Circulating CO shift process of saturation tower

A process and gas shift technology, applied in the field of CO shift process, can solve the problems of short catalyst life, easy over-temperature, high energy consumption, and achieve the effects of long stable operation period, mild operating environment and reduced steam consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

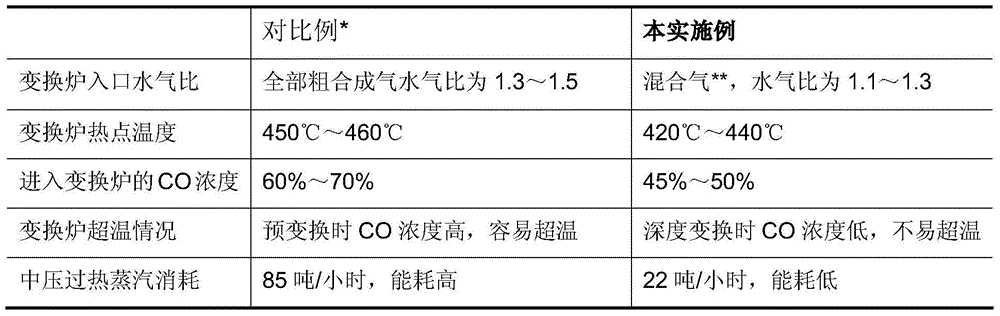

[0026] This embodiment is used in conjunction with a typical fertilizer plant that produces 300,000 tons / year of synthetic ammonia and 520,000 tons / year of urea through gasification of Shell pulverized coal gasification.

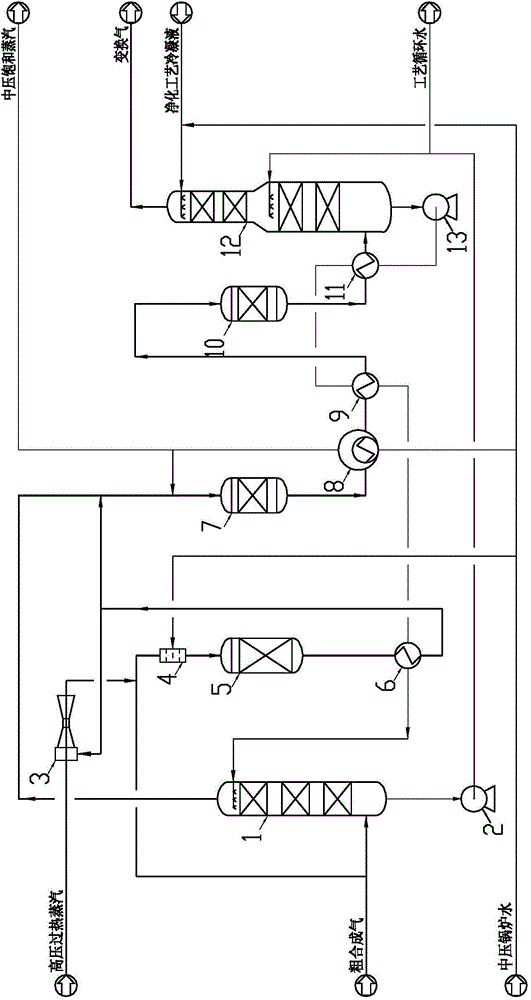

[0027] like figure 1 As shown, the saturated tower cycle CO shift process includes the following steps:

[0028] The crude oil sent from the pulverized coal gasification unit has a temperature of 155°C to 165°C, a pressure of 3.65Mpa (G) to 3.75Mpa (G), a water / dry gas molar ratio of 0.18 to 0.19, and a CO dry basis volume content of 60% to 70%. The synthesis gas is divided into two streams, the volume ratio of the first stream of crude synthesis gas to the second stream of crude synthesis gas is 70-80:30-20;

[0029] The first stream of crude synthesis gas enters the saturation tower 1 from the lower part of the side wall of the saturation tower, and contacts with the process circulating water with a temperature of 205°C to 215°C sent from the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com