Styrene oxidation method

A technology of styrene and oxidant, which is applied in chemical instruments and methods, organic chemistry, molecular sieve catalysts, etc. It can solve the problems of reactor shutdown, increase of device operating cost, and decrease of catalytic activity, so as to prolong the service life and prolong the service life of a single pass , the effect of reducing the regeneration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

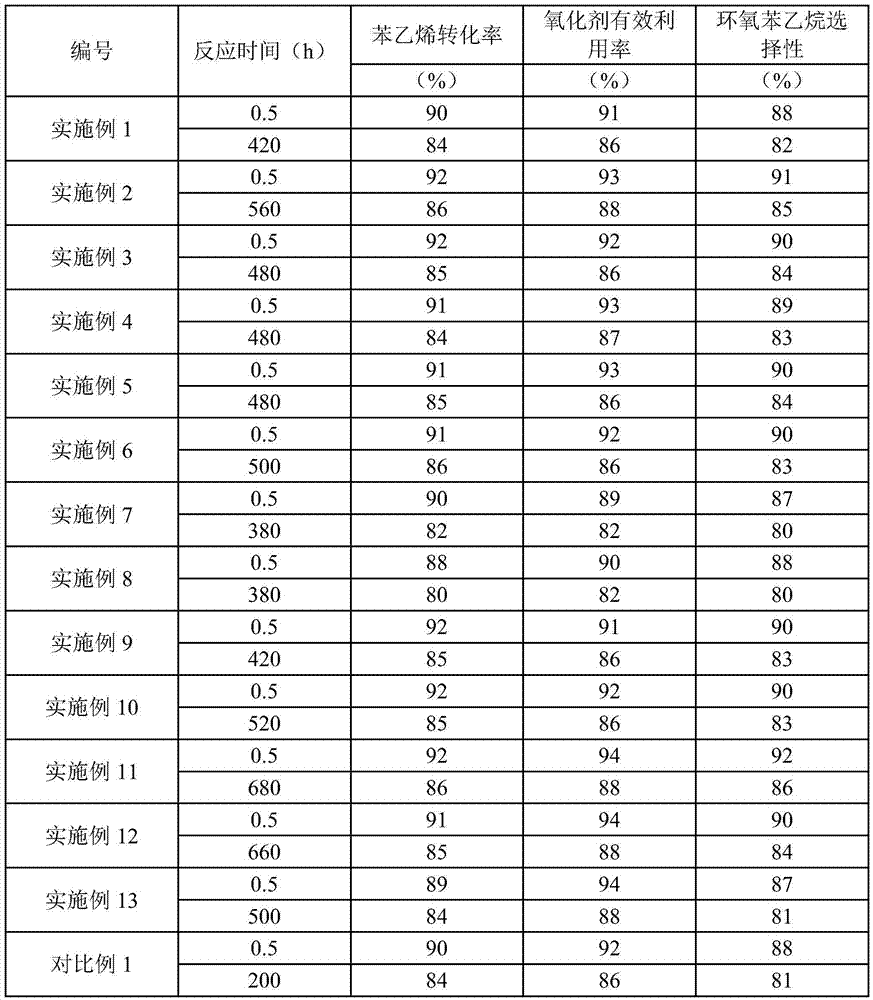

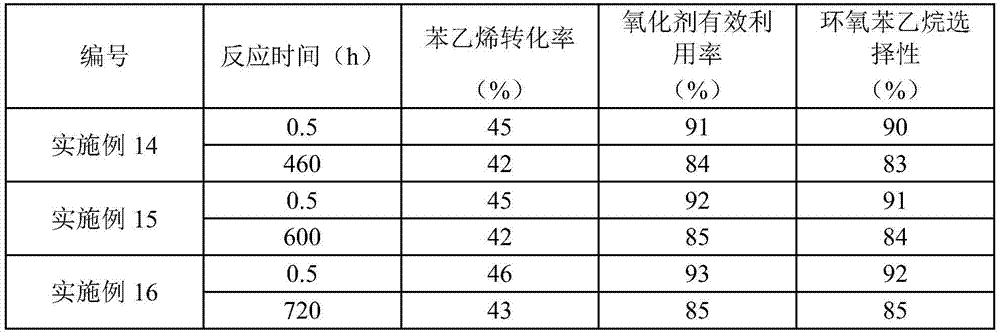

Examples

Embodiment approach

[0066] According to the method of the present invention, the amounts (mass) of the titanium-silicon molecular sieves loaded in the first to nth catalyst beds may be the same or different. According to one implementation, when m is any integer in the interval [2, n], W m-1 / W m 0.1-20, W m-1 / W m Preferably it is 0.5 or more, More preferably, it is 1 or more, More preferably, it is 2 or more. Here, W m-1 is the mass of catalyst loaded in the m-1th catalyst bed, W m is the mass of catalyst loaded in the mth catalyst bed. W m-1 / W m Preferably it is 15 or less, and more preferably 10 or less. More preferably, W m-1 / W m For 2-8:1. When the catalyst is a shaped titanium silicate molecular sieve, W m-1 and W m It is determined by the content of the titanium-silicon molecular sieve in the shaped titanium-silicon molecular sieve. In addition, the amount of catalyst loaded in each catalyst bed can be reasonably determined according to needs (such as production capacity),...

Embodiment 1

[0094] The catalyst used in this example is titanium-silicon molecular sieve TS-1, prepared according to the method described in Zeolites, 1992, Vol.12, pages 943-950, and the specific method is as follows.

[0095] At room temperature (20°C), mix 22.5g tetraethyl orthosilicate with 7.0g tetrapropylammonium hydroxide as a template, add 59.8g distilled water, stir and mix, then hydrolyze at normal pressure and 60°C for 1.0h , to obtain a hydrolysis solution of tetraethyl orthosilicate. Under vigorous stirring, a solution consisting of 1.1 g of tetrabutyl titanate and 5.0 g of anhydrous isopropanol was slowly added to the hydrolysis solution, and the resulting mixture was stirred at 75° C. for 3 h to obtain a clear transparent colloid. The colloid was placed in a sealed stainless steel reaction kettle, and kept at a constant temperature of 170° C. for 36 hours to obtain a mixture of crystallized products. The obtained mixture was filtered, the collected solid matter was washed ...

Embodiment 2

[0101] Styrene was oxidized by the same method as in Example 1, except that the titanium-silicon molecular sieve TS-1 used was prepared by the following method.

[0102] Dissolve tetrabutyl titanate in the alkali source template agent tetrapropyl ammonium hydroxide aqueous solution first, then add silica gel (purchased from Qingdao Silica Gel Factory) to obtain a dispersion. In the dispersion, silicon source: titanium source: alkali source Template agent: water molar ratio is 100:4:12:400, silicon source is SiO 2 In terms of titanium source as TiO 2 In terms of alkali source template agent in N. Seal the above dispersion in the beaker with a parafilm and let it stand at room temperature (25°C, the same below) for 24h, then stir at 35°C for 2h with magnetic stirring to redisperse it. Transfer the re-dispersed dispersion liquid to a sealed reaction kettle, undergo the first stage of crystallization at 140°C for 6h, then cool the mixture down to 30°C and experience the second s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com