SAPO-18 molecular sieve, method for synthesizing SAPO-18 molecular sieve and method for preparing olefin from methanol

A technology of SAPO-18, synthesis method, applied in molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate and other directions, can solve problems such as unsatisfactory catalyst service life, increase production cost, reduce production efficiency, etc. The effect of thermal crystallization time, improving production efficiency, and prolonging the service life of one pass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] According to the first aspect of the present invention, the present invention provides a kind of synthetic method of SAPO-18 molecular sieve, and this method comprises the following steps:

[0025] (1) provide a kind of mixed solution, described mixed solution contains aluminum source, phosphorus source, silicon source, templating agent and water;

[0026] (2) aging the mixed solution;

[0027] (3) hydrothermal crystallization of the aged mixed solution;

[0028] (4) The mixture obtained by hydrothermal crystallization is subjected to solid-liquid separation, and the obtained solid phase is dried and optionally calcined.

[0029] According to the method of the present invention, the template is a composite template, comprising a first template and a second template, the first template is N,N-diisopropylamine, and the second template is At least one of triethylamine, diethylamine and isopropylamine, and the molar ratio of the first templating agent to the second templa...

Embodiment 1

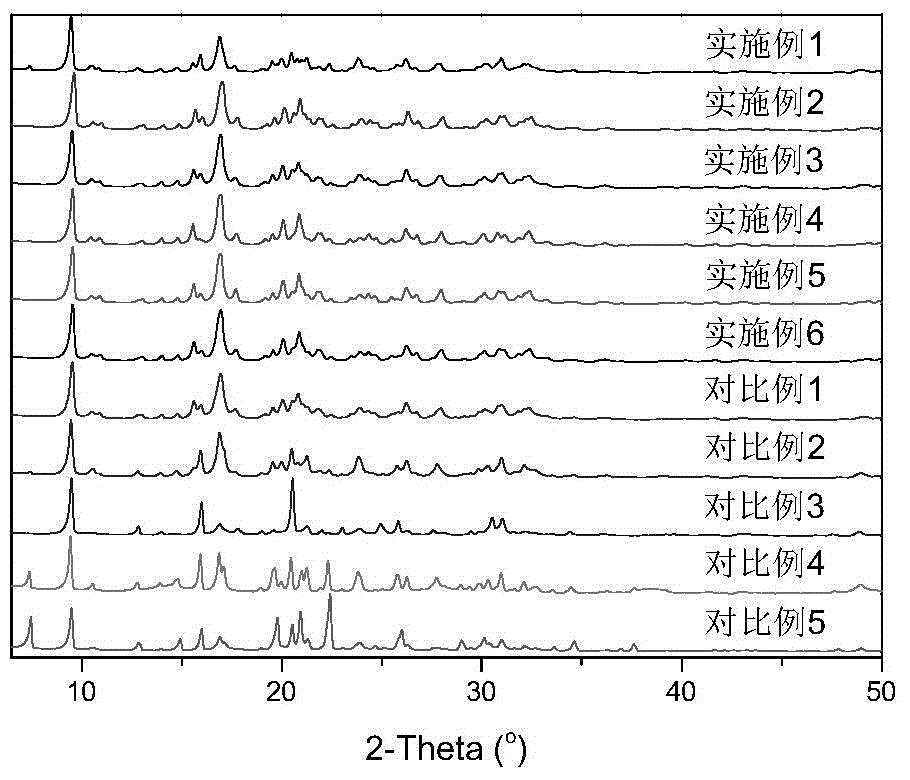

[0052] 13.15g pseudo-boehmite and 29.76g deionized water are mixed and stirred, and a mixed solution of 16.60g phosphoric acid (concentration is 85wt%) and 14.88g deionized water is added with vigorous stirring, and 7.20g silica sol (SiO 2 Content is the mixed solution of 40wt%) and 14.88g deionized water. After stirring at room temperature for 1 hour, 10.32 g of N,N-diisopropylethylamine (99 wt%) and 8.09 g of triethylamine were added, stirred for 2 hours, and the formed jelly was aged at room temperature (25° C.) for 2 hours. The aged mixed solution was put into a stainless steel crystallization kettle, and hydrothermally crystallized at 180° C. for 96 hours. The mixture obtained by hydrothermal crystallization was filtered, and the obtained solid phase was washed with deionized water, dried at 120° C. for 5 hours, and then calcined at 650° C. for 8 hours in an air atmosphere. The obtained molecular sieve is carried out X-ray diffraction analysis (results such as figure 1 ...

Embodiment 2

[0054] The molecular sieve was prepared by the same method as in Example 1, except that the amount of N,N-diisopropylethylamine (99 wt%) was 18.61 g, and the amount of triethylamine was 1.62 g. The obtained molecular sieve is carried out X-ray diffraction analysis (results such as figure 1 Shown), confirmed to be SAPO-18 molecular sieve. The molecular sieve yields and relative crystallinity are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com