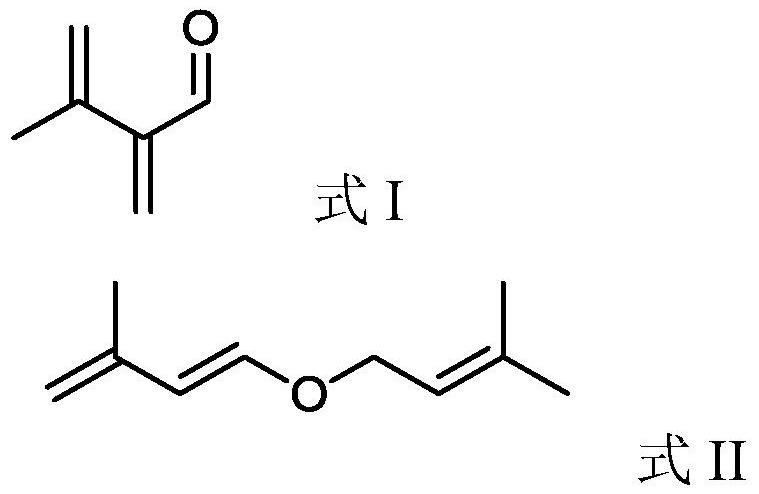

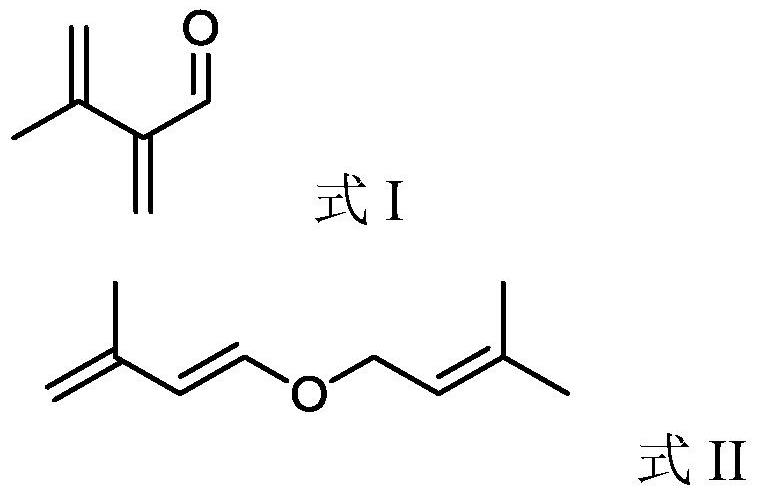

Preparation method of 3-methyl-2-butenal

A kind of butenal and methyl technology, which is applied in the field of preparation of 3-methyl-2-butenal, can solve the problems of increasing operating costs, unfavorable continuous and stable operation of devices, and clogging of a catalyst bed of a feed pipeline by carbon formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] (2) Preparation of catalyst:

[0043] ①Add 8g AgNO to 10ml of deionized water 3 , 0.60g Cu(NO 3 ) 2 , 0.015g CsNO 3 and 0.02gMg(NO 3 ) 2 , stir until completely dissolved;

[0044] ②In a round bottom flask, add 5g of α-Al 2 o 3 For the carrier, soak it in the solution of step ① for 1 hour, take out the carrier, drain it, remove the excess solution, and then dry it at 5KPa(A) and 80°C;

[0045] ③Put the carrier impregnation obtained in step ② into a round-bottomed flask, then add 10wt% oxalic acid solution to soak for 2 hours, drain the carrier after taking it out, remove the excess solution, and then put it under the conditions of 5KPa(A) and 150°C down to dry;

[0046] ④Put the impregnated carrier obtained in step ③ into a muffle furnace for roasting, first roast at 260°C for 0.5h, then raise the temperature to 400°C within 0.5h, continue roasting for 5h, and finally use hydrogen reduction for 5h to obtain an oxidation reaction catalyst , denoted as catalyst A;...

Embodiment 1

[0056] (1) Preparation of 3-methyl-2-butenal

[0057] Fresh 3-methyl-3-butenol was gasified at 150°C, and fed into a fixed-bed reactor with an inner diameter of 1 cm filled with 2 ml of catalyst A at a rate of 0.12 mol / h; meanwhile, according to The oxygen-alcohol ratio is 0.5, and the water-alcohol ratio is 1.2 to prepare a mixed gas of air and water vapor (oxygen content is 6.16mol%), and the mixed gas is preheated and fed together with unsaturated alcohol vapor into the fixed-bed reactor ; Control the reaction temperature to 390°C and the reaction volume space velocity to 29756h -1 . After the reaction was completed, gas chromatography analysis of the reaction product showed that the reaction conversion rate was 74.5%, and the total selectivity of 3-methyl-3-butenal and 3-methyl-2-butenal was 96.8%.

[0058] (2) reclaim 3-methyl-3-butenol

[0059] After the gas-phase oxidation products are rearranged according to the above method, the reaction liquid is sent to the dehyd...

Embodiment 2

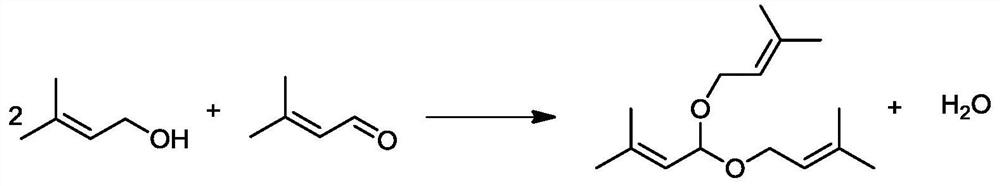

[0061] The fresh 3-methyl-3-butenol and the 3-methyl-3-butenol (conjugated compound content 0.5wt%) reclaimed by the previous examples are mixed in a mass ratio of 3:1, and then mixed with O 2 The oxygen-containing gas with a concentration of 3mol% is pretreated according to the volume ratio of oxygen-containing gas:unsaturated alcohol=100:1 at a pressure of 1 bar (A) and a temperature of 70°C for a treatment time of 10 minutes; The concentration of the conjugated compound was reduced to 500 ppm.

[0062] The obtained unsaturated alcohol is gasified at 150°C, and fed at a rate of 0.12mol / h to a fixed-bed reactor filled with 2ml of Catalyst A with an inner diameter of 1cm; The ratio is 1.2 to prepare the mixed gas of air and water vapor (oxygen content is 6.16mol%), and after the mixed gas is preheated, it is fed into the fixed-bed reactor together with unsaturated alcohol vapor; the reaction temperature is controlled at 390 ° C, and the reaction Volumetric airspeed 29756h -1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com