Method for flushing reverse osmosis membrane

A reverse osmosis membrane and backwashing technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the pollution of the membrane filtration surface and the first stage of the reverse osmosis system, difficult to remove pollutants, and prolong the reverse osmosis system. Stable operation cycle and other problems, to achieve the effect of extending stable operation cycle, slowing concentration polarization, and improving the service life of membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

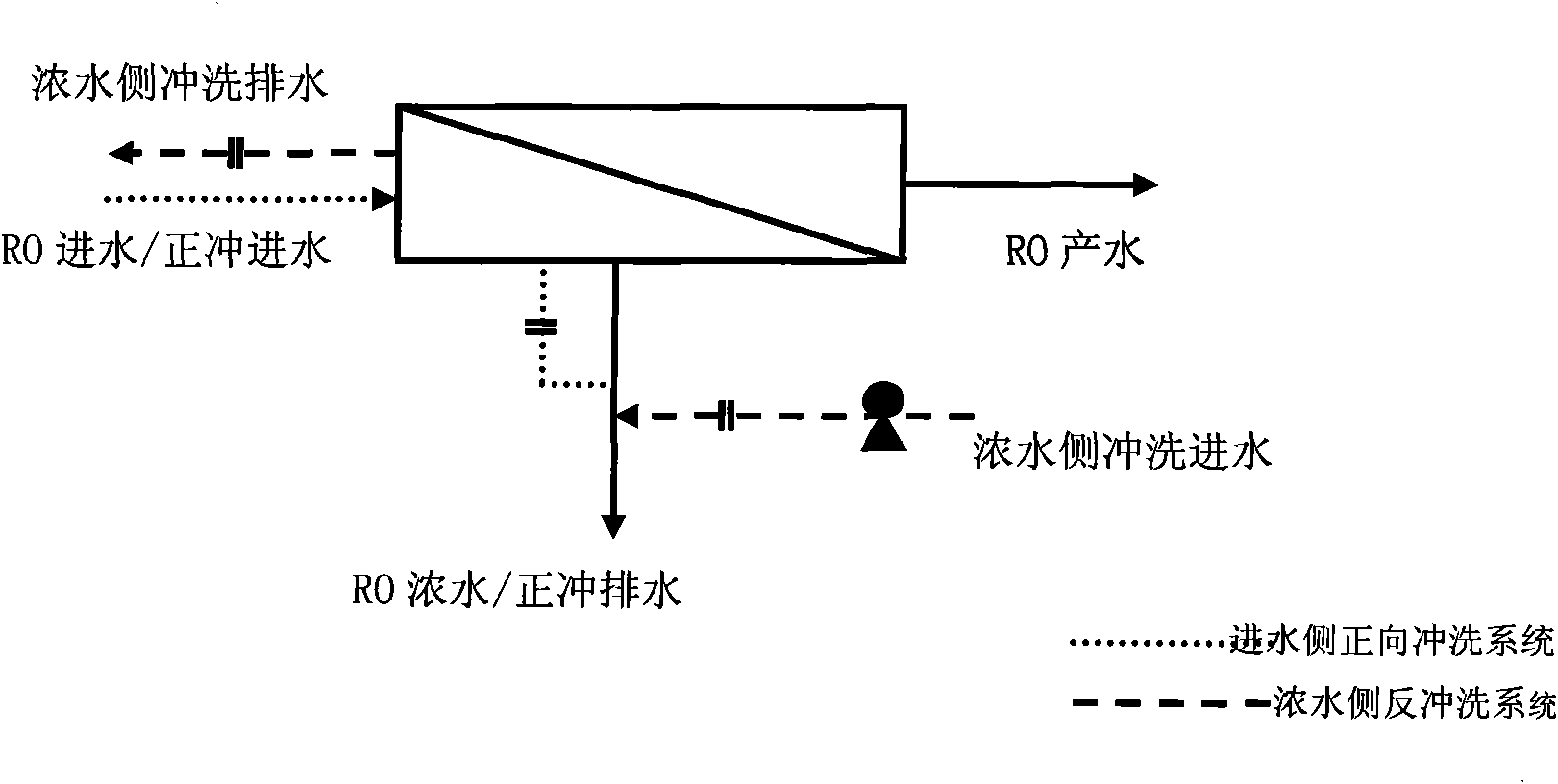

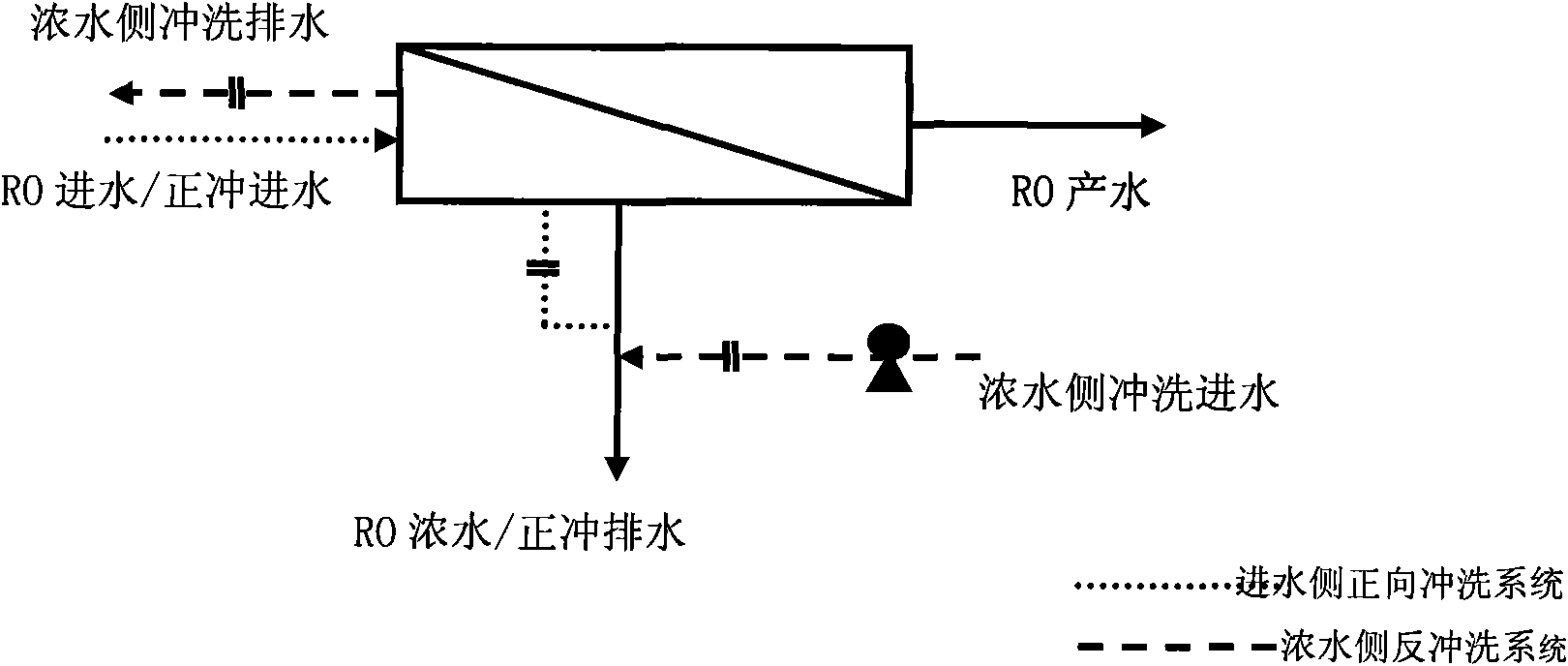

Image

Examples

Embodiment 1

[0034] A petrochemical enterprise olefin production plant process water, circulating cooling water sewage membrane advanced treatment device.

[0035] (1) Sewage water quality:

[0036] The water quality of the sewage treated by the reverse osmosis unit is shown in Table 2.

[0037] Table 2

[0038] Analysis Project

unit

average value

highest value

lowest value

pH

8.4

8.5

8.2

mg / L

4.3

6.3

0.7

always hard

mg / L as CaCO 3 count

875

1056

511

calcium hard

mg / L as CaCO 3 count

440

528

390

mg / L

242

283

131

mg / L

544

734

235

total iron

mg / L

1.43

4.16

0.77

NTU

6.8

12.0

2.9

mg / L

0.04

6.60

0.01

total silicon

mg / L

8.33

15.70

2.20

COD

mg / L

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com