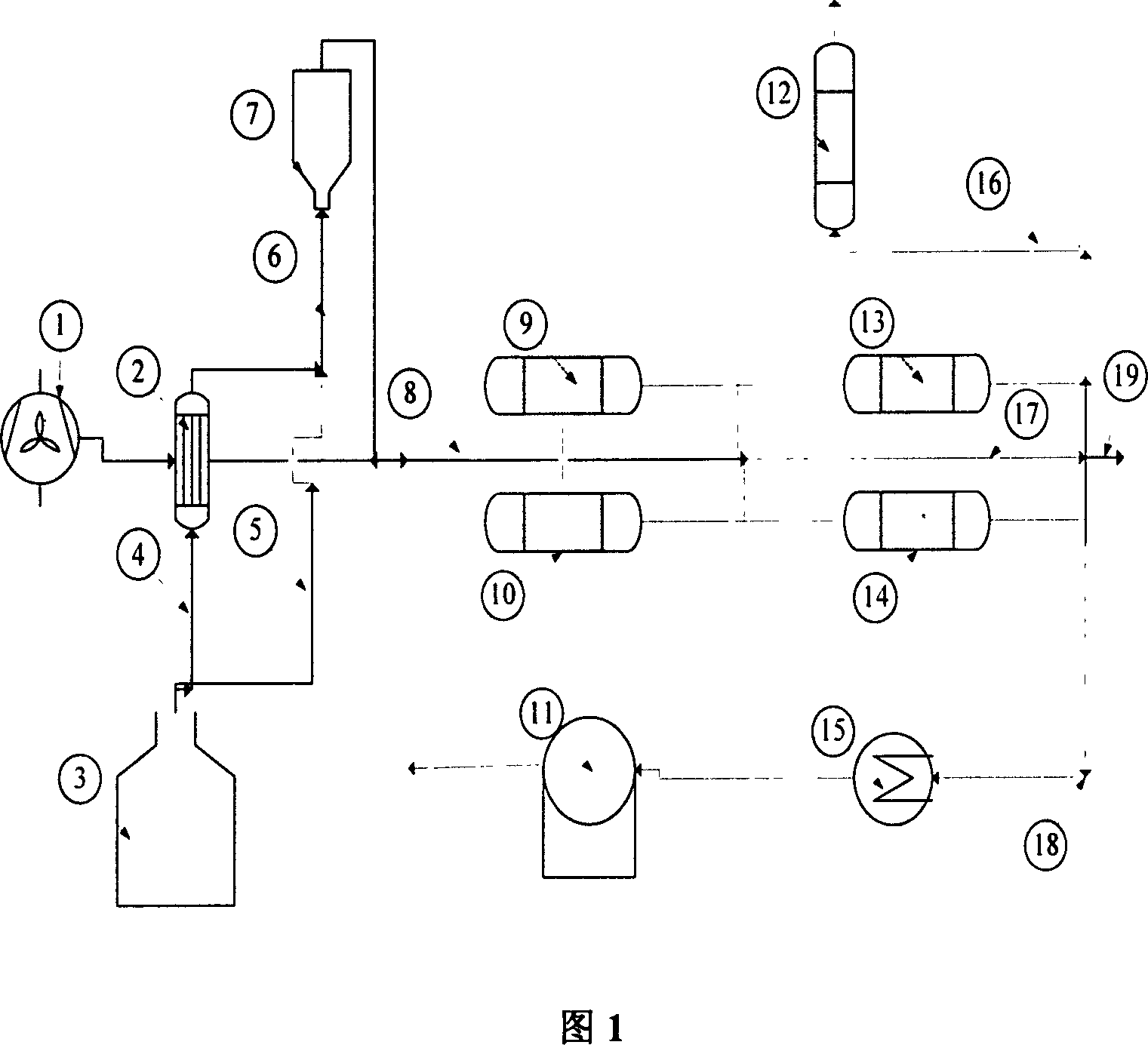

Flue gas hydrargyrum-removing method by catalytic oxidation

A technology for catalytic oxidation and mercury oxidation, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Load 6 kg of catalyst Fe6# on 60 kg of specific surface area of 120m 2 / g honeycomb Al2O3, the load is 10%, put this material into the catalytic bed, the catalytic bed is located behind the particle collection device ESP, the flue gas flow rate is 5000m 3 / h, the imported mercury concentration is 10-30μg / m 3The adsorbent of the adsorption bed adopts a honeycomb metal filter adsorbent with a total weight of 50 kg and a capacity of 20 mg / g of mercury oxide. It can absorb about 1000g of mercury oxide. The concentration of mercury in the flue gas treated by the catalytic bed and the adsorption bed is 100ng / m3 3 , direct emptying. The activity of the catalyst decreases due to the influence of fly ash on the surface. The catalyst regeneration treatment is carried out every 2 months. The operation is as follows: use an air compressor to pump air into the heat exchanger, and use a The flue gas passes through the heat exchanger to preheat the above-mentioned cold air to o...

Embodiment 2

[0030] Catalyst SCR3# loaded on a specific surface area of 120m 2 / g, on honeycomb aluminum oxide with a weight of 45 kg, put it into the adsorption bed, the adsorption bed is located behind the electrostatic precipitator (ESP), and the flue gas flow rate is 15000m 3 / h, the imported mercury concentration is 0.3-0.5mg / m 3 The material in the following adsorption bed is honeycomb-shaped activated carbon with a total weight of 100 kg and an adsorption capacity of mercury oxide of 360 mg / g. After passing through the catalytic bed and the adsorption bed, the concentration of mercury in the flue gas is 0.05μg / m 3 , direct emptying. The activity of the catalyst is affected by the fly ash and leads to a decrease. Every 4 months, an air compressor is used to inject air into the heat exchanger, and at the same time, the former flue gas with a temperature of 900 ° C passes through the heat exchanger to heat the above-mentioned cold air, and the temperature is 600 ℃, the regeneratio...

Embodiment 3

[0032] 10 kg of catalyst Pd1# loaded on a specific surface area of 1500m 2 / g, the weight is on the honeycomb activated carbon adsorbent of 120 kilograms, is made into Pd1# / activated carbon adsorbent, and its load capacity is 8.3%. The adsorption capacity of Pd1# / activated carbon to mercury oxide is 210mg / g. Put it into the catalytic bed, the catalytic bed is located behind the electrostatic precipitator (ESP) of the particle collection device, and the flue gas flow rate is 1000000m 3 / h, the mercury content is 10~20μg / m 3 change between. After passing through the catalytic / adsorption bed, the concentration of mercury in the flue gas is 0.2μg / m 3 , direct emptying. Every 2 months, the air compressor is used to pump air into the heat exchanger, and at the same time, the front flue gas with a temperature of 600°C is used to heat the above-mentioned cold air through the heat exchanger to obtain regeneration at a temperature of 250°C and a flow velocity of 8m / s Gas, the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com