Apparatus and method for microwave enhanced membrane distillation process

A distillation process and membrane strengthening technology, applied in the field of membrane distillation, can solve the problems of membrane fouling and low membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

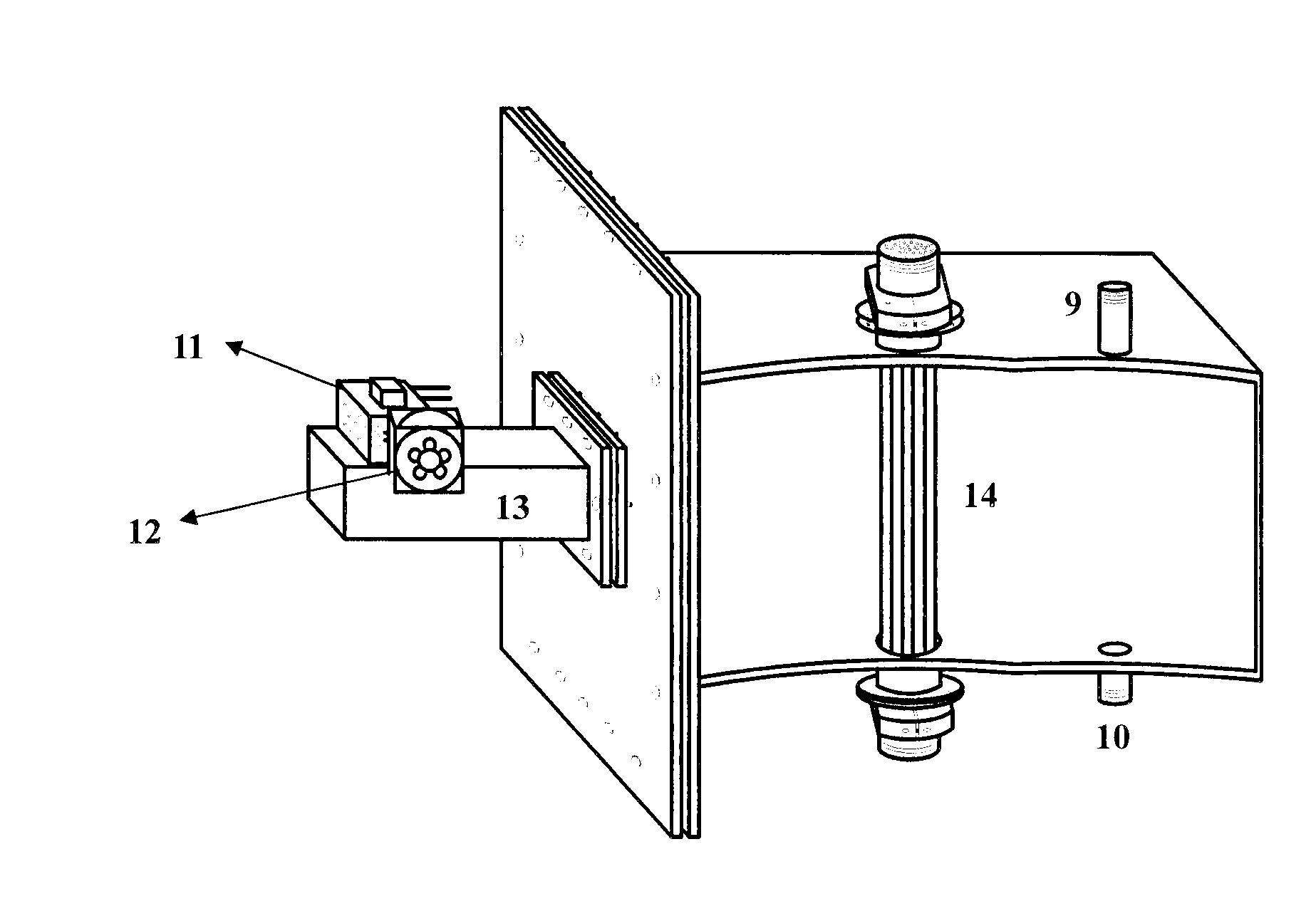

[0024] In view of the greater throughput of the vacuum membrane distillation process, this embodiment adopts vacuum membrane distillation and microwave vacuum membrane distillation respectively, and carries out microwave-assisted on-line cleaning and drying of contaminated membranes. The specific application scope of the present invention is not limited by this embodiment . Below taking sodium chloride aqueous solution as feed liquid, verify the practicability of the present invention by comparative test.

[0025] Basic conditions:

[0026] (1) Feed liquid: NaCl aqueous solution, conductivity is about 6000μs / cm; cleaning solution: deionized water, conductivity is about 2μs / cm; microwave power 1000W;

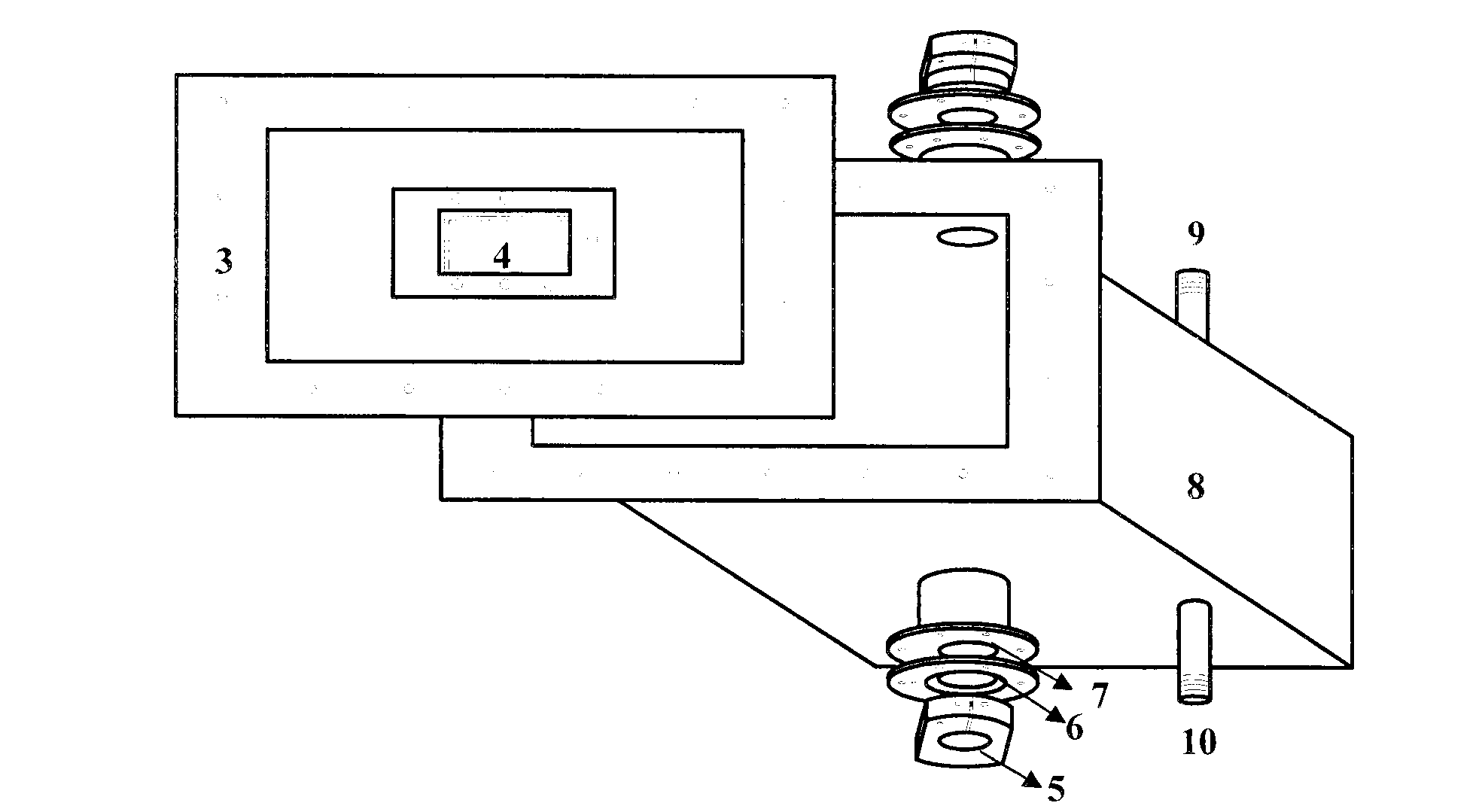

[0027] (2) Cavity parameters: cavity size 350mm×215mm×330mm, cavity volume 25L;

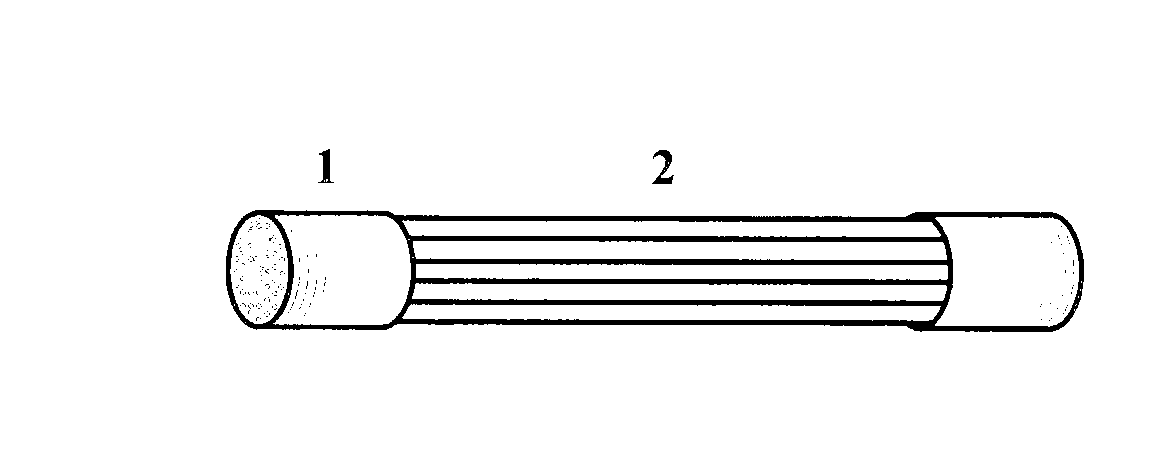

[0028] (3) Hollow fiber membrane module parameters: PVDF hollow fiber membrane module, membrane head diameter 320mm, effective working length 180mm, effective membrane area 0.107m 2 ;

[0029] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com