Method for purifying mesitylene through thermal coupling

A technology of mesitylene and thermal coupling, applied in distillation purification/separation, organic chemistry, etc., can solve the problems of unsatisfactory separation effect, weakened competitiveness of the final device, poisonous catalyst, etc., to prolong the stable operation period and facilitate separation. , reduce the effect of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

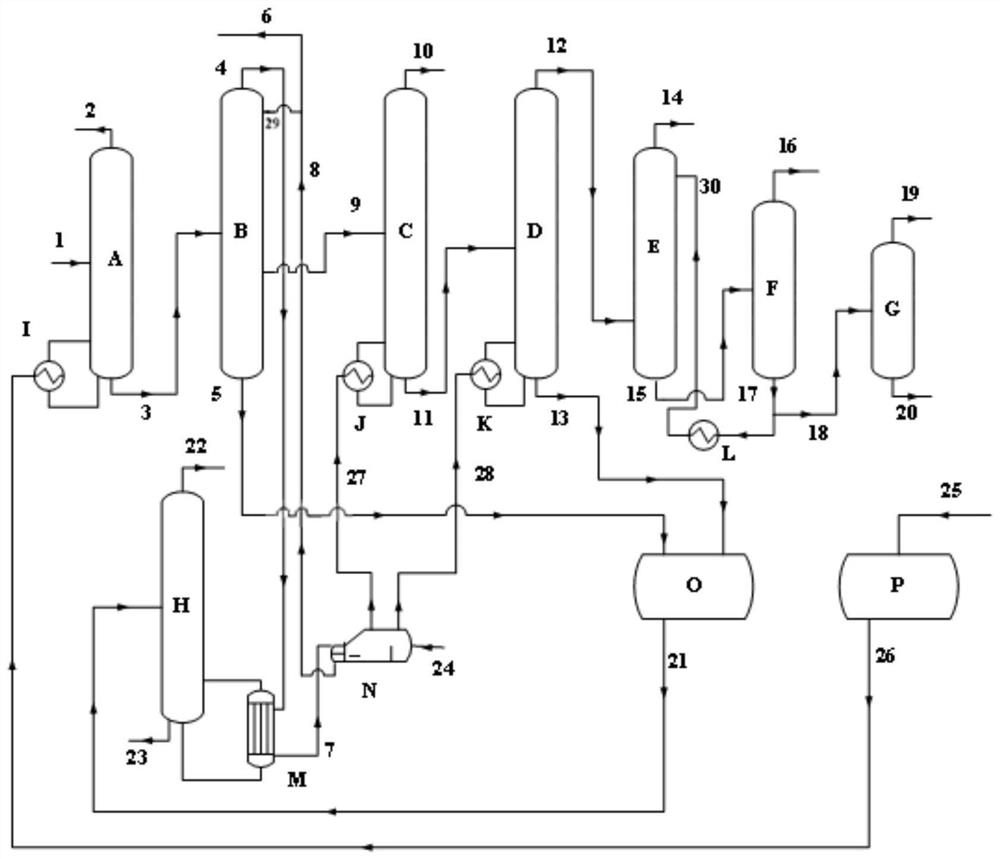

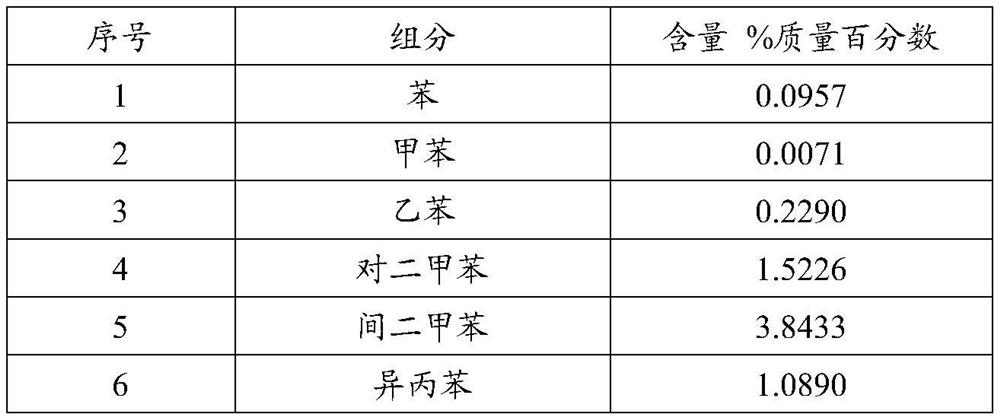

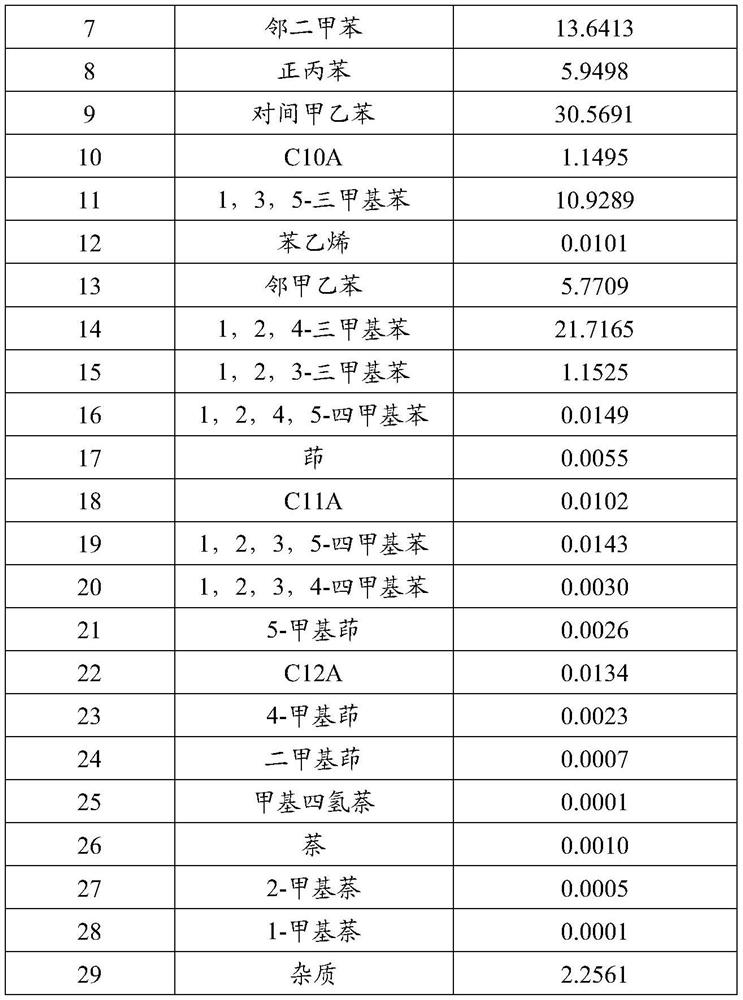

[0048] A method for thermally coupled purification of mesitylene:

[0049] Purification part:

[0050] (1) Firstly, it is necessary to reform C9 aromatics stream 1, enter the decarburization eight tower A from the 15th theoretical plate, and remove C8 aromatics stream 2 from the top of the tower through ordinary rectification;

[0051] (2) the tower kettle of decarburization tower A obtains and contains removal carbon 8 stream 3 and enters pretreatment tower B by the 40th theoretical plate, removes gaseous phase stream 4 from tower top, and gaseous phase stream 4 is SA1000I# high-boiling point aromatic hydrocarbon solvent ; The tower kettle obtains the heavy component flow 5 rich in mesitylene and enters the buffer tank O; extracts the flow 9 rich in mesitylene from the side line of the 70th theoretical plate of the pretreatment B tower;

[0052] (3) The stream 9 that is rich in mesitylene enters the light removal tower C from the 56th theoretical plate, and the m-p-methyleth...

Embodiment 2

[0075] A method for thermally coupled purification of mesitylene:

[0076] Purification part:

[0077] (1) First, the reformed C9 aromatics stream 1 that needs to be separated enters the decarburization eight tower A from the 35th theoretical plate, and the C8 aromatics are removed from the top of the tower by ordinary rectification;

[0078] (2) contain and remove C8 stream 3 and enter pretreatment tower B by the 64th theoretical plate, remove gaseous phase stream 4 from tower top, gaseous phase stream 4 is SA1000I# high-boiling aromatic hydrocarbon solvent; The heavy component flow 5 of the heavy component enters the buffer tank O; From the side line of the 80th theoretical plate of the pretreatment B tower, the flow 9 rich in mesitylene is extracted;

[0079] (3) The stream 9 that is rich in mesitylene enters the light removal tower C from the 45th theoretical plate, and the m-p-methylbenzene in the stream is precisely separated, and the stream 10 (SA1000II# high) that is ...

Embodiment 3

[0102] A method for thermally coupled purification of mesitylene:

[0103] Purification part:

[0104] (1) First, the reformed C9 aromatics stream 1 that needs to be separated enters the decarburization eight tower A from the 35th theoretical plate, and the C8 aromatics are removed from the top of the tower by ordinary rectification;

[0105] (2) contain and remove carbon 8 stream 3 and enter pretreatment tower B by the 90th theoretical plate, remove the gaseous phase stream 4 of most p-toluene and light components from the top of the tower; The heavy component stream 5 of trimethylbenzene enters buffer tank O; From the side line of the 120th theoretical plate of the pretreatment B tower, the stream 9 rich in mesitylene is extracted;

[0106] (3) The stream 9 that is rich in mesitylene enters the light removal tower C from the 66th theoretical plate, and the m-p-methylethylbenzene in the stream is precisely separated, and the stream 10 (SA1000II# high) rich in m-p-methylbenze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com