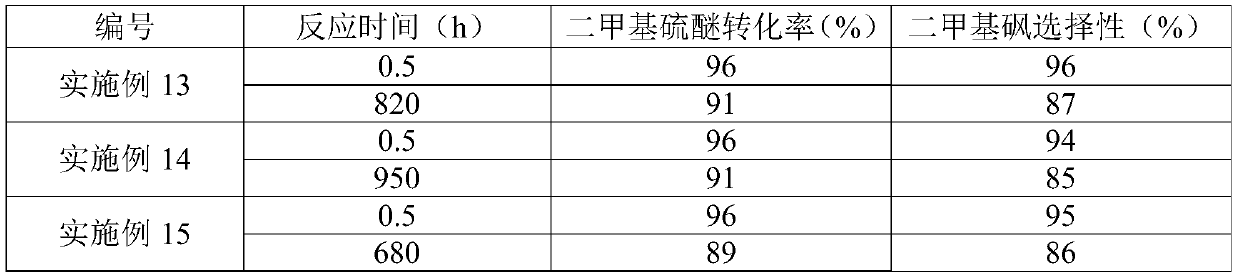

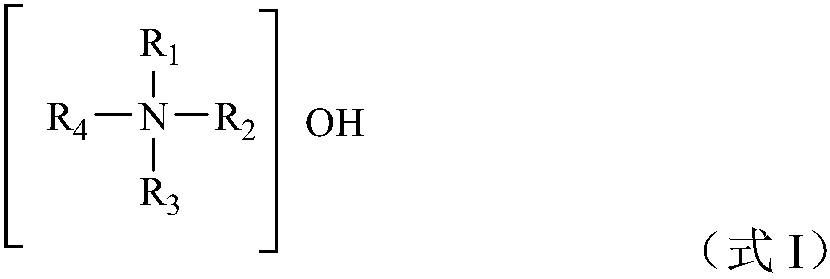

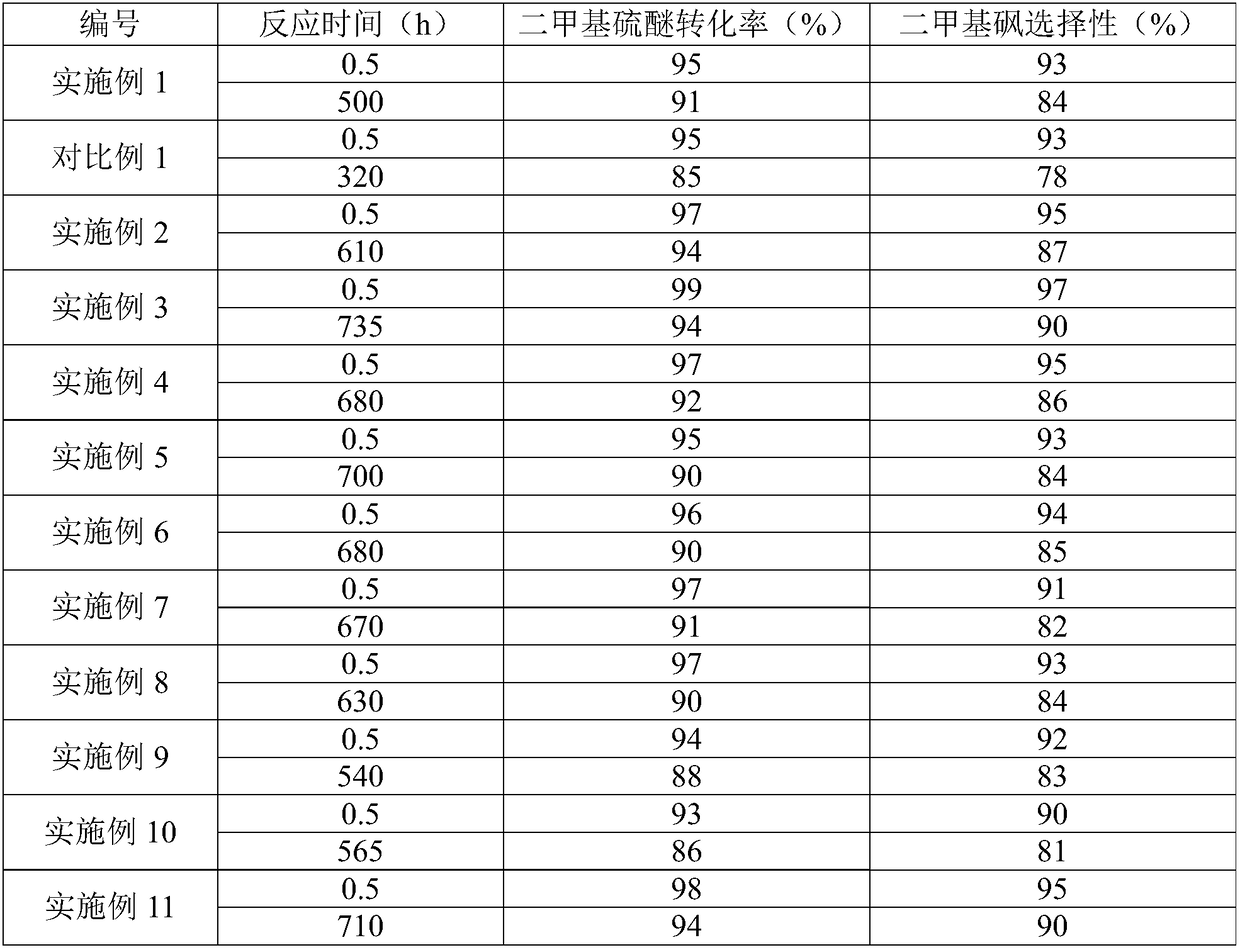

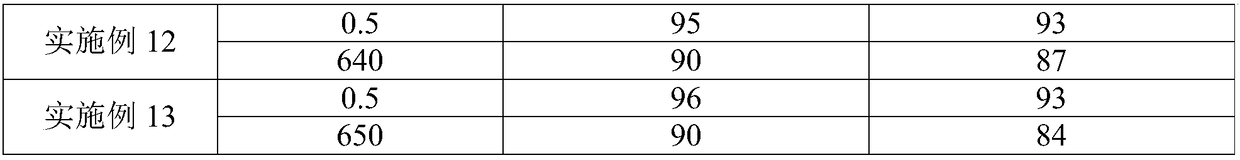

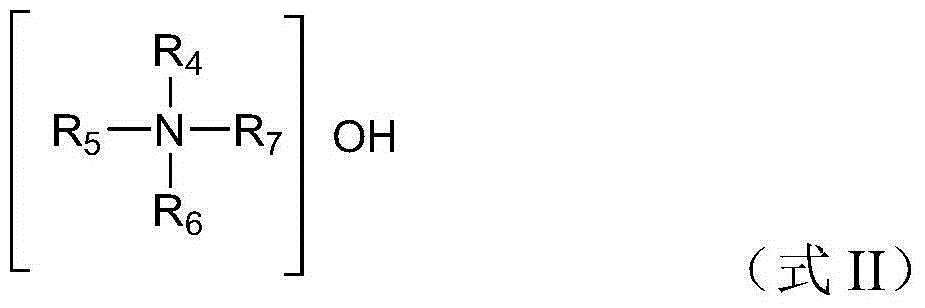

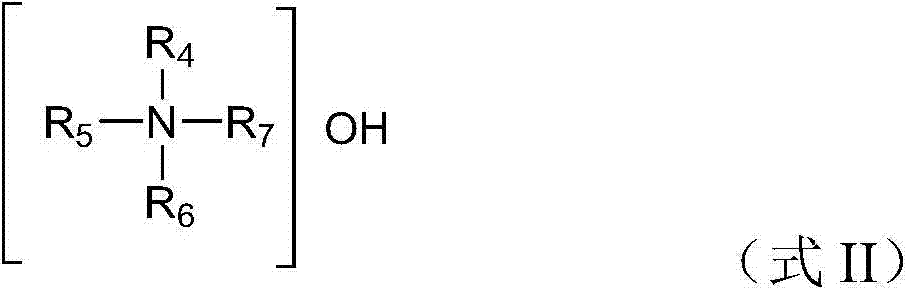

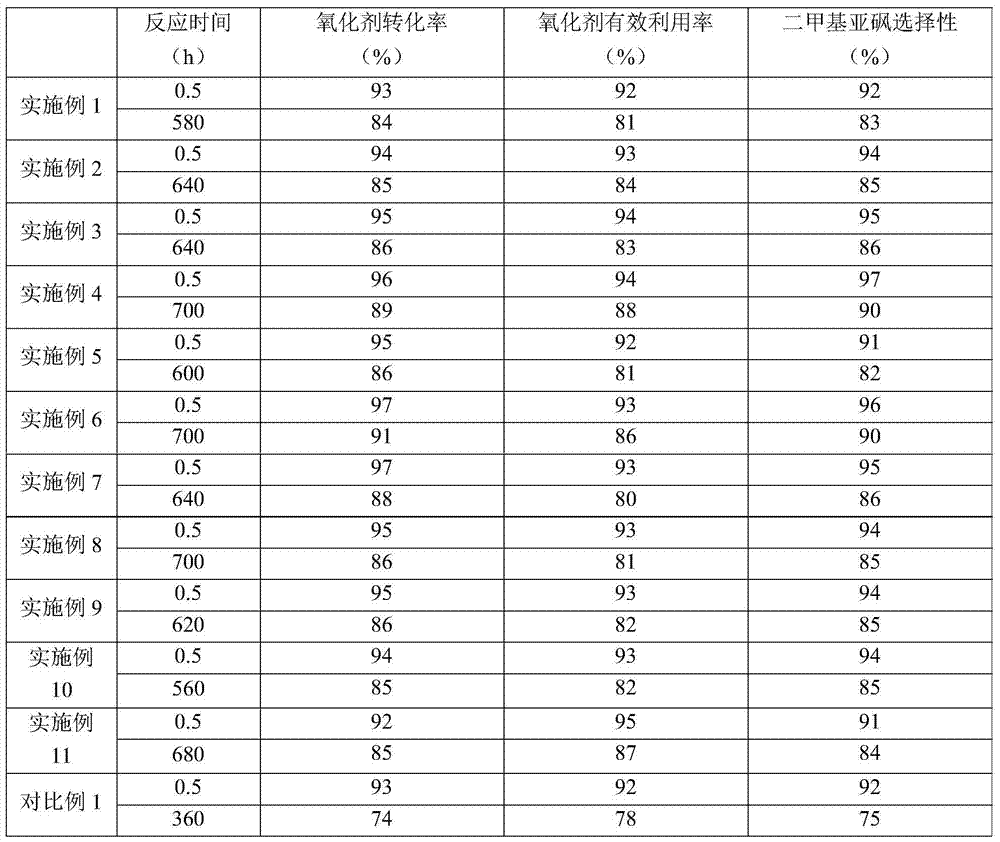

Sulfoether oxidation method

ActiveCN105367459AExtended one-way service lifeExtend stable running timeOrganic chemistryOrganic compound preparationMolecular sieveFixed bed

The invention discloses a sulfoether oxidation method. The method comprises the steps that a liquid mixture is continuously fed into a fixed-bed reactor, and the liquid mixture flows through catalyst bed layers under the oxidation reaction condition to be reacted with titanium silicalite molecular sieves filled in the catalyst bed layers in a contacted mode, wherein the liquid mixture contains sulfoether, at least one oxidizing agent and at least one selectable solvent. The method further comprises the step that when the selectivity of a target oxidation product decreases to a certain degree, the content of the oxidizing agent in the liquid mixture is increased till the selectivity of the target oxidation product is raised to meet the requirement. By means of the sulfoether oxidation method, the selectivity of the target oxidation product can be maintained within a higher range even under the long-periodic continuous operation condition, therefore, the one-way service life of the titanium silicalite molecular sieves serving as a catalyst is effectively prolonged, the regeneration period of the catalyst is shortened, and the stable operation time of a device is prolonged. In addition, the sulfoether oxidation method is simple, easy to carry out and beneficial for industrial production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ethylene cracking material by hydrogenation of liquefied gas

ActiveCN108085061BImprove hydrogenation activityAverage reaction speedGaseous mixture working upHydrocarbon oils treatment productsHydrogenReaction speed

The invention discloses a method for producing an ethylene cracking material through liquefied gas hydrogenation. The method is characterized in that liquefied gas and hydrogen pass through a hydrogenation reactor through a cocurrent flowing mode, then are contacted with a hydrogenation catalyst under hydrogenation technical condition and subjected to a reaction; the hydrogenation reactor comprises more than two reaction segments, and according to a contact sequence with a reaction material, the activity of the catalyst in a downstream reaction segment is higher than the activity of the catalyst in an upstream reaction segment. The method reduces the relative average reaction speed at an entrance of a catalyst bed layer, changes problem of large relative average reaction speed at the entrance of the catalyst bed layer, a difference of the average reaction speed of each segment of the catalyst bed layer is greatly reduced, and the relative average reaction speed of each segment of the catalyst bed layer is more uniform.

Owner:CHINA PETROLEUM & CHEM CORP +1

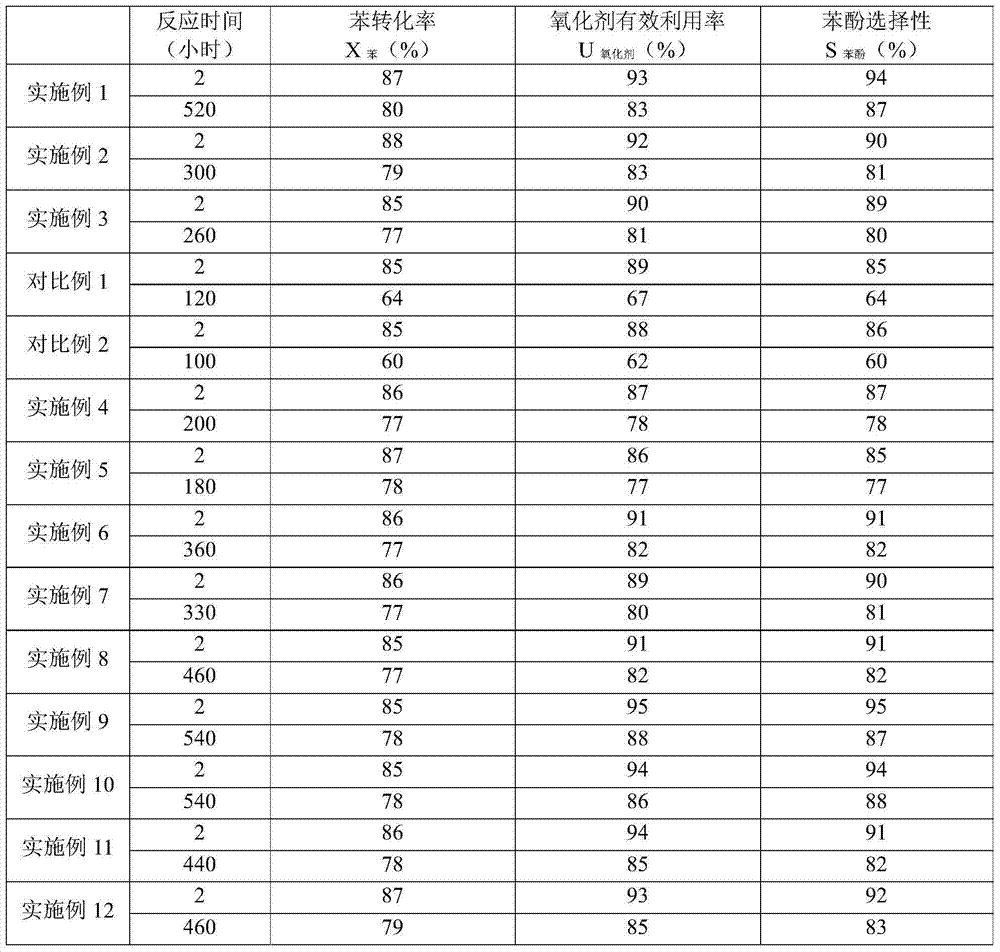

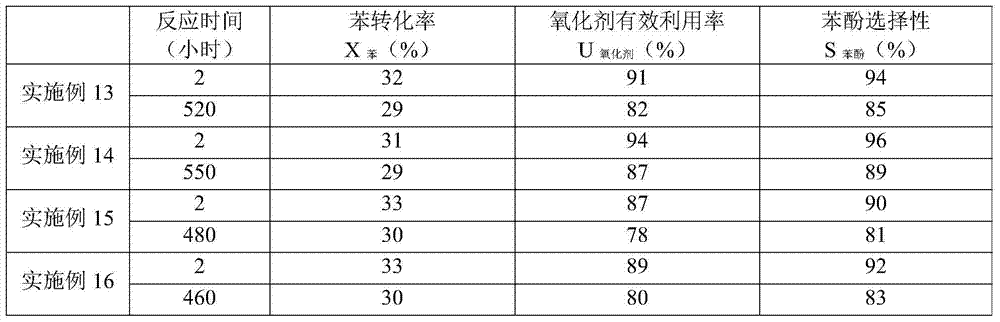

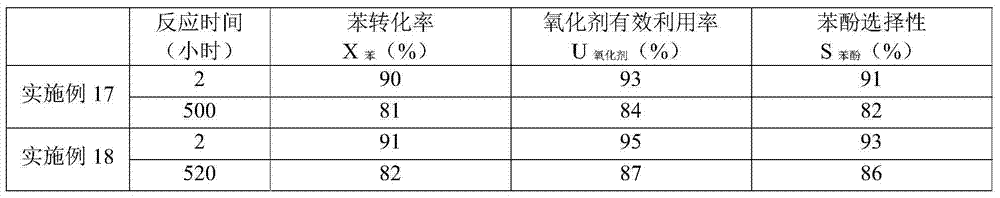

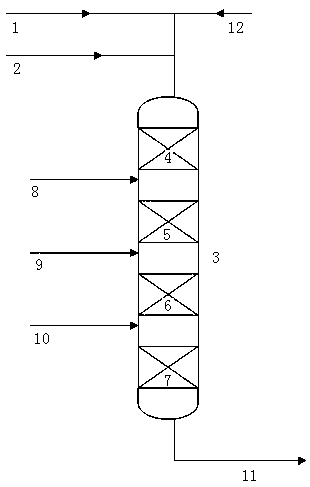

A kind of benzene oxidation method

ActiveCN105523896BHigh selectivityExtended one-way service lifeOrganic chemistryOrganic compound preparationBenzeneMolecular sieve

The invention discloses a benzene oxidation method. The method comprises the step of enabling a liquid mixture to sequentially flow through a first catalyst bed layer and a second catalyst bed layer under oxidation reaction conditions, wherein the liquid mixture contains benzene, an oxidant and an optional solvent, the first catalyst bed layer and the second catalyst bed layer each is loaded with titanium silicalite molecular sieves, and the superfacial velocity of the liquid mixture flowing through the first catalyst bed layer is lower than that of the liquid mixture flowing through the second catalyst bed layer. According to the method, in a long-time continuous operating process, the single-pass service lives of the titanium silicalite molecular sieves as a catalyst can be effectively prolonged, the regeneration frequency is lowered, the production efficiency of a device is increased, and the operating cost of the device is reduced; and the availability of the oxidant is relatively high. In addition, the method is high in operability, in a practical application process, two reaction zones are arranged in series, and the inner diameter of the reaction zone located at upstream is enabled to be greater than that of the reaction zone located at downstream.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for preparing ethylene cracking material by hydrogenation of liquefied gas

ActiveCN106753561BReduce reaction temperature rise"warm bag" gentleGaseous mixture working upHydrocarbon oils treatment productsHydrogenation reactionReaction temperature

The invention discloses a method for preparing ethylene cracking feed by hydrogenation of liquefied gas. Liquefied gas and hydrogen pass through a hydrogenation reactor in a parallel flow manner and is in contact with hydrogenation catalysts for reaction; two or more hydrogenation catalyst bed layers are arranged in the hydrogenation reactor; the hydrogen enters the two or more hydrogenation catalyst bed layers from different feeding openings respectively; the amounts of the hydrogen entering all the hydrogenation catalyst bed layers are 5 to 95 volume percent of chemical hydrogen consumption required by reaction separately; except the last hydrogenation catalyst bed layer, the sum of total amounts of the hydrogen entering other hydrogenation catalyst bed layers is smaller than the required chemical hydrogen consumption. According to the method disclosed by the invention, by controlling partial pressures of the hydrogen entering different catalyst bed layers, the reaction speed is effectively controlled, and accurate control over the conversion rate is realized, so that reaction temperature rise of all sections of catalyst bed layers in the reactor is reduced, further the carbon deposit speed of the catalyst is retarded, and the single-pass service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of sulfone

ActiveCN107556222BSlow down inactivationExtended one-way service lifeOrganic chemistryMolecular sieve catalystsMolecular sieveTitanium

The invention discloses a method for preparing sulfone. The method comprises that a contact reaction between a reaction mixture and a titanium-silicalite molecular sieve is performed in a reactor forobtaining a product mixture containing sulfone, wherein the reaction mixture comprises thioether, an oxidizing agent and an optional solvent, and when the selectivity of the target oxidation product is lower than an expected value, the method also comprises increasing the pressure in the reactor until the selectivity of the target oxidation product rises above the expected value. The method can effectively delay the deactivation rate of the titanium-silicon molecular sieve which is used as a catalyst, prolong the one-way service life of the titanium-silicon molecular sieve, reduce the regeneration frequency of the titanium-silicon molecular sieve, reduce the production cost, and also can improve the operation efficiency of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

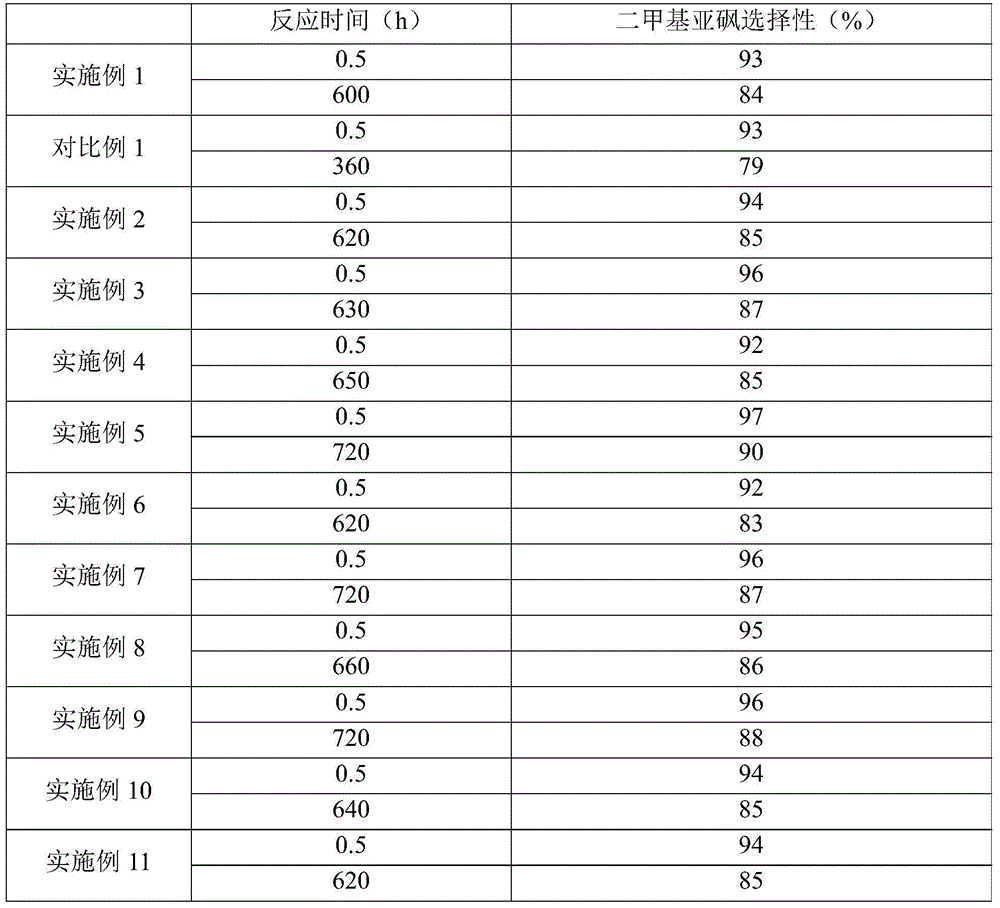

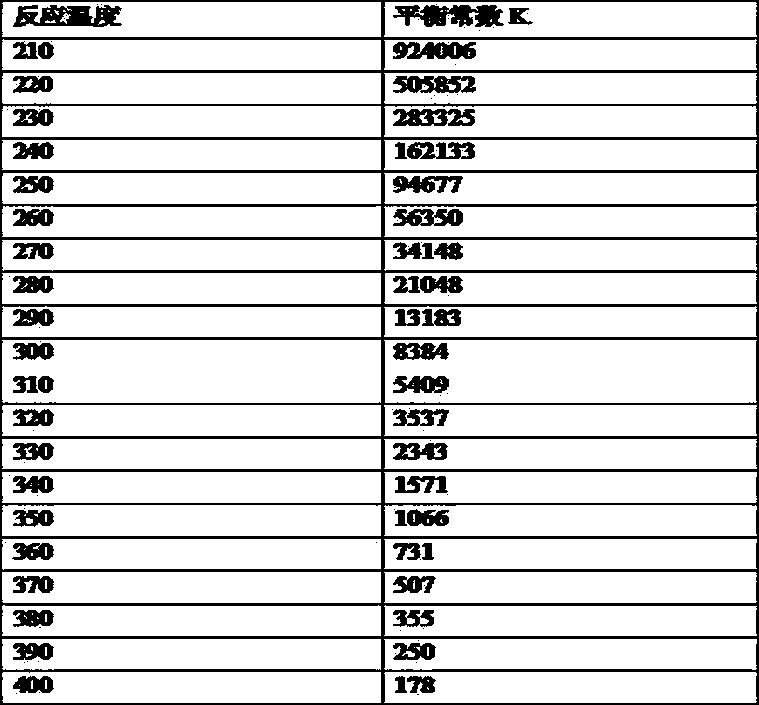

Method for utilizing refinery acid gas

ActiveCN113527159ASolve the problem of excessive acid gasEfficient use ofSulfide preparationMolecular sievePtru catalyst

The method for utilizing the refinery acid gas comprises the following steps: contacting the refinery acid gas containing hydrogen sulfide with an acid medium, and then contacting with methanol in a reactor heated by molten salt in the presence of a catalyst containing an MFI structure molecular sieve to obtain a mixture containing dimethyl sulfide; and a step of when the methanol conversion rate is reduced to the condition 1 or the dimethyl sulfide selectivity is reduced to the condition 2, performing an operation of reducing the flow rate of the air flow passing through the molten salt until the methanol conversion rate is increased to satisfy the condition 3 and the dimethyl sulfide selectivity is increased to satisfy the condition 4. The method can solve the problem of excessive acid gas in a refinery plant, and has the characteristics of low operation cost and capability of effectively prolonging the one-way service life of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

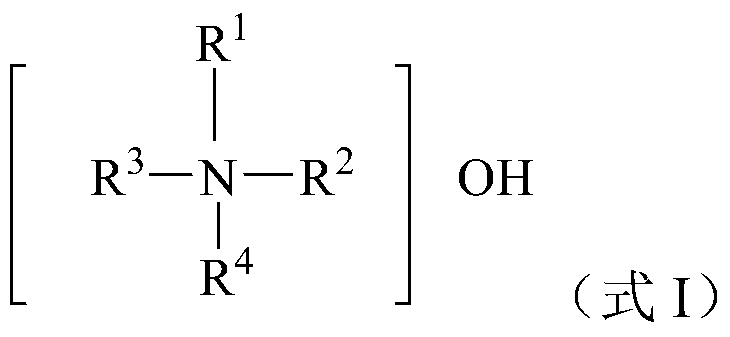

A kind of thioether oxidation method

ActiveCN105523972BHigh selectivityQuality improvementOrganic chemistryOrganic compound preparationMolecular sievePtru catalyst

The invention discloses an oxidation method for thioether. The method comprises the step of subjecting a liquid mixture and a titanium-silicate molecular sieve to contacting under the condition of oxidation reaction, wherein the liquid mixture comprises thioether, at least one oxidant, at least one alkaline substance and at least one optional solvent; and when selectivity of a target oxidation product is lower than an expected value, the method also comprises the steps of improving the quality of the alkaline substance in the liquid mixture and optionally improving the quality of the oxidant in the liquid mixture. The method provided by the invention can maintain the selectivity of the target oxidation product at a high level for a long time, effectively prolong the single-way service life of the titanium-silicon molecular sieve used as a catalyst, and reduce regeneration frequency of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method for sulfone

ActiveCN108794360ASlow down inactivationExtended one-way service lifeOrganic chemistryMolecular sieve catalystsMolecular sieveTitanium

The invention discloses a production method for sulfone. The production method for the sulfone comprises the steps of enabling a reaction mixture which contains thioether, at least one oxidizing agentand at least one selectable solvent to be in contact reaction with a titanium silicalite molecular sieve in a reactor; transferring out reaction heat by using a heat exchange medium in a contact reaction process, wherein the molar ratio of the oxidizing agent to the thioether is greater than 2; when sulfone selectivity is reduced, adjusting the condition of heat exchange to reduce the amount of the transferred reaction heat until the sulfone selectivity returns to an expected value; and maintaining the amount of the transferred reaction heat. By the method, the deactivation speed of the titanium silicalite molecular sieve as a catalyst can be reduced effectively, the single-strip service life of the titanium silicalite molecular sieve is prolonged, the regeneration frequency of the titanium silicalite molecular sieve is reduced, on the one hand, thioether conversion rate and the sulfone selectivity are maintained at high level for a long time, and on the other hand, the total servicelife of the titanium silicalite molecular sieve is prolonged, the production cost is reduced, and meanwhile, the running efficiency of the device can further be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for oxidation of olefin

ActiveCN105524024AHigh quality contentExtended service lifeOrganic chemistryMolecular sieveOrganic solvent

The invention provides a method for oxidation of olefin. The method comprises the step of subjecting a liquid mixture which contains olefin and an oxidant and optionally contains an organic solvent to passing through a catalyst bed in a rectifying tower under the condition of oxidation reaction, wherein the catalyst bed is provided with a titanium-silicate molecular sieve. The method for oxidation of olefin provided by the invention can obtain stable conversion rate of the oxidant and high selectivity of a target oxidation product in the process of long-time continuous operation. Specifically, the method provided by the invention has high selectivity of epoxides and low selectivity of by-products, so subsequent separation and purification difficulty is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for oxidizing olefins

The invention provides a method for oxidizing olefins, the method comprising: under oxidation reaction conditions, making a liquid phase mixture containing olefins, an oxidizing agent and optionally an organic solvent flow through a catalyst bed in a rectification column, wherein, The catalyst bed layer contains titanium silicon molecular sieve. By adopting the method of the present invention to oxidize olefins, relatively stable oxidant conversion rate and high selectivity of target oxidation products can be obtained during long-term continuous operation. In particular, by adopting the method of the present invention, the selectivity of epoxides is high, and the selectivity of by-products is low, thereby reducing the difficulty of subsequent separation and purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for oxidizing olefins

ActiveCN105524026BSelective pick-upHigh quality contentOrganic chemistryChemical recyclingMolecular sieveTitanium

The invention discloses a method for oxidizing alkenes, which comprises contacting and reacting a liquid mixture with a titanium-silicon molecular sieve under oxidation reaction conditions, and removing the heat of reaction with a heat exchange medium during the contact reaction process, the liquid mixture containing Olefin, at least one oxidant, and optionally at least one solvent, wherein, when the target oxidation product drops below a desired value, the method further includes adjusting the conditions of the heat exchange to reduce the amount of heat of reaction removed and may Optionally increase the quality of the oxidant in the liquid mixture to increase the selectivity of the target oxidation product until the expected value is met. The method can maintain the selectivity of the target oxidation product at a high level during long-term continuous operation, effectively prolongs the single-pass service life of the titanium-silicon molecular sieve as a catalyst, and reduces the regeneration frequency of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of sulfone

ActiveCN107235869BSlow down inactivationExtended one-way service lifeOrganic chemistryMolecular sieve catalystsMolecular sieveSulfur Ethers

The invention discloses a preparation method for a sulphone. The preparation method for the sulphone comprises contacting a reaction mixture with a titanium silicate molecular sieve in a reactor for reaction, so as to obtain a product mixture containing the sulphone, wherein the reaction mixture contains a sulfur ether, an oxidant and a selectable solvent. When the conversion rate of the oxidant is lower than an expected value, the method additionally comprises improving the temperature of a liquid mixture until the conversion rate of the oxidant rises again to a value equal to or more than the expected value. The method is capable of effectively delaying the deactivation speed of the titanium silicate molecular sieve used as a catalyst, prolonging the one-way service life of the titanium silicate molecular sieve, reducing the regeneration frequency of the titanium silicate molecular sieve and reducing production cost, but also can improve the operation efficiency of an employed apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxidation method for olefin

ActiveCN105524020AHigh selectivityIncrease temperatureOrganic chemistryChemical recyclingMolecular sieveTitanium

The invention discloses an oxidation method for olefin. The method comprises the step of subjecting a liquid mixture and a titanium-silicate molecular sieve to contacting under the condition of oxidation reaction, wherein the liquid mixture comprises olefin, at least one oxidant, and at least one optional solvent; and when selectivity of a target oxidation product is lower than an expected value, the method also comprises the steps of improving a feeding temperature of the liquid mixture and optionally improving the quality of the oxidant in the liquid mixture. The method provided by the invention can maintain the selectivity of the target oxidation product at a high level for a long time, effectively prolong the single-way service life of the titanium-silicon molecular sieve used as a catalyst, and reduce regeneration frequency of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Allyl Alcohol Oxidation Method

ActiveCN108250161BExtended one-way service lifeExtended service lifeOrganic chemistryMolecular sieve catalystsMolecular sievePtru catalyst

The present invention relates to a method for oxidation of allyl alcohol, the method comprising: under oxidation reaction conditions, making the reaction feed containing allyl alcohol, oxidant and optional at least one solvent sequentially flow through the first catalyst bed layer to the last The nth catalyst bed layer, each of the catalyst beds is filled with at least one titanium-silicon molecular sieve, and the titanium-silicon molecular sieve is at least partly modified titanium-silicon molecular sieve, and the modified titanium-silicon molecular sieve is a modified titanium-silicon molecular sieve. The modified titanium-silicon molecular sieve includes contacting the titanium-silicon molecular sieve as a raw material with a modifying solution containing nitric acid and peroxide. The method can prolong the single-pass service life of the catalyst, and can stabilize the conversion rate of the raw material, the effective utilization rate of the oxidant and the selectivity of the target oxidation product at a relatively high level even if the catalyst is operated continuously for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for oxidizing olefins

ActiveCN105524025BExtended one-way service lifeExtended service lifeOrganic chemistryChemical recyclingMolecular sieveReaction temperature

The invention discloses a method for oxidizing olefins, which comprises contacting and reacting a liquid mixture containing olefins and at least one oxidizing agent with titanium-silicon molecular sieves in a reactor under oxidation reaction conditions, wherein the selectivity of the target oxidation product is reduced to Below the expected value, the reaction temperature and optionally the mass of oxidant in the liquid mixture is increased until the target oxidation product meets the expected value. The method can effectively prolong the single-pass service life of the titanium-silicon molecular sieve used as the catalyst, reduce the regeneration frequency of the catalyst, improve the production efficiency, improve the operation stability, and prolong the total service life of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of thioether oxidation method

ActiveCN105367460BExtended one-way service lifeReduce regeneration frequencyOrganic chemistryOrganic compound preparationFixed bedSolvent

The invention discloses a sulfide oxidation method, which comprises continuously feeding a liquid mixture into a fixed-bed reactor, making the liquid mixture flow through the catalyst bed under oxidation reaction conditions, so as to be mixed with the catalyst bed packed in the catalyst bed. Titanium-silicon molecular sieve contact reaction, the liquid mixture contains thioether, at least one oxidizing agent and optionally at least one solvent, wherein the method also includes when the conversion rate of the oxidizing agent and / or the selectivity of the target oxidation product decreases to a certain extent , increase the weight hourly space velocity of thioether until the conversion rate of the oxidant and / or the selectivity of the target oxidation product increase to meet the requirements. The method of the present invention can maintain the conversion rate of the oxidant and / or the selectivity of the target product in a relatively high range even if it operates continuously for a long period, thereby effectively prolonging the single-pass service life of the titanium-silicon molecular sieve as a catalyst and reducing the regeneration frequency. Extend the stable operation time of the device. The method of the invention is simple and easy to implement, and is beneficial to industrial production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of chloropropene oxidation method

ActiveCN106967010BExtended one-way service lifeStable conversion rateOrganic chemistryMolecular sieve catalystsMolecular sieveApparent velocity

The present invention discloses an allyl chloride oxidation method, which comprises that a reaction material containing allyl chloride, an oxidizing agent and a solvent sequentially flows through catalyst bed layers from 1 to n under an oxidation reaction condition, wherein n is an integer of more than 2, and the catalyst bed layer is filled with at least a titanium-silicon molecular sieve; and when the reaction material passes through the catalyst bed layers from 1 to n, at least a flow carrier is introduced into the position between at least a pair of the adjacent catalyst bed layers among the catalyst bed layers from 1 to n, such that the apparent velocity of the reaction stream positioned in the downstream catalyst bed layer is higher than the apparent velocity of the reaction stream positioned in the upstream catalyst bed layer in the pair of the adjacent catalyst bed layers by adopting the flowing direction of the reaction material as the reference. With the method of the present invention, the one-way service life of the titanium-silicon molecular sieve can be effectively prolonged, the effective utilization rate of the oxidizing agent can be improved, and the target product selectivity can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

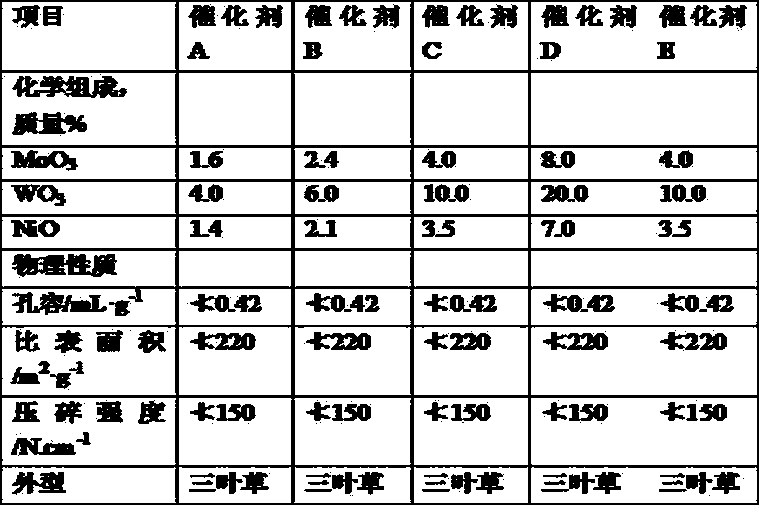

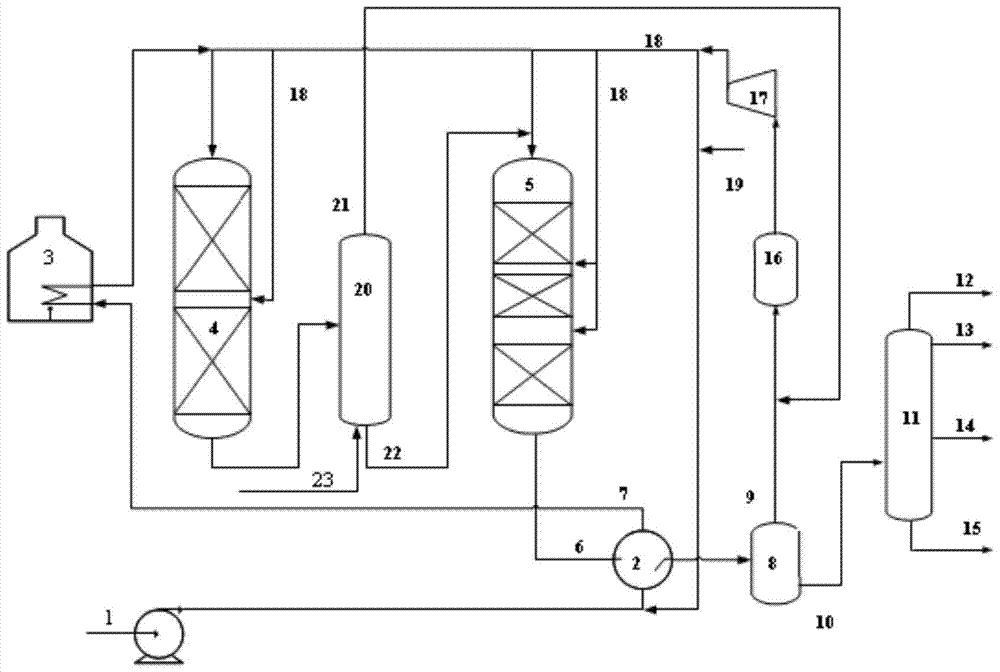

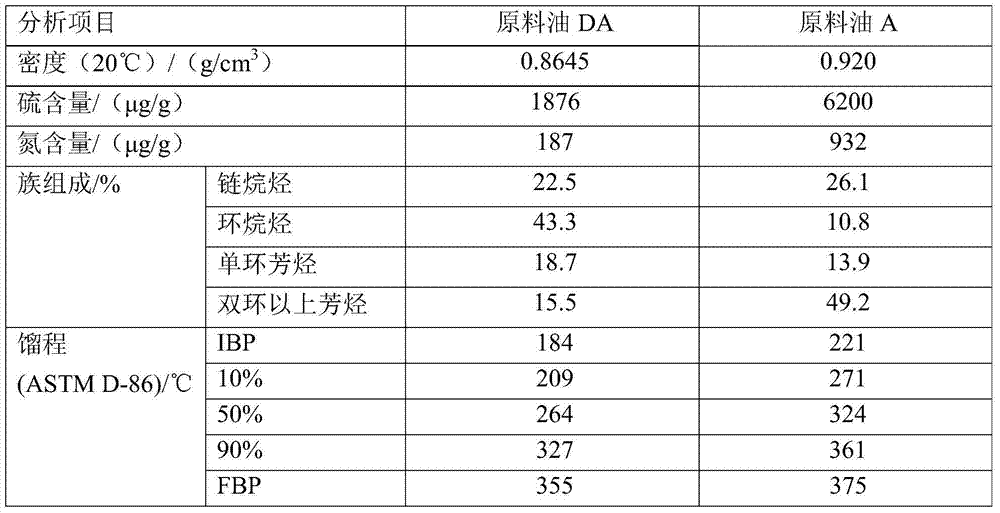

Hydrogenation production method of a kind of jet fuel

ActiveCN105462613BReduce sulfur contentReduce nitrogen contentTreatment with hydrotreatment processesHydrogenHigh density

The present invention discloses a jet fuel hydrogenation production method, which comprises that under a hydrorefining reaction condition, raw material oil, hydrogen and a hydrorefining catalyst contact, a gas phase stream is separated from the obtained effluent so as to obtain a liquid phase stream, the liquid phase stream, hydrogen and a hydrocracking catalyst contact under a hydrocracking reaction condition, and the jet fuel is separated from the obtained effluent, wherein the total aromatic hydrocarbon content in the raw material oil is more than or equal to 40 wt%, the saturation rate of the bicyclic aromatic hydrocarbon in the raw material oil is 45-85% through the hydrorefining reaction condition, and the saturation rate of the monocyclic aromatic hydrocarbon in the liquid phase stream is 60-95% through the hydrocracking reaction condition. According to the present invention, with the method, in the conventional fixed bed reactor, the high density jet fuel meeting the 6# jet fuel standard specified by GJB1603 can be produced even by using the poor quality catalytic cracking diesel fuel as the raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of thioether oxidation method

ActiveCN105367457BExtended one-way service lifeExtend the period of stable operationOrganic chemistryMolecular sieve catalystsMolecular sieveFixed bed

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com