Telescopic guide rail integrated with cable collection function

A telescopic guide rail and guide rail technology, which is applied in the field of guide rails, can solve problems such as wasting time, affecting the heat dissipation function of equipment, and being unsightly, and achieve the effects of avoiding signal interference, prolonging the aging time, and facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

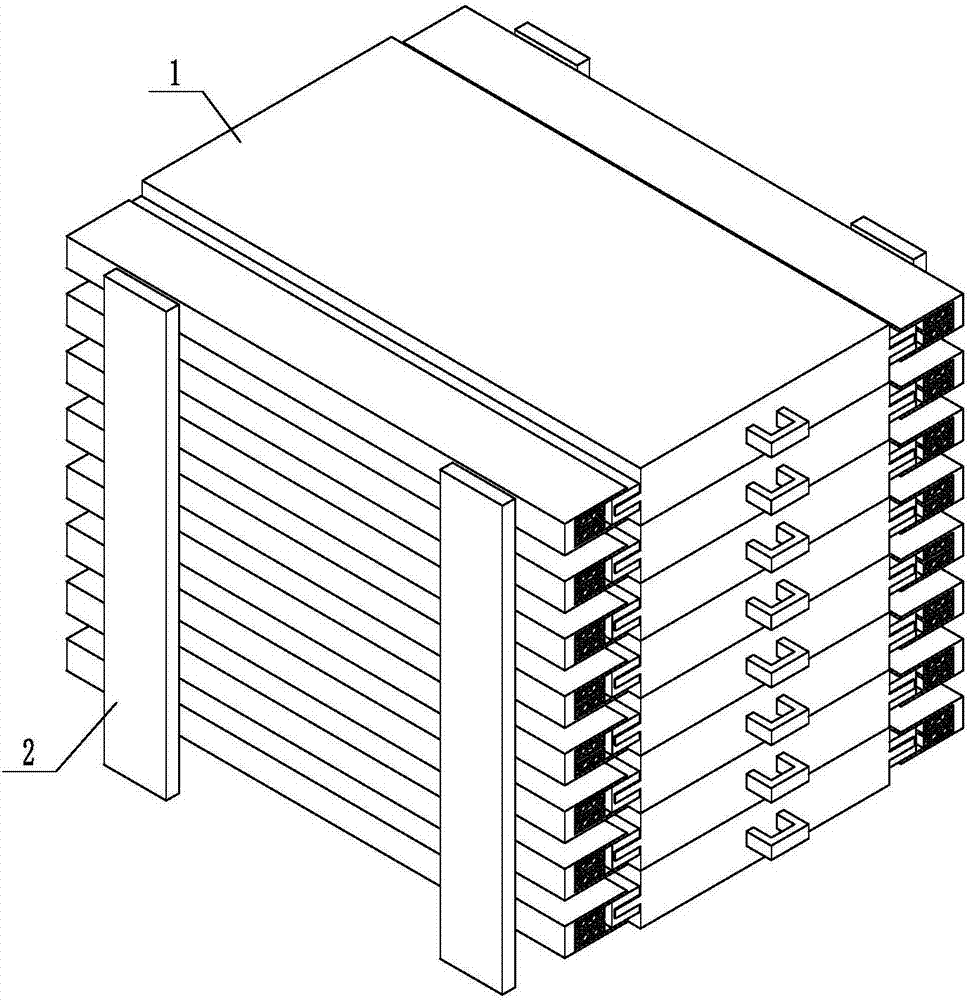

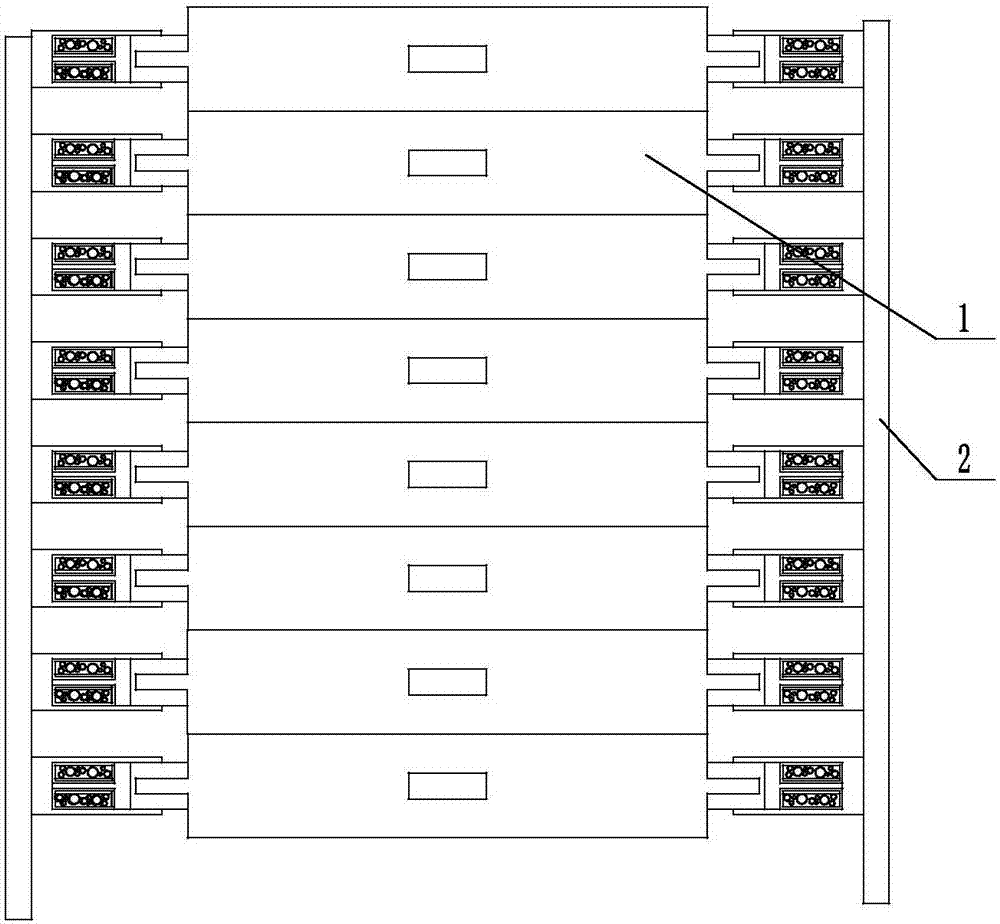

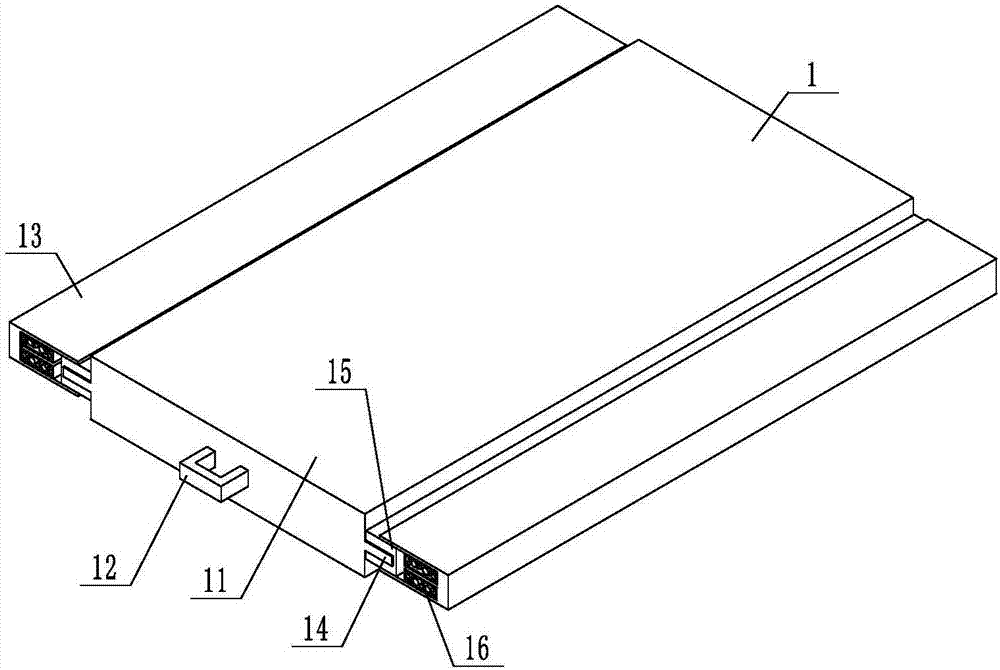

[0029] Such as Figure 1 to Figure 6 As shown, the retractable guide rail with integrated cable collection function includes several sets of guide rail assemblies 1 , and several guide rail assemblies 1 are connected through columns 2 . The guide rail assembly 1 includes two guide rail back pieces 13 connected to the uprights 2, the guide rail back piece 13 and the guide rail front piece 15 are connected by a connecting mechanism 18, the length and overlap between the guide rail back piece and the guide rail front piece The length can be adjusted according to the distance between the two columns, which can meet the installation requirements of mainstream cabinets in the market.

[0030] The connecting mechanism 18 can be an engaging buckle or a bolt and nut. It is cheaper to connect the front piece of the guide rail to the rear piece of the guide rail by means of bolts and nuts.

[0031] There is a flexible connection belt 16 in the back piece of the guide rail, and the cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com