Hydrogenation production method of a kind of jet fuel

A technology for jet fuel and production method, which is applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve problems such as increasing process complexity, and achieves protection of catalytic activity, reduction of carbon deposition rate, and low cetane number. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

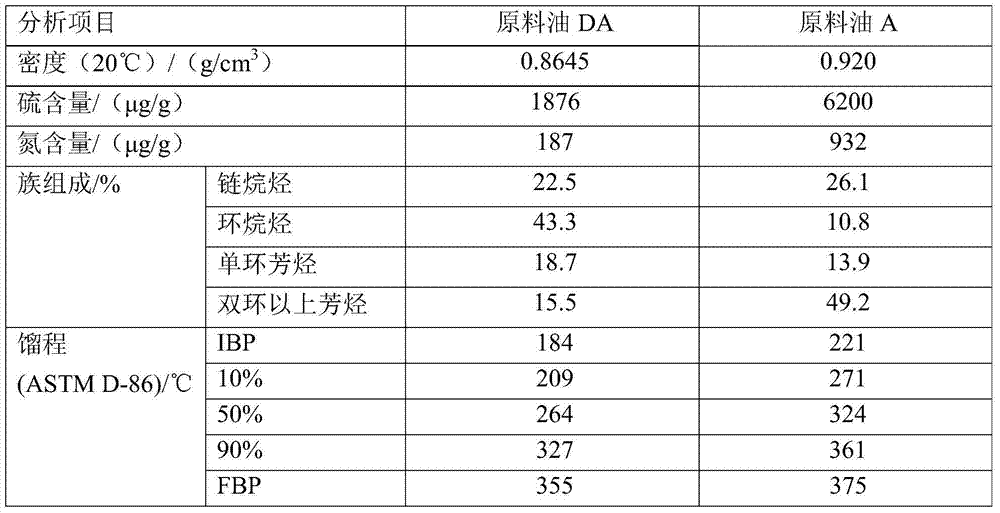

[0094] The feed oil A used in this example is catalytically cracked diesel oil, the properties of which are listed in Table 1.

[0095] This embodiment is carried out in two fixed-bed reactors, the first fixed-bed reactor is filled with a hydrofinishing catalyst, and the second fixed-bed reactor is filled with a hydrocracking catalyst and a supplementary hydrofinishing catalyst, wherein, The loading volume ratio of hydrofinishing catalyst, hydrocracking catalyst and supplementary hydrofinishing catalyst is 40:60:10; both hydrofinishing catalyst and supplementary hydrofinishing catalyst were purchased from Changling Branch of China Petroleum & Chemical Corporation The brand name of the catalyst is RS-2000, and the hydrocracking catalyst is the catalyst of the brand name RHC-5 purchased from Changling Branch of China Petroleum & Chemical Corporation.

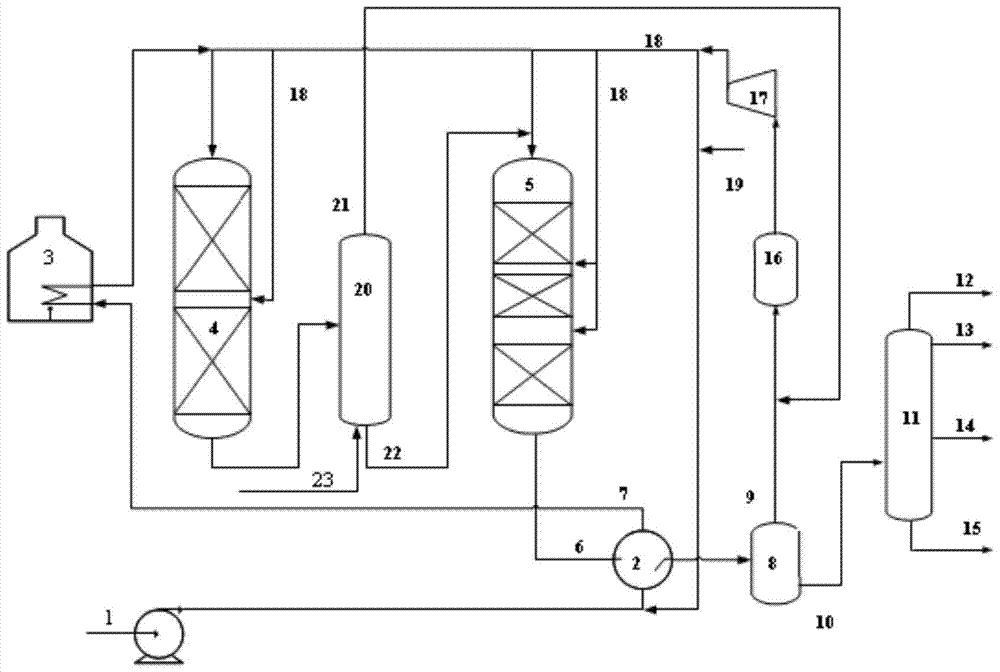

[0096] This example refers to figure 1 The process shown produces jet fuel, and the specific process flow is as follows.

[00...

Embodiment 2

[0108] The feed oil B used in this example is catalytically cracked diesel oil, the properties of which are listed in Table 3.

[0109]This embodiment is carried out in two fixed-bed reactors, the first fixed-bed reactor is filled with a hydrofinishing catalyst, and the second fixed-bed reactor is filled with a hydrocracking catalyst and a supplementary hydrofinishing catalyst, wherein, The loading volume ratio of hydrofinishing catalyst, hydrocracking catalyst and make-up hydrofinishing catalyst is 60:40:10.

[0110] Hydrofinishing catalysts and make-up hydrofinishing catalysts were prepared as follows.

[0111] With 3000 grams of Silica Gel 955 commercial silica gel (U.S. Davison Chemical company product, SiO 2 The content is 99.8% by weight) and 75 grams of scallop powder are evenly mixed, and then mixed with 84 milliliters of nitric acid (concentration 65-68 weight percent, analytically pure, product of Shantou Xilong Chemical Factory) and 4200 milliliters of water. The ...

Embodiment 3

[0120] Jet fuel was produced in the same manner as in Example 2, except that the hydrofinishing catalyst used and the make-up hydrofinishing catalyst used were prepared as follows:

[0121] With 200 ml of dilute ammonia solution containing 21.9 g of ammonium paramolybdate (NH 3 The concentration is 10% by weight) to impregnate 200 grams of silica carrier S for 2 hours, then dry at 120° C. for 4 hours, and then bake at 460° C. for 4 hours to obtain a molybdenum-containing carrier loaded with molybdenum oxide. Then, the molybdenum-containing carrier was impregnated with 156 ml of an aqueous solution containing 13.3 g of cobalt nitrate and 4.4 g of nickel nitrate for 2 hours, followed by drying at 120° C. for 4 hours, and then calcining at 470° C. for 4 hours to obtain the hydrorefining catalyst. The composition of the catalyst was determined by X-ray fluorescence spectrometry, wherein, MoO 3 The content of NiO is 8.0% by weight, the content of NiO is 0.6% by weight, and the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com