Flue gas hydrargyrum-removing method by catalytic oxidation

A technology of catalytic oxidation and mercury oxidation, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of difficult elemental mercury, difficult material regeneration, secondary pollution, etc., and achieves small matrix damage and reduced operating costs. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

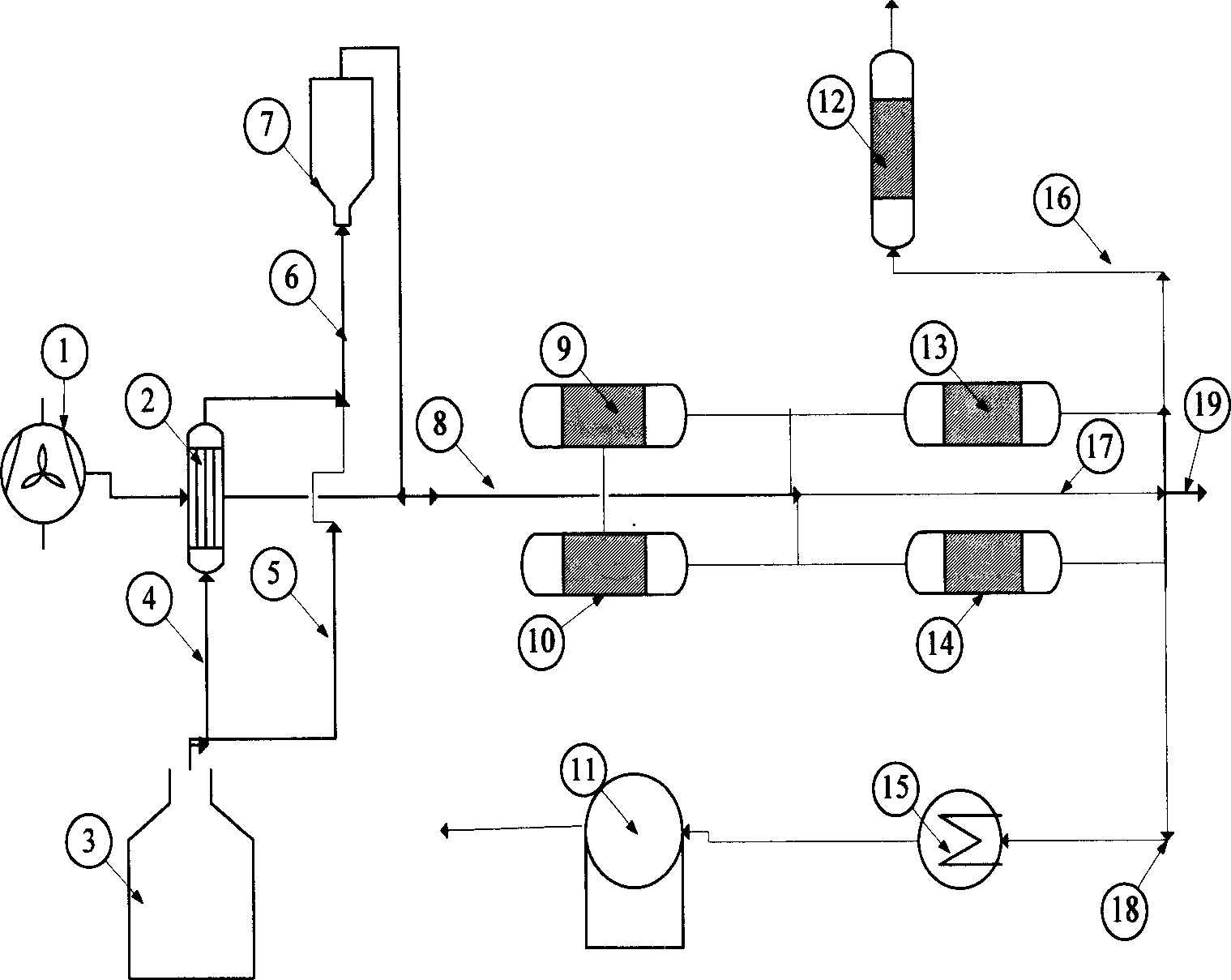

Method used

Image

Examples

Embodiment 1

[0029] 6 kg of catalyst Fe6: supported on 60 kg of specific surface area of 120m 2 / g honeycomb Al2O3, the load is 10%, this material is put into the catalytic bed, the catalytic bed is located behind the particle collection device ESP, the flue gas flow rate is 5000m 3 / h, the imported mercury concentration is 10-30μg / m 3 The adsorbent of the adsorption bed adopts a honeycomb metal filter adsorbent with a total weight of 50 kg and a capacity of 20 mg / g of mercury oxide. It can absorb about 1000g of mercury oxide. The concentration of mercury in the flue gas treated by the catalytic bed and the adsorption bed is 100ng / m3 3 , direct emptying. The activity of the catalyst decreases due to the influence of fly ash on the surface, and the catalyst regeneration treatment is carried out every 2 months. The heater preheats the above-mentioned cold air to obtain regeneration gas with a temperature of 480°C and a flow velocity of 7m / s. The regeneration gas passes through the cata...

Embodiment 2

[0031] Catalyst SCR3# loaded on a specific surface area of 120m 2 / g, on honeycomb aluminum oxide with a weight of 45 kg, put it into the adsorption bed, the adsorption bed is located behind the electrostatic precipitator (ESP), and the flue gas flow rate is 15000m 3 / h, the imported mercury concentration is 0.3-0.5mg / m 3 The material in the following adsorption bed is honeycomb-shaped activated carbon with a total weight of 100 kg and an adsorption capacity of mercury oxide of 360 mg / g. After passing through the catalytic bed and the adsorption bed, the concentration of mercury in the flue gas is 0.05μg / m 3 , direct emptying. The activity of the catalyst is affected by the fly ash and leads to a decrease. Every 4 months, an air compressor is used to inject air into the heat exchanger, and at the same time, the former flue gas with a temperature of 900 ° C passes through the heat exchanger to heat the above-mentioned cold air, and the temperature is 600 ℃, the regeneratio...

Embodiment 3

[0033] 10 kg of catalyst Pd1# loaded on a specific surface area of 1500m 2 / g, the weight is on the honeycomb activated carbon adsorbent of 120 kilograms, is made into Pd1# / activated carbon adsorbent, and its load capacity is 8.3%. The adsorption capacity of Pd1# / activated carbon to mercury oxide is 210mg / g. Put it into the catalytic bed, the catalytic bed is located behind the electrostatic precipitator (ESP) of the particle collection device, and the flue gas flow rate is 1000000m 3 / h, the mercury content is 10~20μg / m 3 change between. After passing through the catalytic / adsorption bed, the concentration of mercury in the flue gas is 0.2μg / m 3 , direct emptying. Every 2 months, the air compressor is used to pump air into the heat exchanger, and at the same time, the front flue gas with a temperature of 600°C is used to heat the above-mentioned cold air through the heat exchanger to obtain regeneration at a temperature of 250°C and a flow velocity of 8m / s Gas, the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com