Fully automatic control nanofiltration membrane on-line large flushing method

A nanofiltration membrane and fully automatic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems affecting the treatment efficiency of printing and dyeing wastewater, the system can continue to operate for a short time, and the continuous operation time is short , to achieve the effect of prolonging the stable operation period, slowing down the fouling of the membrane surface, and reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

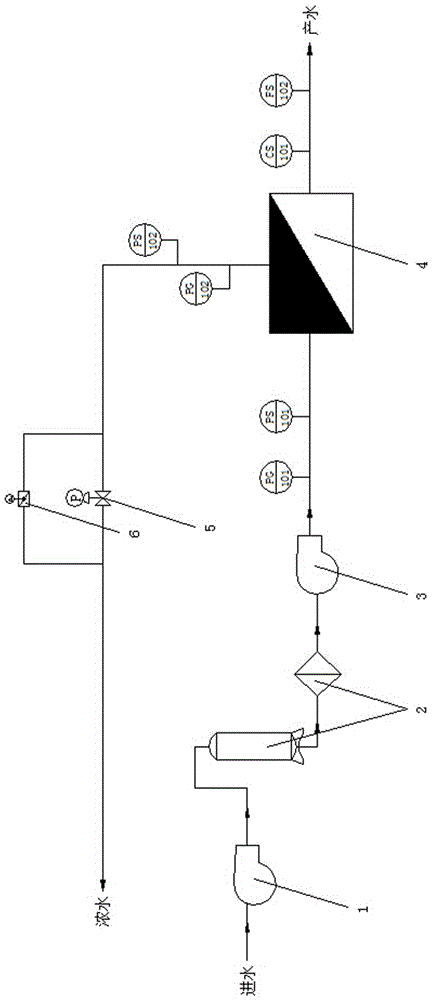

Image

Examples

Embodiment

[0019] Embodiment: Aiming at the problems of high pollution degree and short running time when nanofiltration reuses reverse osmosis concentrated water in the printing and dyeing industry, the present invention provides a fully automatic controlled nanofiltration membrane washing method, which can effectively slow down membrane surface pollution, To extend the operating cycle and reduce the difficulty of cleaning.

[0020] The present invention is aimed at the process optimization of the reverse osmosis concentrated water reuse process of printing and dyeing enterprises, and the main parameters of the influent water quality are as follows in Table 1:

[0021] Test items value unit COD 150-300 mg / L hardness 1-3 mmol / L Conductivity 8000-15000 us / cm pH 8-9 Chloride 2000-3000 mg / L

[0022] The online large washing method of fully automatic control nanofiltration membrane of the present invention comprises the following step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com