Solid-containing heavy oil vacuum distillation apparatus and method

A technology of process method and process device, which is applied in the direction of hydrocarbon oil distillation control/regulation, hydrocarbon distillation, petroleum industry, etc., can solve the problems of shortening the service life of equipment, not pointing out the corrosion effect of furnace tubes, etc., and achieve the system operation cycle Long, low energy consumption level of the system, reducing the effect of wear and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

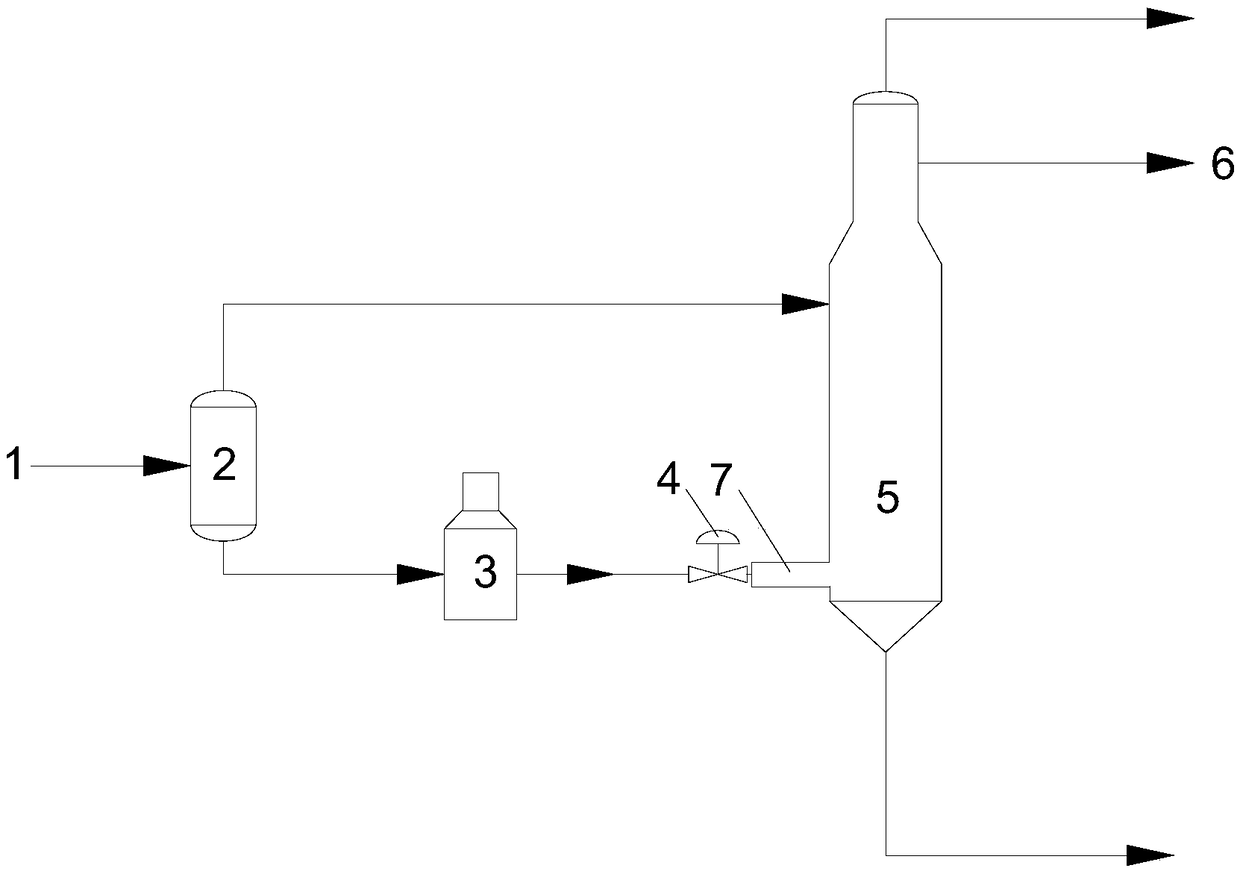

[0065] This embodiment provides a vacuum distillation process and a vacuum distillation process device containing solid heavy oil using the vacuum distillation process. The process device includes a reaction unit 1 and a vacuum flash tank 2 connected in sequence , decompression heating furnace 3, pressure control device 4, pre-flash device 7 and decompression tower 5;

[0066] The raw material inlet of the decompression flash tank 2 is connected with the reaction unit 1, the flash top gas outlet of the decompression flash tank 2 is directly connected with the decompression tower 5, and the bottom outlet of the decompression flash tank 2 is connected with the decompression heating furnace 3 connected.

[0067] The outlet of the decompression heating furnace 3 is connected with the inlet of the pre-flash device 7 through the pressure control device 4 .

[0068] The pre-flash device 7 is welded at the bottom of the decompression tower 5, the aspect ratio of the pre-flash device ...

Embodiment 2

[0079] This embodiment provides a vacuum distillation process and a vacuum distillation process device containing solid heavy oil using the vacuum distillation process. Described processing device is identical with embodiment 1 except.

[0080] The solid-containing atmospheric column bottom oil comes from the reaction unit 1 of the kerosene mixing process, and the solid-containing atmospheric column bottom oil contains 10wt% solid particles, and the average particle diameter of the solid particles is 60 μm. The particles are a combination of catalyst powder, powder coke and rust, and the active materials of the catalyst powder are Fe and Ni.

[0081] The reaction temperature of the reaction unit is 380° C., the reaction pressure of the reaction unit is 12 MPa, and the hydrogen-oil ratio of the reaction unit is 700.

[0082] The vacuum distillation process method using the described solid heavy oil vacuum process device comprises the steps:

[0083] (1) In the decompression fla...

Embodiment 3

[0087] This embodiment provides a vacuum distillation process and a vacuum distillation process device containing solid heavy oil using the vacuum distillation process. The process equipment is the same as in Example 1.

[0088] The solid-containing atmospheric column bottom oil comes from the reaction unit 1 of the heavy oil suspension bed hydrogenation process, and the solid-containing atmospheric column bottom oil contains 15wt% solid particles, and the average particle diameter of the solid particles is 40 μm, so The solid particles are a combination of catalyst powder and rust, and the active materials of the catalyst powder are Ni, Co and Mo.

[0089] The reaction temperature of the reaction unit is 420° C., the reaction pressure of the reaction unit is 16 MPa, and the hydrogen-oil ratio of the reaction unit is 900.

[0090] The vacuum distillation process method using the described solid heavy oil vacuum process device comprises the steps:

[0091] (1) In the decompre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com