Cleaning method of porous separation membrane

A porous separation membrane and membrane separation technology, applied in the field of membrane separation, can solve problems such as membrane fouling and membrane separation process cannot run stably for a long time, and achieve the goal of preventing clogging, prolonging the stable operation period, and improving process economy and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

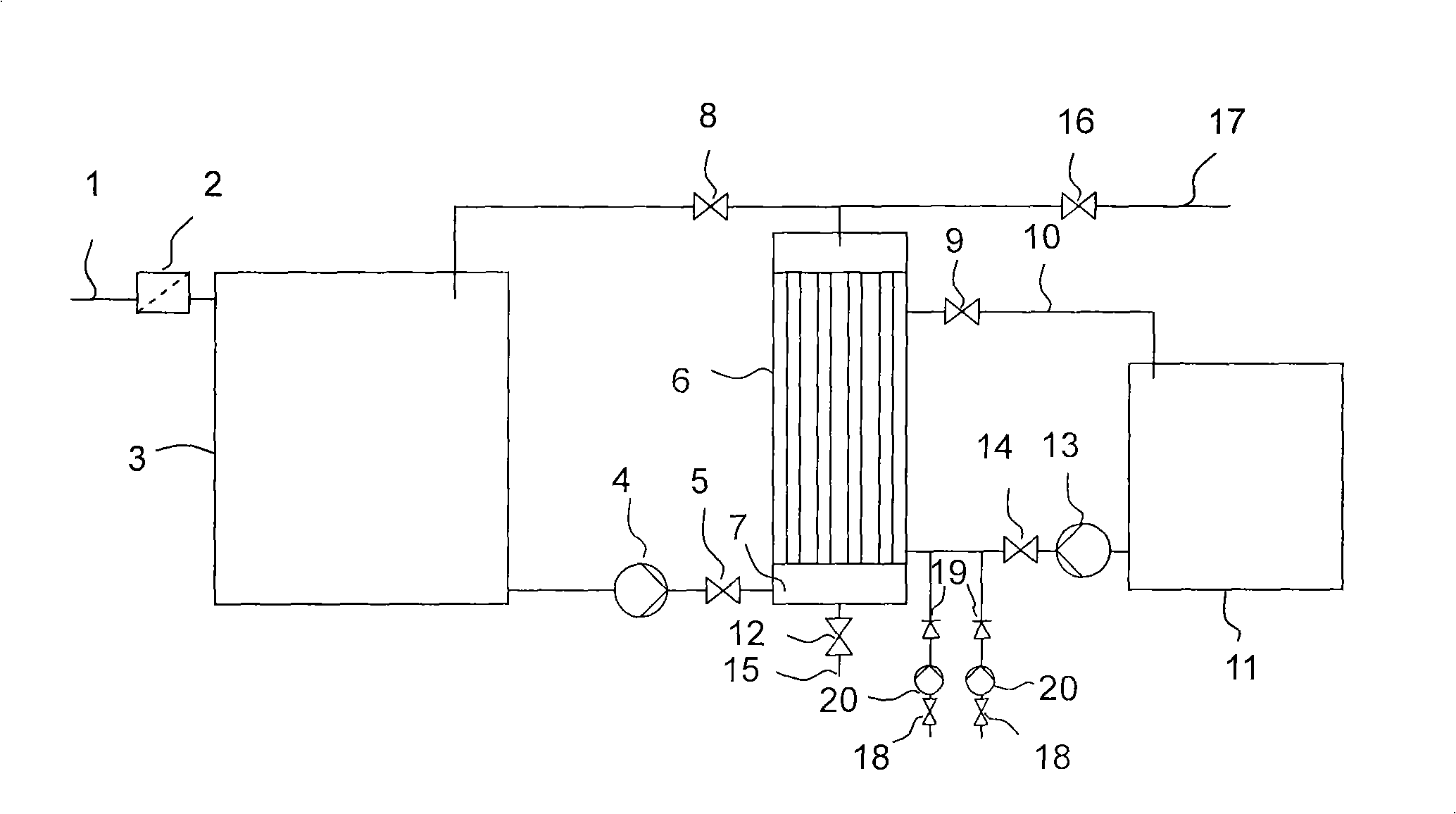

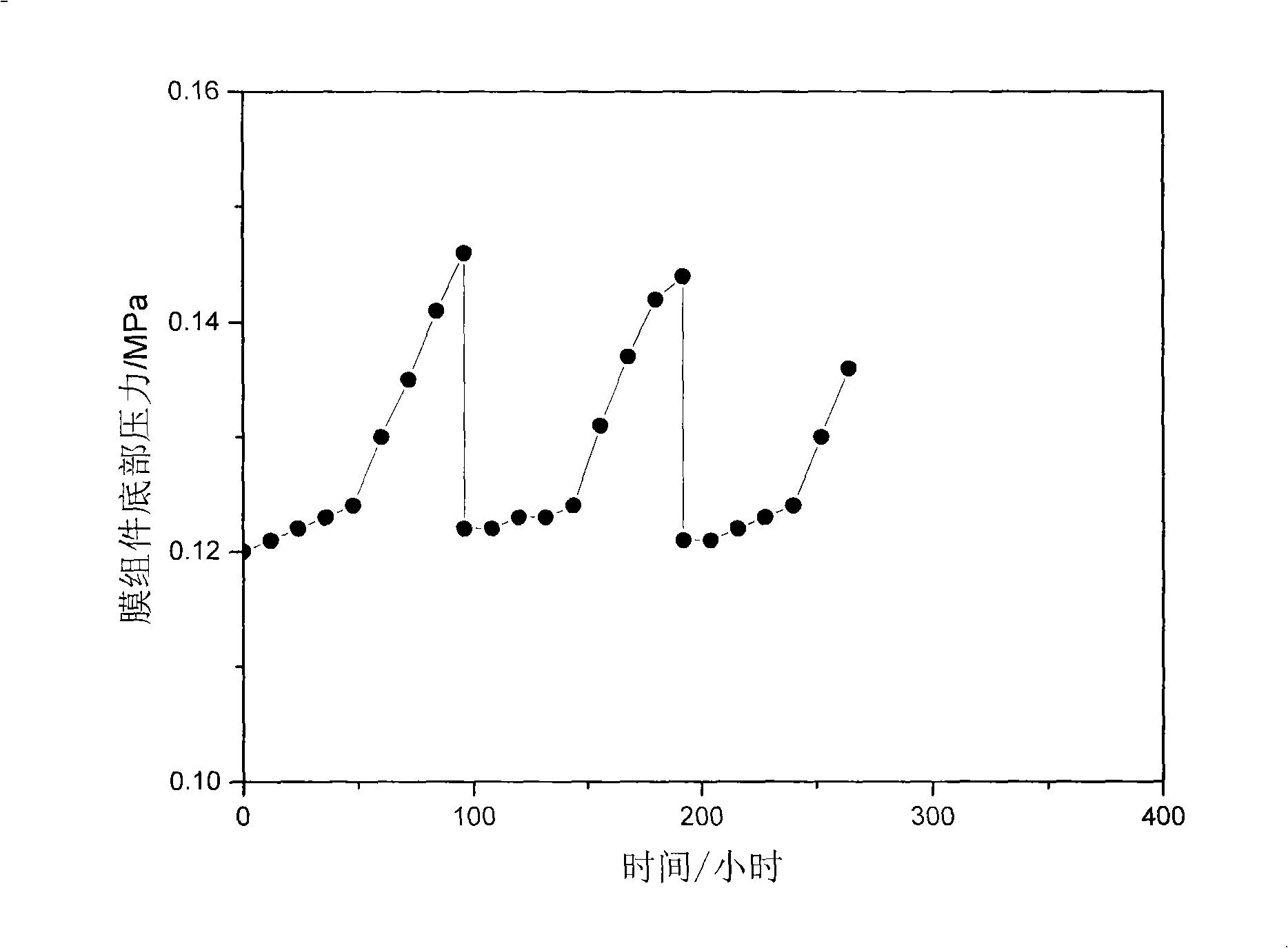

[0022] in such as figure 1 In the described membrane separation process for treating suspension liquid with high solid content, the cleaning unit at the bottom of the membrane module combined with the enhanced chemical backwashing process is applied, and the starting pressure of the cleaning unit at the bottom of the membrane module is set to 0.145Mpa. During the operation of the membrane separation system, the pressure at the bottom of the membrane module rises with time. When the start-up pressure is reached, the bottom cleaning program of the membrane module is started, that is, the bottom cleaning of the membrane module is realized in the backwashing step of the enhanced chemical backwashing process. Valve 16, open valve 14, open valve 12, start the backwash pump 13, the cleaning program at the bottom of the membrane module starts counting, after counting, open valve 16, close valve 12, and continue backwashing until the end of backwashing. figure 2 The change of the pre...

Embodiment 2

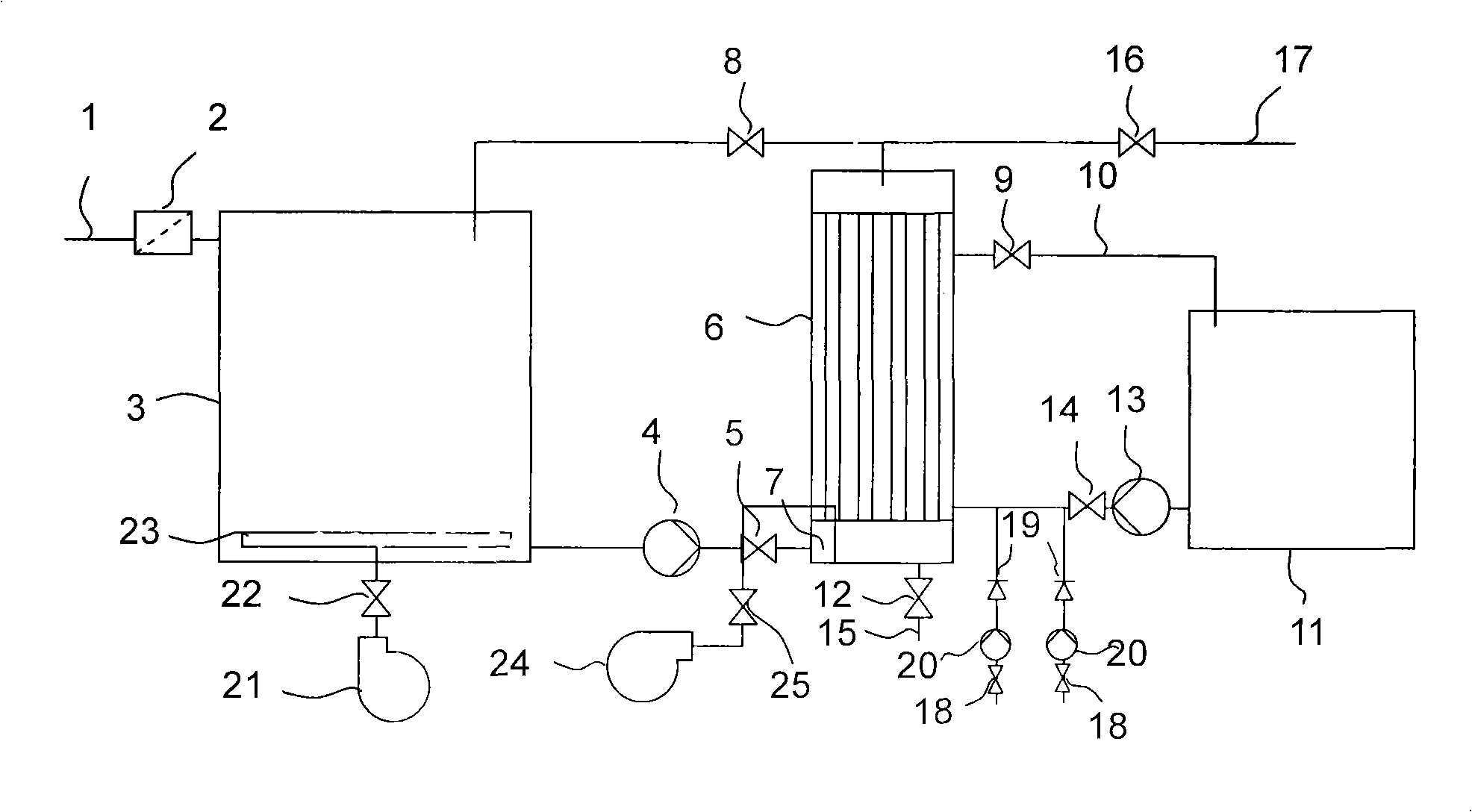

[0024] image 3 Applications of the invention to airlift membrane modules and bioreactor systems are described. Different from the membrane separation process of the aforementioned solid content suspended liquid, a bubbling system consisting of a blower 21, a valve 22 and a gas distributor 23 is installed at the bottom of the source water pool, in order to provide appropriate flow rate for the bacterial population in the bioreactor. Oxygen; an air blowing system consisting of a blower 24 and a valve 25 is installed at the bottom of the membrane module, the main purpose is to provide air buoyancy and reduce the accumulation of activated sludge on the membrane surface. Set the starting pressure of the cleaning unit at the bottom of the membrane module to 0.155Mpa, Figure 4 It is an application example of membrane module bottom cleaning unit in airlift membrane module and bioreactor system. The pressure at the bottom of the membrane module gradually increases with time, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com