Method for autothermal thermophilic aerobic digestion of sludge and device thereof

A high-temperature aerobic digestion and sludge self-heating technology, applied in the fields of environmental protection and comprehensive utilization of resources, can solve the problems of affecting the stable operation of the process, low oxygen transfer efficiency, high cost of pure oxygen aeration, and achieve construction investment and operating costs Low, good homogenization effect, accelerated reproduction and growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Raw sludge (taken from Guangzhou Liede Sewage Treatment Plant, the sludge water content percentage is 94.5%, the pH value is 7.23, the sludge volatile organic matter VSS is 29.5g / L, and the chemical oxygen demand COD is 18042mg / L, dissolved oxygen DO is 2.1mg / L, oxidation-reduction potential ORP is -246mV) into the tank through the mud inlet; fill the water bath jacket with water; turn on the stirring motor (rotating speed is 100r / min) and the blower ( The air pressure is 0.2MPa), and the aeration rate is controlled by a rotameter to 0.4m 3 / min; By adjusting the valve of the sludge return pipe, the return sludge is 0.4m 3 / min flow for circular aeration; turn on the electric heating tube, adjust the temperature to 60°C, and start the domestication reaction;

[0044] (2) After 7 days, discharge 50% of the total volume of sludge in the reactor through the sludge outlet, and then add raw sludge with the same volume as the discharged sludge;

[0045] (3) Step (2) is ...

Embodiment 2

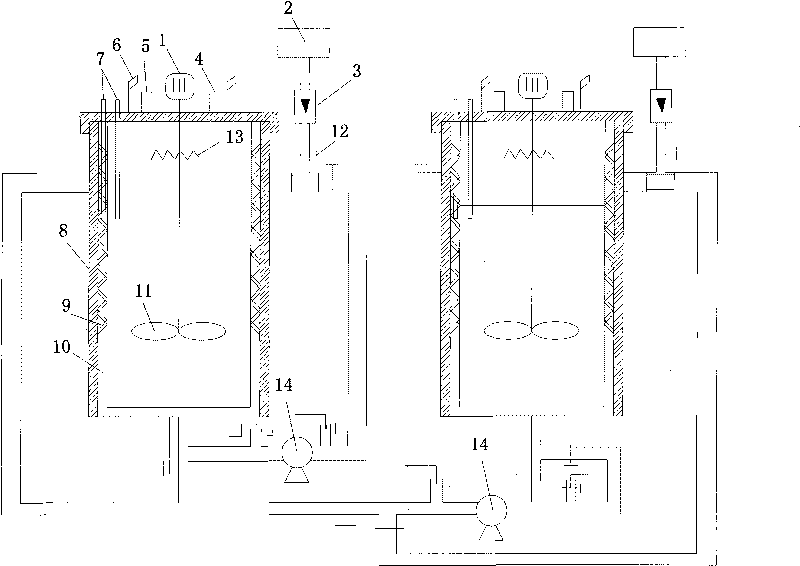

[0048] In this embodiment, a digestion device with two reactors is used to carry out autothermal high-temperature aerobic digestion of sludge. The reactor includes a tank and a cover on the tank; a stirring motor is arranged above the cover. , a mud inlet and a gas collection port; the stirring motor extends into the tank body, and the lower end of the stirring motor is provided with a blade; the tank body is provided with a water bath cover, the water bath cover is close to the inner wall of the tank, and the inside of the water bath cover is provided with an electric heating tube; The bottom of the tank body is provided with a sludge discharge port, and the branch of the sludge discharge port is connected with the sludge return pipe, and the sludge return pipe is connected with the two reactors; the top of the cover is provided with two temperature sensors, of which One temperature sensor extends into the inside of the tank body, and the other temperature sensor extends into ...

Embodiment 3

[0056] (1) Raw sludge (taken from Guangzhou Liede Sewage Treatment Plant, the sludge water content percentage is 97%, the pH value is 7.21, the sludge volatile organic matter VSS is 38.6g / L, and the chemical oxygen demand COD is 15028mg / L, dissolved oxygen DO is 2.5mg / L, oxidation-reduction potential ORP is -215mV) into three tanks through the mud inlet; fill water inside the water bath jacket; turn on the stirring motor (rotational speed is about 105r / min) And blower (air pressure is 0.3MPa), the aeration rate is controlled by rotameter to 0.1m 3 / min; By adjusting the valve of the sludge return pipe, the return sludge will flow at a rate of 0.05m 3 / min flow for circular aeration; turn on the electric heating tube, adjust the temperature to 70°C, and start the domestication reaction;

[0057] (2) After 6 days, discharge 70% of the total volume of sludge in the first reactor through the sludge outlet, and replenish the same volume of sludge in the second reactor as the disch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com