Catalyst feeding programmed control system and method

A catalyst and feeding technology, applied in the field of program control, to achieve the effect of rapid blockage removal, labor intensity reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

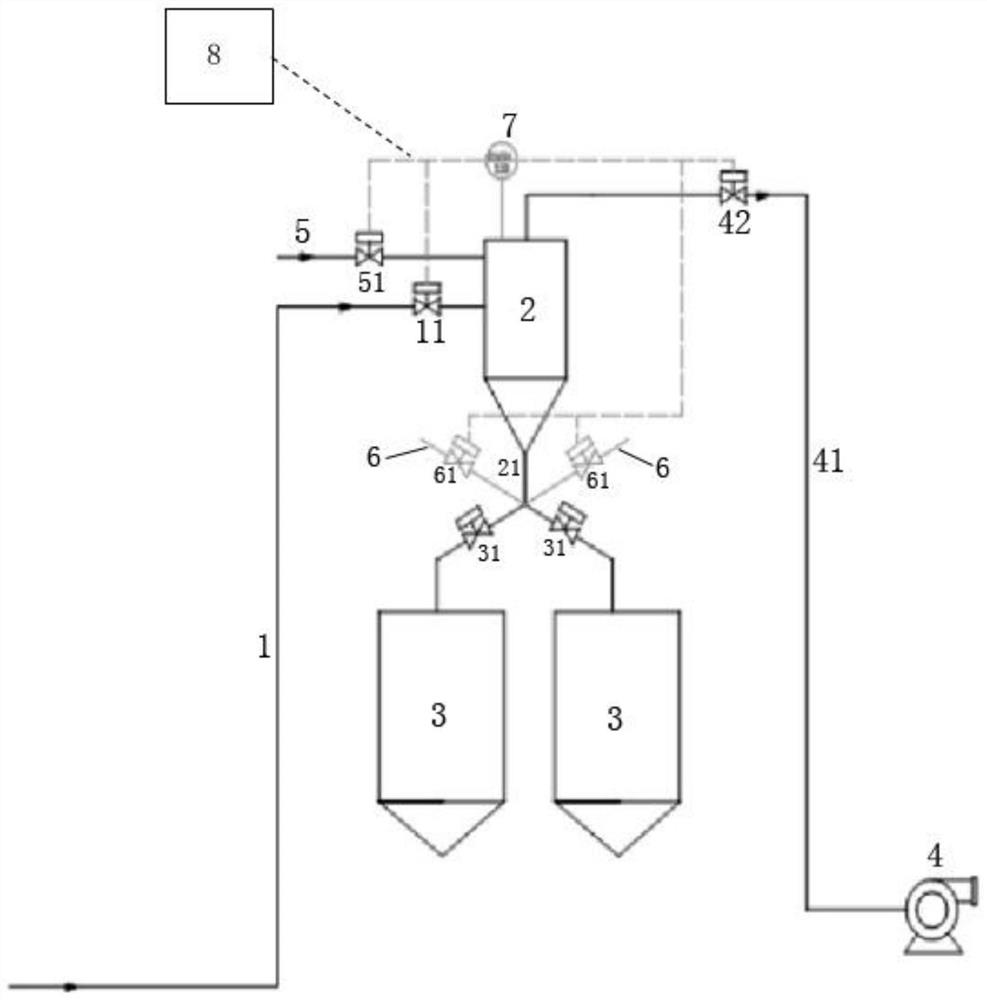

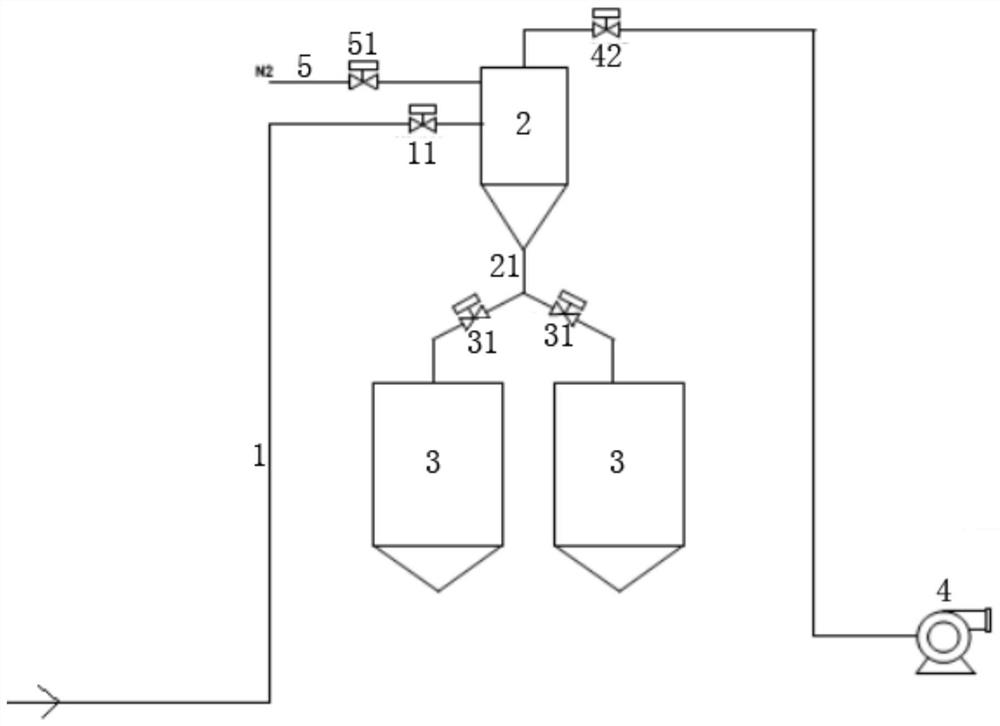

[0038] In an exemplary embodiment, a catalyst feeding program control system is provided, such as figure 1 , 2 As shown, the system includes a catalyst feed pipeline 1, a separator 2, a silo 3, a vacuum pump 4 and a DCS program control unit 8, and the separator 2 is connected to the catalyst feed pipeline 1, the silo 3, and the vacuum pump 4 respectively;

[0039] The catalyst feeding pipeline 1 is provided with a first control valve 11, the separator 1 is connected with the vacuum pump 4 through a vacuum pipeline 41, the vacuum pipeline 41 is provided with a second control valve 42, and the separator 1 The lower end of the separator 2 is connected to the silo 3 through the feeding pipeline 21, the feeding pipeline 21 is provided with a third control valve 31, the upper part of the separator 2 is connected with a gas pressurizing pipeline 5, and the gas pressurizing The pipeline 5 is provided with a fourth control valve 51;

[0040] The third control valve 31 is connected t...

Embodiment 2

[0051] In conjunction with embodiment 1, in this embodiment, a kind of catalyst feed program control method is provided, and described method comprises:

[0052] An interlock program is set in the DCS program control unit 8, which includes the control of the first control valve 11, the second control valve 42, the third control valve 31, the fourth control valve 51 and the purge solenoid valve 61 information;

[0053] The second control valve 42, the first control valve 11, the fourth control valve 51, and the third control valve 31 are sequentially opened through the interlocking procedure to start the feeding process of the catalyst. 30 seconds (adjustable) to close, and the third control valve 31 is opened to delay 300 seconds (adjustable) to close to complete a feeding cycle.

[0054] In the feeding process, the pressure in the separator 2 is detected in real time by the pressure transmitter 7, and whether the separator 2 is blocked is judged according to the detection va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com