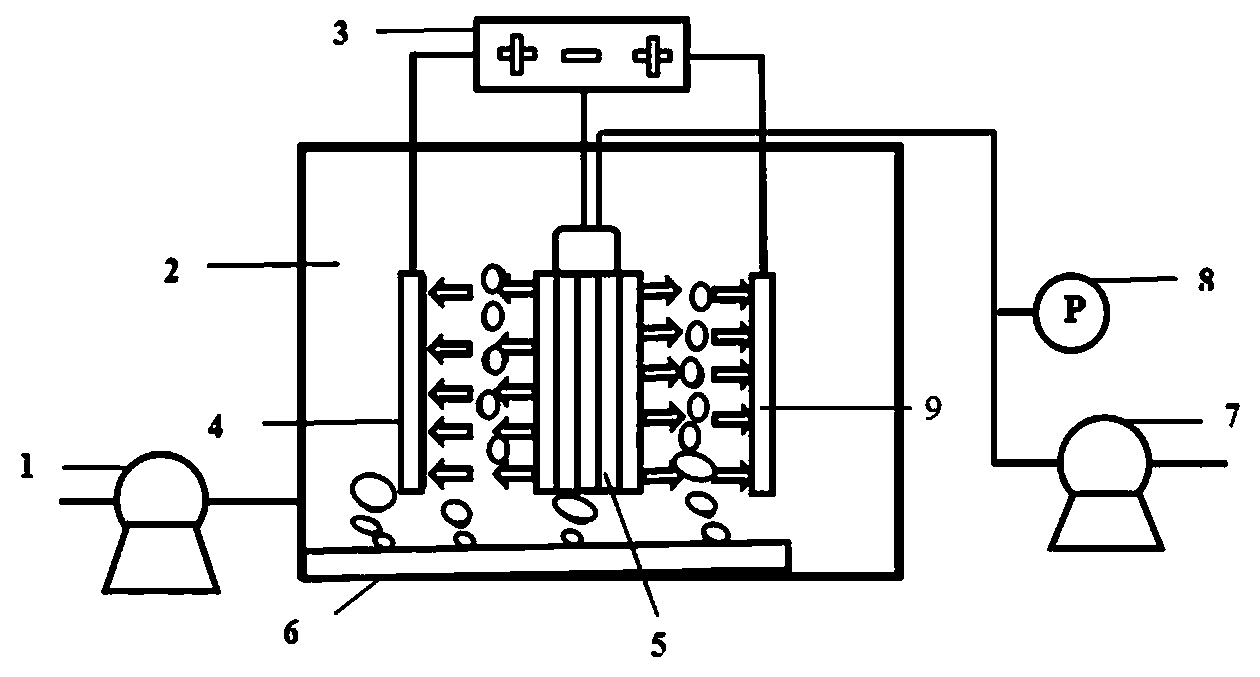

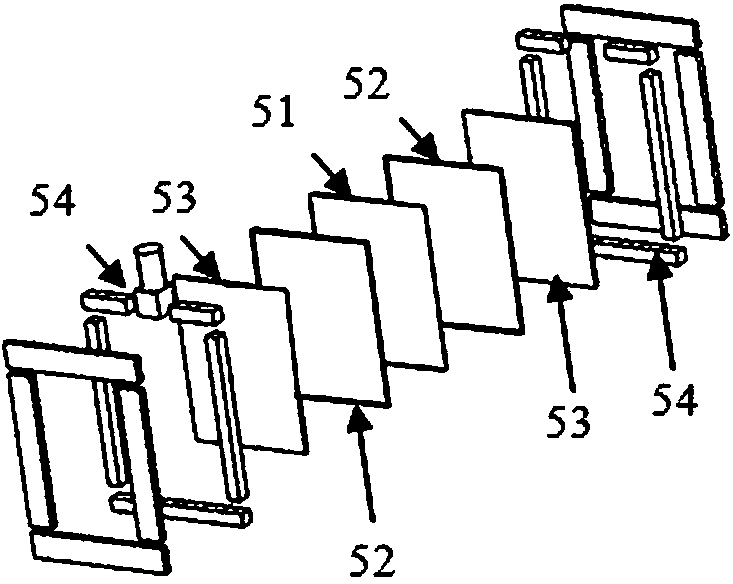

System for treating sludge by rotary electrodes in combination with flat sheet membrane

A technology of rotating electrodes and flat membranes, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of affecting the external electric field control membrane, weakening electric field strength, increasing electrode resistance, etc. Improve digestion efficiency and effluent quality, prolong stable operation period, and prevent sludge deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Compared with the ordinary membrane sludge treatment system, the rotating electrode coupled flat membrane sludge treatment system provided by the present invention has a lower hydraulic retention time of 3-4g / L when the sludge concentration is 3-4g / L, and a gas-water ratio of 60:1. Both are 24 hours, and the water is continuously operated within 15 days of a sludge discharge cycle, and the membrane flux is 17L / (m 2 h). However, the sludge VSS cumulative digestibility of the system of the present invention is 10% higher than that of the common system, and the membrane pressure rise rate and effluent COD (chemical oxygen demand) of the system of the present invention are respectively about 20% and 15% lower than the common system.

Embodiment 2

[0045] Compared with the ordinary membrane sludge treatment system, the rotating electrode coupled flat membrane sludge treatment system provided by the present invention has a lower hydraulic retention time when the sludge concentration is 3-4g / L, the gas-water ratio is 40:1, Both are 8 hours, and the water is continuously operated within 30 days of a sludge discharge cycle, the sludge concentration is about 35 g / L, and the membrane flux is 15L / (m 2 h). However, the membrane pressure rise rate and effluent COD of the system of the present invention are about 23% and 10% lower than those of the conventional system, respectively.

[0046] The rotating electrode coupled flat membrane sludge treatment system provided by the present invention has the following beneficial effects:

[0047] 1) The cathode membrane module is negatively charged, which can repel and prevent the same negatively charged sludge flocs and membrane pollutants from depositing on its surface, prolong the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com