Preparation method for fire preventing and extinguishing colloid material for coal mines

A colloidal material and anti-fire extinguishing technology, which is applied in the direction of fire prevention equipment, etc., can solve the problems of rare fire extinguishing material research, high cost of composite hydrogel, and low fire extinguishing efficiency, so as to improve fire extinguishing efficiency, good fire extinguishing effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

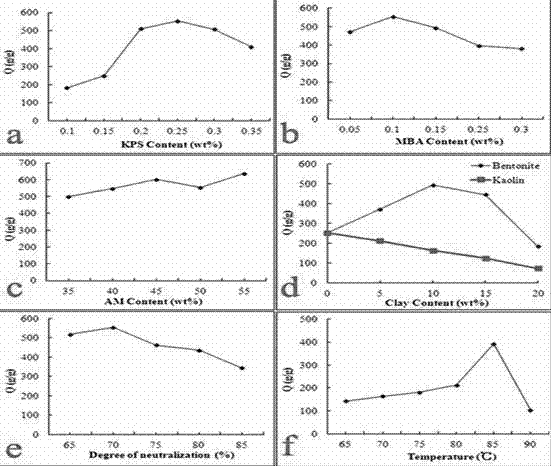

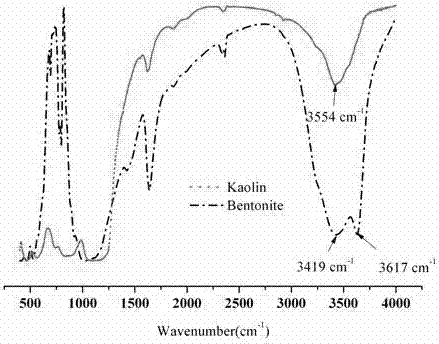

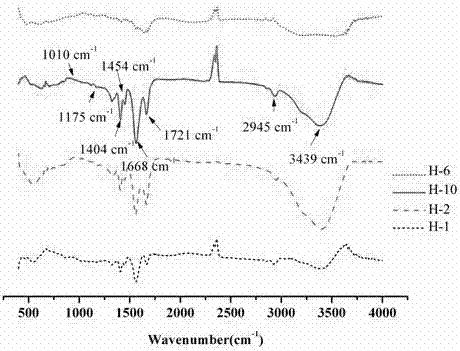

Embodiment 1

[0033] At room temperature, titrate acrylic acid with a sodium hydroxide solution with a mass fraction of 25%, and stir while dripping, so that the neutralization degree of acrylic acid is 70%; add bentonite to water, and stir to make a suspension with a concentration of 20 wt%. Add kaolin into water, stir to make a suspension with a concentration of 20 wt%; add neutralized acrylic acid, kaolin, bentonite, propylene to a 500mL four-necked bottle equipped with a magnetic stirrer, a thermometer and an airway Amide, N,N'-methylenebisacrylamide, potassium persulfate, in which the mass ratio of acrylic acid: kaolin: bentonite: acrylamide = 100:5:10:50, acrylic acid: N,N'-methylenebis Acrylamide: Potassium persulfate mass ratio = 100:0.25:0.1, start the magnetic stirrer, protect with nitrogen, and gradually raise the temperature to 80°C, react for 2 hours, after the reaction, take out the product, cut it into pieces, and put it in an oven at 90°C Medium drying to constant weight to ...

Embodiment 2

[0036] At room temperature, titrate acrylic acid with a sodium hydroxide solution with a mass fraction of 25%, stirring while dripping, so that the neutralization degree of acrylic acid is 60%; add bentonite to water and stir to make a suspension with a concentration of 25 wt%. Add kaolin into water and stir to make a suspension with a concentration of 25 wt%. Add neutralized acrylic acid, kaolin, bentonite, and propylene to a 500mL four-necked bottle equipped with a magnetic stirrer, a thermometer, and an airway tube. Amide, N, N'-methylenebisacrylamide, potassium persulfate, wherein the mass ratio of acrylic acid: kaolin: bentonite: acrylamide = 100:10:10:60, acrylic acid: N,N'-methylene The mass ratio of bisacrylamide:potassium persulfate=100:0.2:0.05, start the magnetic stirrer, protect it with nitrogen, and gradually raise the temperature to 80°C, react for 2 hours, after the reaction, take out the product, cut it into pieces, and put it at 100°C Baked in an oven to const...

Embodiment 3

[0039] At room temperature, titrate acrylic acid with a sodium hydroxide solution with a mass fraction of 25%, and stir while dripping, so that the neutralization degree of acrylic acid is 90%; add bentonite to water, and stir to make a suspension with a concentration of 15% by weight; Add kaolin into water and stir to make a suspension with a concentration of 15% by weight; add neutralized acrylic acid, kaolin, bentonite, acrylamide, N, N'-methylenebisacrylamide, potassium persulfate, wherein the mass ratio of acrylic acid: kaolin: bentonite: acrylamide = 100: 20: 5: 45, the mass ratio of acrylic acid: initiator: crosslinking agent = 100 : 0.15: 0.25, start the magnetic stirrer, pass nitrogen protection, and gradually raise the temperature to 80°C, and react for 1.5 h. After the reaction, the product was taken out, cut into pieces, and dried in an oven at 95°C to constant weight to obtain a dry granular product, which was crushed and passed through an 80-mesh sieve. The wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com