Activation method and reaction device for preparing methyl ethyl ketone catalyst through sec-butyl alcohol dehydrogenation

An activation method, sec-butanol technology, applied in the field of sec-butanol dehydrogenation catalyst activation, can solve the problems of accelerating the condensation reaction rate of alcohol and ketone, decreasing catalyst activity, reducing catalyst activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

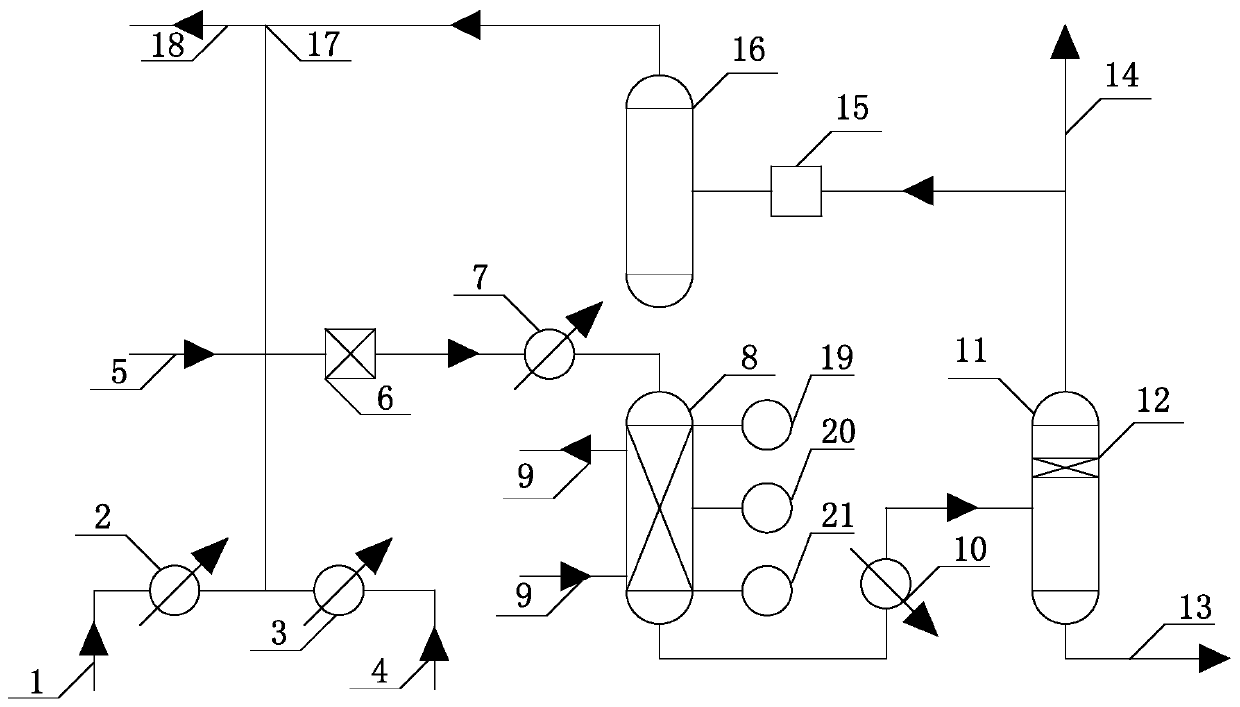

Image

Examples

Embodiment 1

[0067] The catalyst is calculated by weight percentage, and the composition is as follows: CuO 45%, ZnO 35%, Al 2 O 3 17%, K 2 CO 3 3%.

[0068] The catalyst is cylindrical.

[0069] The activation method of the catalyst for the dehydrogenation of sec-butanol to methyl ethyl ketone described in Example 1 consists of the following steps:

[0070] (1) Removal of catalyst physically adsorbed water

[0071] Using nitrogen as the heat carrier, the reactor bed temperature was raised to 190°C at a heating rate of 15°C / h, and the physically adsorbed water of the catalyst was removed by purging. The nitrogen space velocity was 260h -1 .

[0072] (2) Initial stage of reduction

[0073] When the bed temperature of the reactor stabilizes at 190°C, water vapor and nitrogen are introduced before the introduction of sec-butanol, and the nitrogen space velocity is 1400h -1 , The feed molar ratio of steam to nitrogen is 1:10.

[0074] After the steam and nitrogen are introduced and the bed temperature of...

Embodiment 2

[0116] The sec-butanol dehydrogenation device used in Example 2 is the same as that in Example 1. The reactor in Example 2 is an isothermal tube-and-tube reactor with a height-to-diameter ratio of 100:1. There are 10,000 tubes in the reactor. . The column tubes are filled with catalyst, the shell side is heat-conducting oil, and a baffle plate is installed in the shell side.

[0117] The catalyst is calculated by weight percentage, the composition is as follows: CuO 40%, ZnO 40%, Al 2 O 3 18%, K 2 CO 3 2%.

[0118] The catalyst is cylindrical.

[0119] The activation method of the sec-butanol dehydrogenation to methyl ethyl ketone catalyst described in Example 2 consists of the following steps:

[0120] (1) Removal of catalyst physically adsorbed water;

[0121] Using nitrogen as the heat carrier, the reactor bed temperature was raised to 160°C at a heating rate of 10°C / h, and the physically adsorbed water of the catalyst was removed by purging. The nitrogen space velocity was 200h ...

Embodiment 3

[0132] The catalyst is calculated by weight percentage, the composition is as follows: CuO50%, ZnO30%, Al 2 O 3 19%, K 2 CO 3 1%.

[0133] The catalyst is cylindrical.

[0134] The reactor in Example 3 is an isothermal tube-and-tube reactor, with an internal tube height-to-diameter ratio of 200:1, and there are 3000 tube tubes in the reactor. The column tubes are filled with catalyst, the shell side is heat-conducting oil, and a baffle plate is installed in the shell side.

[0135] The activation method of the catalyst for preparing methyl ethyl ketone by dehydrogenation of sec-butanol described in Example 3 consists of the following steps:

[0136] (1) Removal of catalyst physically adsorbed water

[0137] Using nitrogen as the heat carrier, the reactor bed temperature was raised to 180°C at a heating rate of 30°C / h, and the physically adsorbed water of the catalyst was removed by purging. The nitrogen space velocity was 800h -1 .

[0138] (2) Initial stage of reduction

[0139] At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com