Method for preparing ethylene cracking feed by hydrogenation of liquefied gas

A technology in the direction of liquefied gas and feed, which is used in the processing of gas mixtures, petroleum industry, hydrocarbon oil treatment products, etc., which can solve the problem of difficult to achieve the quality of steam cracking raw materials, affecting the single-pass service life of the catalyst, and fast carbon deposition in the catalyst bed. and other problems, to achieve the effect of gentle temperature bulb, reducing the temperature rise of the reaction, and reducing the temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

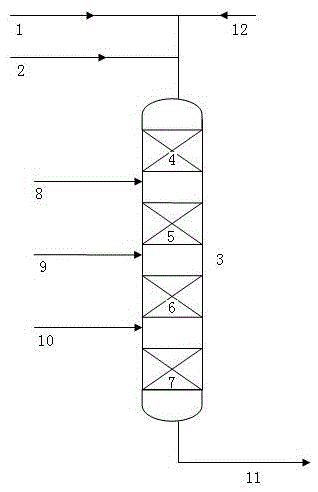

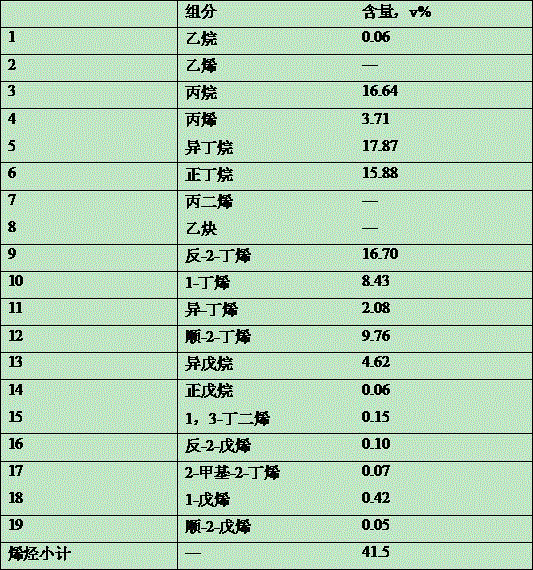

[0048] The reaction adopts a fixed-bed reactor and feeds upwards. The catalyst is loaded in four stages, from top to bottom, the catalyst volume fraction of each stage is: 10%, 15%, 25%, 50%. The reaction is divided into four stages to feed hydrogen, and the amount of hydrogen fed to each stage of the bed is respectively: the amount of hydrogen entering the first catalyst bed in the first stage is 30v% of the chemical hydrogen consumption required for the reaction, and the amount of hydrogen entering the second catalyst bed in the second stage The amount of hydrogen in the bed is 30v% of the chemical hydrogen consumption required for the reaction, the amount of hydrogen entering the third catalyst bed in the third stage is 30v% of the chemical hydrogen consumption required for the reaction, and the fourth stage enters the fourth catalyst bed The amount of hydrogen is 50v% of the chemical hydrogen consumption required for the reaction. In addition to the liquefied gas, the rea...

Embodiment 2

[0061] Raw material used in this embodiment, catalyst are the same as embodiment 1. Distillate oil (coker gasoline) was not introduced during the reaction. The hydrogenation process conditions and results are listed in Table 7. The amount of carbon deposited in each section of the catalyst bed after operation is shown in Table 8.

[0062] Table 7 Operating conditions and results of liquefied gas hydrogenation reactor

[0063] Reaction conditions Pressure / MPa 5.0 Liquefied gas volume space velocity / h -1

1.5 1st stage bed inlet temperature / °C 165 1st stage bed outlet temperature / °C 237 1st stage bed temperature rise / ℃ 72 2-stage bed inlet temperature / °C 237 2-stage bed outlet temperature / °C 305 2-stage bed temperature rise / ℃ 68 3-stage bed inlet temperature / °C 305 3-stage bed outlet temperature / °C 346 3-stage bed temperature rise / ℃ 41 4th stage bed inlet temperature / °C 346 4th stage bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com