The application of condition monitoring and fault diagnosis technology in the operation management of refrigeration unit

A technology for fault diagnosis and refrigeration units, which is used in measuring devices, complex mathematical operations, and ultrasonic/sonic/infrasonic measurements, which can solve problems such as high maintenance costs, equipment failures, and long downtime, and achieve stable operation cycle improvement and maintenance. The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

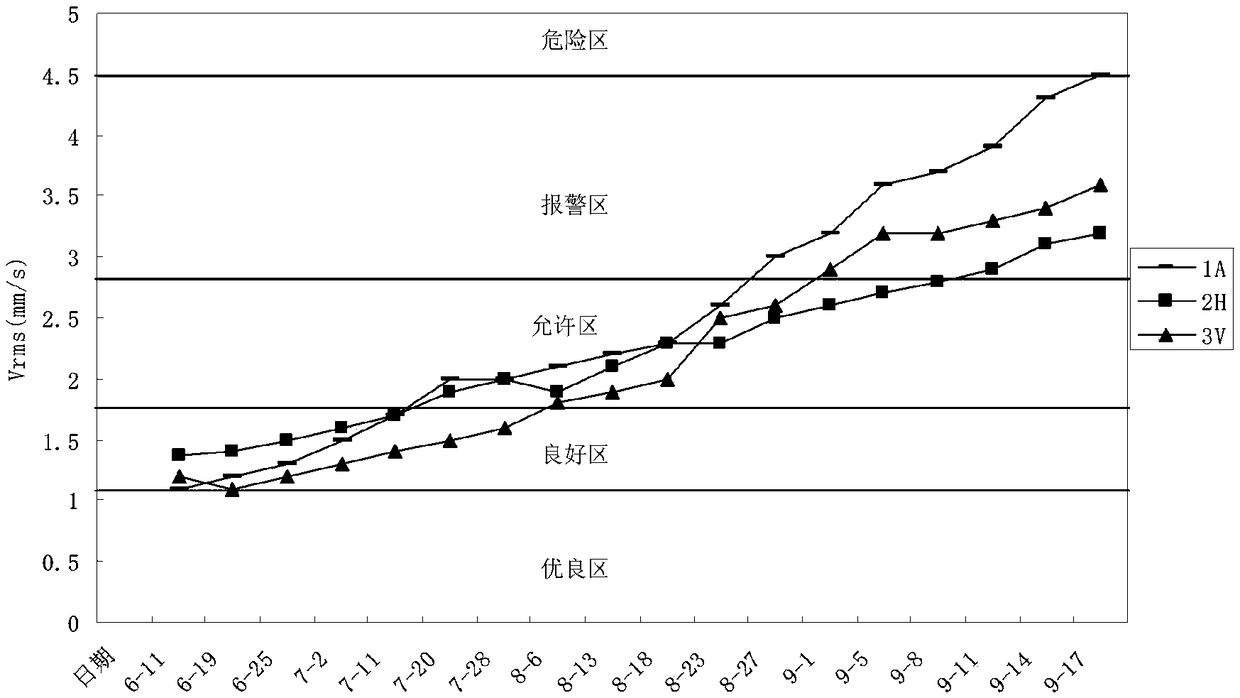

[0019] 1. Vibration parameter analysis and fault diagnosis:

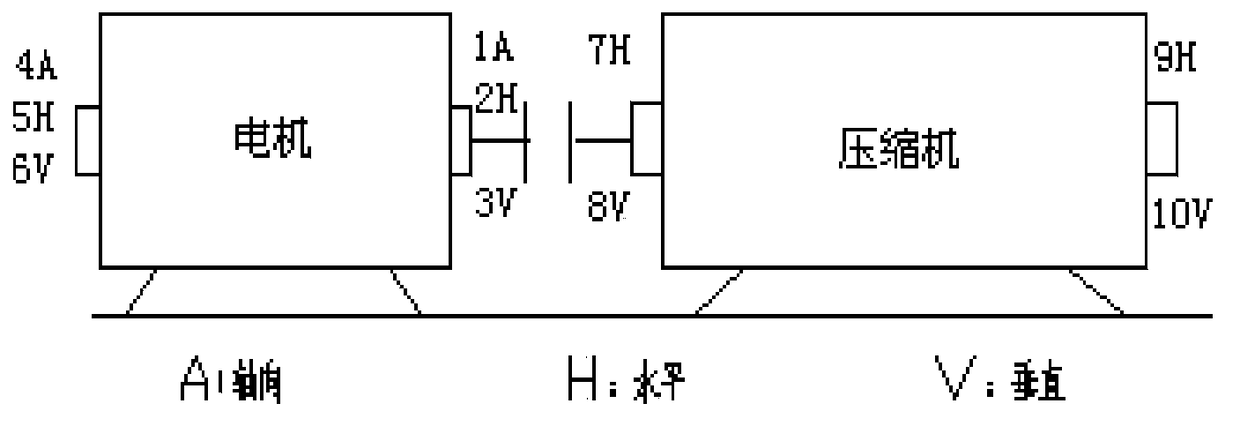

[0020] 1. Equipment introduction and measuring point layout

[0021] LG20CF2B620 (refrigeration capacity 617.9kw under standard working conditions, shaft power 175kw, power frequency: 49.5Hz) type refrigeration unit, the twin-screw compressor of this refrigeration unit is connected to the motor by a diaphragm elastic coupling.

[0022] The measuring point is usually selected as the vibration-sensitive part of the equipment, that is, the part where the bearing is located (including three positions of vertical, axial and horizontal). Once the measuring point is selected, it should be marked to ensure that the signal is obtained from the same position every time it is monitored. If the measuring instrument is integrated, the probe should be consistent with the measuring direction, and the angle deflection sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com