Method for producing ethylene cracking material through dry gas hydrogenation

An ethylene cracking and dry gas technology, which is applied in the processing of gas mixtures, the petroleum industry, and the treatment of hydrocarbon oils, etc., can solve the problems of concentrated reaction heat release, high hot spot temperature and temperature envelope, and large differences in dry gas composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

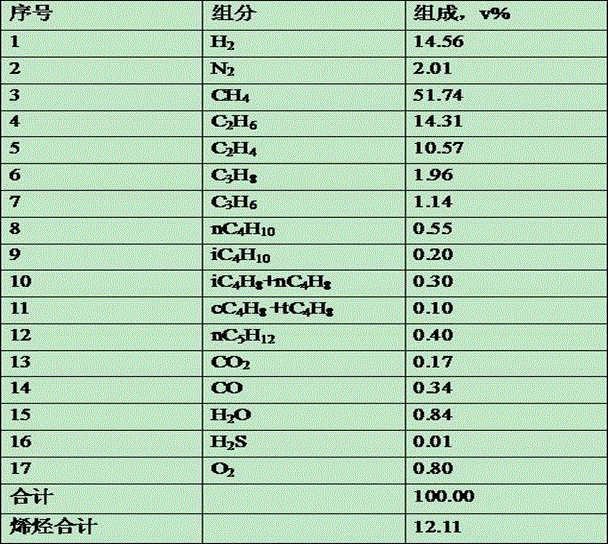

[0064] The reaction adopts a fixed bed reactor with upper feed; the catalyst adopts four-stage packing, and the packing ratio is the same as that of Comparative Example 1. From top to bottom, the catalysts are A, B, A, D in sequence. Its physical properties are listed in Table 3. The hydrogenation feed gas is coking dry gas, whose composition is shown in Table 2. The reaction feed includes only coking dry gas. The reaction conditions and results are shown in Table 5.

[0065] From the reaction results in Table 5, it can be seen that if the catalyst grading scheme of the present invention is adopted and only a single coking dry gas feed is used for hydrogenation reaction, the temperature rise of the reaction bed is 259℃; Up to 41°C.

[0066] In addition, from the reaction results in Table 5, it can be seen that after adopting the catalyst grading scheme of the present invention, the maximum temperature of the reaction bed is 396°C, the hot spot temperature can be controlled with...

Embodiment 2

[0068] The reaction adopts a fixed bed reactor with upper feed; the catalyst adopts four-stage packing, and the packing ratio is the same as that of Comparative Example 1. From top to bottom, the catalysts are A, B, A, D in sequence. Its physical properties are listed in Table 3. The hydrogenation feed gas is coking dry gas, whose composition is shown in Table 2. In addition to the coking dry gas, the reaction feed also contains catalytic diesel, and the feed is fed in parallel with the coking dry gas. The main properties of catalytic diesel are shown in Table 4. The reaction conditions and results are shown in Table 5.

[0069] From the reaction results in Table 5, it can be seen that compared with Example 1, after the two improved methods of catalyst grading filling and introduction of catalytic diesel, the reaction "warm bulb" is further reduced, and the reaction temperature rise is reduced from the original 259°C. To 173°C; but the average reaction temperature was 312.4°C...

Embodiment 3

[0071] The reaction adopts a fixed bed reactor with upper feed; the catalyst adopts four-stage packing, and the packing ratio is the same as that of Comparative Example 1. From top to bottom, the catalysts are A, B, A, D, and their physical properties are listed in Table 3. The hydrogenation feed gas is coking dry gas, whose composition is shown in Table 2. In addition to the coking dry gas, the reaction feed is also fed with No. 5 jet fuel (RP-5), which is fed in parallel with the coking dry gas. The main properties of No. 5 jet fuel (RP-5) are shown in Table 4. The reaction conditions and results are shown in Table 5.

[0072] From the reaction results in Table 5, it can be seen that after the two improved methods of catalyst grading filling and No. 5 jet fuel (RP-5), the reaction "warm bulb" can also be greatly reduced, and the reaction temperature rise can be reduced from the original At 259°C, it was reduced to 173°C; but the average reaction temperature was 312.6°C, almo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com