Patents

Literature

44results about How to "Extend the period of stable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

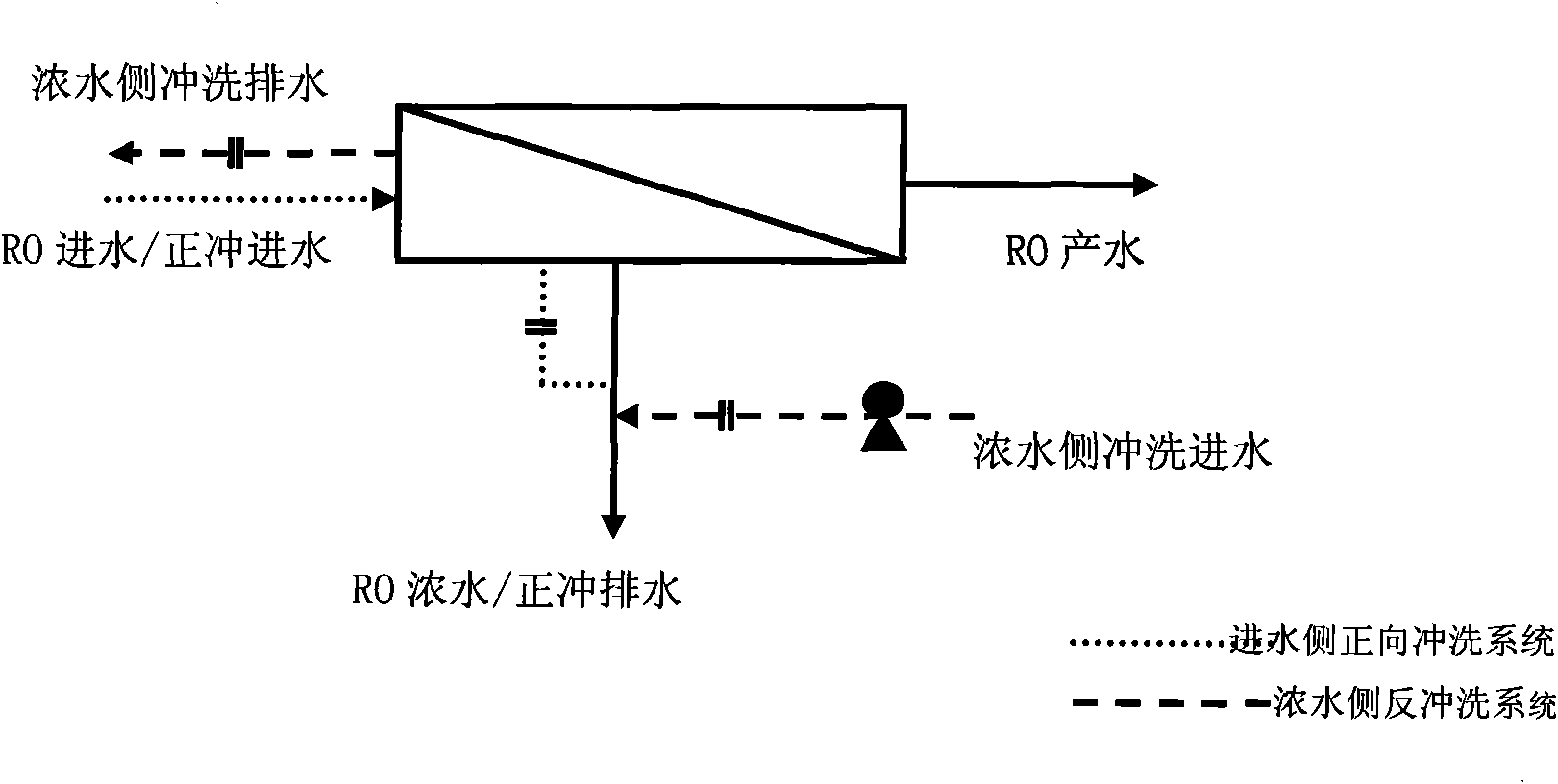

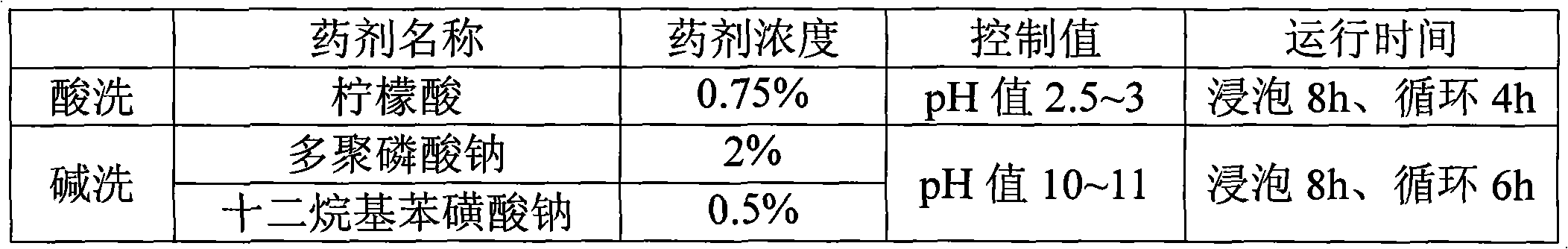

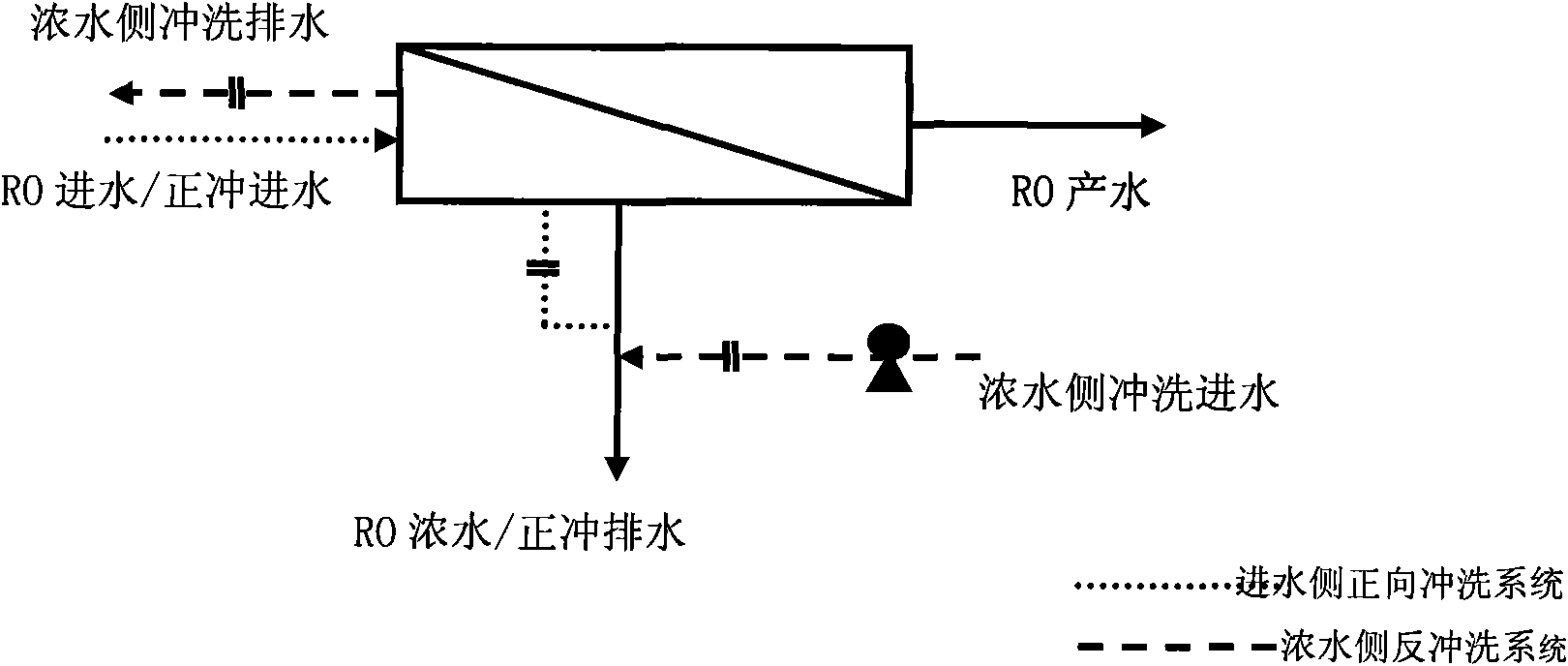

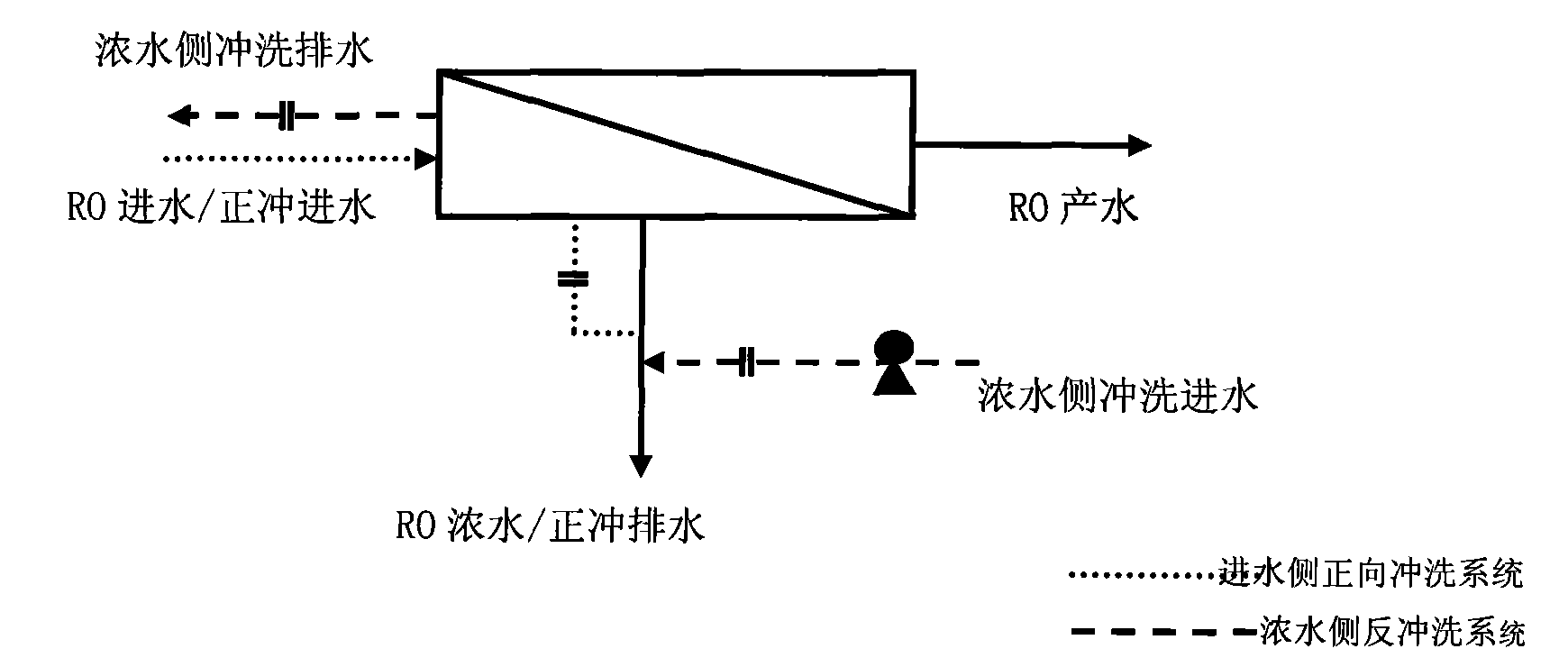

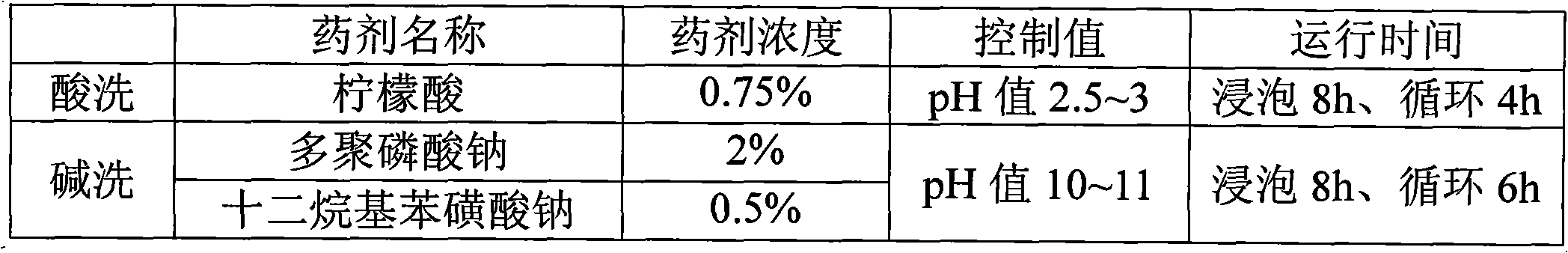

Method for flushing reverse osmosis membrane

ActiveCN102049198AReduce concentration polarizationImprove stabilityReverse osmosisWater/sewage treatment bu osmosis/dialysisColloidal silicaSewerage

The invention provides a method for flushing a reverse osmosis (RS) membrane, which aims at the problems of filtration surface contamination and first-section contamination of a reverse osmosis system membrane caused by high salt, organic colloidal silica, high molecular organic contaminants and microbiological remains during reverse osmosis treatment of olefin production process water, circulating cooling water and sewerage. In the method, positive flushing and concentrated water side reverse flushing are adopted, and agents such as an organic solvent and the like are matched, so hydraulic flushing is formed on the RO membrane filtration surface, blocking contaminants on the membrane surface which cannot be chemically removed are obviously removed, the problem of the first-section contamination of a membrane system is solved, and stable running period of the RO system is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

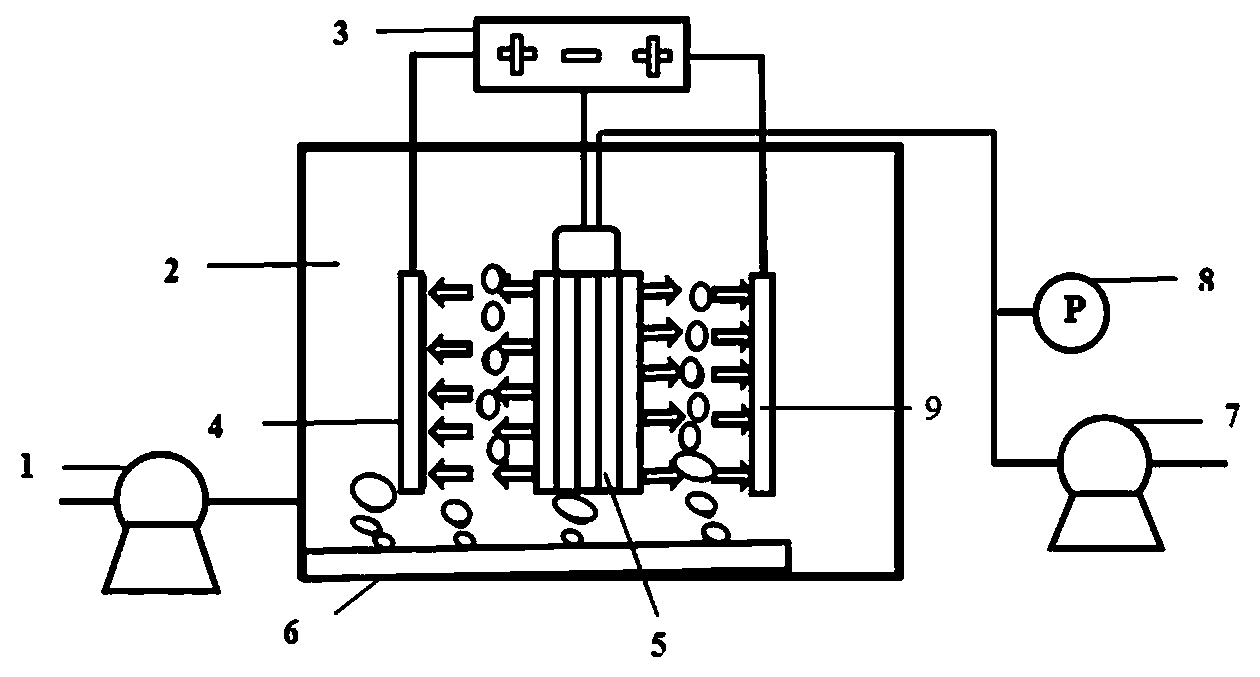

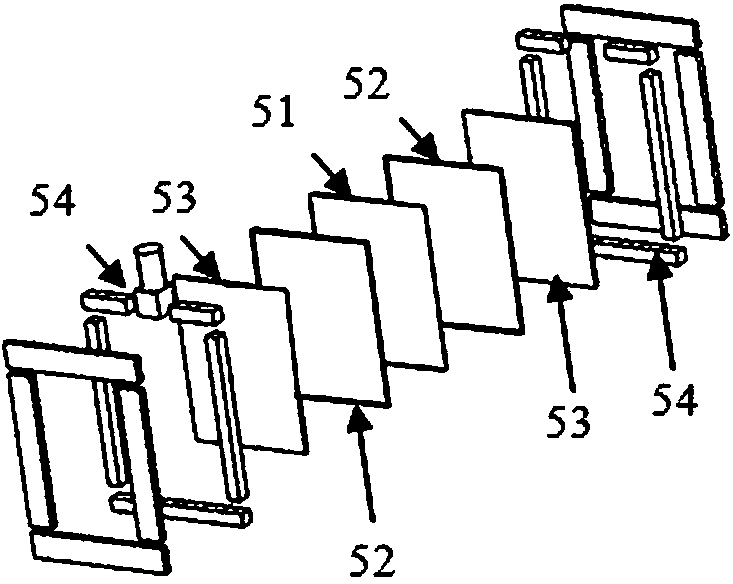

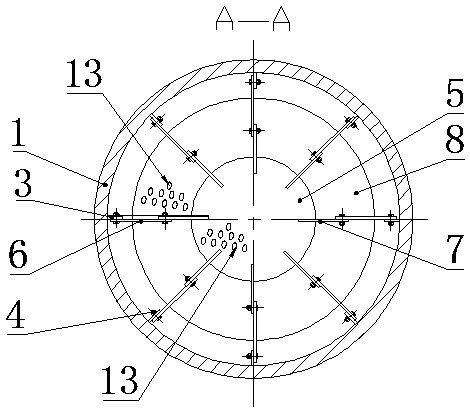

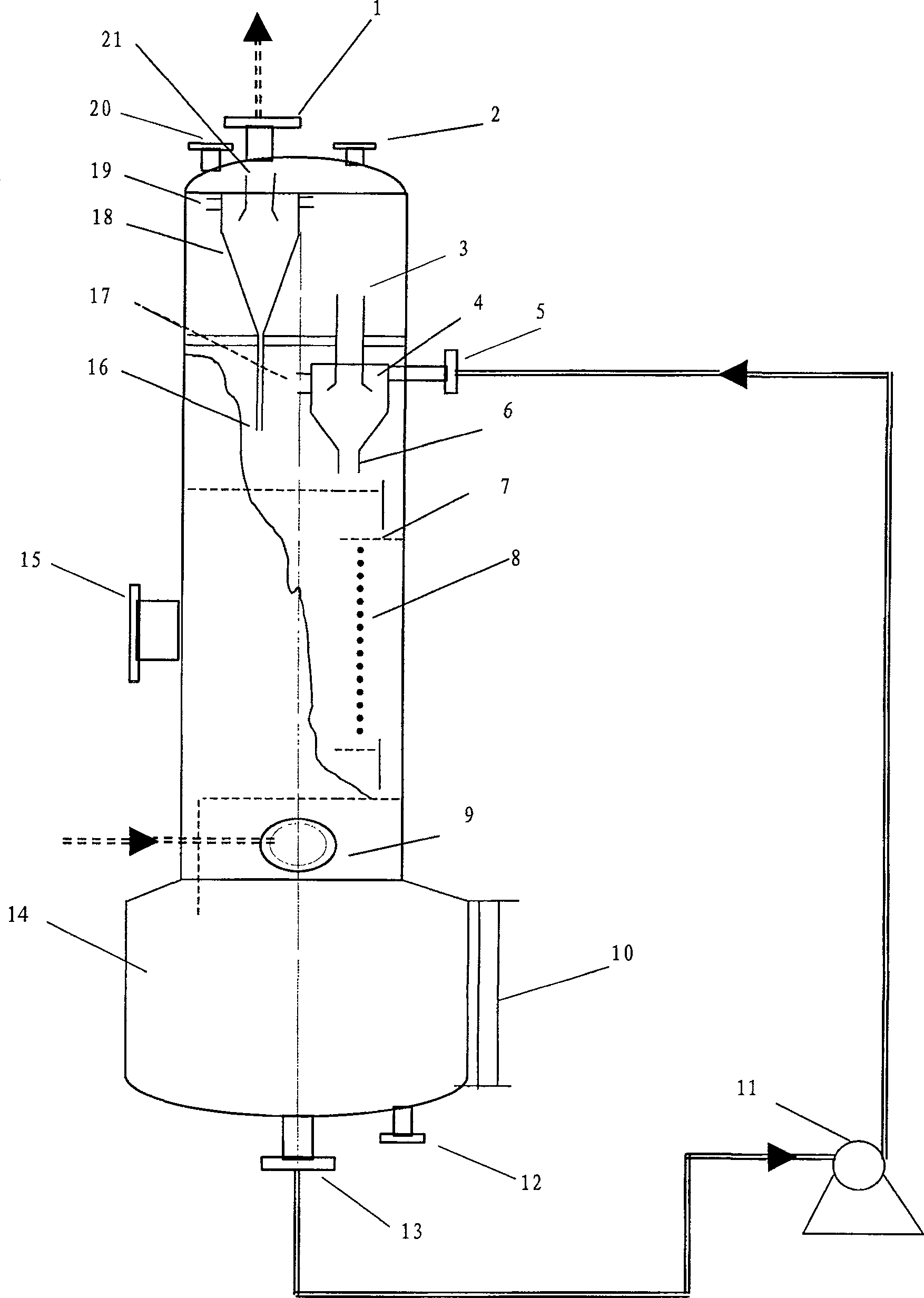

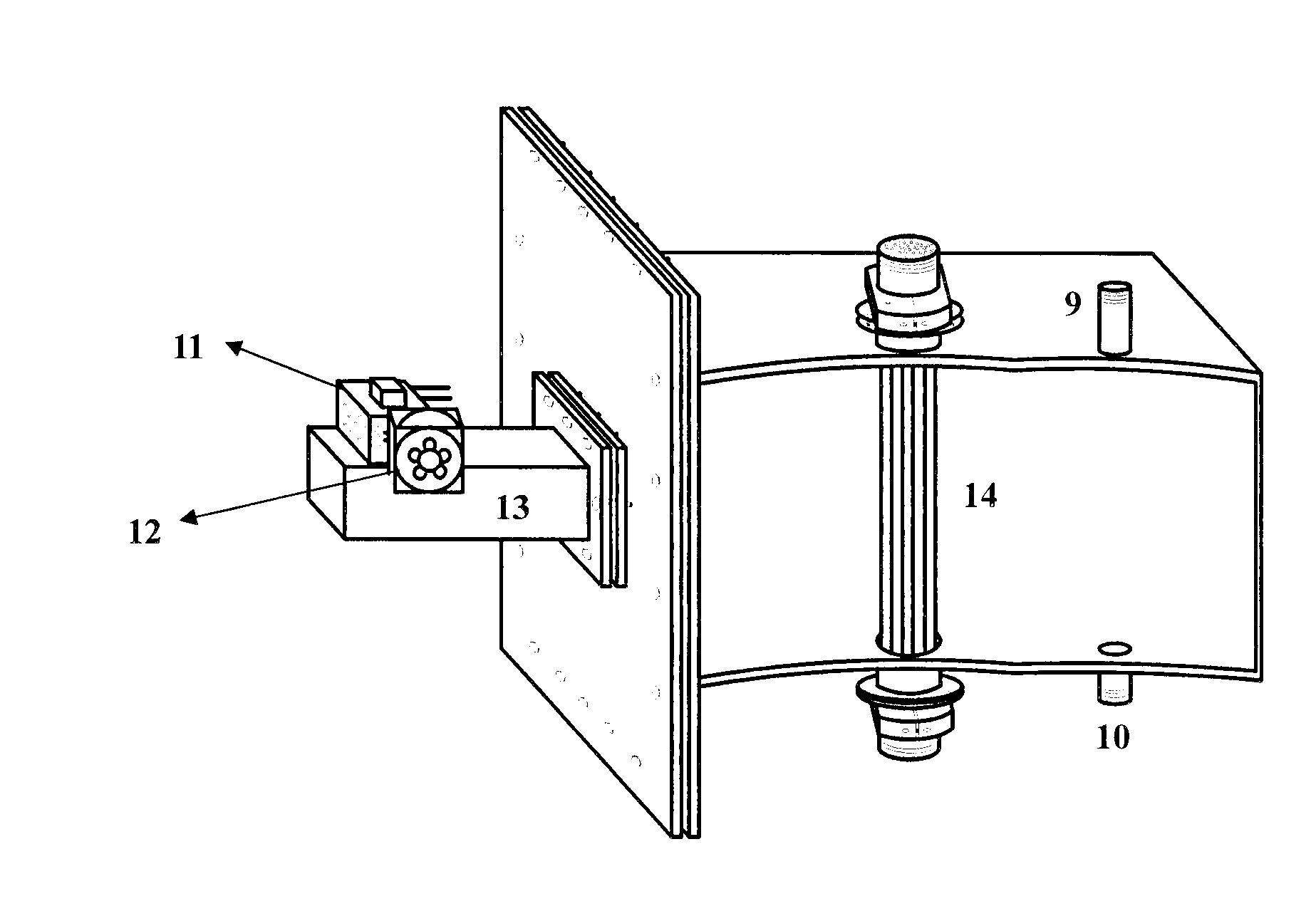

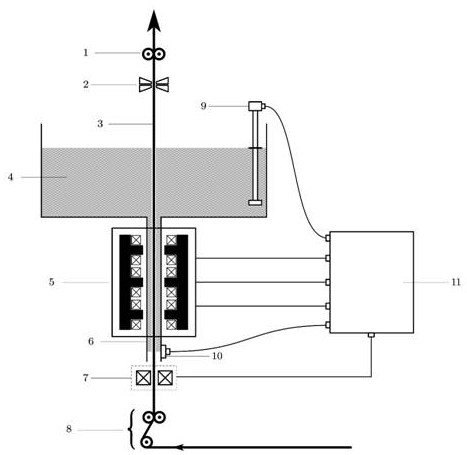

System for treating sludge by rotary electrodes in combination with flat sheet membrane

InactiveCN103979762AImprove digestion efficiencyImprove effluent qualitySludge treatmentWater qualityElectro flocculation

The invention discloses a system for treating sludge by rotary electrodes in combination with a flat sheet membrane. The system comprises a membrane treatment sludge reactor, an aeration device, a cathode membrane assembly, a first anode and a second anode, anode rotation control devices and a circuit control device, wherein the aeration device is arranged at the bottom inside the membrane treatment sludge reactor, the cathode membrane assembly is arranged inside the membrane treatment sludge reactor and located above the aeration device, the first anode and the second anode are both arranged inside the membrane treatment sludge reactor and located at both sides of the cathode membrane assembly, the anode rotation control devices are respectively arranged inside the first anode and the second anode and electrically connected with the first anode and the second anode and the circuit control device is respectively electrically connected with the first anode, the second anode and the cathode membrane assembly. According to the system disclosed by the invention, by applying an electric field in sludge, the cathode membrane assembly contamination is reduced; by use of anode electrochemical and electro flocculation technologies, the digestion efficiency of sludge and the effluent quality are improved; the deposition of sludge and microorganism is prevented by virtue of the rotation of anodes, the effective electric field strength is maintained and the dewatering performance of sludge is improved.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

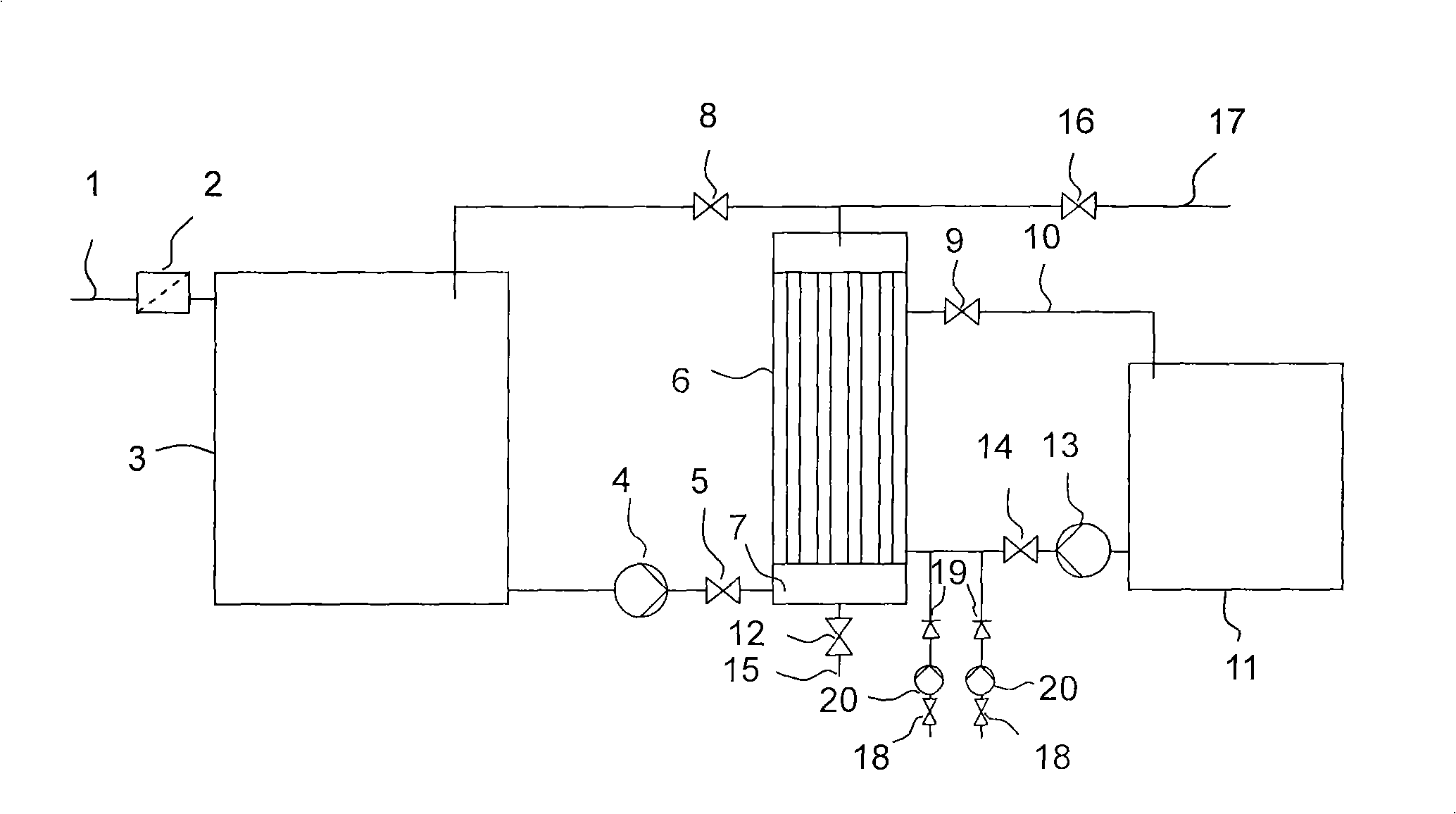

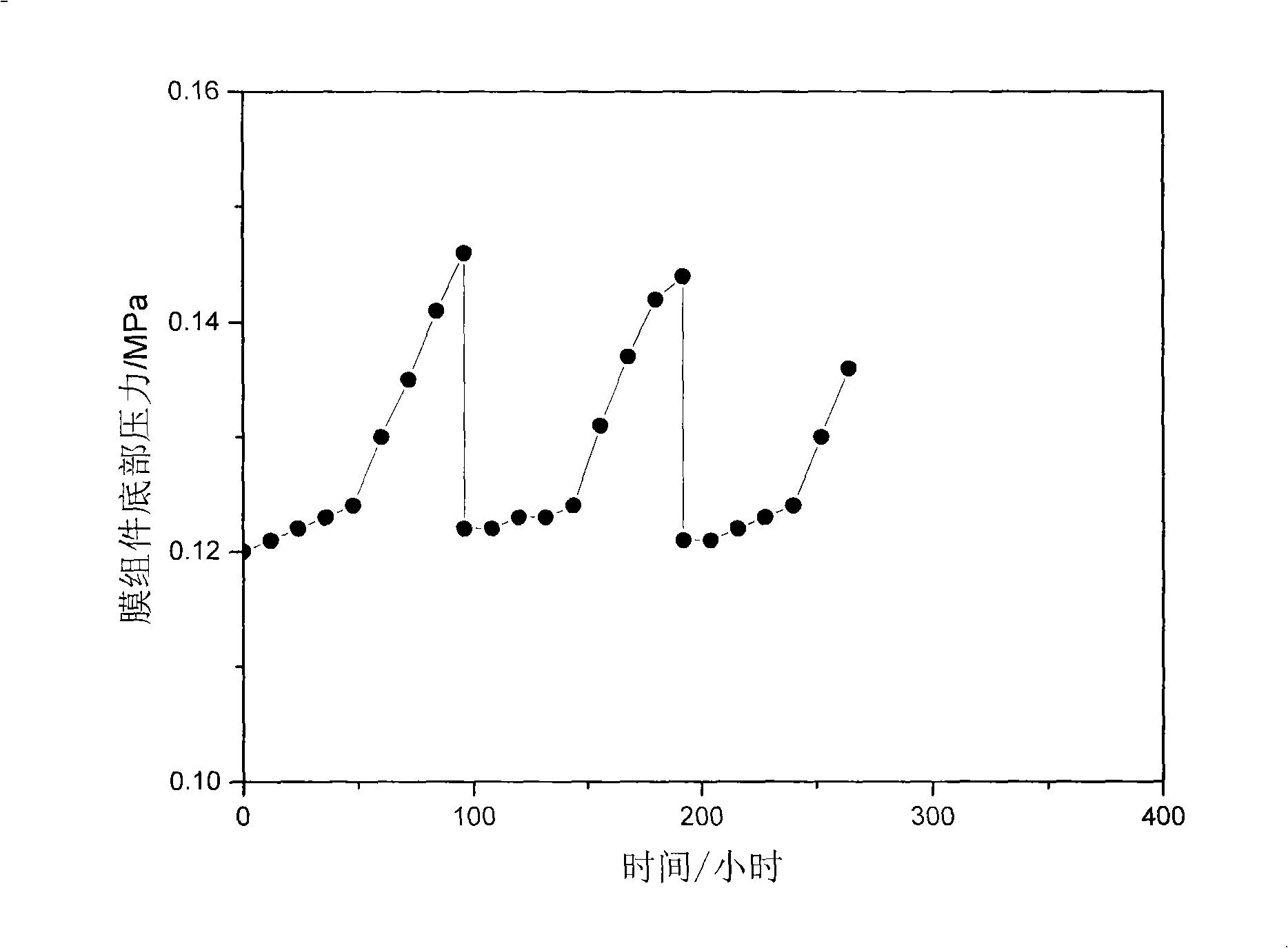

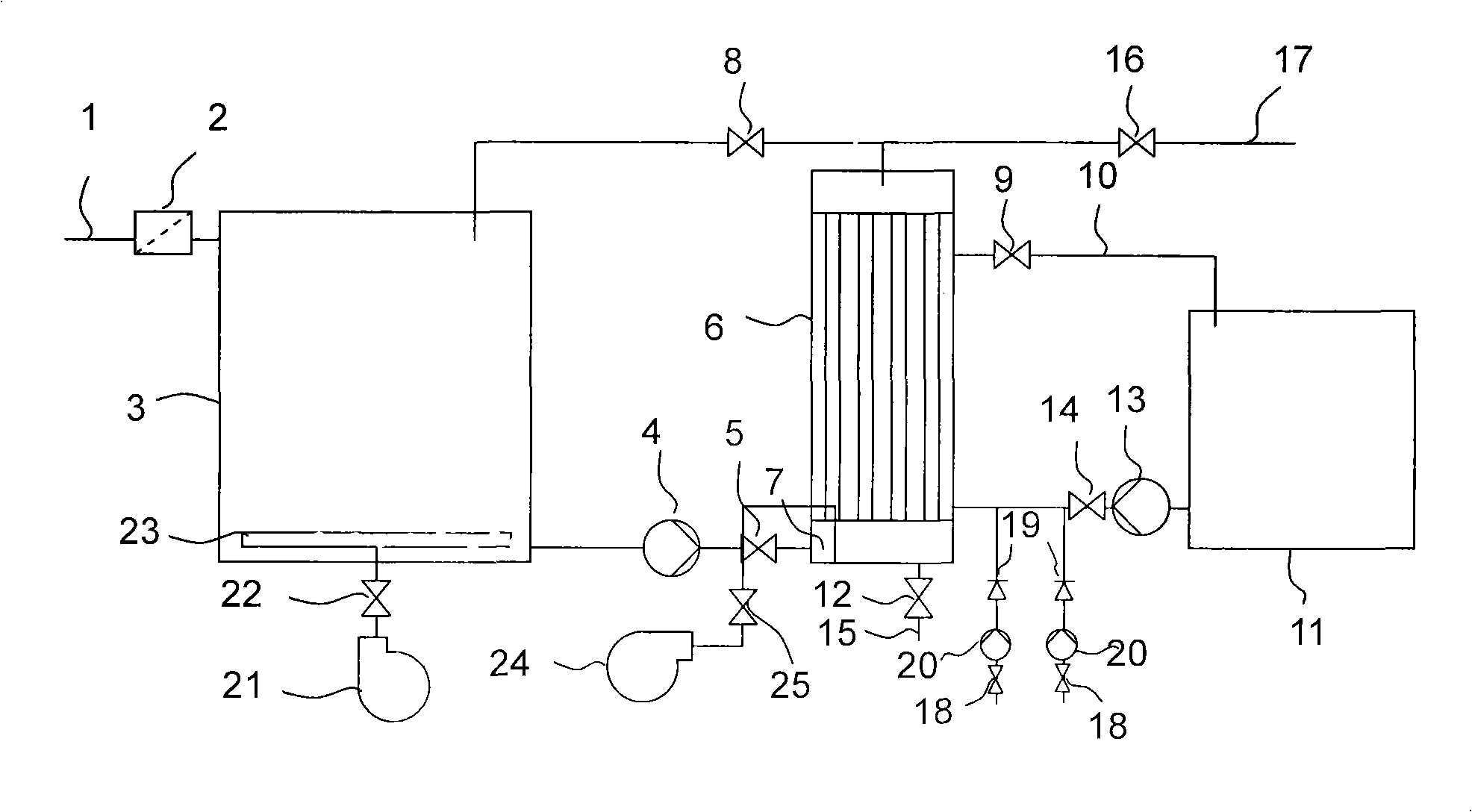

Cleaning method of porous separation membrane

InactiveCN101524625AAvoid cloggingExtend the period of stable operationSemi-permeable membranesSeparation technologyCleaning methods

The invention relates to a cleaning method of a porous separation membrane, belonging to the technical field of membrane separation. The cleaning method of the porous separation membrane is characterized in that a membrane module bottom cleaning unit is applied in the membrane separation process of treating materials with high solid content, i.e., a start parameter is activated, a circulating pump (4) and valves (5), (9) and (14) are closed, and valves (8) and (12) are opened; liquid in a membrane module flows out of the membrane module under the action of the weight and flushes contaminants deposited at the bottom of the membrane module out of the membrane module; the start parameter can be one of a filter counter, a filter time interval, start pressure and a trans-membrane pressure difference or all or part of the same; and the membrane module bottom cleaning unit singly runs or is integrated to the backflushing process to enhance the cleaning effect. The invention has the advantages that the cleaning method effectively prevents a membrane flow passage and a flow passage entry from being blocked, prolongs the stable operation period of the membrane separation process and is widely suitable for a membrane biological reactor, and the like in the membrane separation process of treating the materials with high solid content.

Owner:DALIAN UNIV OF TECH

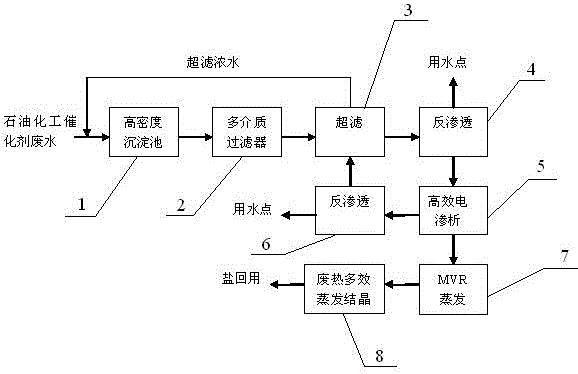

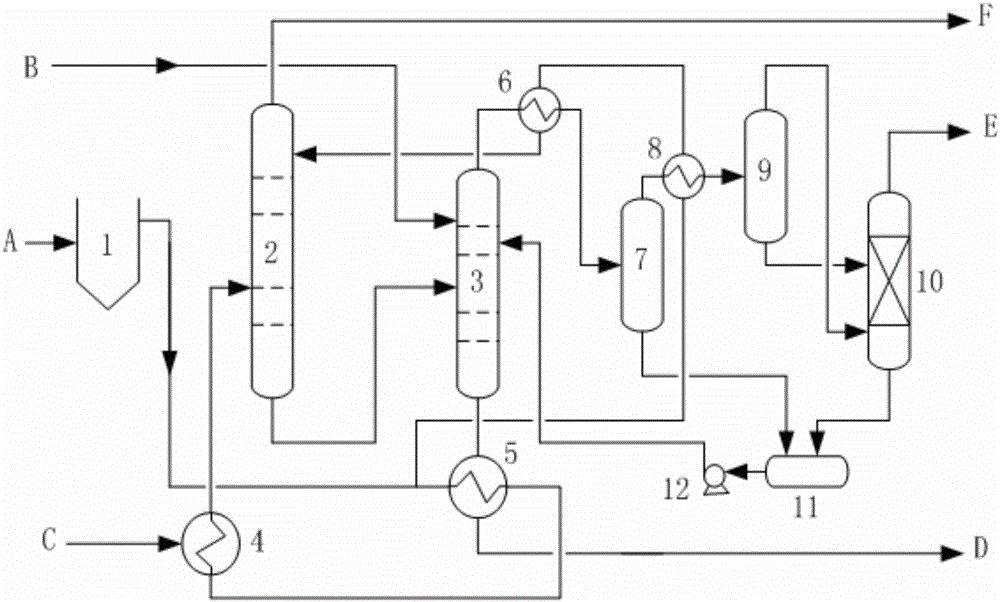

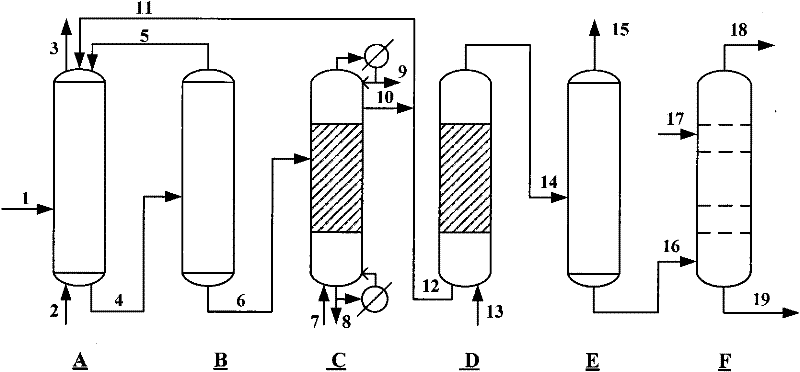

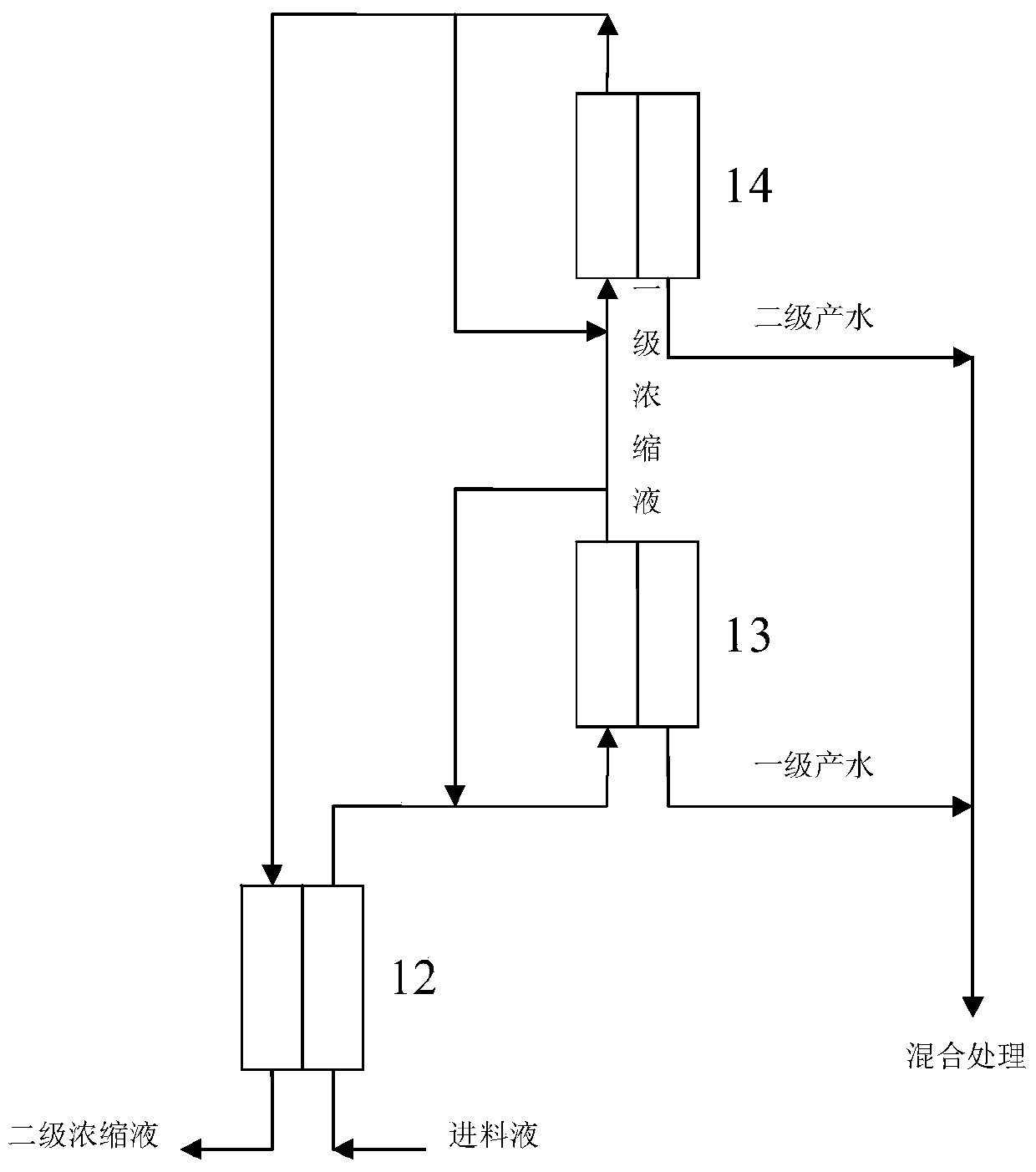

Oil refining catalyst wastewater zero-discharging treatment method

InactiveCN105084630AImprove water qualityImprove sedimentation efficiencyGeneral water supply conservationMultistage water/sewage treatmentWater desalinationFiltration

The invention relates to an oil refining catalyst wastewater zero-discharging treatment method. The oil refining catalyst wastewater zero-discharging treatment method comprises the following steps that (1) oil refining catalyst wastewater is treated in a high-density sedimentation tank to obtain sedimentation wastewater; (2) the sedimentation wastewater is fed into a multi-media filter to obtain produced water of the multi-media filter; (3) the produced water of the multi-media filter is fed into an ultra-filtration system and is further treated to obtain ultra-filtration water; (4) the ultra-filtration water is regulated to be weak-acidic and then is fed into a sea water desalination type reverse-osmosis system, and reverse-osmosis concentrated water is obtained through treatment; (5) the reverse-osmosis concentrated water is fed into an efficient electrodialysis system for concentration or into a conventional reverse-osmosis system for reverse osmosis respectively according to the salt content of the reverse-osmosis concentrated water; (6) the electrodialytic concentrated water is fed into a mechanical vapor compression (MVR) evaporator for concentration, the concentrated liquid is fed into a waste heat multiple-effect evaporative crystallization system, further evaporative concentration and crystallization are conducted on the concentrated wastewater, centrifugal dewatering is conducted on the concentrated liquid to obtain solid salt for recycling, and the produced water is reused. The oil refining catalyst wastewater zero-discharging treatment method is obvious in treatment effect and low in operation cost.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

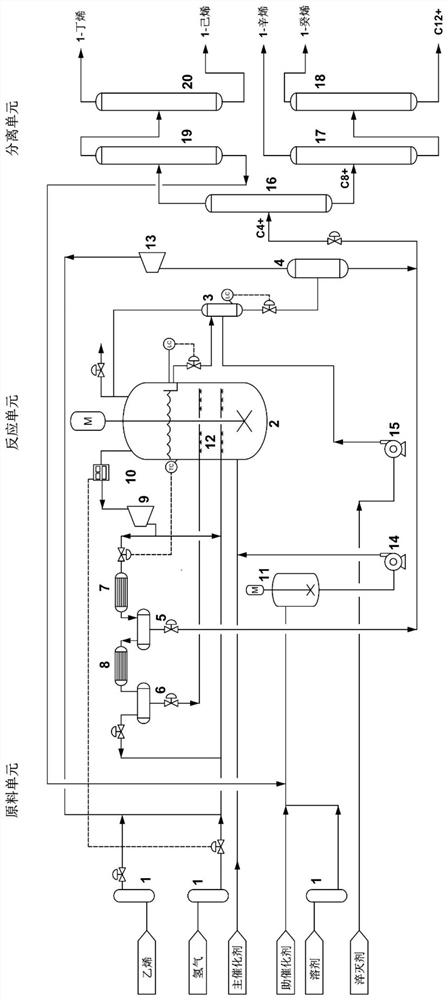

Production device and production process for producing linear alpha-olefin through ethylene selective oligomerization

ActiveCN113233951ASimple separation processConducive to continuous long-term operationHydrocarbonsBulk chemical productionSide productProcess engineering

The invention provides a production device and a production process for producing linear alpha-olefin through ethylene selective oligomerization, and belongs to the technical field of homogeneous catalysis. The device comprises a raw material pretreatment unit, a reaction unit and a separation unit, the reaction unit comprises a reaction kettle, a circulating fan, a primary condenser, a primary condensate tank, a secondary condenser and a secondary condensate tank which are sequentially communicated, and the primary condensate tank is communicated with the separation unit; the secondary condensate tank is communicated with a reaction kettle; a temperature sensor is arranged in the reaction kettle, a gas regulating valve is arranged between the primary condenser and the circulating fan, the gas regulating valve and the temperature sensor are interlocked, and the opening degree of the regulating valve is controlled through the temperature of the reaction kettle. The process and the device are mainly used for an ethylene oligomerization process, and have the characteristics that the activity of the catalyst is promoted to be improved, the selectivity of linear alpha-olefin is improved, the secondary reaction degree in which the product participates is low, high-carbon byproducts are few, and the reaction heat removal capability is strong.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

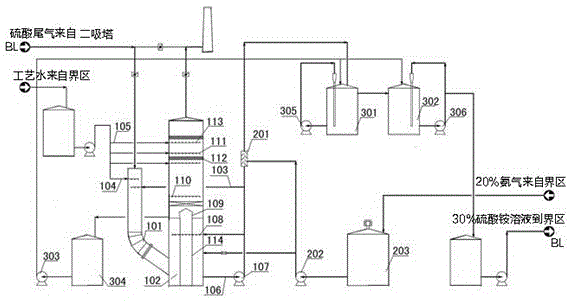

Sulfuric acid tail gas desulphurization device and method

InactiveCN104998530AImprove desulfurization efficiencyIncrease contact areaChemical industryDispersed particle separationTowerCirculating pump

The invention relates to a sulfuric acid tail gas desulphurization device and method. A multi-layer spraying, cleaning and defogging device and anti-blocking design are adopted in a desulphurization tower, and the three functions of desulphurization, cleaning and defogging are integrated by the tower. The bottom of the desulphurization tower is connected into a liquid outlet pipe and a circulating pump. The circulating pump is connected to a mixing device through a pipe. The mixing device is connected with an ammonia water pump through a pipe and connected into an ammonia water tank. Circulating solutions in the tower are ammonium sulfite and ammonium hydrogen sulfite. The higher desulphurization efficiency can be reached. The mixing device is connected into a first-level oxidation tank through a pipe and connected into a second-level oxidation tank. Secondary hydrogen peroxide oxidation outside the desulphurization tower is conducted, an ammonium sulfite solution and hydrogen peroxide fully react with each other through stirring of the air, the oxidation rate of the ammonium sulfite can reach over 98%, the quality of a by-product ammonium sulfate solution is guaranteed reliably, absorption, adjustment and oxidation are conducted on sulfuric acid tail gas, ammonium sulfate is generated, operating devices are fewer, and low power consumption and the energy-saving effect are achieved.

Owner:武汉宇青环保科技有限公司

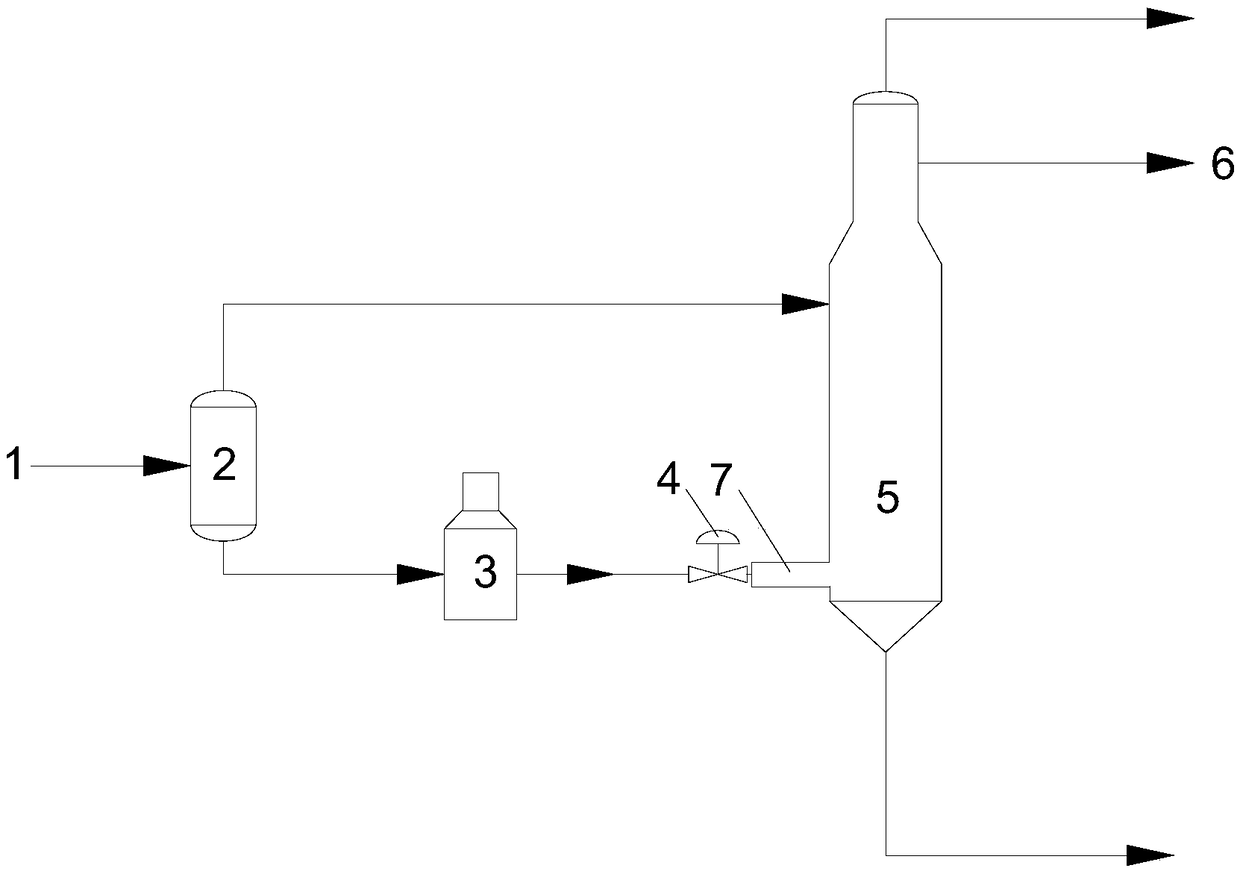

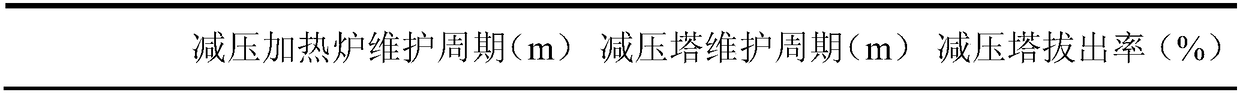

Solid-containing heavy oil vacuum distillation apparatus and method

InactiveCN109181744AGuaranteed pullout rateReduce corrosion wearHydrocarbon distillation control/regulationEconomic benefitsSolid particle

The invention relates to a solid-containing heavy oil vacuum distillation apparatus and method. The method comprises: (1) performing vacuum flashing treatment on bottom oil containing solids under atmospheric pressure to obtain flash top gas and flash bottom oil, and (2) directly feeding the flash top gas into a vacuum tower, heating the flash bottom oil and feeding the flash bottom oil into the vacuum tower. The apparatus and method guarantee the extraction rate of the vacuum distillation tower, reduce the wear and corrosion of the solid particles in the oil component to the vacuum furnace and the furnace tube, improve the operation cycle of the vacuum furnace and improve the economic benefits.

Owner:胜帮科技股份有限公司

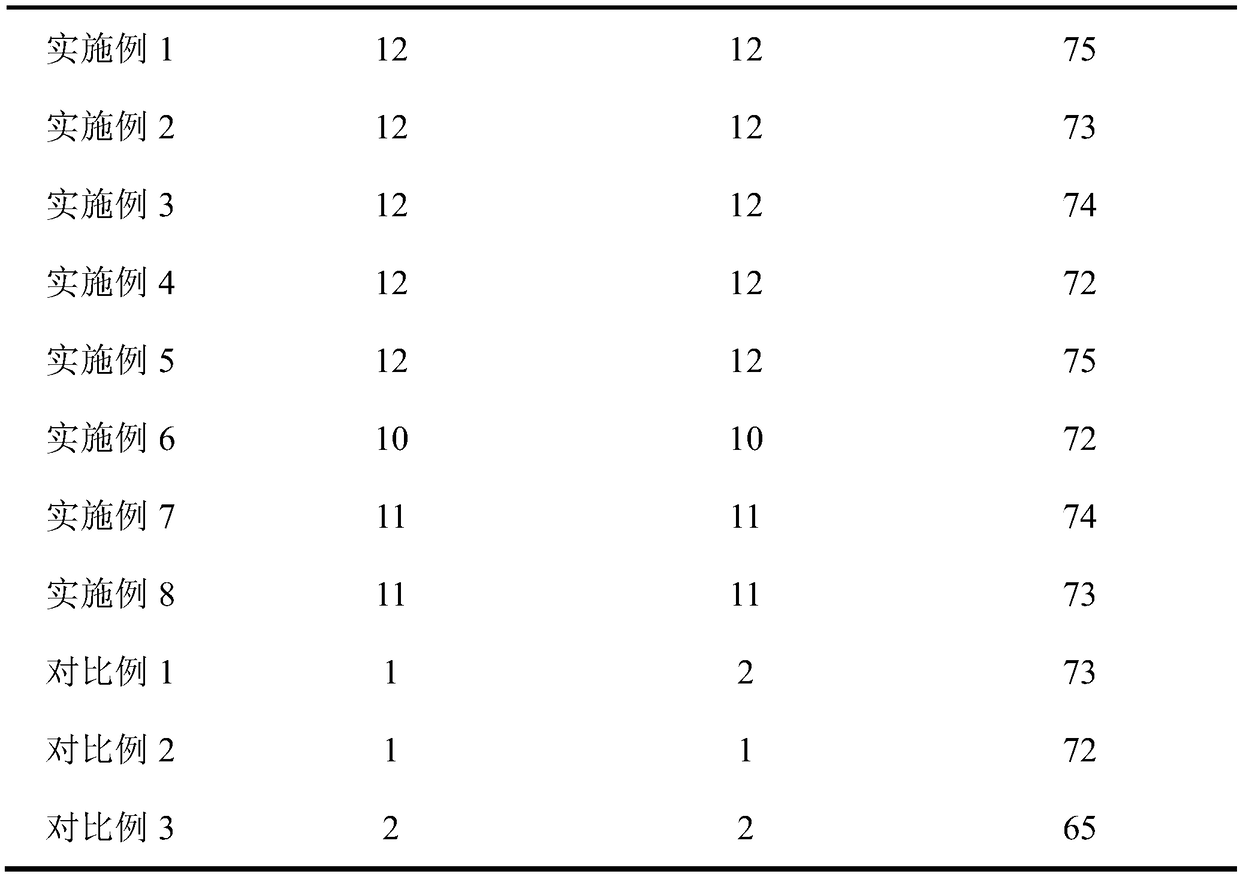

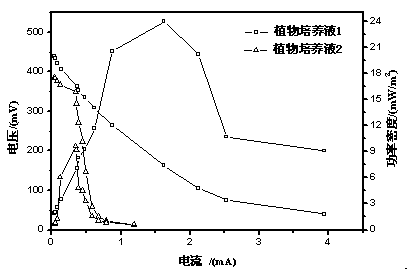

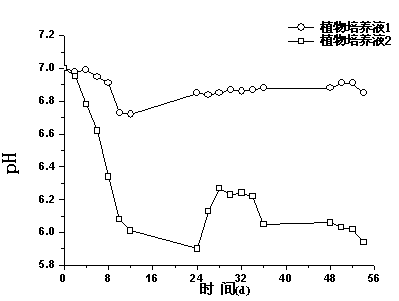

Environmental-friendly roof system capable of generating electric energy and application of system

InactiveCN103165932AImprove energy efficiencyReduce energy lossRoof covering using slabs/sheetsRoof covering using tiles/slatesElectrochemistryNatural resource

The invention discloses an environmental-friendly roof system capable of generating electric energy, and application of the system and belongs to the field of environment conservation and new energy. The environmental-friendly roof system comprises a soil layer, plants planted in the soil layer, a water layer above the soil layer, and a plurality of cell units, wherein each cell unit comprises a positive electrode and a negative electrode which are connected with each other by virtue of a lead; the positive electrodes are embedded in the soil layer, and the negative electrodes are positioned in the water layer; the root systems of the plants are close to the positive electrodes, and the stem leaves of the plants penetrate through the negative electrodes and are above the water layer; and the plurality of cell units are connected with one another by leads and then are connected with an energy storage device which is connected with a load. According to the invention, soil microorganisms can convert solar energy into electric energy in an electrochemistry system, so that the environmental-friendly roof system is environment-friendly and has high energy utilization efficiency. The environmental-friendly roof system has a simple structure, depends on natural resources, does not need too much daily maintenance, is low in construction and running cost, and is suitable for promotion in modern cities.

Owner:NANJING UNIV OF TECH

Method for flushing reverse osmosis membrane

ActiveCN102049198BSlow down the phenomenon of concentration polarization on the filter surfaceMitigating pollution problems with hard-to-remove pollutantsWater/sewage treatment bu osmosis/dialysisReverse osmosisColloidal silicaOrganic solvent

Owner:CHINA PETROLEUM & CHEM CORP +1

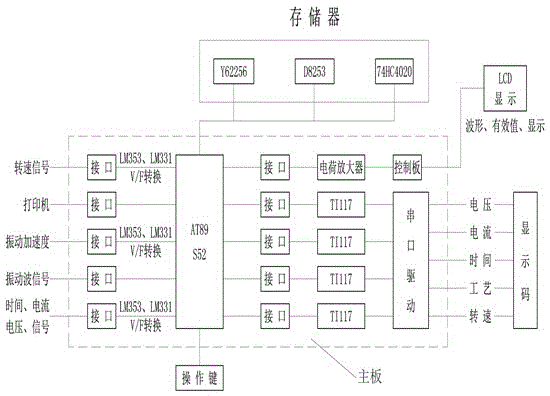

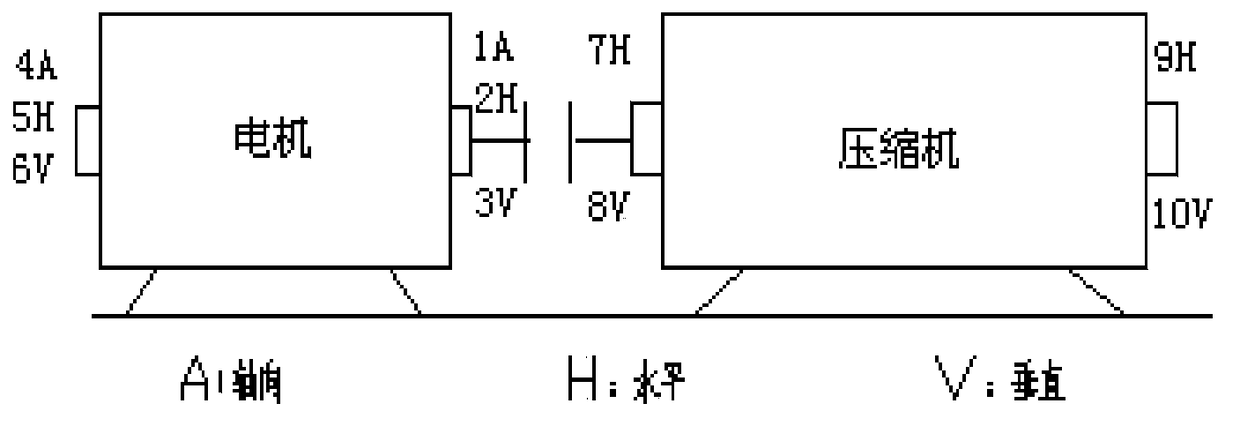

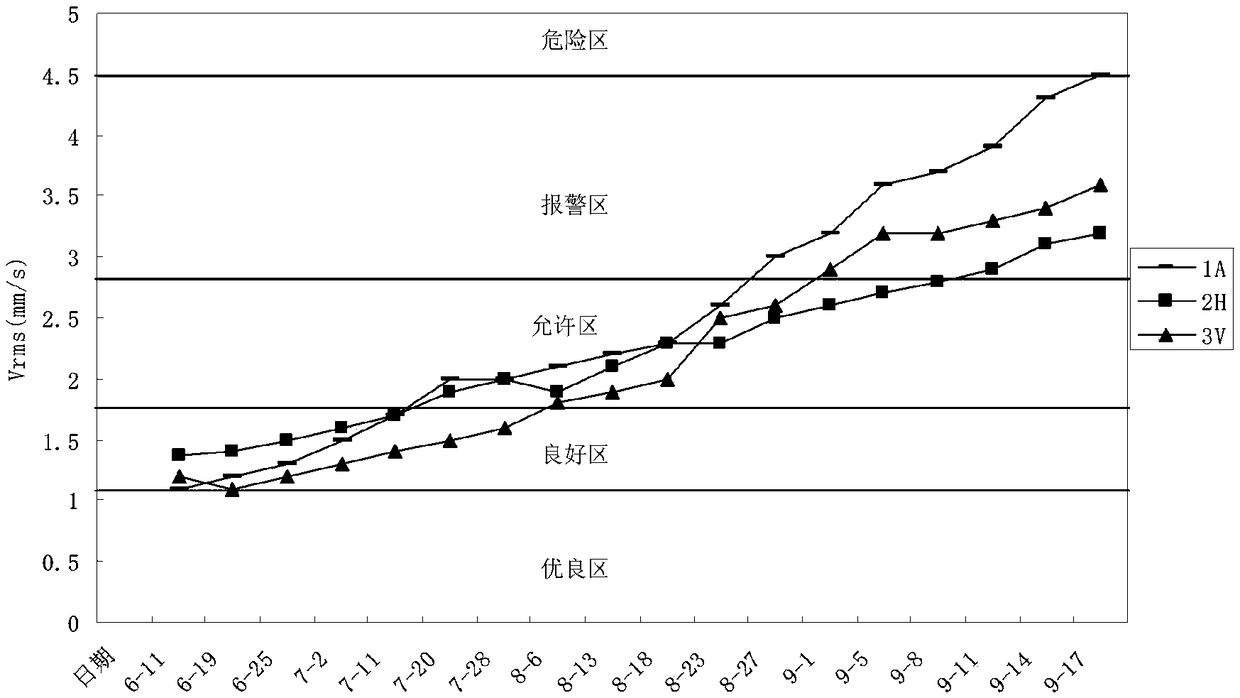

The application of condition monitoring and fault diagnosis technology in the operation management of refrigeration unit

PendingCN109446482AReduce maintenance costsExtend the stable operation periodSubsonic/sonic/ultrasonic wave measurementComplex mathematical operationsLubricationDevice failure

The invention discloses the application of a state monitoring and fault diagnosis technology in the operation management of a refrigerating unit. At the initial stage of equipment failure, the vibration thereof will change, such as vibration amplitude change, vibration frequency change, vibration phase change and the like. By using this characteristic, the vibration-related parameters are widely used as the characteristic parameters to characterize the state of the rotating equipment, at the same time, the temperature, pressure, oil pressure, oil temperature lubrication parameters and currentand other parameters are referenced. These parameters can be recorded, sorted out and analyzed to grasp the operation status of the equipment, thereby effectively solving the problem that the sudden shutdown failure of the refrigeration unit affects the normal production, timely finding out the hidden trouble of the failure and make scientific and reasonable maintenance plan and scheme, avoiding the occurrence of destructive failure, improving the reliability and stability of the operation of the equipment, and reducing the maintenance cost.

Owner:天津长芦汉沽盐场有限责任公司

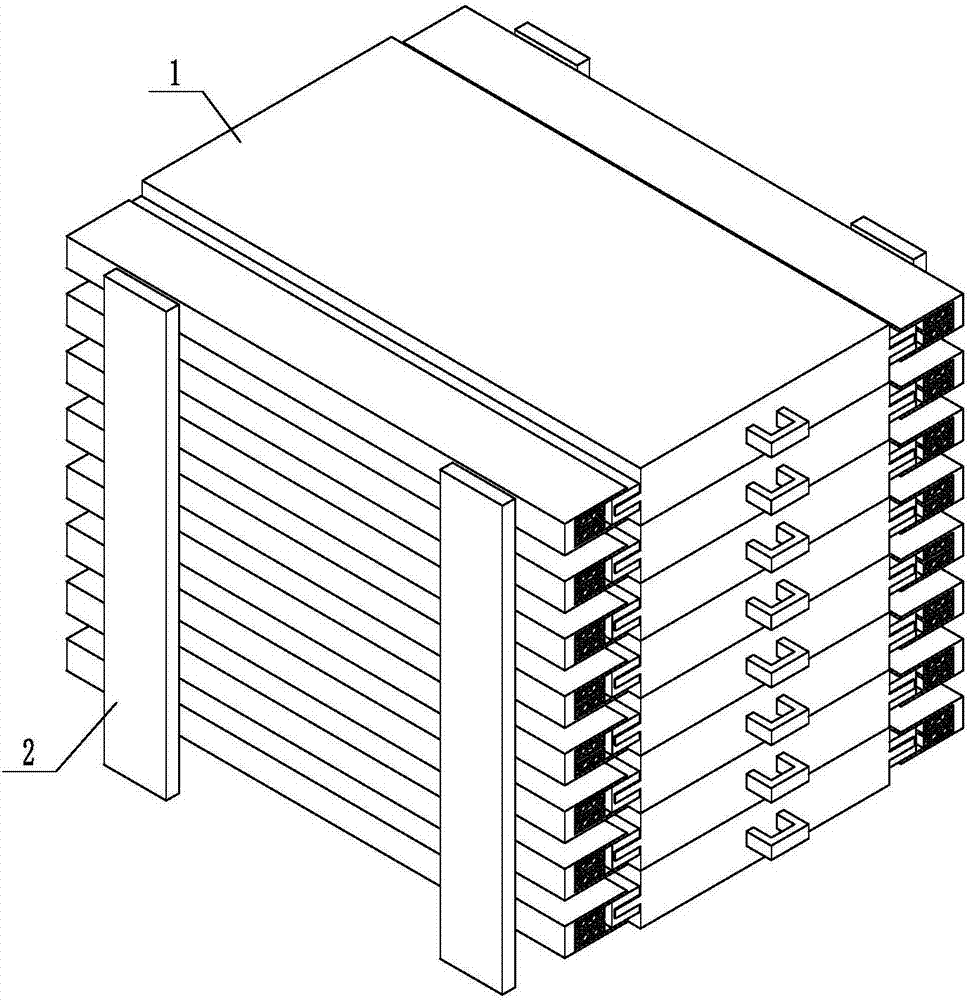

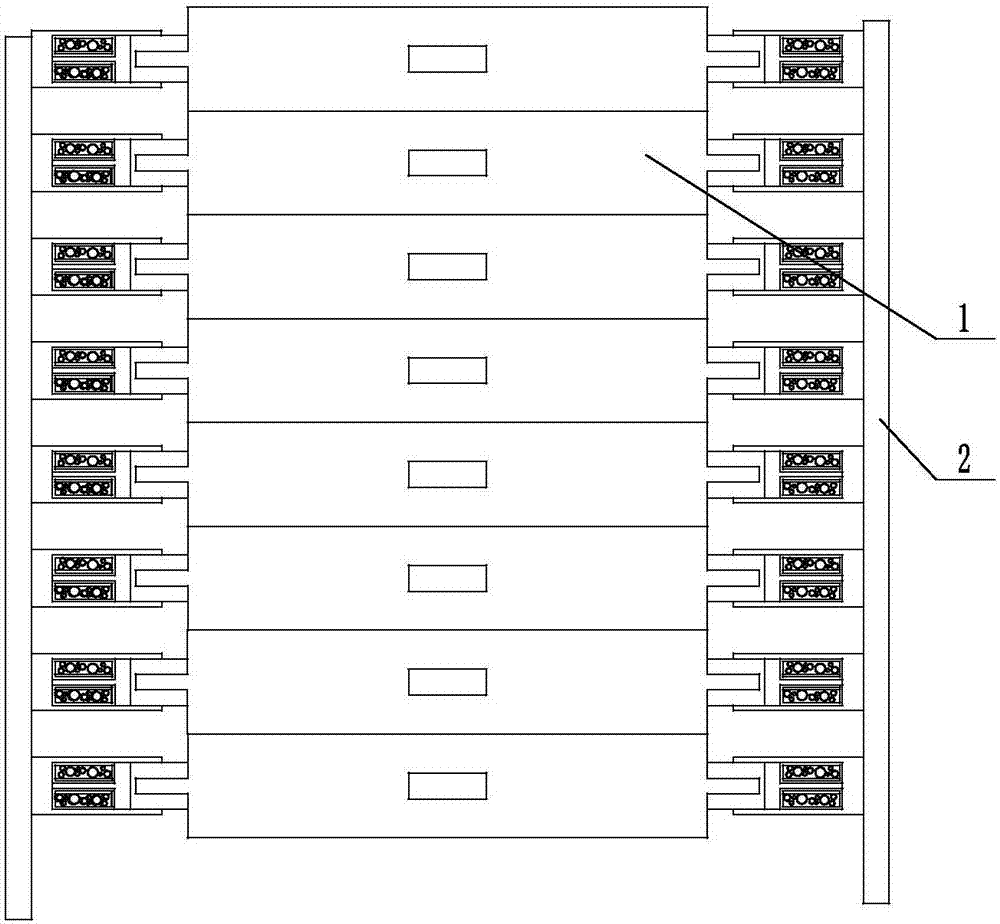

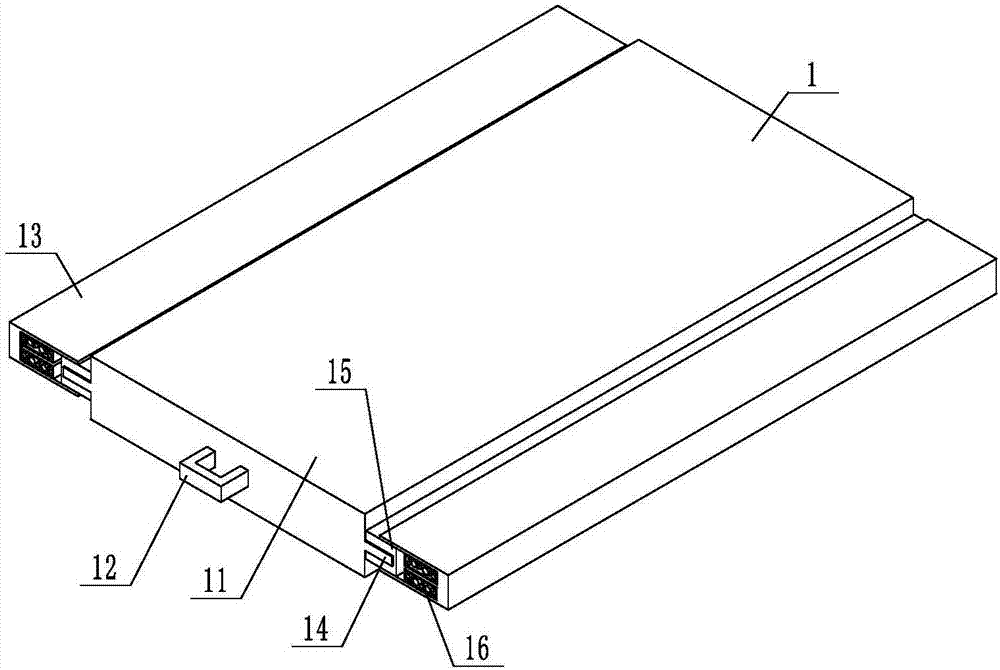

Telescopic guide rail integrated with cable collection function

The invention discloses a telescopic guide rail integrated with a cable collection function, and relates to the field of guide rails. The telescopic guide rail comprises a plurality of groups of guide rail components, wherein the guide rail components comprise guide rail back sheets; soft connection belts are arranged in the guide rail back parts; cables are arranged in the soft connection belts; guide rail pushing-pulling grooves are formed in guide rail front sheets; the guide rail pushing-pulling grooves are in slide fit with case fixing bars; the case fixing bars are connected with a pulling box; and the pulling box is connected with the soft connection belts. Through adoption of the telescopic guide rail, cables are arranged on two sides of a machine in a tidy and attractive way. Compared with a conventional back-end lead groove design, the telescopic guide rail has the advantages that heat dissipation at a back end of the machine is facilitated more; the aging time of the machine is prolonged; and the stable running period of the machine is prolonged. Cables of the machine can be identified more easily, and faulty operations such as wrong unplugging and wrong plugging are avoided. Mutual signal interference can be avoided through classified arrangement of strong current cables and weak current cables.

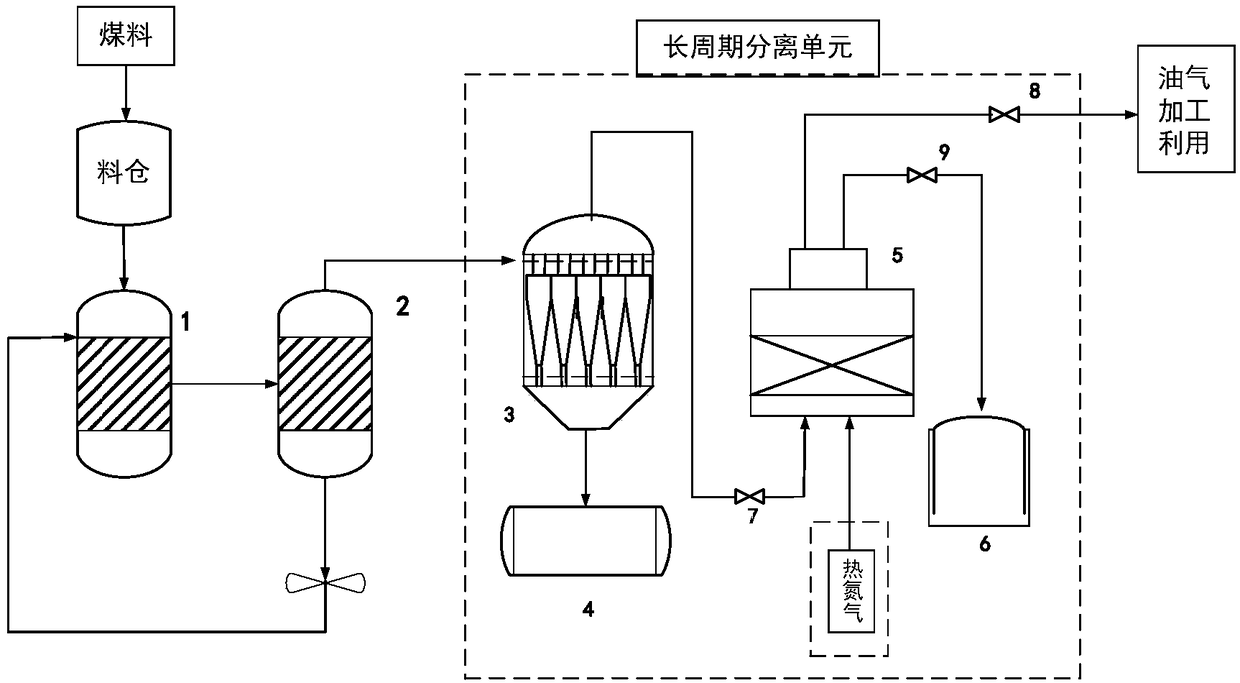

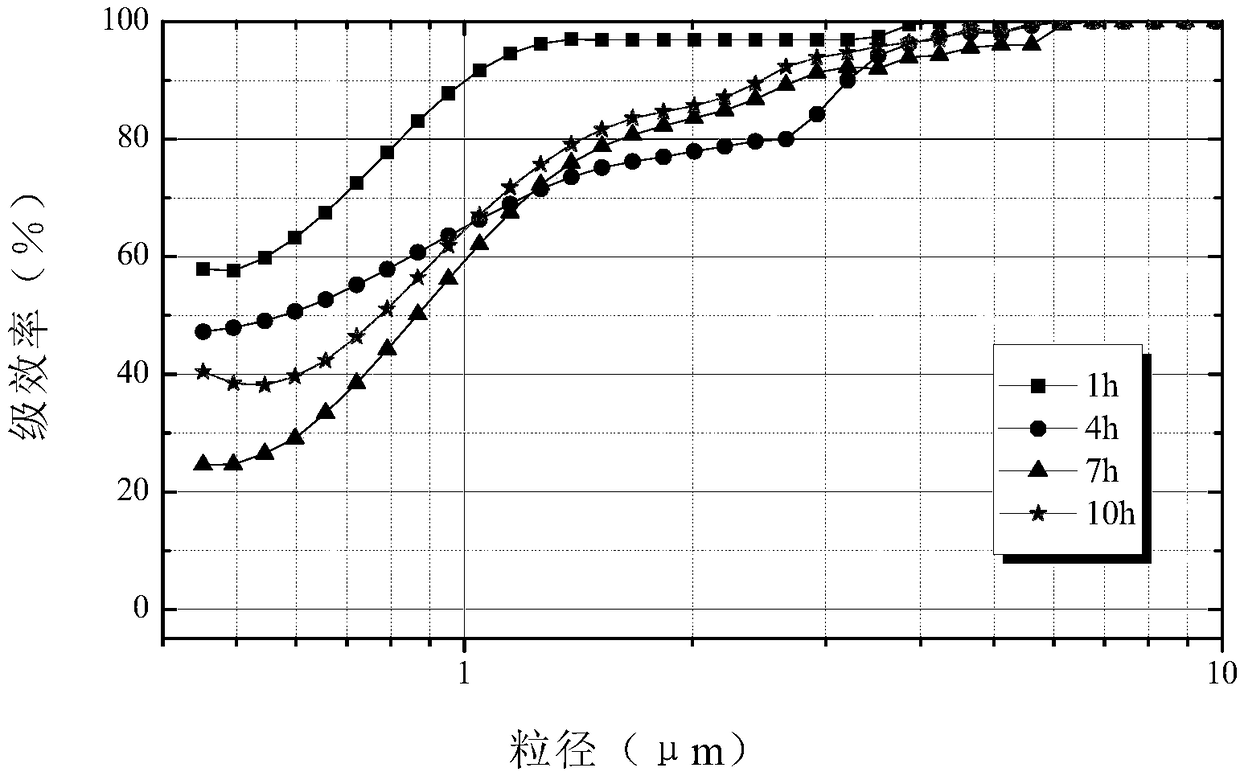

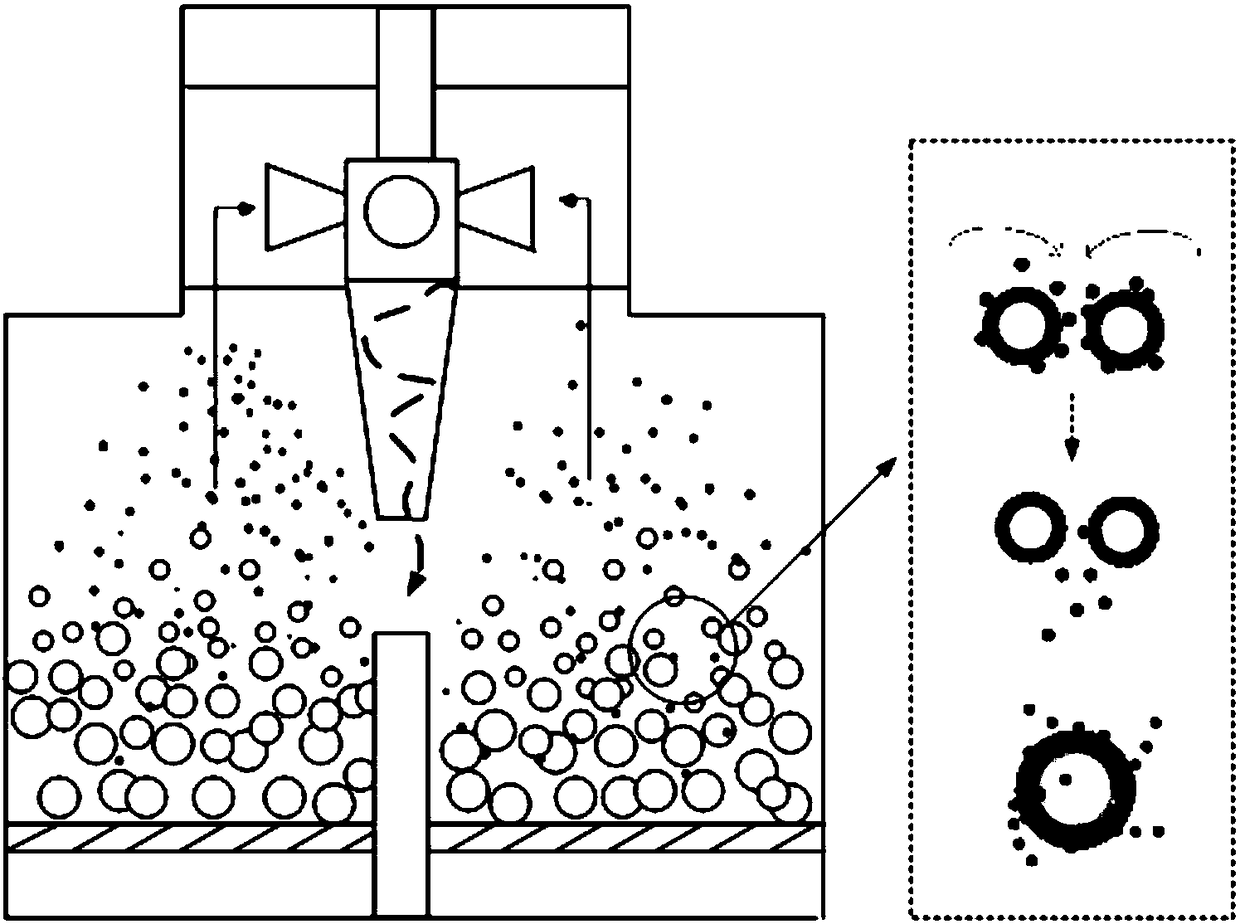

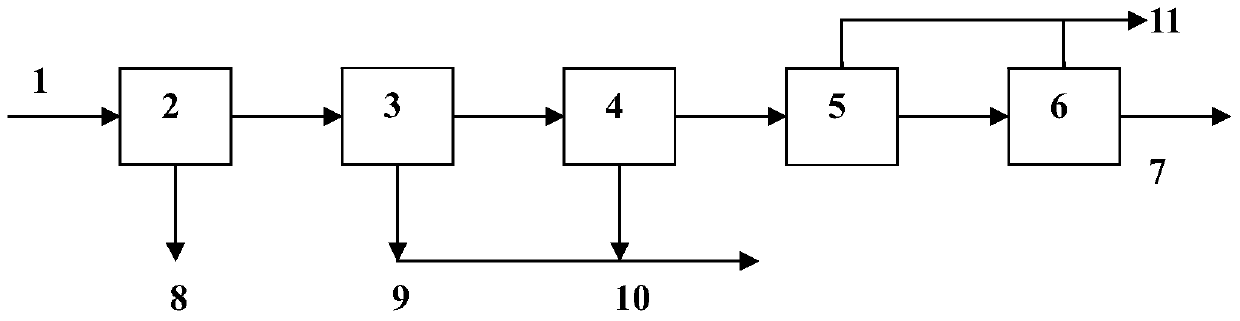

Coal pyrolysis flue gas control treatment equipment continuous operation period prolonging method and coal pyrolysis flue gas control treatment equipment continuous operation period prolonging apparatus

ActiveCN108325311AExtend the period of stable operationImprove removal efficiencyCombination devicesGas purification with selectively adsorptive solidsControl treatmentFiltration

The present invention relates to a coal pyrolysis flue gas control treatment equipment continuous operation period prolonging method and a coal pyrolysis flue gas control treatment equipment continuous operation period prolonging apparatus, and provides a coal pyrolysis flue gas control treatment equipment continuous operation period prolonging method, which comprises: (i) carrying out pre-separation treatment on raw material flue gas in a coal pyrolysis process through micro-swirling flow separation to remove large-particle-size catalyst particles from the flue gas; (ii) carrying out gas flowbalancing on the obtained flue gas, and feeding into the particle bed of a boiling bed separator to filter out fine particles entrained in the flue gas; and (iii) discharging the clean flue gas obtained through the two filtrations so as to be processed and utilized. The invention further provides a coal pyrolysis flue gas control treatment equipment continuous operation period prolonging apparatus.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

A kind of wax oil hydrogenation treatment method

ActiveCN104927902BIncrease the atomic ratio of hydrogen to carbonEfficient removalHydrocarbon oils treatmentWaxHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +2

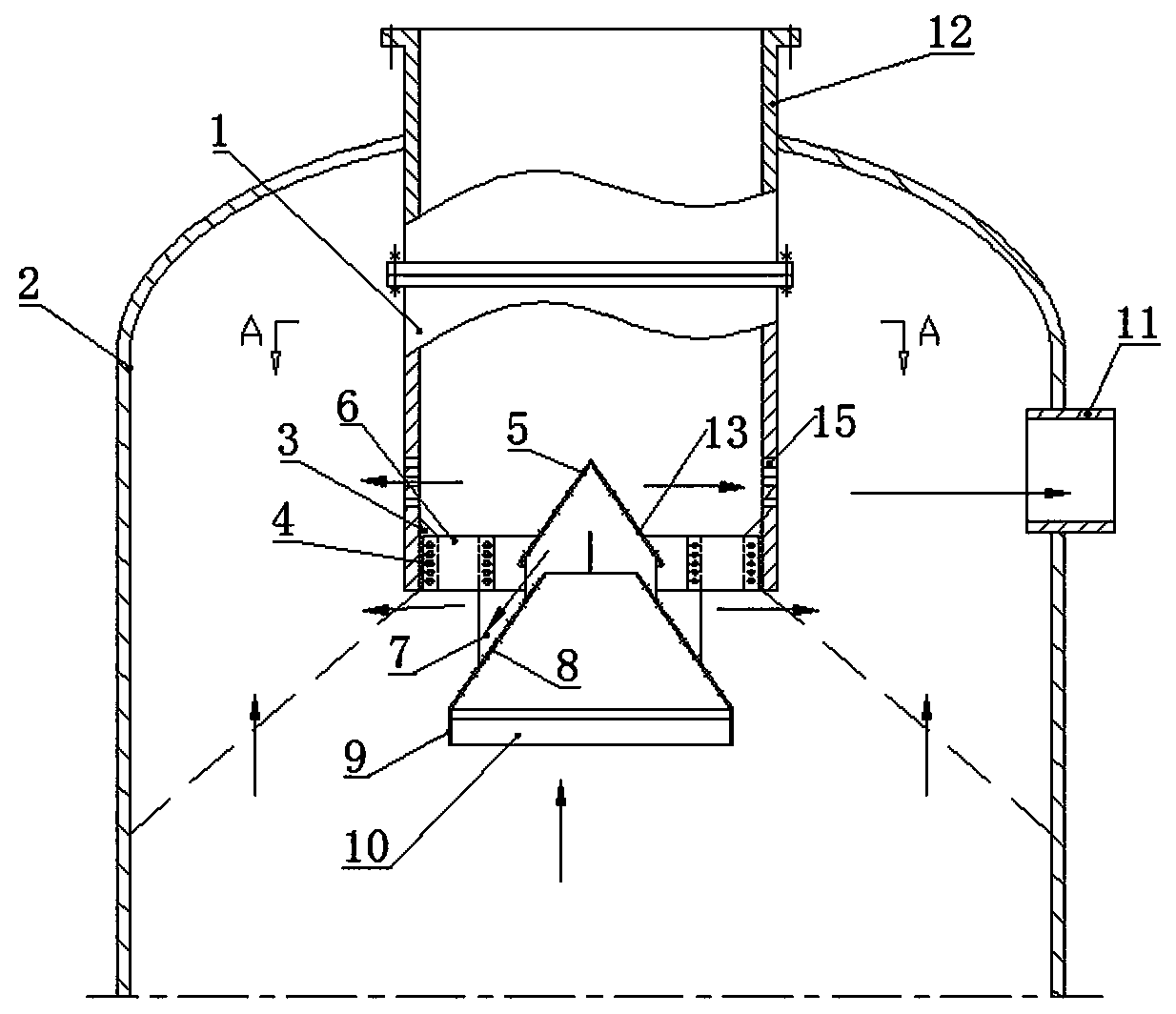

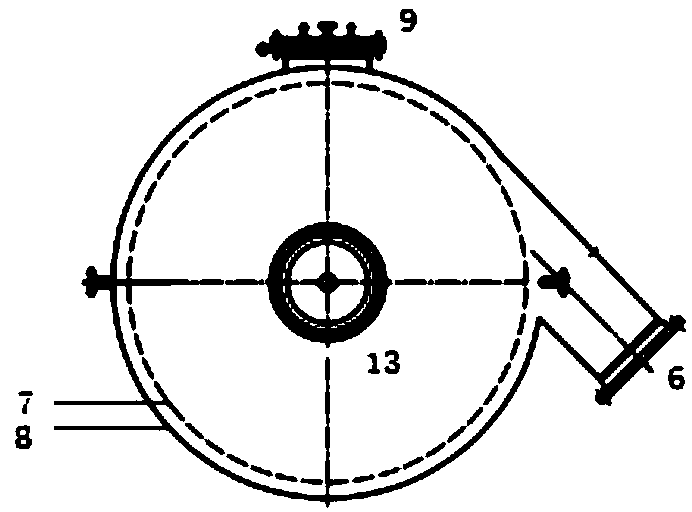

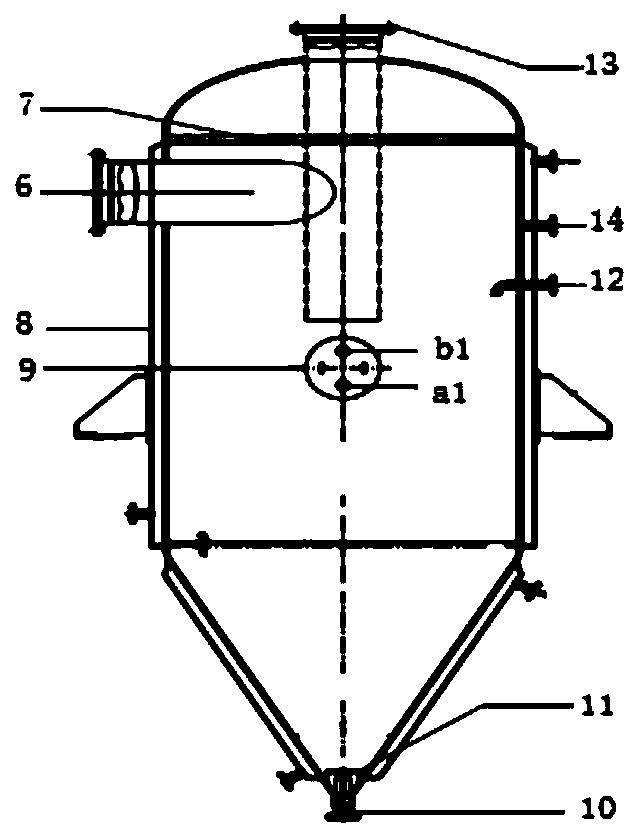

Fixed bed slag vapourizing furnace distributing device

PendingCN108753361AExtend the period of stable operationReduce maintenance costsGasifier feeding meansChemical industrySlagMechanical drive

The invention discloses a fixed bed slag vapourizing furnace distributing device. The fixed bed slag vapourizing furnace distributing device comprises a material canister and a material-guiding part,the material canister is arranged below a charging adapter at top of a vapourizing furnace, the material-guiding part is fixed in a lower end of the material canister through a material-guiding fixedmechanism, the material-guiding part comprises a conical top cap and a material distribution cone arranged below the conical top cap, and pores are uniformly arranged at the conical top cap and the material distribution cone. According to the invention, a mechanical driving apparatus and a rotation part are not provided, furnace overhaul due to fault of the rotation part can be avoided, a stable operation period of a vapourizing furnace is increased, the unkeep maintenance cost of the vapourizing furnace is reduced, and the cost consumption due to gas from bump fragmentation by stirring the solid raw materials is reduced.

Owner:云南煤化集团工程技术有限公司 +1

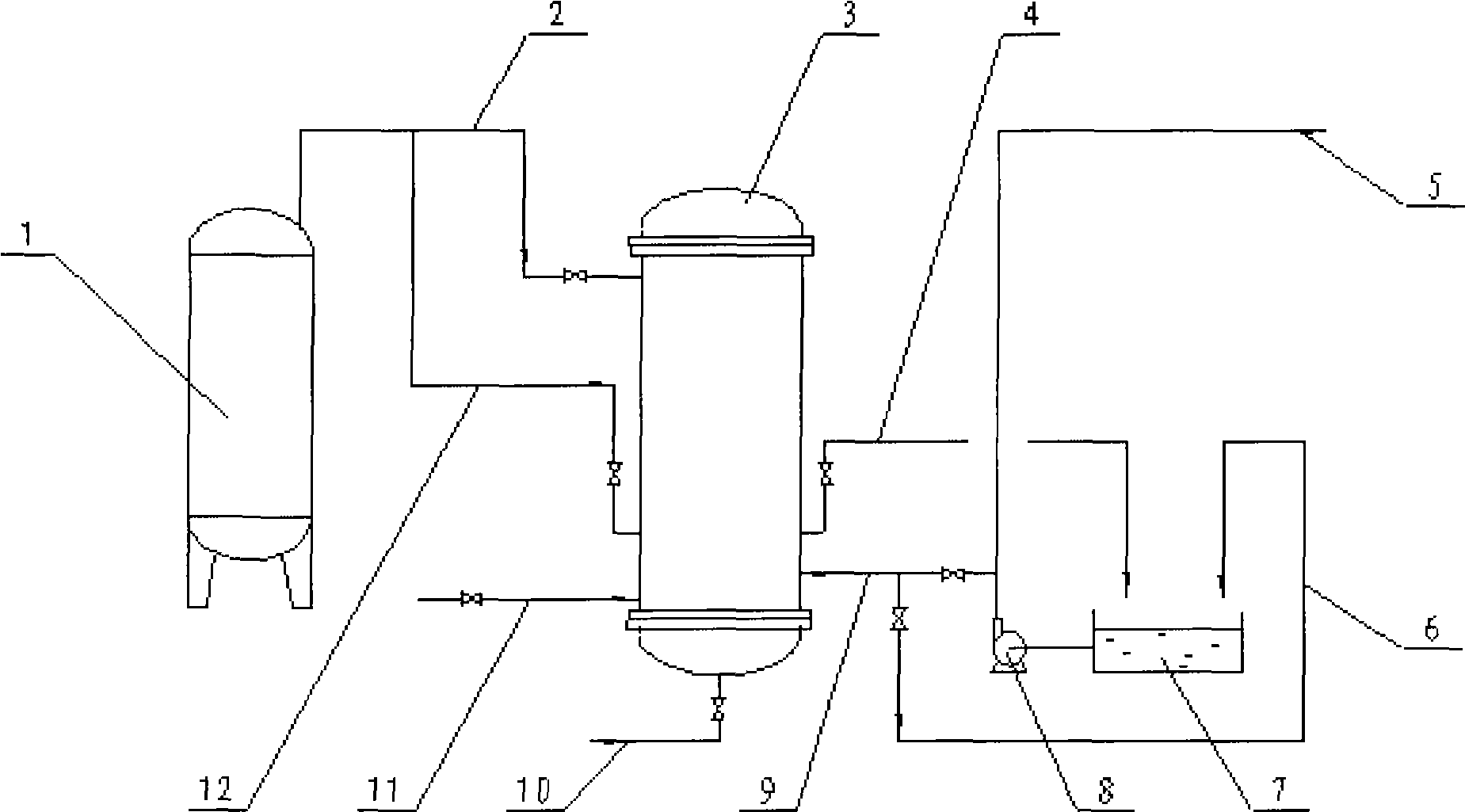

Method and device for secondarily filtering doctor solution by side stream

InactiveCN101530693AReduce suspended sulfur and secondary salt contentReduce tower pluggingFiltration circuitsFilter regenerationTanninProcess engineering

The invention relates to a method and a device for secondarily filtering a doctor solution by side stream, and belongs to the technical field of purification of the doctor solution of synthesis ammonia. The method adopts a doctor solution side-stream filter process, and desulfurizes the doctor solution by a doctor solution side-stream filter system and a filter regeneration system which regenerates the filter system; and the device consists of the doctor solution side-stream filter system and the filter regeneration system. The invention is suitable for tannin extract normal pressure desulfurization systems; and after the doctor solution shunted on a doctor solution main pipeline is desulfurized by the device, suspending sulfur and secondary salt contents in deficient liquid after the desulfurization can be effectively reduced, and phenomenon of tower blockage of a desulfurizing tower is reduced. The method and the device not only improve the desulfurization efficiency of the tannin extract desulfurization systems and prolong the stable operation cycle of the systems, but also reduce the discharge of the doctor solution due to tower cleaning; and the suspending sulfur particles after the desulfurization are not discharged and have no pollution, the phenomenon of the tower blockage of the desulfurizing tower is reduced, and the system is stably operated in a long cycle; and the method and the device realize online operation and online back washing, and optimally configure a back washing solution to prevent the back washing solution polluting the environment.

Owner:YANKUANG GRP CO LTD +1

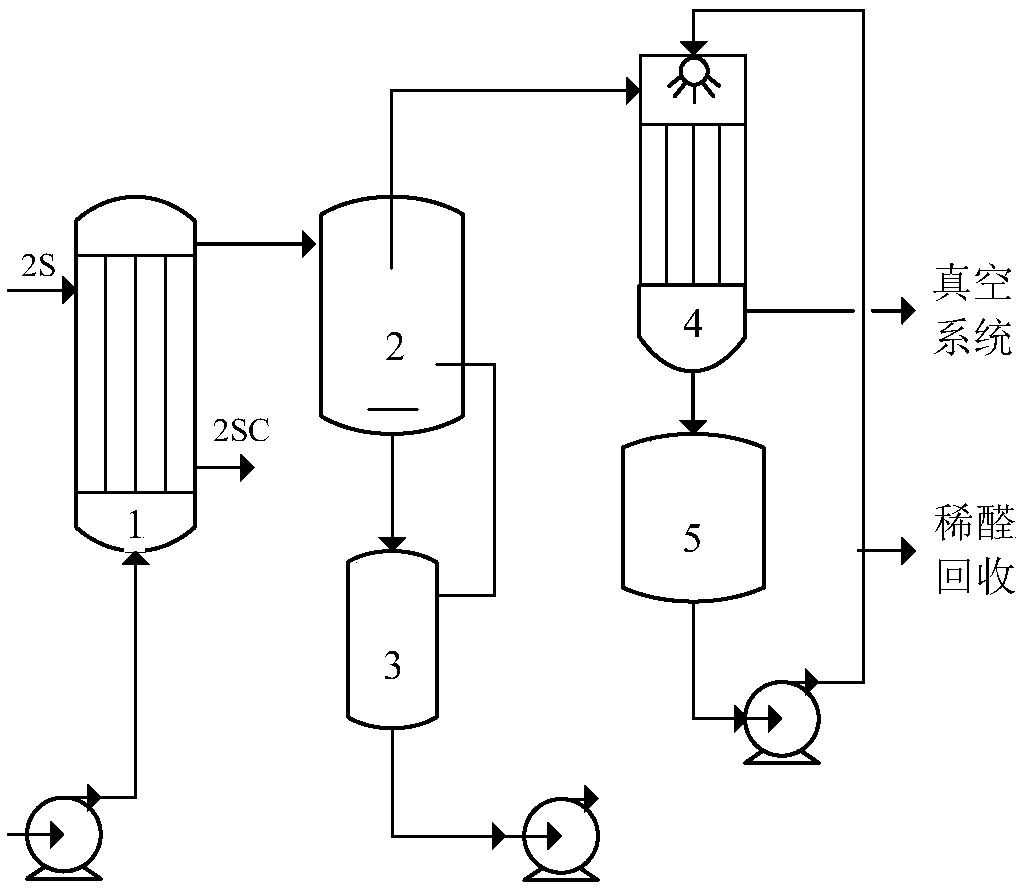

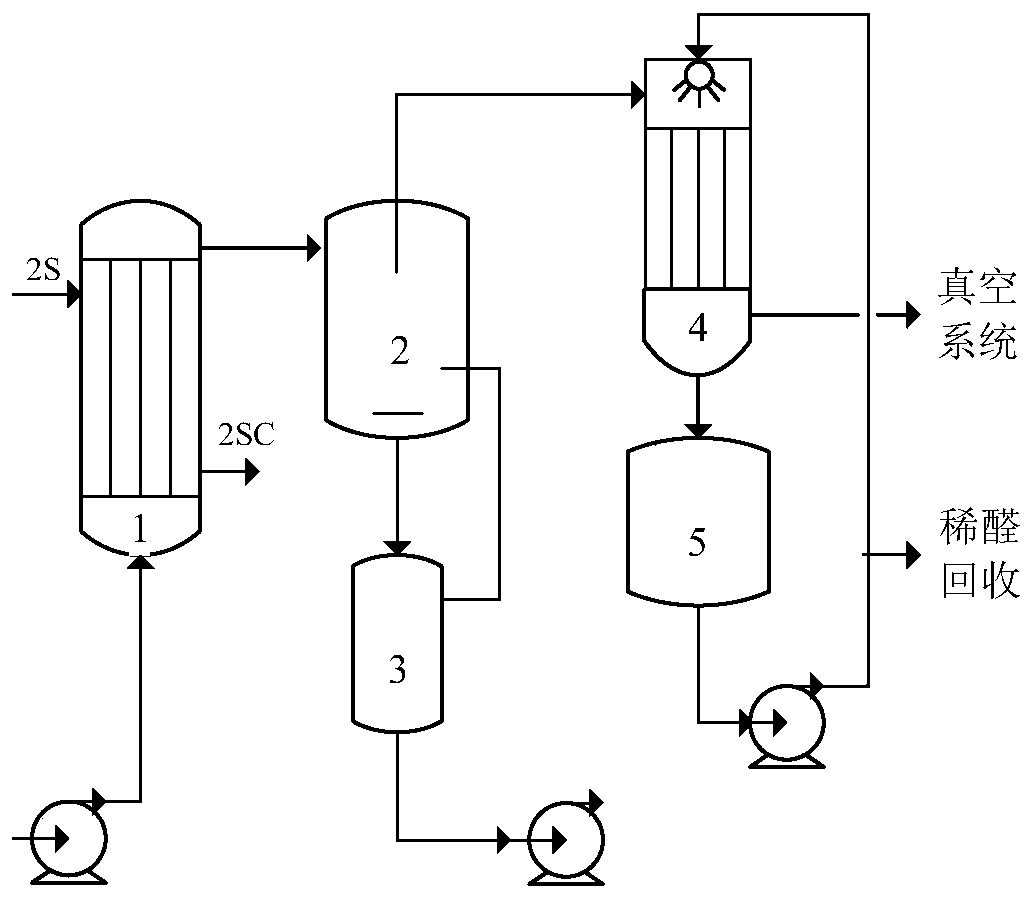

Device, system and process for formaldehyde concentrating

ActiveCN109529389AReduce recycling volumeReduce consumptionEvaporator accessoriesVacuum distillation separationGas phaseEngineering

The invention discloses a device, a system and a process for formaldehyde concentrating. The device is a formaldehyde concentrating vacuum separator, which is a circular cylinder structure and which is provided with a jacket on the external wall. One end of the circular cylinder structure is provided with a gas phase outlet, and the other end is provided with a liquid phase outlet. The cylinder wall of the circular cylinder structure is provided with a material inlet pipe. The material discharging direction of the material inlet pipe is tangent to the wall of the circular cylinder structure. The material inlet pipe is adjacent to the gas phase outlet, and the cylinder wall of the circular cylinder structure is provided with an annular liquid retaining ring the center of which is on the axis of the circular cylinder structure. The liquid retaining ring is located between the material inlet pipe and the gas phase outlet. The gas phase outlet is provided with a gas discharging pipe. The gas inlet of the gas discharging pipe is between the material inlet pipe and the liquid phase outlet. The device enables greatly improved concentration separation efficiency and reduces the recovery amount of lean formaldehyde and steam consumption.

Owner:YANKUANG GRP CO LTD

Method and device for removing hydrogen sulphide from mixture gas containing low-concentration hydrogen sulphide

ActiveCN100518892CRemove the stenchSolve absorptionDispersed particle separationPhysical chemistryMethylethylene Glycol

A method for removing hydrogen sulfide from a mixed gas containing low-concentration hydrogen sulfide gas is provided, comprising: providing an absorbing liquid, the absorbing liquid being selected from N-methylglycolamine solution, monoethanolamine solution, diethanolamine Solution, and their mixture; under the absolute pressure of 0.05-0.30MPa, the absorption liquid at 18-42°C is contacted with the mixed gas containing low-concentration hydrogen sulfide gas at 20-52°C, and the mixed gas is sequentially counter-current Absorption and swirl absorption to reduce the concentration of hydrogen sulfide in the mixed gas to 10ppm or lower; and perform swirl gas-liquid separation on the mixed gas entraining the absorption liquid. Also provided is a device for removing hydrogen sulfide from a mixed gas containing low-concentration hydrogen sulfide gas.

Owner:EAST CHINA UNIV OF SCI & TECH

Step-by-step pressure reducing deacidification and deamination method and system for coal chemical industry wastewater

InactiveCN106554115AReduce mutual interferenceReduce cloggingFatty/oily/floating substances removal devicesMultistage water/sewage treatmentHigh concentrationChemical synthesis

The invention discloses a step-by-step pressure reducing double-reactor deacidification and deamination method and system for coal chemical industry wastewater. Waste water generated due to coal gasification and coking and containing volatile acid and ammonia nitrogen firstly passes through a deacidification reactor to remove acidic gas, then pressure reducing is performed, the waste water enters a deamination reactor, and the pressure difference of the two reactors is 20-200 KPa. Certain-contraction ammonium ions in NaOH solution decomposition water are added into the upper portion of the deamination reactor, gas exhausted out of the top of the deamination reactor is subjected to double flash evaporation and passes through an ammonia concentration reactor so that concentrated ammonia gas can be collected, and deaminated waste water flowing out of the bottom of the deamination reactor is conveyed into a subsequent workshop section for treatment after exchanging heat with to-be-treated waste water. After the method is adopted for treatment, the sulfur remaining amount of the waste water is smaller than 20 mg / L, and the ammonia remaining amount is smaller than 100 mg / L. The method has the beneficial effects of being high in deacidification and deamination precision, stable in running, low in energy consumption, mature in technology and easy to operate and control, can be used for treating the waste water generated in the coal gasification, coking and chemical synthesis process and containing high-concentration volatile acid and ammonia nitrogen.

Owner:西安润格环保科技有限公司

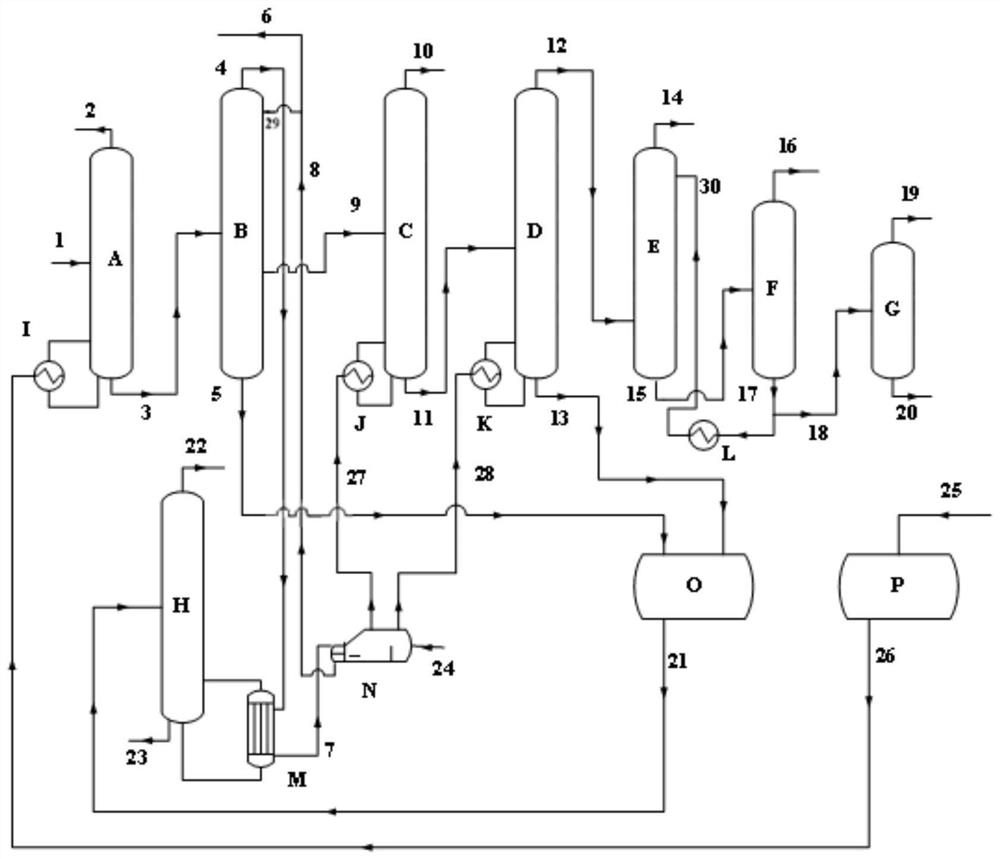

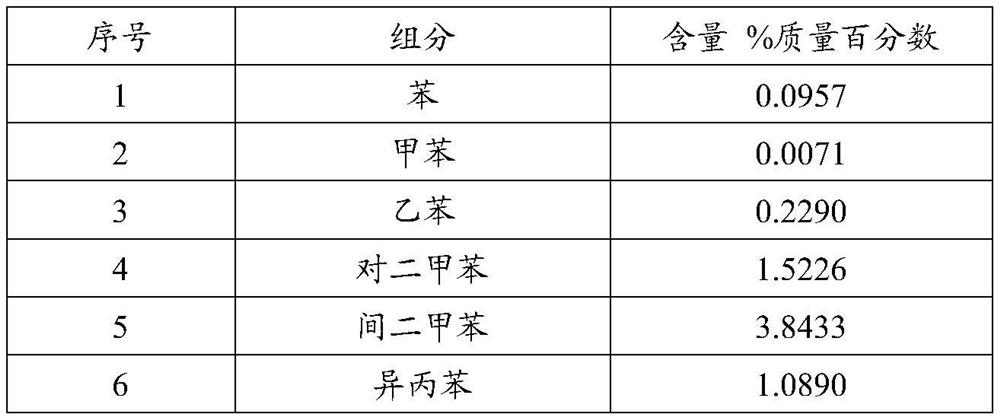

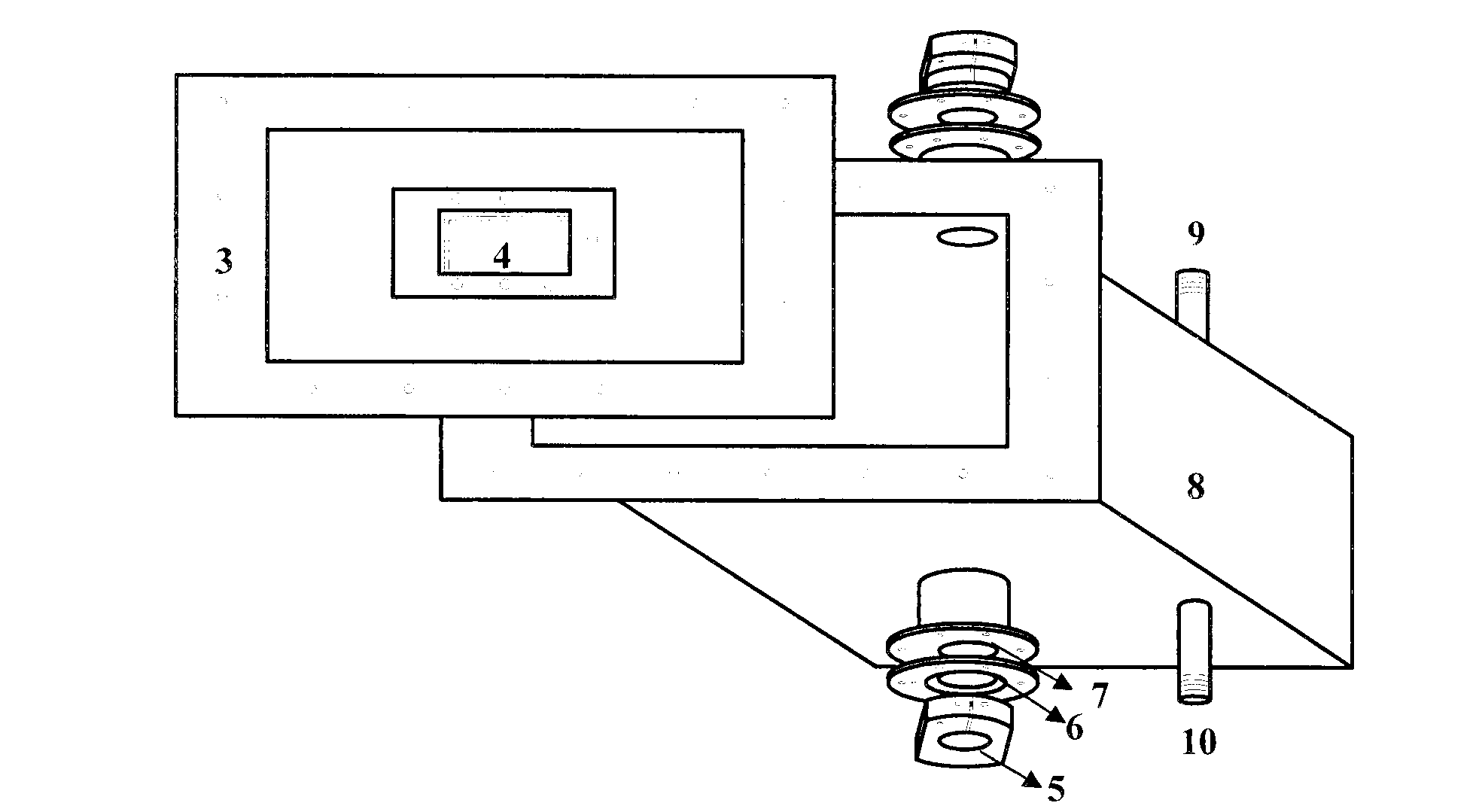

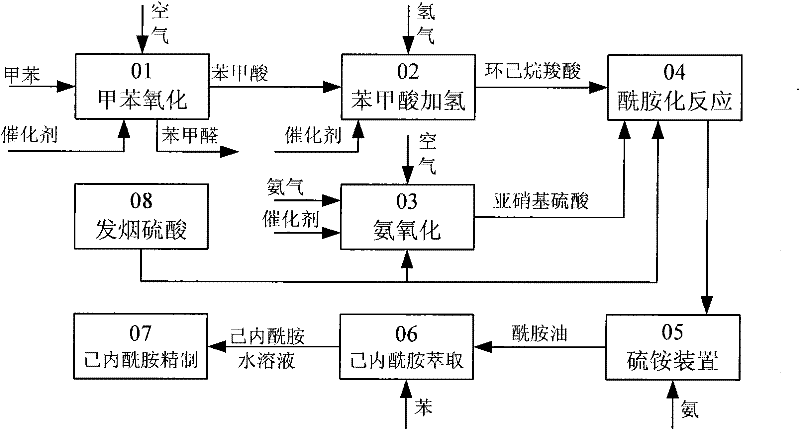

Method for purifying mesitylene through thermal coupling

PendingCN114292155AReduce dosageTake advantage ofDistillation purification/separationExtractive distillationGlycerol

The invention belongs to the technical field of sym-trimethylbenzene refining, and particularly relates to a method for purifying sym-trimethylbenzene through thermal coupling, a purification part and a thermal coupling part are included, and the purification part mainly comprises a decarburization tower A, a pretreatment tower B, a light component removal tower C, a heavy component removal tower D, an extractive distillation tower E, a solvent desorption tower F and a buffer tank O; the thermal coupling part comprises the following steps: heating a 1, 2, 4-trimethylbenzene tower H, a light component removal tower C and a heavy component removal tower D by utilizing tower top gas phase material flow heat energy of a pretreatment tower B; and a composite solvent of glycerol and dimethyl sulfoxide is introduced into the extractive distillation tower E. According to the invention, through a thermal coupling means, gas phase latent heat at the tower top is fully utilized, steam condensate and heat thereof are also fully utilized, energy consumption is reduced, the cost of the adopted solvent is relatively low, the boiling point is also relatively low, and the method is suitable for industrial production. The operation temperature required in the operation process is low, the cost is reduced, the energy consumption is reduced, and the method is easy to recycle.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Apparatus and method for microwave enhanced membrane distillation process

InactiveCN102989319AImprove throughputExtend the period of stable operationDistillationMembrane distillationProcess engineering

The present invention provides an apparatus and a method for a microwave enhanced membrane distillation process. According to the present invention, a microwave reaction chamber for microwave and negative pressure operation is manufactured, and comprises six parts such as a chamber, a chamber top cover, a microwave head interface, a component fixation flange, a pressing flange and a membrane head locking member; a membrane assembly for operation in a microwave field is designed and manufactured, penetrates through the component fixation flange on the chamber, and is fixed through the pressing flange, the membrane head locking member, a silica gel gaskets and other accessories; a microwave magnetron is connected with the chamber top cover through the microwave head interface so as to achieve a microwave environment in the chamber; and a water circulating pump, steam catching, condensation and other equipment are complemented so as to achieve organic combination of microwave radiation, the membrane assembly and the membrane distillation process, such that the microwave enhanced membrane distillation process can be achieved, and microwave-assisted online cleaning and drying of pollution films can be concurrently achieved.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

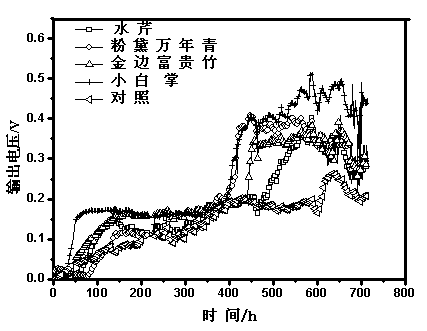

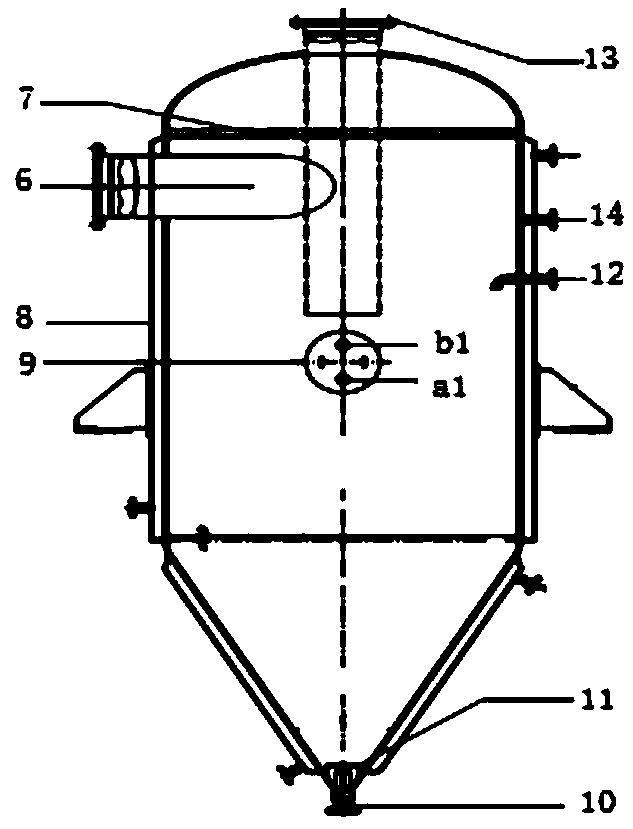

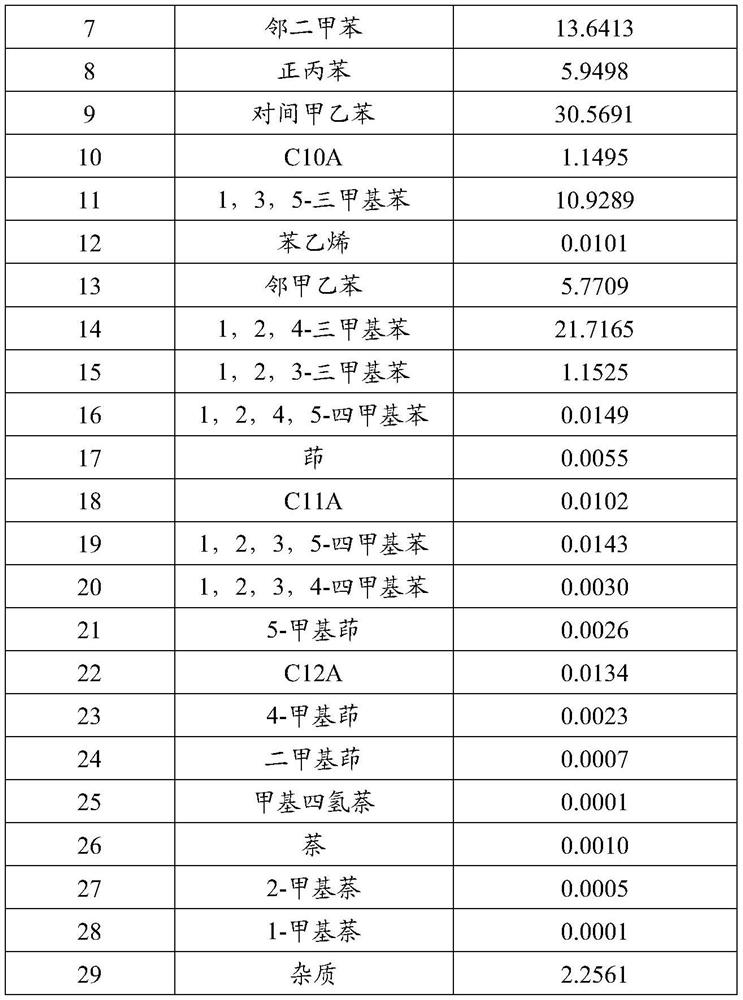

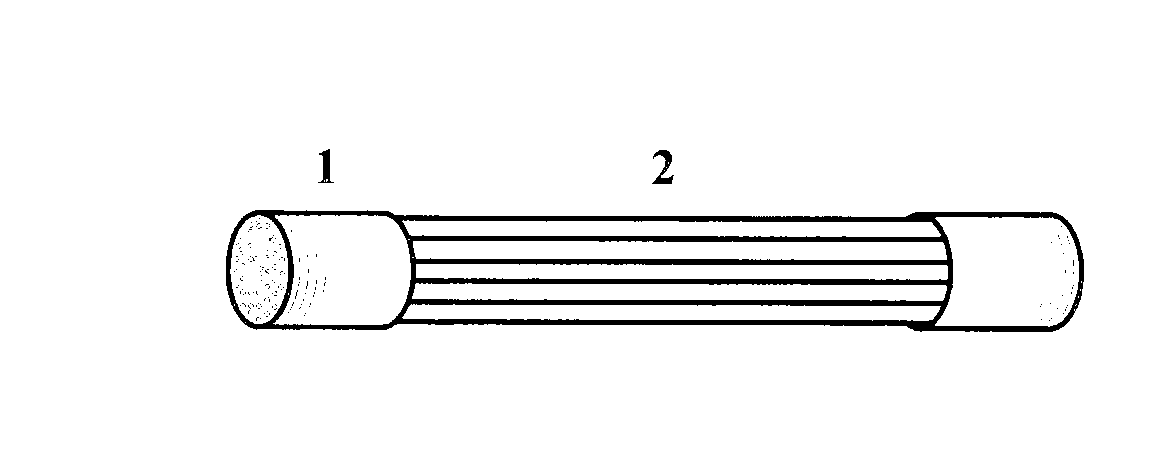

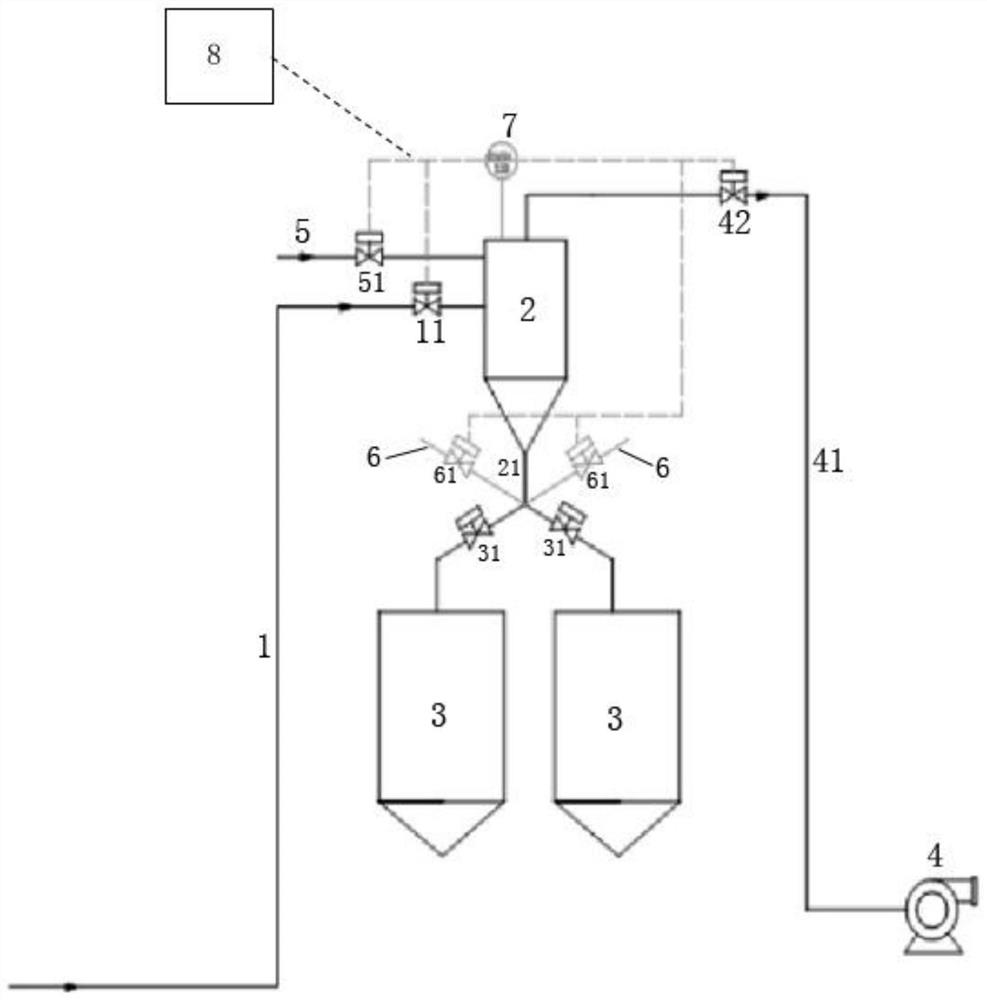

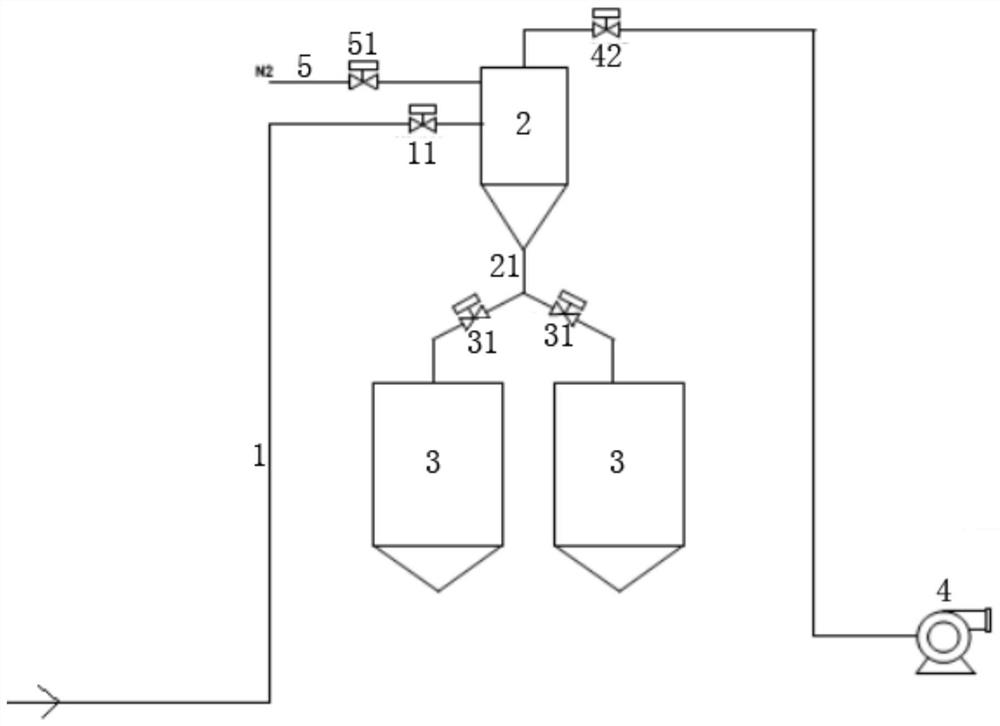

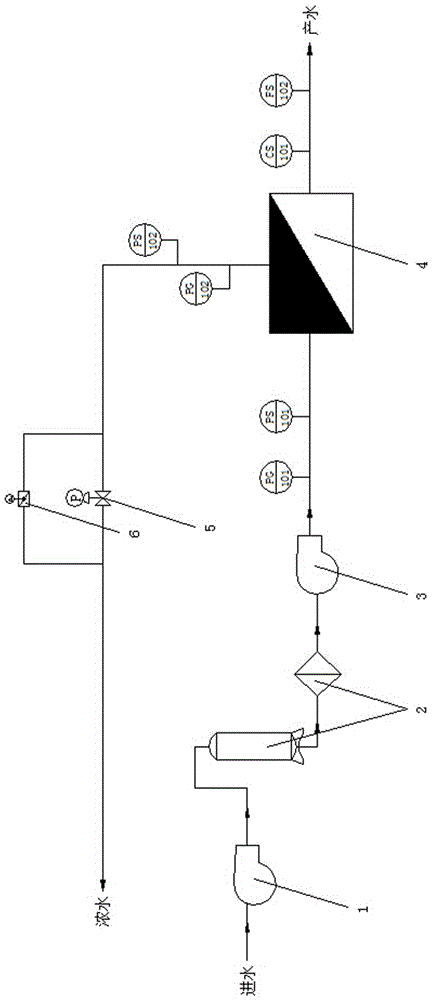

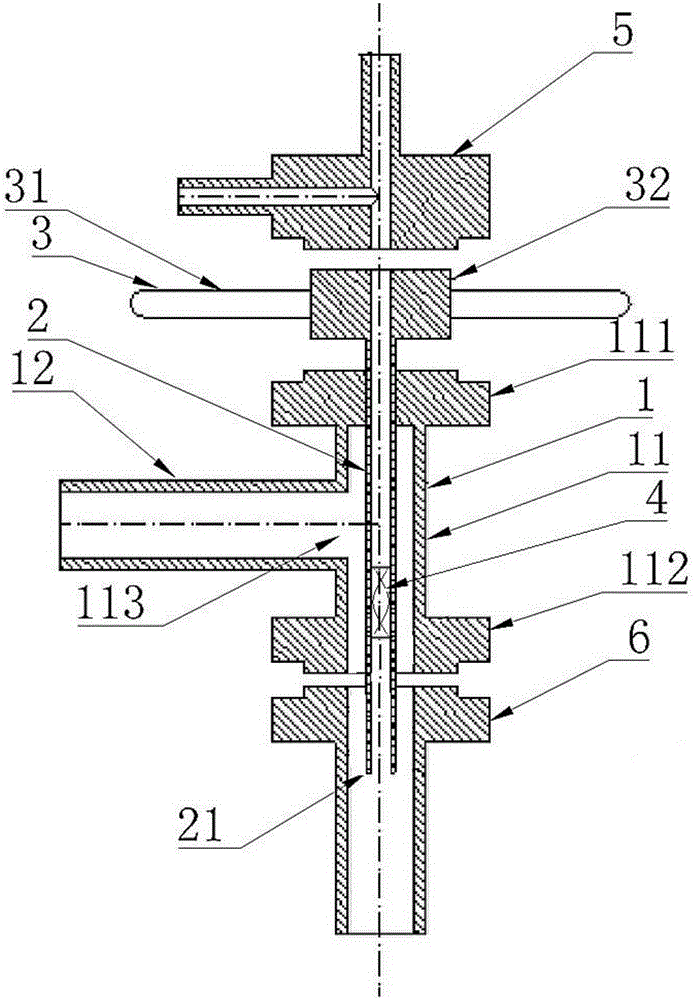

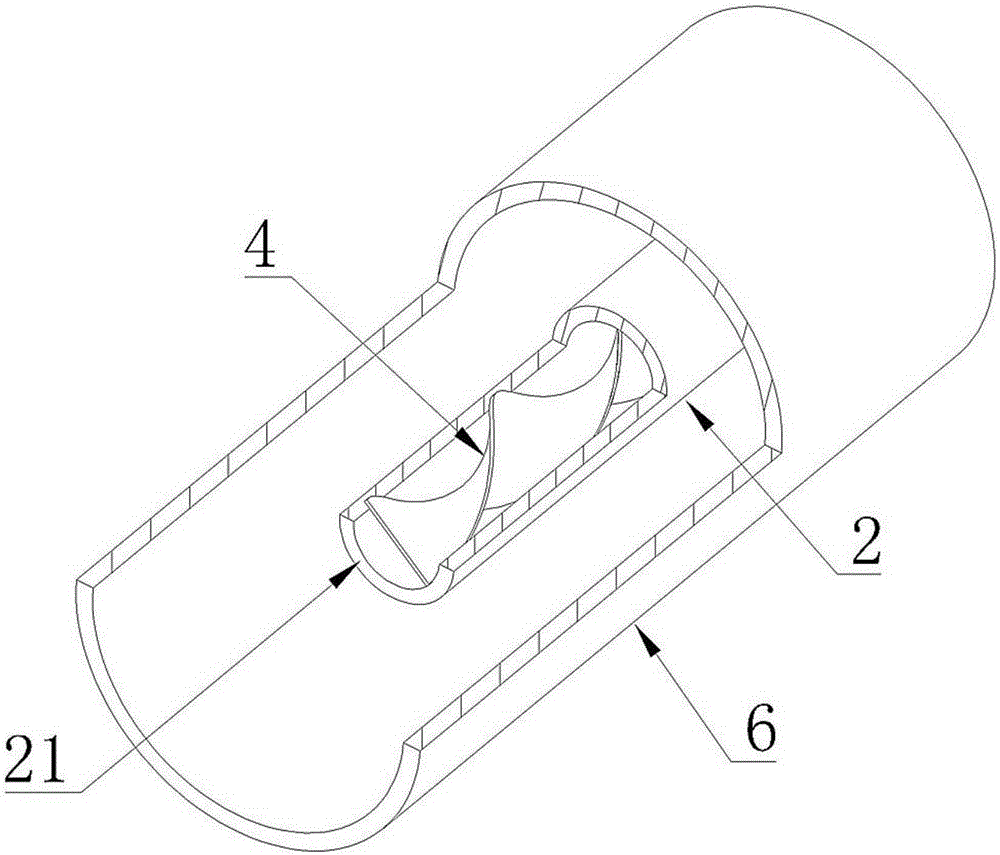

Catalyst feeding programmed control system and method

PendingCN114044365ARealize automatic controlSimple structureBulk conveyorsPtru catalystControl system

The invention discloses a catalyst feeding programmed control system and method, and belongs to the technical field of program control. The system comprises a catalyst feeding pipeline (1), a separator (2), a stock bin (3), a vacuum pump (4) and a DCS program control unit (8), wherein the lower end of the separator (1) is connected with the stock bin (3) through a discharging pipeline (21), the discharging pipeline (21) is provided with a third control valve (31), and the separator (2) is connected with a gas pressurization pipeline (5); a gas purging pipeline (6) is connected to the third control valve (31), a purging electromagnetic valve (61) is arranged on the gas purging pipeline (6), a hole is formed in the top of the separator (2), a pressure transmitter (7) is installed in the hole, and a DCS program control unit (8) is connected with the first control valve (11), the second control valve (42), the third control valve (31), the fourth control valve (51) and the purging electromagnetic valve (61). According to the invention, the automatic unblocking of the system is realized by additionally arranging pressure interlocking and a purging gas circuit and redesigning an interlocking program.

Owner:重庆金维实业有限责任公司

A formaldehyde concentration device, system and process

ActiveCN109529389BReduce recycling volumeReduce consumptionEvaporator accessoriesVacuum distillation separationFluid phaseGas phase

The invention discloses a device, a system and a process for formaldehyde concentrating. The device is a formaldehyde concentrating vacuum separator, which is a circular cylinder structure and which is provided with a jacket on the external wall. One end of the circular cylinder structure is provided with a gas phase outlet, and the other end is provided with a liquid phase outlet. The cylinder wall of the circular cylinder structure is provided with a material inlet pipe. The material discharging direction of the material inlet pipe is tangent to the wall of the circular cylinder structure. The material inlet pipe is adjacent to the gas phase outlet, and the cylinder wall of the circular cylinder structure is provided with an annular liquid retaining ring the center of which is on the axis of the circular cylinder structure. The liquid retaining ring is located between the material inlet pipe and the gas phase outlet. The gas phase outlet is provided with a gas discharging pipe. The gas inlet of the gas discharging pipe is between the material inlet pipe and the liquid phase outlet. The device enables greatly improved concentration separation efficiency and reduces the recovery amount of lean formaldehyde and steam consumption.

Owner:YANKUANG GRP CO LTD

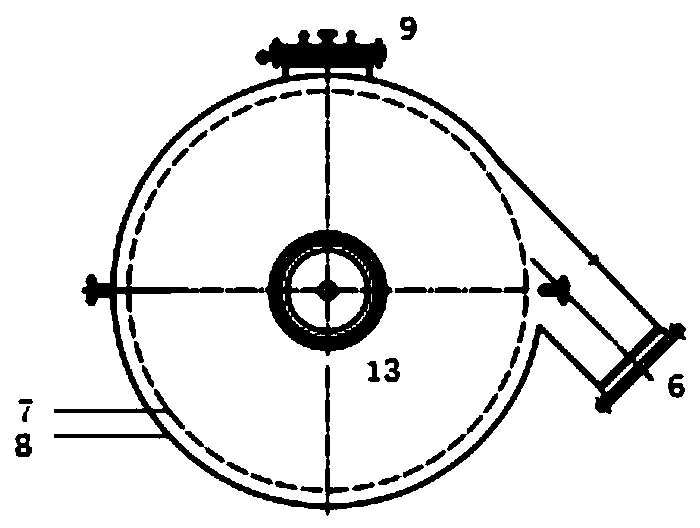

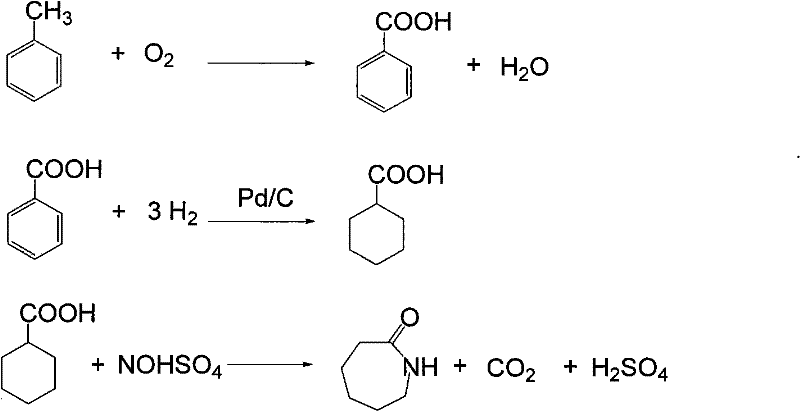

Method for producing caprolactam by methylbenzene

ActiveCN102060767BReduce contentIncrease productivityLactams preparationBenzoic acidPalladium on carbon

Owner:中科化物(大连)科技实业有限公司

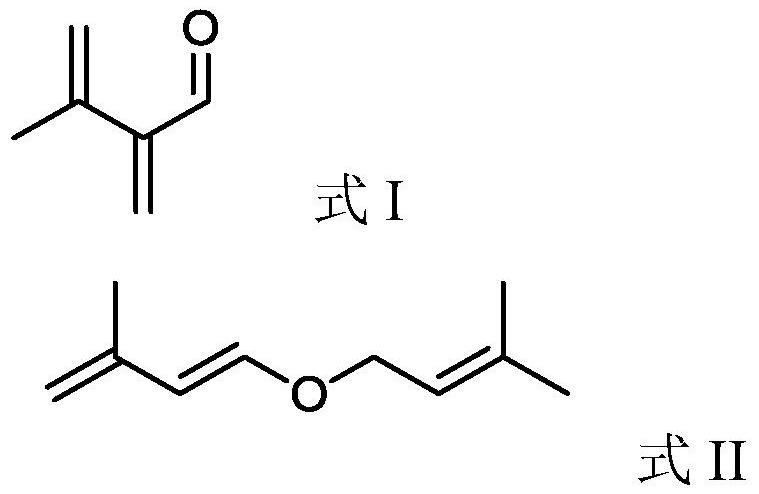

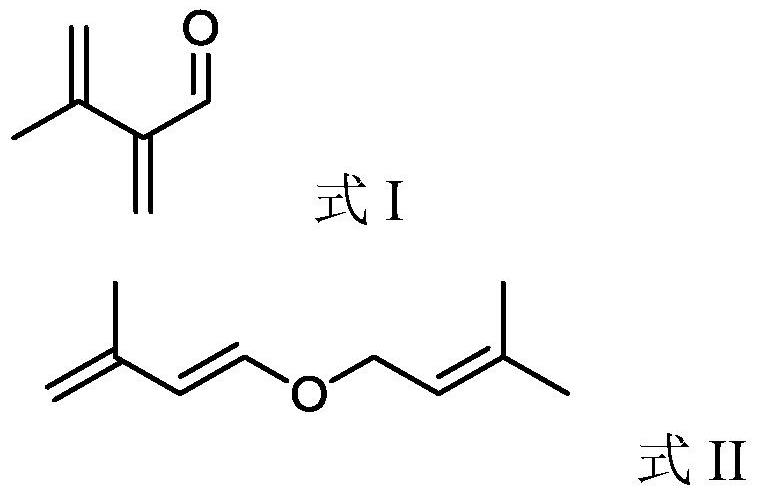

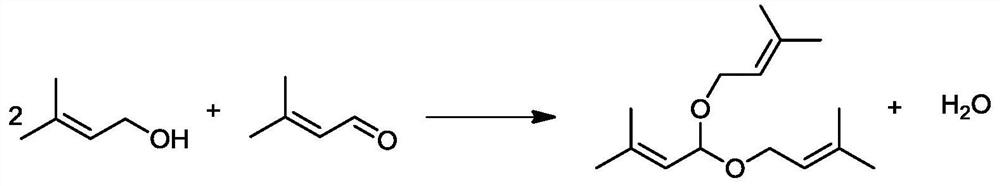

Preparation method of 3-methyl-2-butenal

PendingCN114380677AExtend the period of stable operationReduce processing operating costsCarbonyl compound preparation by oxidationCarbonyl compound separation/purificationPtru catalystAlcohol

The invention discloses a preparation method of 3-methyl-2-butenal, which comprises the following steps: mixing air of which the O2 concentration is controlled below the limit oxygen concentration of unsaturated alcohol with unsaturated alcohol steam, introducing the mixture into a fixed bed reactor filled with an oxidation catalyst, and carrying out gas-phase catalytic oxidation to prepare 3-methyl-2-butenal, the unsaturated alcohol is 3-methyl-2-butenol, 3-methyl-3-butenol or a mixture of the 3-methyl-2-butenol and the 3-methyl-3-butenol. The method provided by the invention can greatly prolong the stable operation period of a reaction device, is beneficial to reducing the process operation cost, and has a good industrial prospect.

Owner:WANHUA CHEM GRP CO LTD

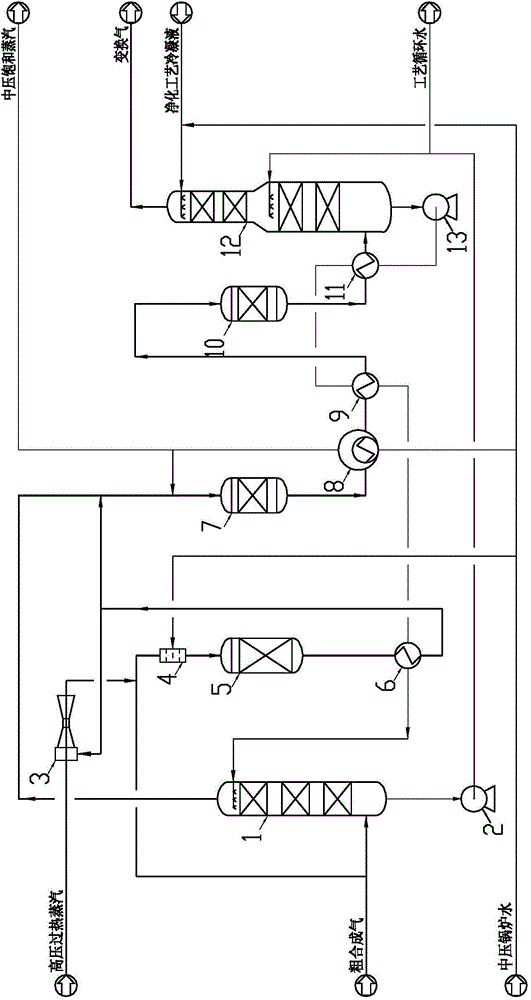

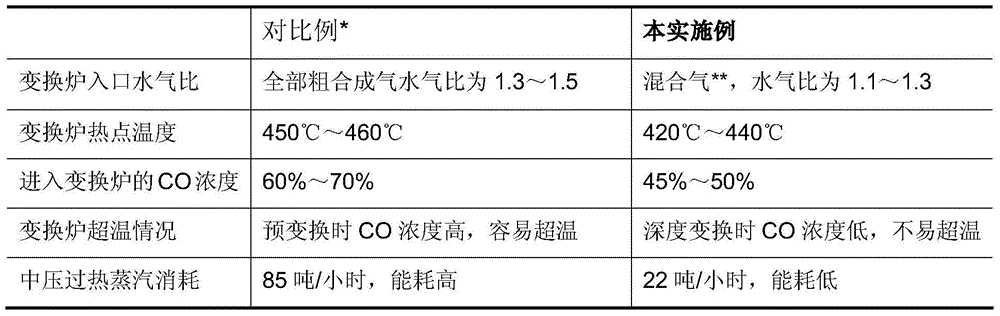

Circulating CO shift process of saturation tower

ActiveCN103881767BReduce consumptionLower operating temperatureChemical industryCombustible gas catalytic treatmentProcess engineeringHigh pressure

The invention relates to a circulating CO shift process of a saturation tower. The circulating CO shift process comprises the following steps that a coarse synthetic gas from a pulverized coal gasification unit is divided into two branches, the first branch of coarse synthetic gas is moisturized and heated in the saturation tower and then mixed with high pressure steam and a first branch of primary shift gas and replenished with medium-pressure boiler water, and then the obtained mixture is fed into a No.1 shift furnace for shift reaction, the obtained primary shift gas is divided into two branches after heat exchange, the second branch of primary shift gas is mixed with the first branch of coarse synthetic gas to obtain a primary shift mixed gas, the primary shift mixed gas is mixed and replenished with medium-pressure steam and then fed into a No.2 shift furnace for continuous shift reaction, and the secondary shift gas is fed into a No.3 shift furnace for reaction after heat exchange. The operation of dividing the coarse synthetic gas and the primary shift gas into branches in the circulating CO shift process, so that the CO concentration entering the shift furnaces is effectively reduced; the operating temperatures of the shift furnaces are low, and the operating environment of a catalyst is mild, so that the service life of the catalyst and the operation period of the device are prolonged; and meanwhile, the amount of steam used is reduced, and the effects of energy conservation and consumption reduction are remarkable.

Owner:SINOPEC NINGBO ENG +2

A kind of dimethyl sulfide oxidation method

ActiveCN105017102BExtend the period of stable operationLow running costOrganic chemistryOrganic compound preparationMolecular sieveTitanium

The invention discloses a dimethyl sulfide oxidation method. The method comprises causing a liquid mixture to pass through a catalyst bed layer filled with at least one titanium silicalite molecular sieve under the conditions of oxidation reaction, wherein the liquid mixture contains dimethyl sulfide and at least one oxidizing agent. The method comprises switching the flow direction of the liquid mixture in the catalyst bed layer when the catalytic activity of the titanium silicalite molecular sieve in the catalyst bed layer is lower than an expected value, wherein with the flowing direction of the liquid mixture in the catalyst bed layer prior to the switching as the standard, the liquid mixture performs reverse flowing in the catalyst bed layer after the switching. According to the method, even if long-time continuous running is performed, the activity of the catalyst can be maintained within a high range, so that the stable running time of a device is effectively prolonged, and the running cost of the device is reduced. In addition, the method is simple, convenient, practical and favorable for industrial production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of treatment recovery method of phosphoric acid waste liquid

ActiveCN104973725BPromote regenerationSimple and fast operationMultistage water/sewage treatmentPhosphorus compoundsLiquid wasteIndustrial waste water

Owner:CHINA PETROLEUM & CHEM CORP +1

Fully automatic control nanofiltration membrane on-line large flushing method

ActiveCN104211136BExtend the period of stable operationExtended operating cycleReverse osmosisWater/sewage treatment bu osmosis/dialysisHigh concentrationAutomatic control

Owner:XIAMEN LECCAN TECH

A dual-frequency electromagnetic field synergistic sealing device and system for hot dip plating

ActiveCN111926279BReduce magnetic inductionAchieve the effect of suspension plating solutionHot-dipping/immersion processesAC - Alternating currentEngineering

The invention belongs to the technical field of hot dipping, and particularly relates to a double-frequency electromagnetic field cooperative flow sealing device and system for hot dipping. The flow sealing device comprises a three-phase traveling wave magnetic field generator and a single-phase alternating magnetic field generator, wherein the three-phase traveling wave magnetic field generator is arranged on the outer side of a flow sealing distribution channel, and the single-phase alternating magnetic field generator is arranged below the three-phase traveling wave magnetic field generatorand below the liquid level of a plating solution at the bottom of the flow sealing distribution channel. And the frequency of the three-phase alternating current introduced into the three-phase traveling wave magnetic field generator is lower than that of the single-phase alternating current introduced into the single-phase alternating magnetic field generator. The flow sealing device can generate traveling wave electromagnetic force based on a traveling wave magnetic field and electromagnetic repulsion based on a single-phase alternating magnetic field, and through the combined action of thetraveling wave electromagnetic force and the electromagnetic repulsion, large electromagnetic force can be provided to counteract the gravity borne by the plating solution, the plating solution can be stabilized, and liquid leakage caused by uneven stress due to flowing deformation of the plating solution under the influence of workpiece movement is avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

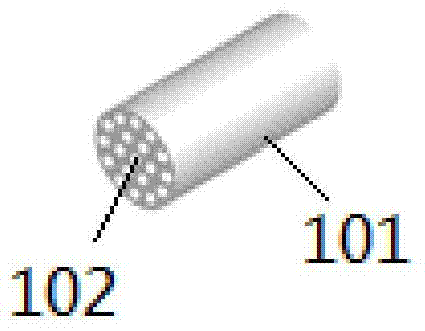

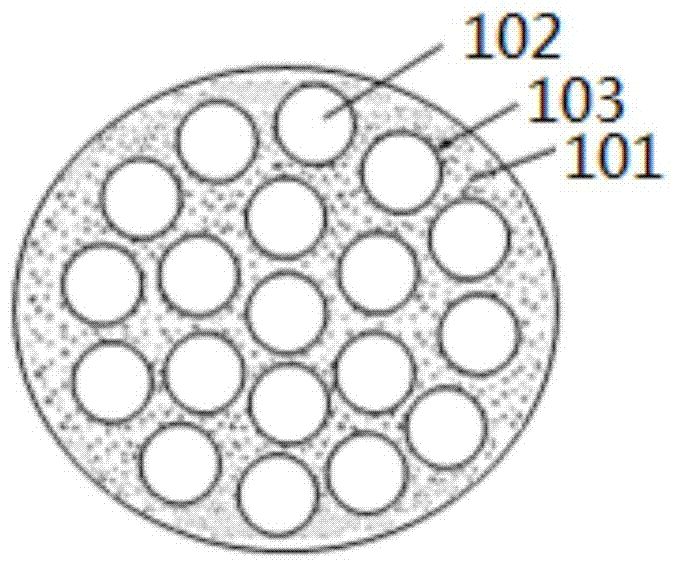

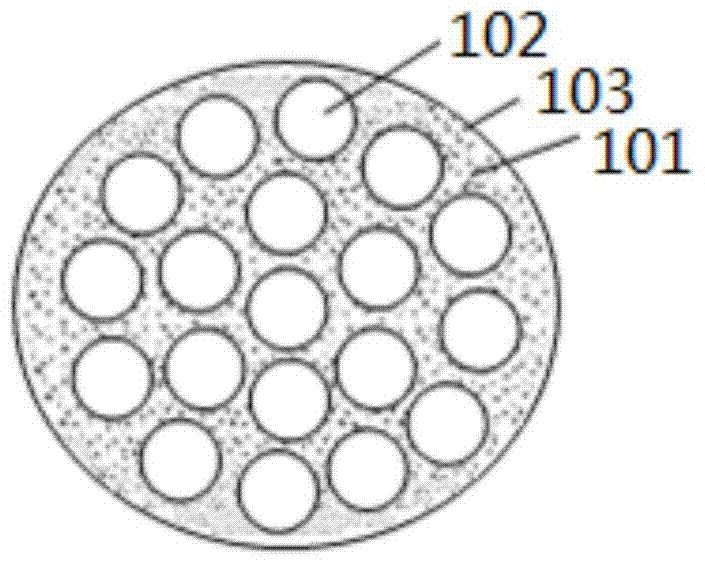

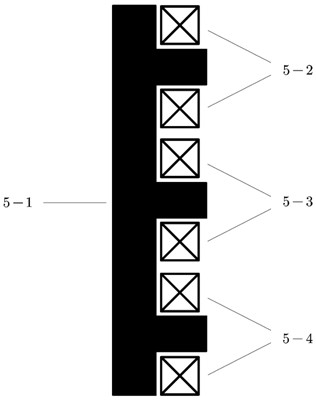

Device for feeding polyolefin catalyst

ActiveCN106345371AImprove flowReduced disassembly and cleaning operationsFeed devicesPolyolefinEngineering

The invention provides a device for feeding a polyolefin catalyst. The device comprises a reactant feeding pipe, a catalyst feeding plug-in pipe which is plugged into the reactant feeding pipe and extends to the downstream of the reactant feeding pipe, and a hydrocyclone arranged in the catalyst feeding plug-in pipe, wherein the hydrocyclone is used for enabling a catalyst passing through the hydrocyclone to flow spirally. Under a condition of no big structural change for the existing catalyst feeding device, the flowing condition in the catalyst feeding device is effectively improved, the stable operation period of the device is prolonged, and the risk of shut down caused by blockage of the catalyst feeding device is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com