Coal pyrolysis flue gas control treatment equipment continuous operation period prolonging method and coal pyrolysis flue gas control treatment equipment continuous operation period prolonging apparatus

A technology for controlling the treatment and operation cycle, applied in the direction of combination devices, separation methods, chemical instruments and methods, etc., can solve the problems of easy clogging of equipment, easy clogging of filter equipment, incomplete removal of dust particles, etc., and achieve stable operation cycle. The effect of prolongation, long service life and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

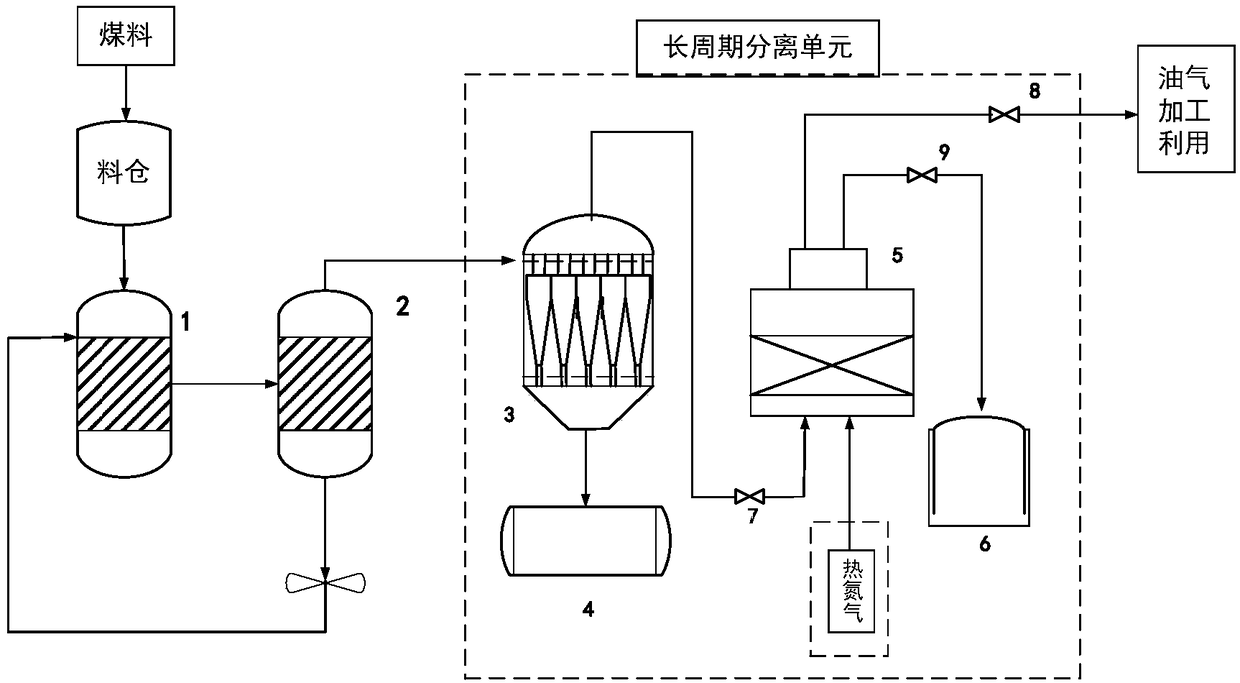

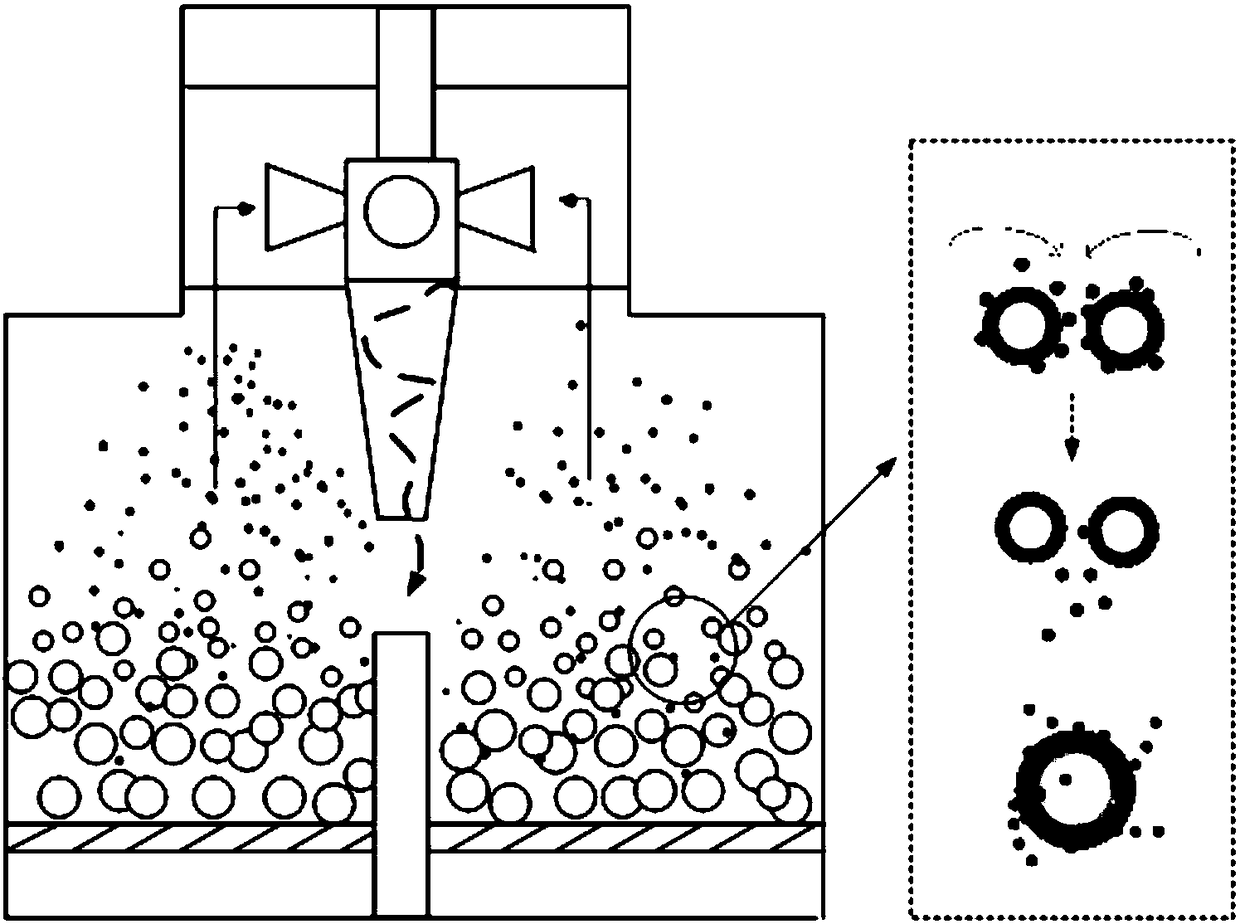

[0075] according to figure 1 The process flow of the ebullated bed separation method for particulate matter in coal pyrolysis flue gas shown is carried out. Separation parameters and separation results are shown in the table below:

[0076]

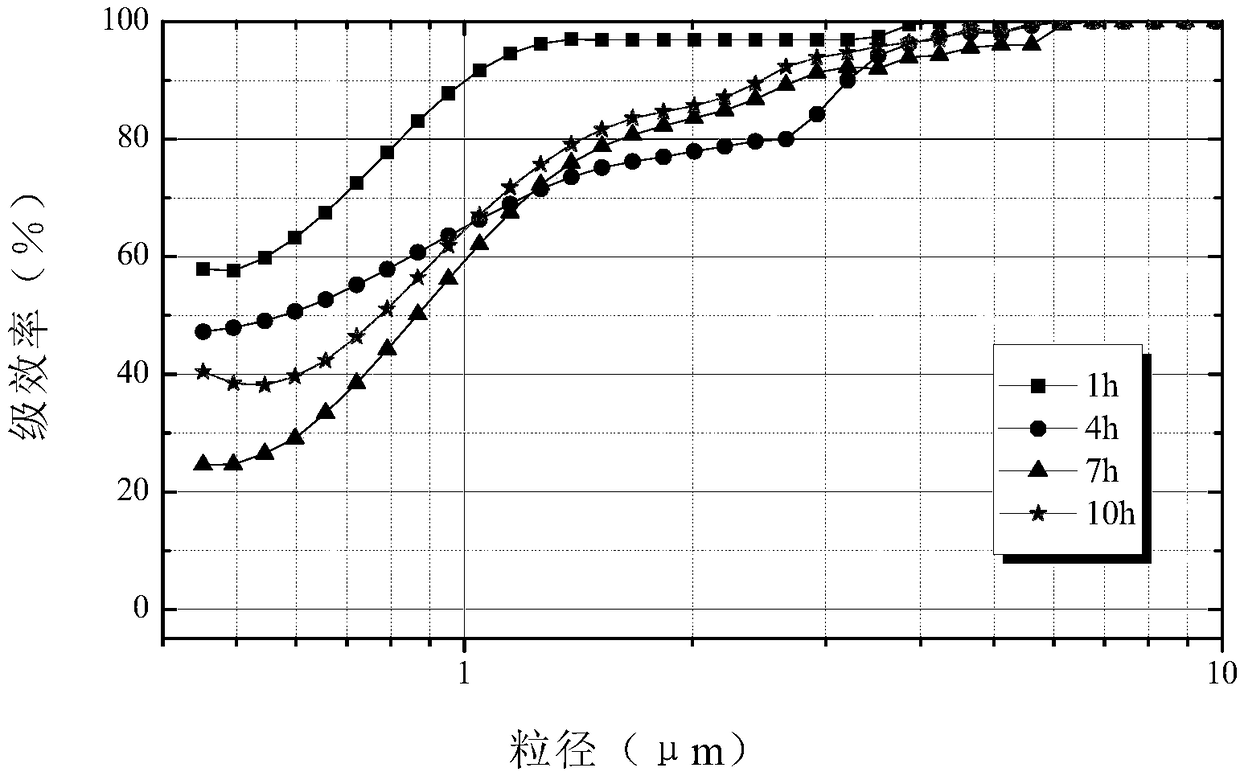

[0077] It can be seen from the above table that after cyclone degreasing and settling operations, the particle dust concentration drops to 30g / Nm 3 Below; after cyclone separation and deep granular bed combined purification, the tar content is reduced to 20g / Nm 3Below that, the outlet particle size distribution drops to 0.5-5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com