Aldol condensation catalyst composition, preparation method thereof, and method for preparing methyl methacrylate by using aldol condensation catalyst composition

An aldol condensation and catalyst technology, applied in the field of aldol condensation catalysts, can solve the problems of short life, easy coking and carbon deposition, poor catalyst stability, etc., and achieve high utilization rate, strong anti-coking ability, high reactivity and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

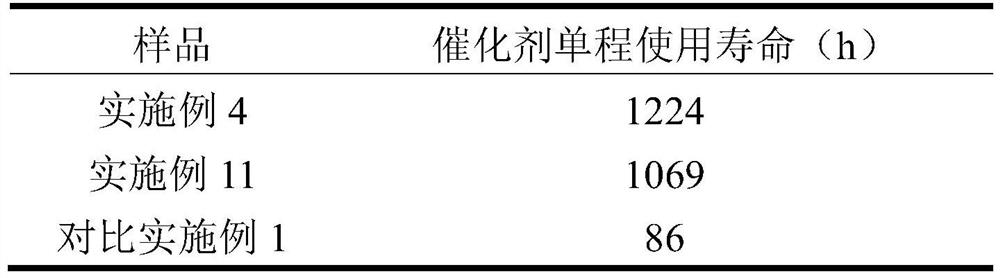

Examples

Embodiment 1

[0068] Weigh 8.8282g Ce(NO 3 ) 3 ·6H 2 O and 3.0487g Zr(NO 3 ) 4 ·5H 2 O was dissolved in 95ml deionized water, after fully dissolved, weigh 100g SiO 2 The carrier is vacuum-impregnated in the above mixed solution with a vacuum degree of 0.09MPa. After vacuum impregnation for 0.5h, transfer to an oven at 20°C and dry for 8h, then raise the temperature to 60°C and continue drying for 4h, and then bake at 550°C in an air atmosphere. 5h gave solid (I).

[0069] Weigh 4.9029g Cs 2 CO 3 , dissolved in 90ml of deionized water, vacuum-impregnated the solid (I) in the active component solution at a vacuum degree of 0.09MPa, after immersion for 0.5h, transferred to an oven at 20°C and dried for 8h, then heated to 60°C to continue Drying for 4h gave solid (II).

[0070] Then weigh 3.6772g Cs 2 CO 3 , according to the first load Cs 2 CO 3 method, the solid (Ⅲ) was obtained.

[0071] Then weigh 2.4514g Cs 2 CO 3 , according to the first load Cs 2 CO 3 method to obtain so...

Embodiment 2

[0076] Weigh 8.8282g Ce(NO 3 ) 3 ·6H 2 O, dissolved in 95ml deionized water, weighed 0.7544g BiCl 3 , dissolved in 5ml concentrated HNO 3 solution, after the two solutions were fully mixed and stirred evenly, the fresh catalyst 10Cs-Ce-Bi / SiO was prepared according to the method and steps in Example 1 2 .

[0077] In a fixed bed reactor, methyl propionate: formaldehyde: methanol molar ratio 5:1:7.5, liquid hourly space velocity 4.0h -1 , 330 ° C conditions, the preparation of methyl methacrylate. After 10 hours of reaction, the one-way conversion rate of methyl propionate was 23.26%, and the selectivity of methyl methacrylate was 92.09%. After 200 hours of reaction, the catalyst sample was analyzed for C element, and the C content was measured to be 4.74wt%.

Embodiment 3

[0079] Weigh 8.8282g Ce(NO 3 ) 3 ·6H 2 O and 0.3208g La(NO 3 ) 3 ·6H 2 O was dissolved in 95ml deionized water, and after fully dissolving, a fresh catalyst 10Cs-Ce-La / SiO was prepared according to the method in Example 1 2 .

[0080] In a fixed bed reactor, methyl propionate: formaldehyde: methanol molar ratio 5:1:7.5, liquid hourly space velocity 4.0h -1 , 330 ° C conditions, the preparation of methyl methacrylate. After 10 hours of reaction, the one-way conversion rate of methyl propionate was 24.20%, and the selectivity of methyl methacrylate was 91.19%. After 200 hours of reaction, the catalyst sample was analyzed for C element, and the C content was measured to be 5.11wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com