Oil refining catalyst wastewater zero-discharging treatment method

An oil refining catalyst and treatment method technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of high sedimentation efficiency and reduction of civil construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

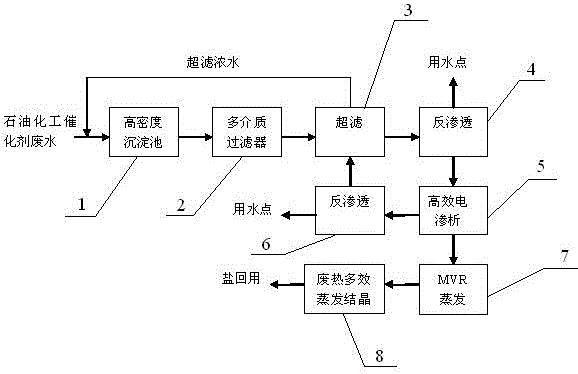

[0023] like figure 1 Shown, a kind of refinery catalyst waste water zero-discharge treatment method comprises the following steps:

[0024] (1) Refinery catalyst wastewater is treated by high-density sedimentation tank 1 (Yizheng Environmental Protection, XJYHB series) integrating inclined tube sedimentation and sludge concentration to remove impurities such as hardness, alkalinity, and COD in wastewater, and obtain wastewater after precipitation;

[0025] (2) The sedimented wastewater enters the multi-media filter 2 (Yixing Environmental Protection, AGF series) to further remove the suspended solids and colloids in the wastewater, and the organic matter, bacteria, viruses, etc. in the water are also partially reduced with the reduction of water turbidity. are removed to obtain the multi-media filter product water and the multi-media filter backwash water respectively; the multi-media filter backwash water is returned to the high-density sedimentation tank 1 for coagulation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com