Patents

Literature

33 results about "Sub-bituminous coal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sub-bituminous coal is a type of coal whose properties range from those of lignite to those of bituminous coal and are used primarily as fuel for steam-electric power generation.

Flue gas hydrargyrum-removing method by catalytic oxidation

InactiveCN1698931ALittle matrix damageReduce pollutionDispersed particle separationPtru catalystSorbent

This invention relates to a catalytic oxidation smoke gas mercury removing method, which is used for controlling and reclaiming the gas mercury, especially for the brown coal and subbituminous coal smoke gas. The method uses the mercury oxidative catalyst and the adsorbent to oxygenize and absorb mercury in the smoke gas, then dissociate and elution the mercuric oxide in high temperature to regenerate it. The heat of the elution gas can be reclaimed by residual heat utilization device, and the high concentration mercury will be reclaimed through cold-trap or processed by the agent in the mercury reactor. The reclaimed mercury and other by-product can be sold to reduce the cost. Said invention uses the thermal instability of the mercuric oxide, and reclaims in the relative lower temperature; the recovery ratio can reach to 98%, meanwhile, it processes post-treatment with the mercury and has no secondary pollution.

Owner:SHANGHAI JIAO TONG UNIV

Earth cementation agent in use for roadway construction

InactiveCN1562851AImprove responseGood water hardnessSolid waste managementOrganic fertilisersPower stationRoad surface

In the invention, two kinds of waste material dry dust discharging coal ash and desulfurize gyp produced by power plant burning sub-bituminous coal or lignitous coal are used as main composition, shell and or cement, calcined gypsum and aluminum sulfate or alunite are used as secondary composition, they are prepared to dry powder soil curing agent by weighing, matching, forced stirring and mixing. The soil can be concreted by mixing a proper quantity of curing agent into the soil and processes of stirring, compacting, soaking and maintaining.

Owner:徐尔昌

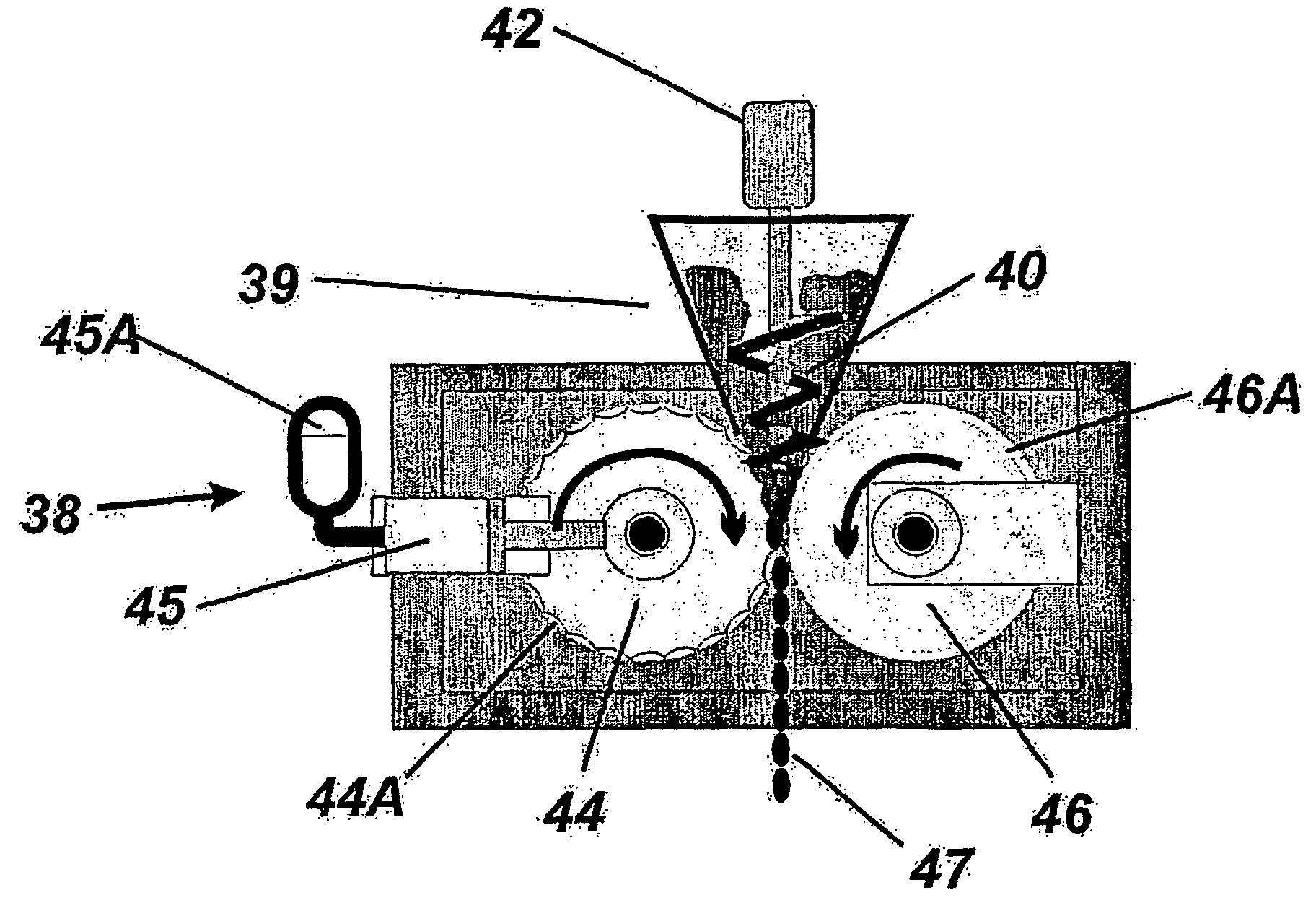

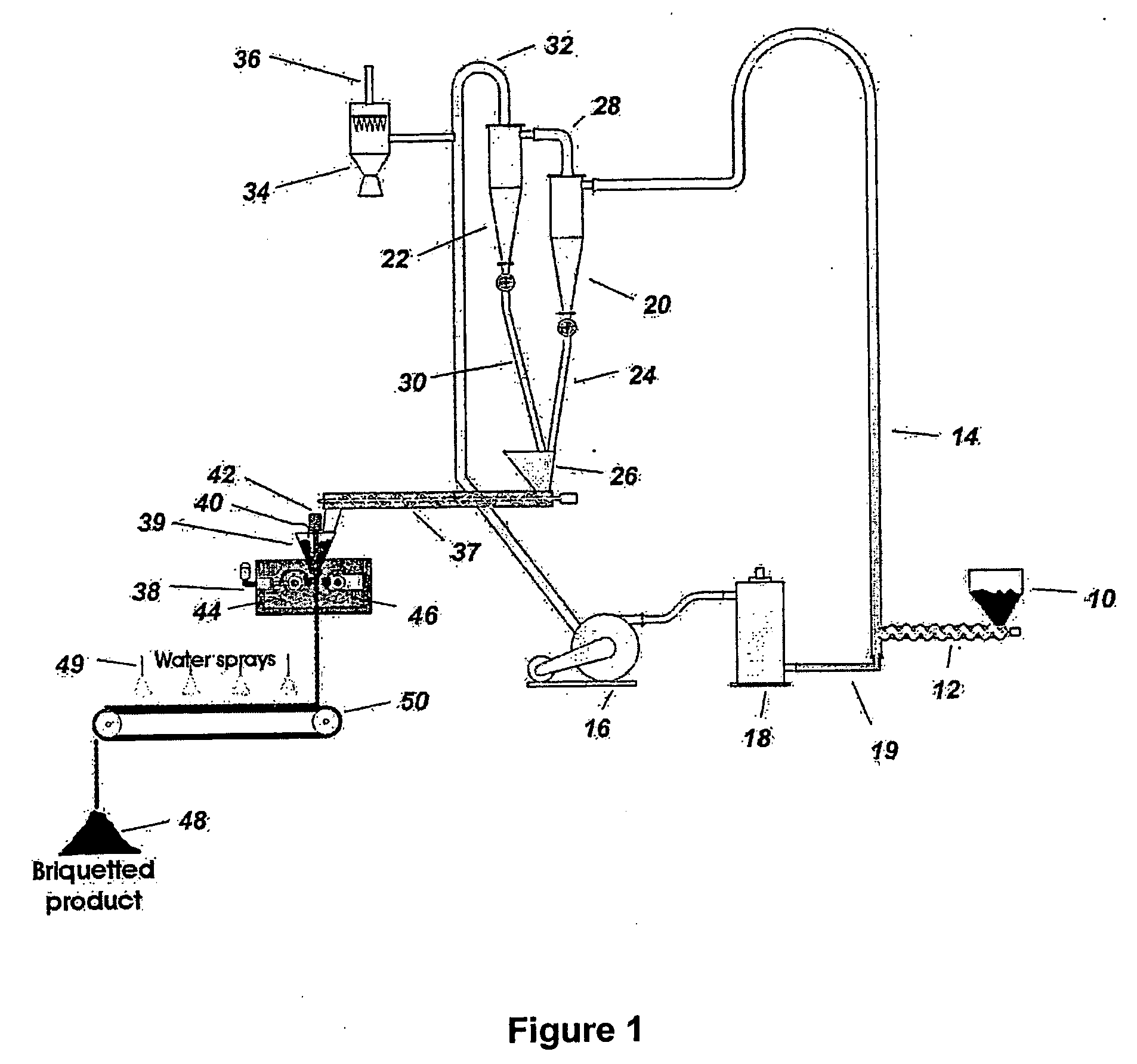

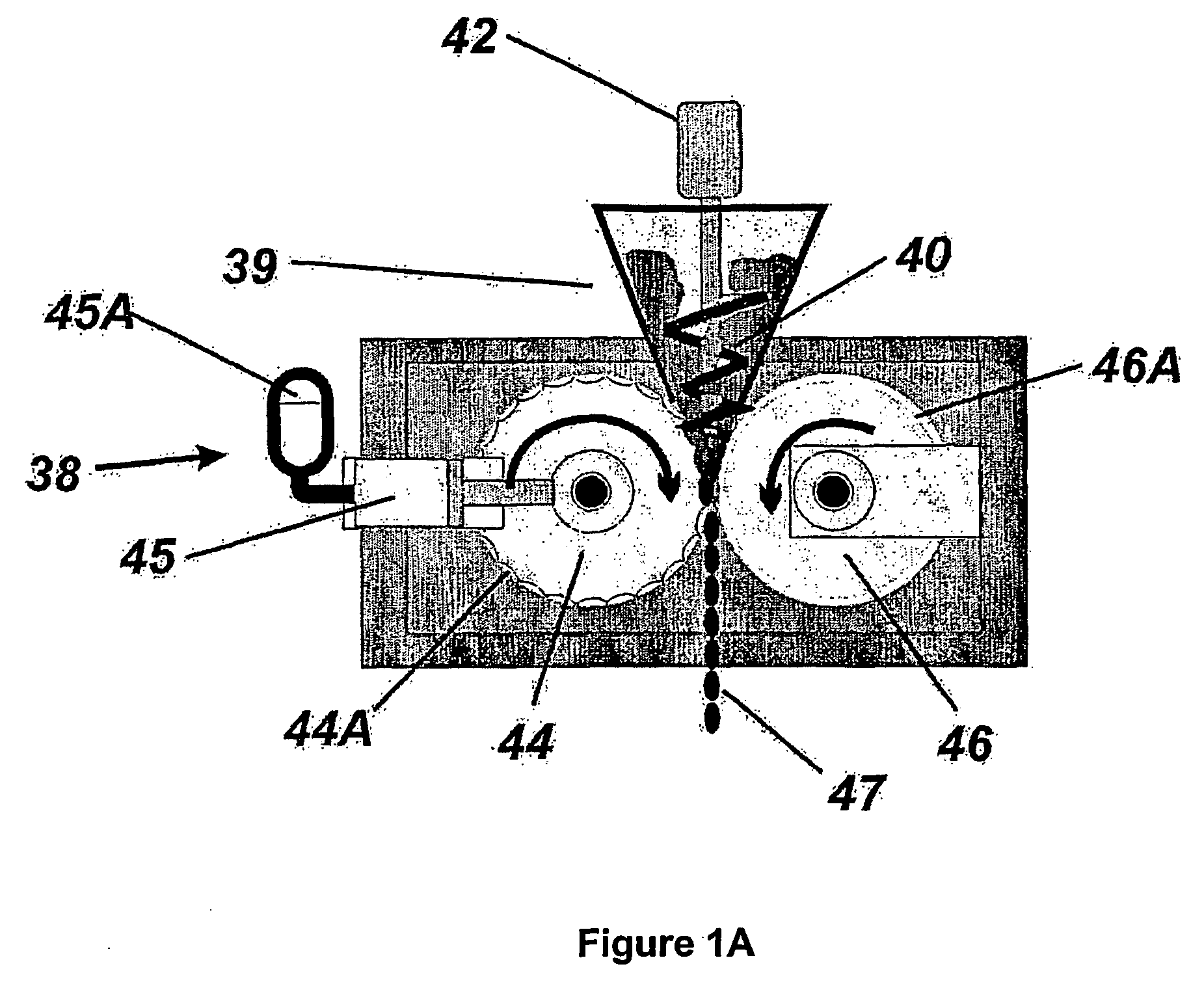

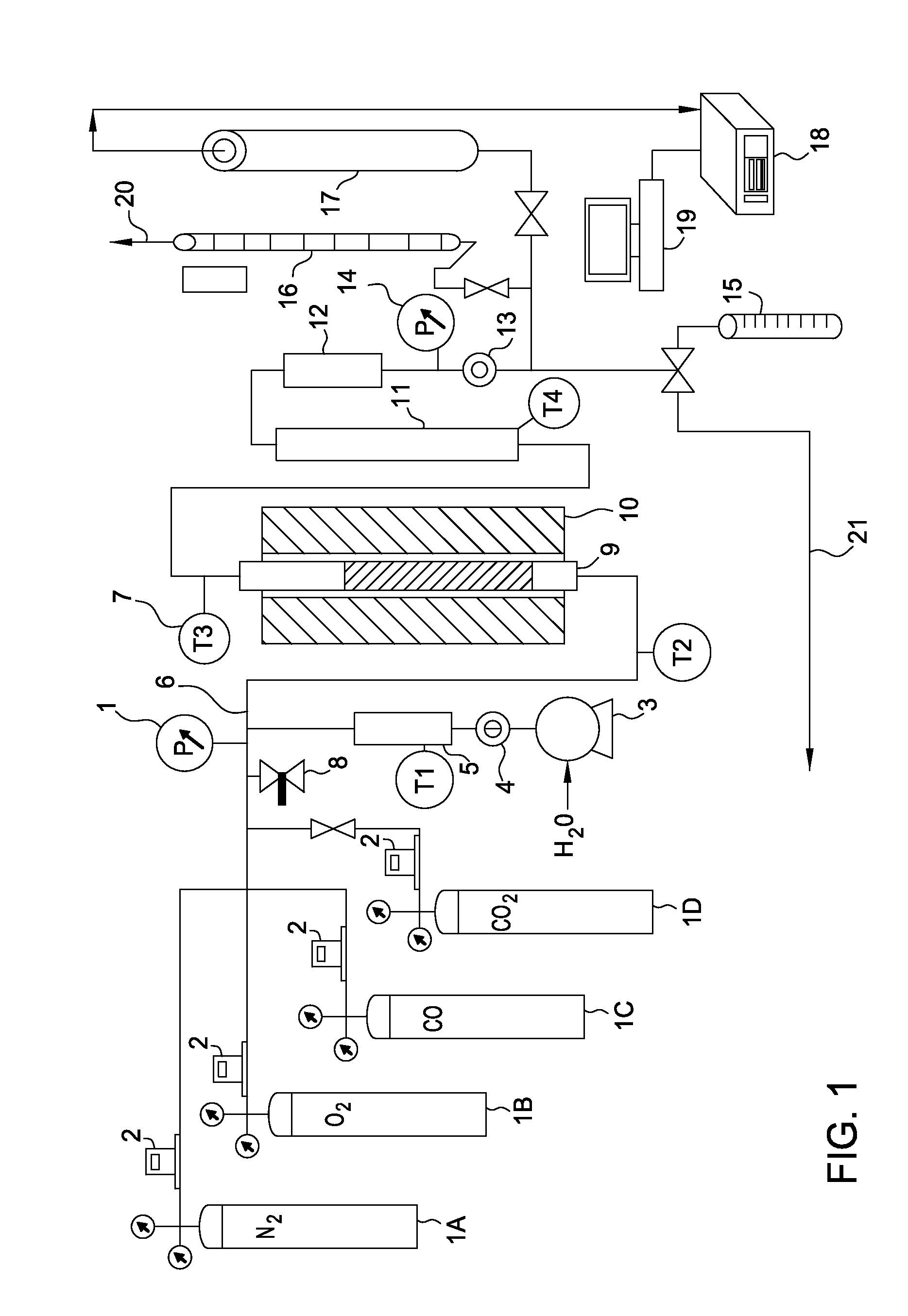

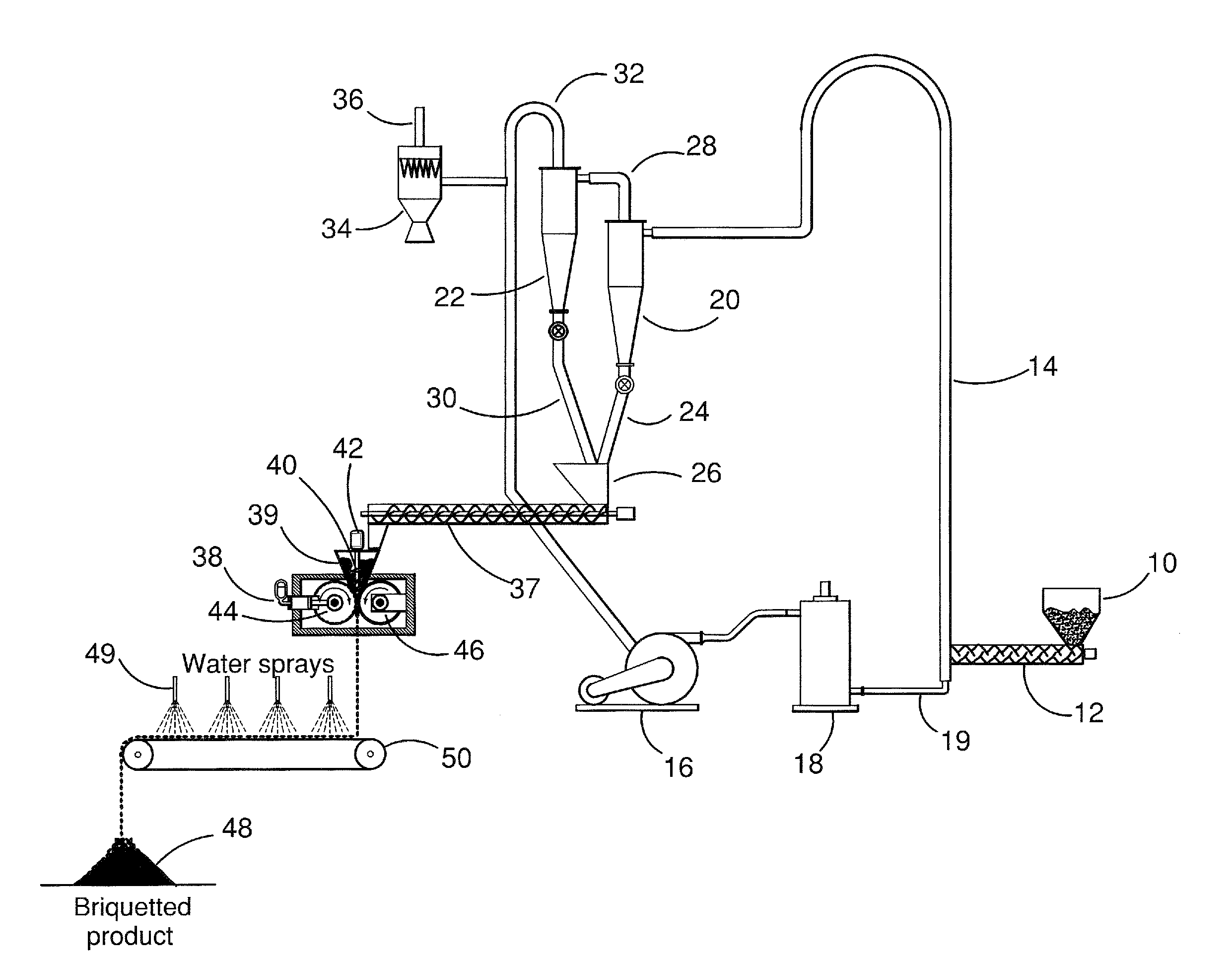

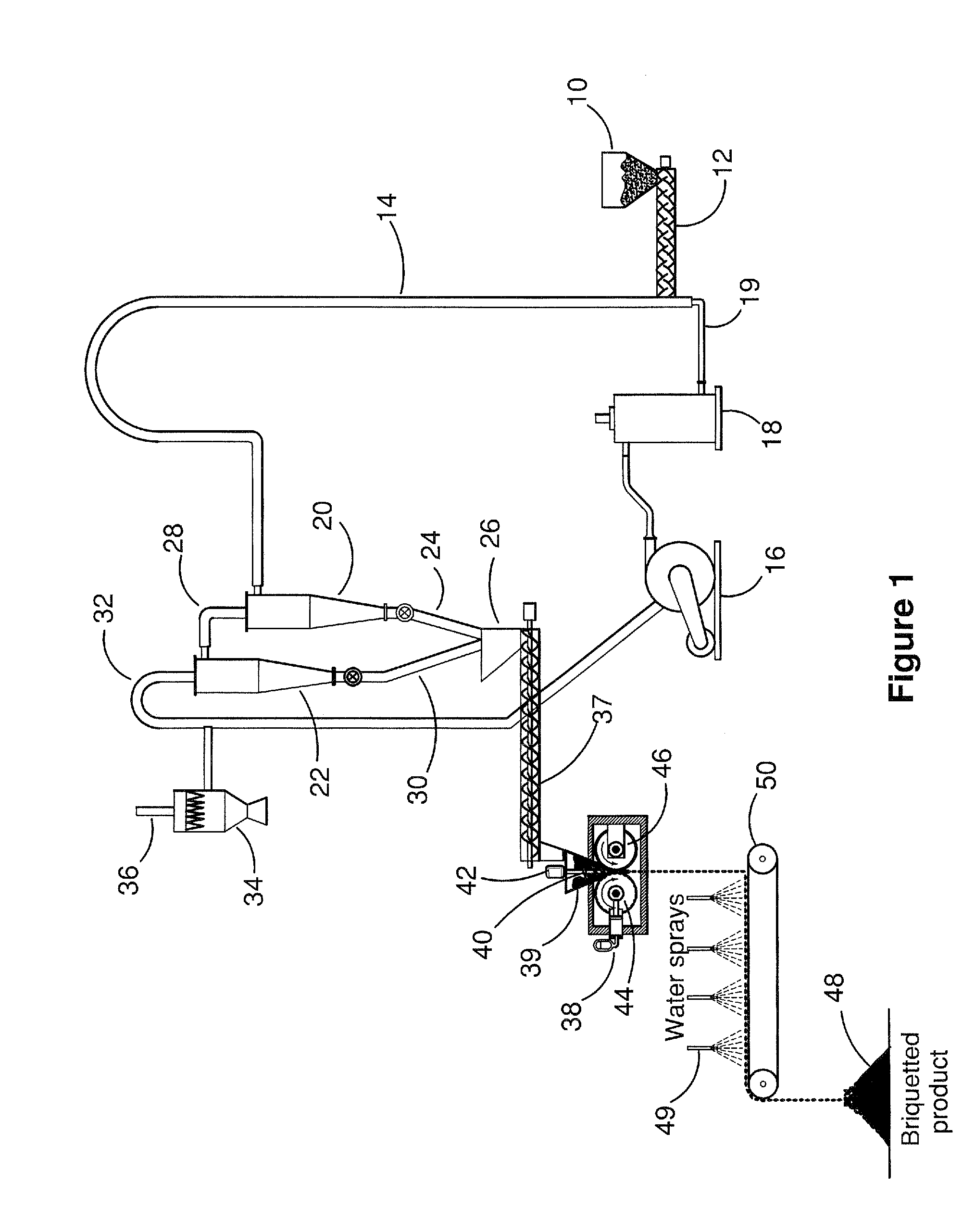

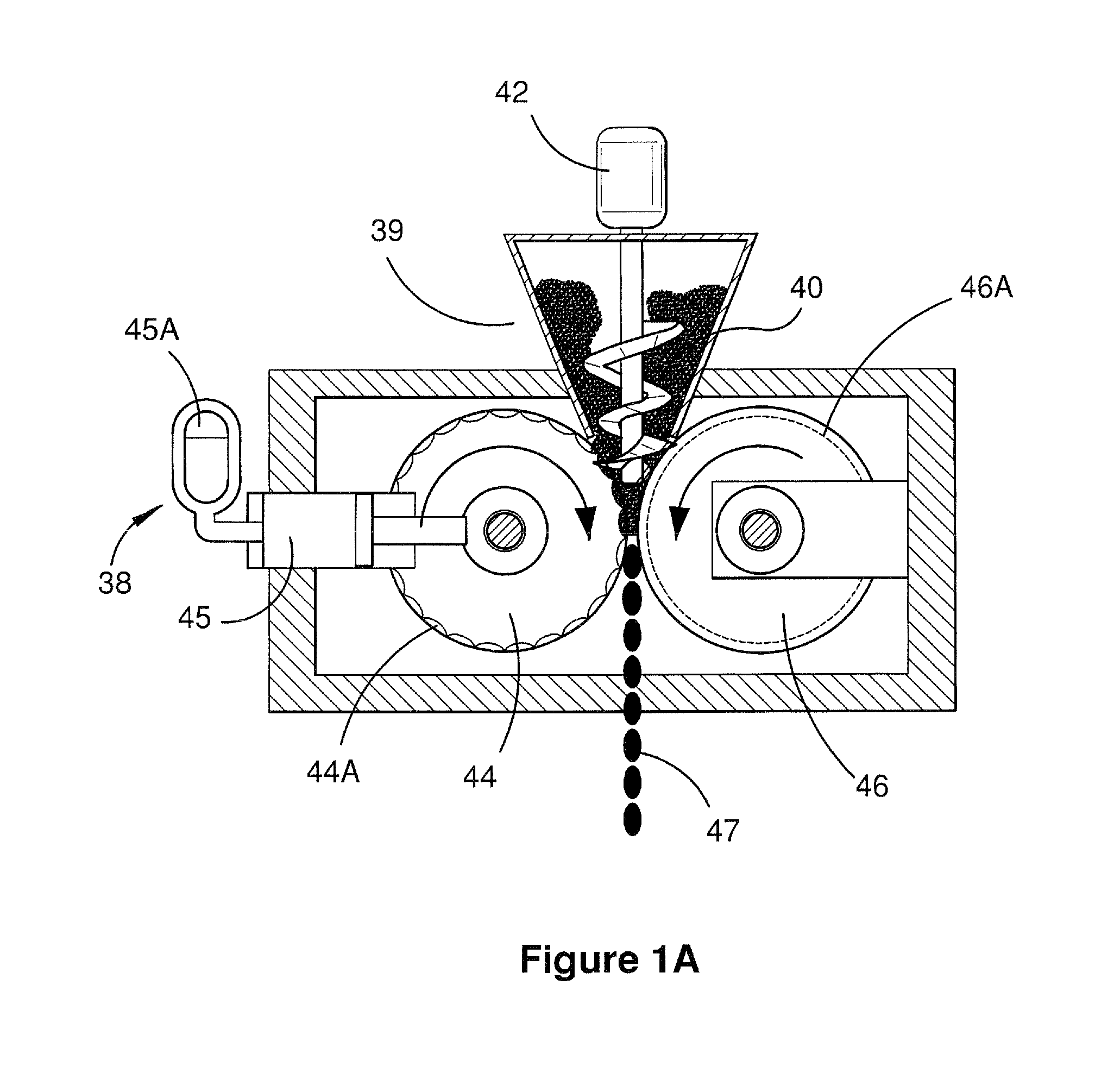

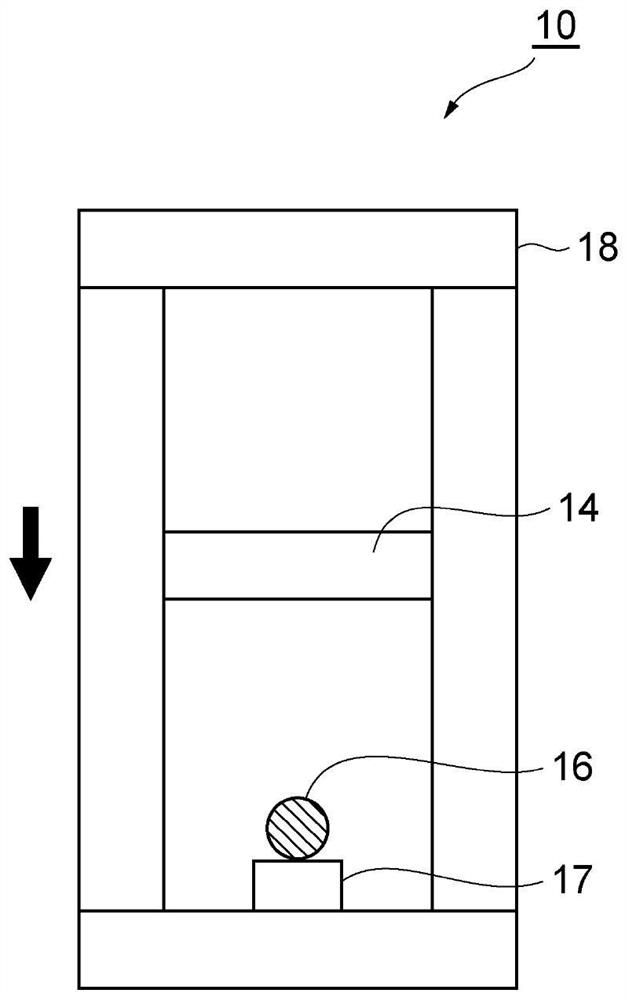

Briquetting process

ActiveUS20060112617A1Reducing pressure buildupLower the volumeConfectioneryBiofuelsParticulatesWater vapor

A process and system is provided for briquetting particulate matter such as moisture-containing bituminous and sub-bituminous coal. This process includes partially drying the particulate matter and feeding, the partially dried particulate matter to a briquetting apparatus under conditions such that water vapour is released from the particulate matter during feeding. The particulate matter is passed through briquette forming rollers to form briquettes. The released water vapour substantially displaces or prevents the ingress of a large proportion of other gaseous components from the atmosphere surrounding an / or intermixed with the particulate matter. The particulate matter that is fed to the briquetting apparatus is surrounded by and intermixed with a gaseous component containing 70 to 100% by volume of water vapour at the point where it enters the briquette-forming part of the briquetting apparatus, such that when the particulate matter is compressed during briquette formation, the water vapour liquefies and the pressure buildup of gaseous material in the thus-formed briquettes is minimised. This reduction in the pressure buildup of gaseous components also acts to reduce blow-back of gases as the coal fines are being formed into briquettes.

Owner:K R KOMAREK +3

High-sulfur fertilizer coal modification method and application thereof in coking coal blending

The invention provides a new technology of thermal solution extraction of high-sulfur fertilizer coal and application thereof in coking coal blending. In the new technology, the high-sulfur fertilizer coal is continuously treated by thermal extraction in a fixed bed reactor or thermal solution extraction in a clearance type reaction still with an organic solvent under proper conditions, after thermal state filtering and separation, a high yield high-sulfur and low-ash thermal solution product is obtained, and the product is used for coking coal blending. By such thermal solution extraction, all the ash component and inorganic sulfur of the thermal solution product are removed, in comparison with the original high-sulfur fertilizer coal, the cohesiveness of the thermal solution product is improved, the sulfur content is reduced obviously, the sulfur is completely the organic sulfur, and the organic sulfur is easy to remove in the subsequent coking process. With the thermal solution product used in the coking coal blending process, the coke quality can be improved obviously, the sulfur content of the coke is lowered, or on the premise of guaranteeing the coke quality, the non-coking coals, such as the subbituminous coal, can be properly added, so that the coal blending coking cost can be lowered, and the coking coal source is stabilized and expanded.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

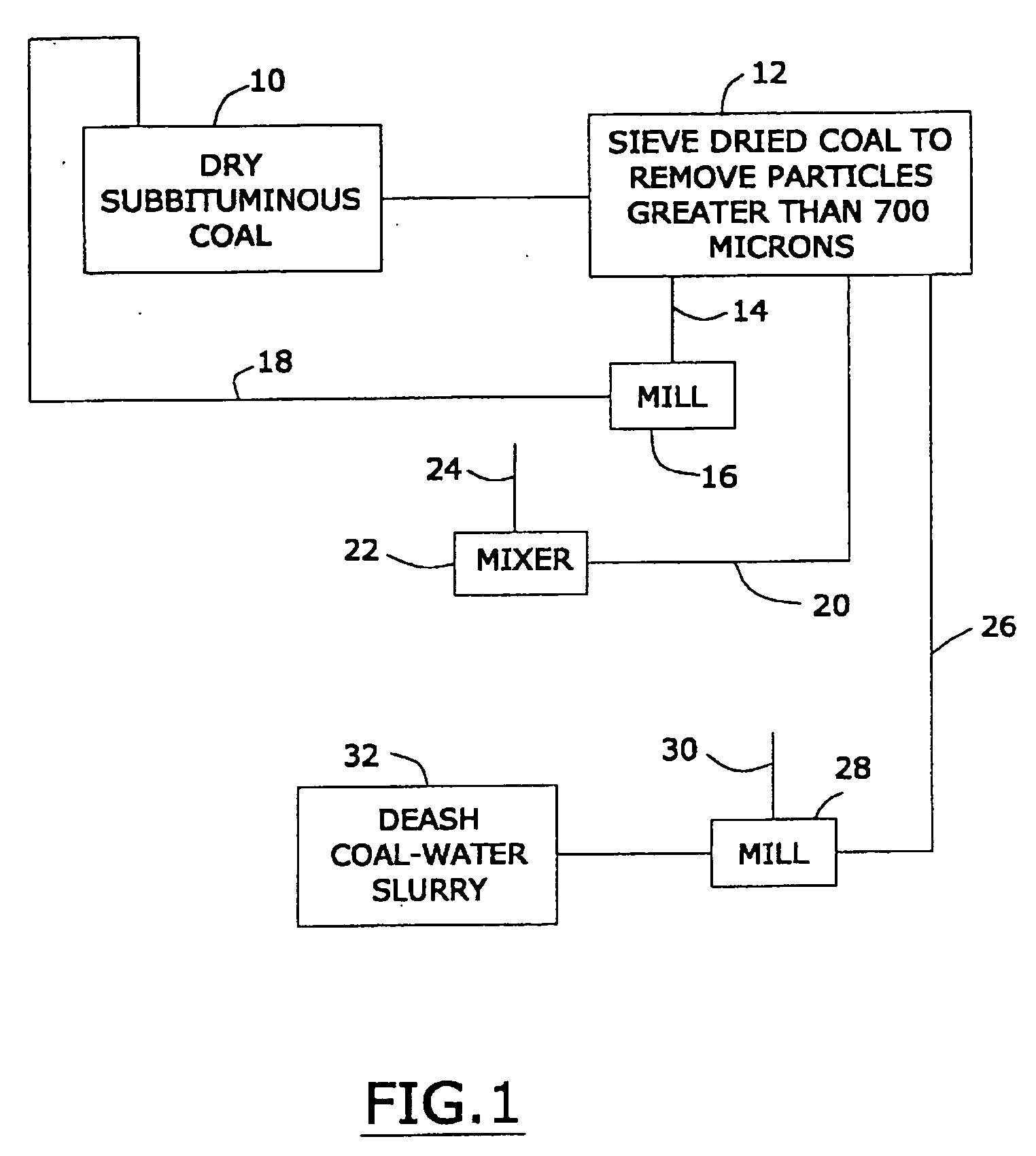

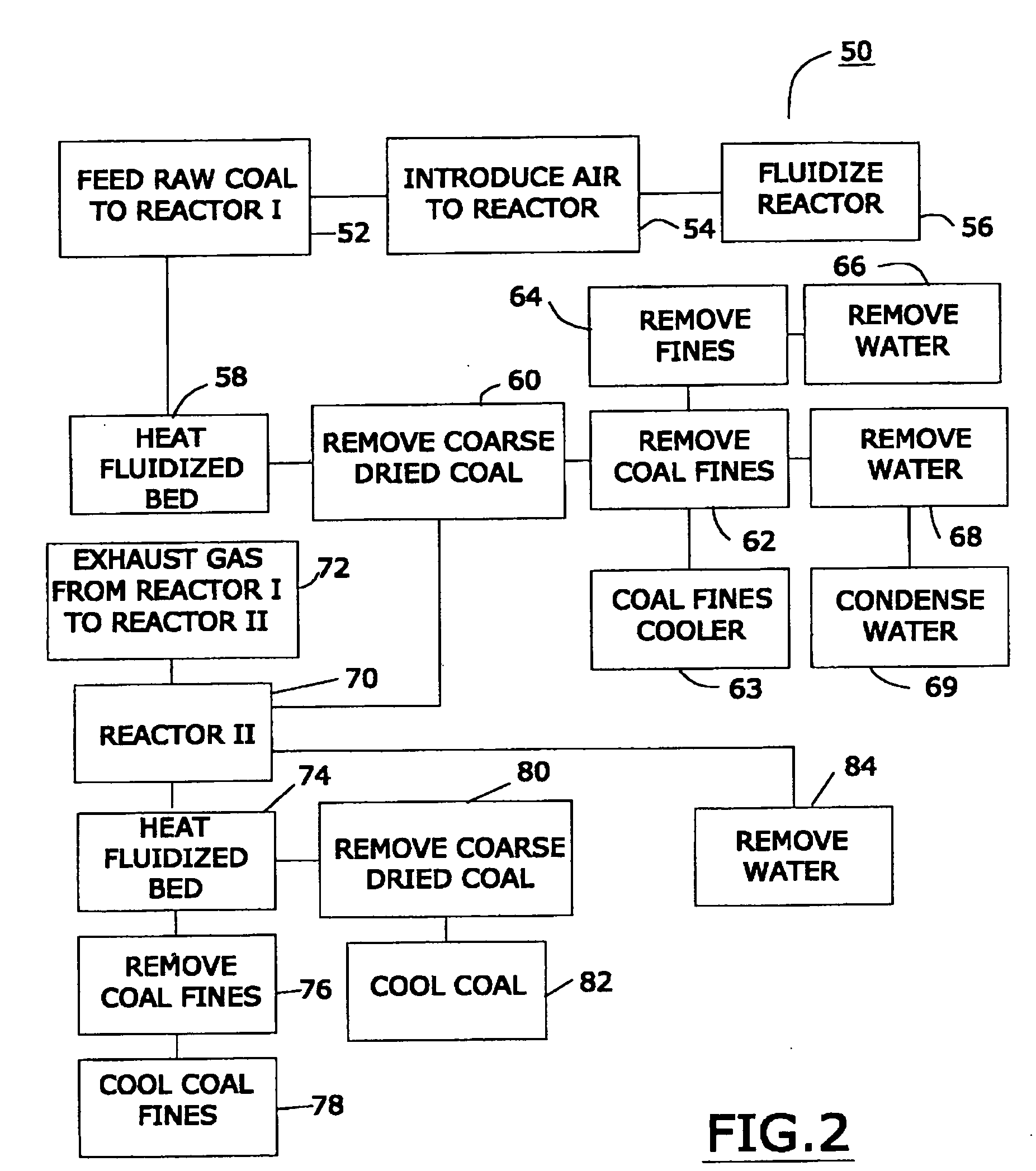

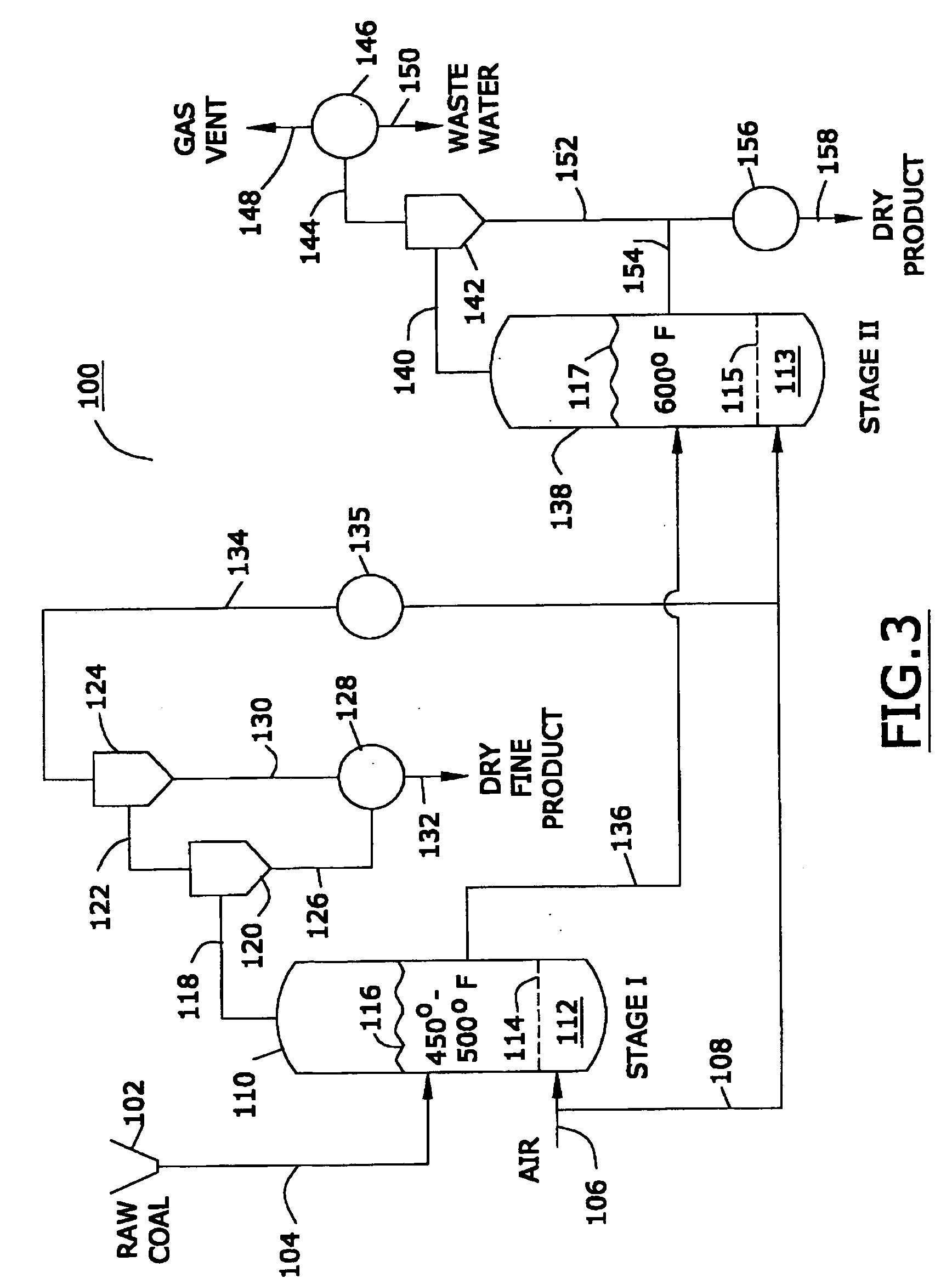

Process for in-situ passivation of partially-dried coal

InactiveUS20060096167A1Reduce capacityAmenable to normal transportInput/output for user-computer interactionElectrophonic musical instrumentsBrown coalFluidized bed

A process to irreversibly dry and passivate lignitic coal, sub-bituminous coal, bituminous coal, or coal char by heating the coal material in the presence of a gas comprised of less than about five volume percent of oxygen (an inert environment) until the coal material has a moisture content of from about 0.01 to about 20 weight percent, heating the partially dried coal material to 100 to about 600 degrees Fahrenheit, charging the heated partially dried coal material to a fluidized bed reactor; feeding air into the fluidized bed reactor; contacting the heated partially dried coal material with the air while maintaining the heated partially dried coal material at a temperature of from about 450 to about 650 degrees Fahrenheit; and, thereafter, removing water from the heated partially dried coal material until no more than about 1 weight percent of water remains in the heated partially dried coal material.

Owner:BIOMASS SECURE POWER INC

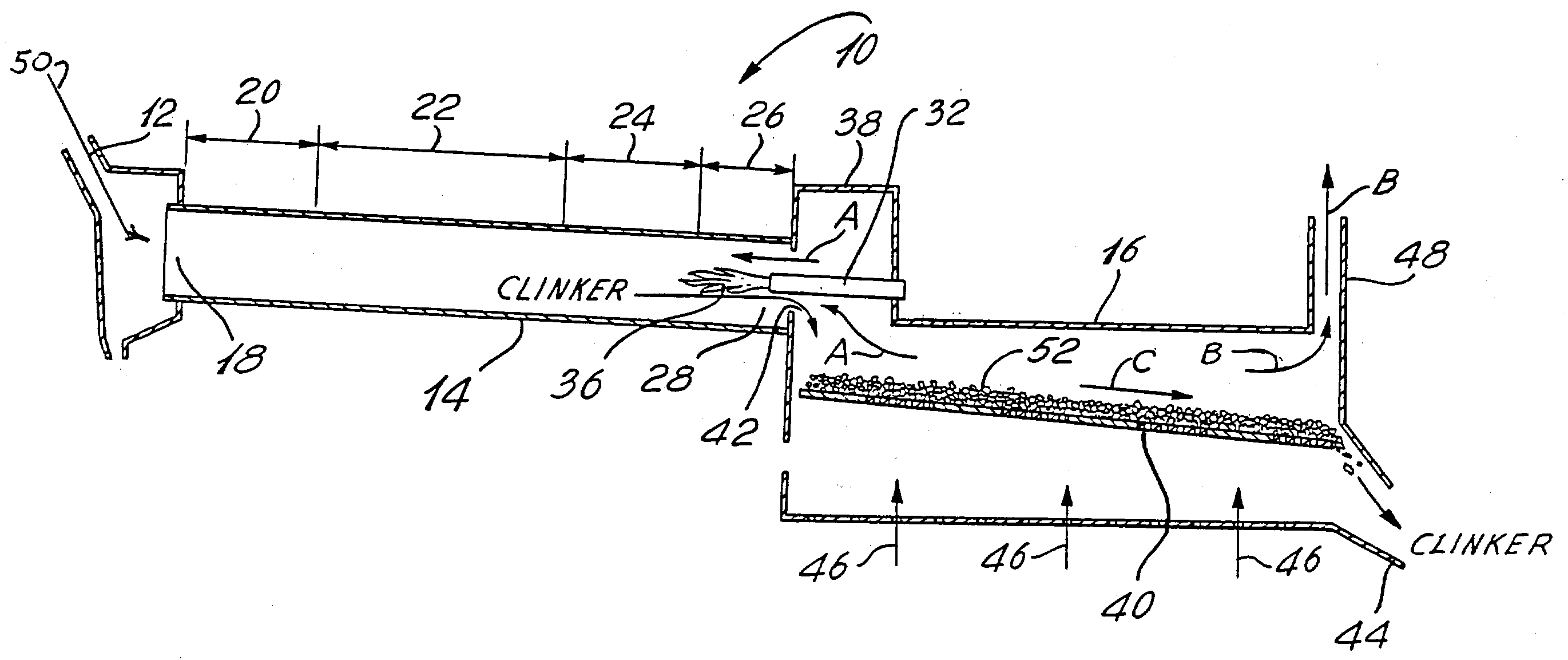

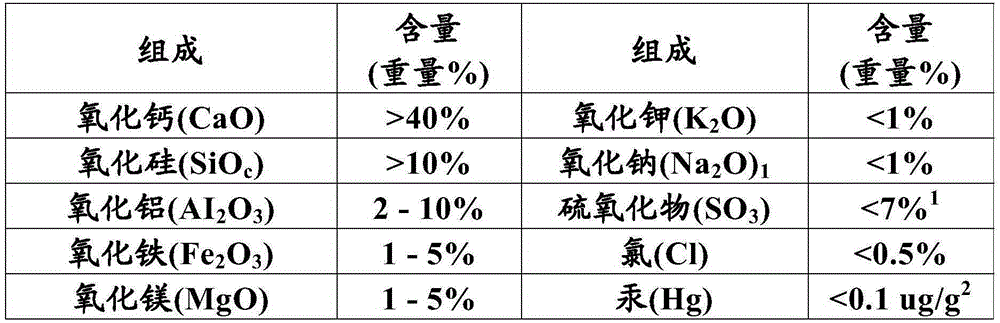

Process for incorporating coal ash into cement clinker

InactiveUS6764544B2Reduce lossesLower requirementRotary drum furnacesCement productionPulverized fuel ashBituminous coal

A method of cement clinker manufacture comprises feeding a clinker feed material containing a source of calcium carbonate into a feed end of a cement kiln, the feed material is heat processed in the kiln to produce cement clinker with emission of carbon dioxide from thermal decomposition of said source of calcium carbonate and discharge of the carbon dioxide from the kiln, and cement clinker is discharged from a discharge end of the kiln; a coal ash derived from burning pulverized lignite or sub-bituminous coal is included in the feed material fed into the feed end to replace a portion of the source of calcium carbonate, and provides a source of calcium as well as other components notably silicon and aluminum, in the formation of the cement clinker, with a lowering of the emission of carbon dioxide in the kiln, per unit weight of cement clinker produced.

Owner:LAFARGE CANADA INC

Process for incorporating coal ash into cement clinker

InactiveUS20040118323A1Reduce lossesLower requirementRotary drum furnacesCement productionPulverized fuel ashBituminous coal

A method of cement clinker manufacture comprises feeding a clinker feed material containing a source of calcium carbonate into a feed end of a cement kiln, the feed material is heat processed in the kiln to produce cement clinker with emission of carbon dioxide from thermal decomposition of said source of calcium carbonate and discharge of the carbon dioxide from the kiln, and cement clinker is discharged from a discharge end of the kiln; a coal ash derived from burning pulverized lignite or sub-bituminous coal is included in the feed material fed into the feed end to replace a portion of the source of calcium carbonate, and provides a source of calcium as well as other components notably silicon and aluminium, in the formation of the cement clinker, with a lowering of the emission of carbon dioxide in the kiln, per unit weight of cement clinker produced.

Owner:LAFARGE CANADA INC

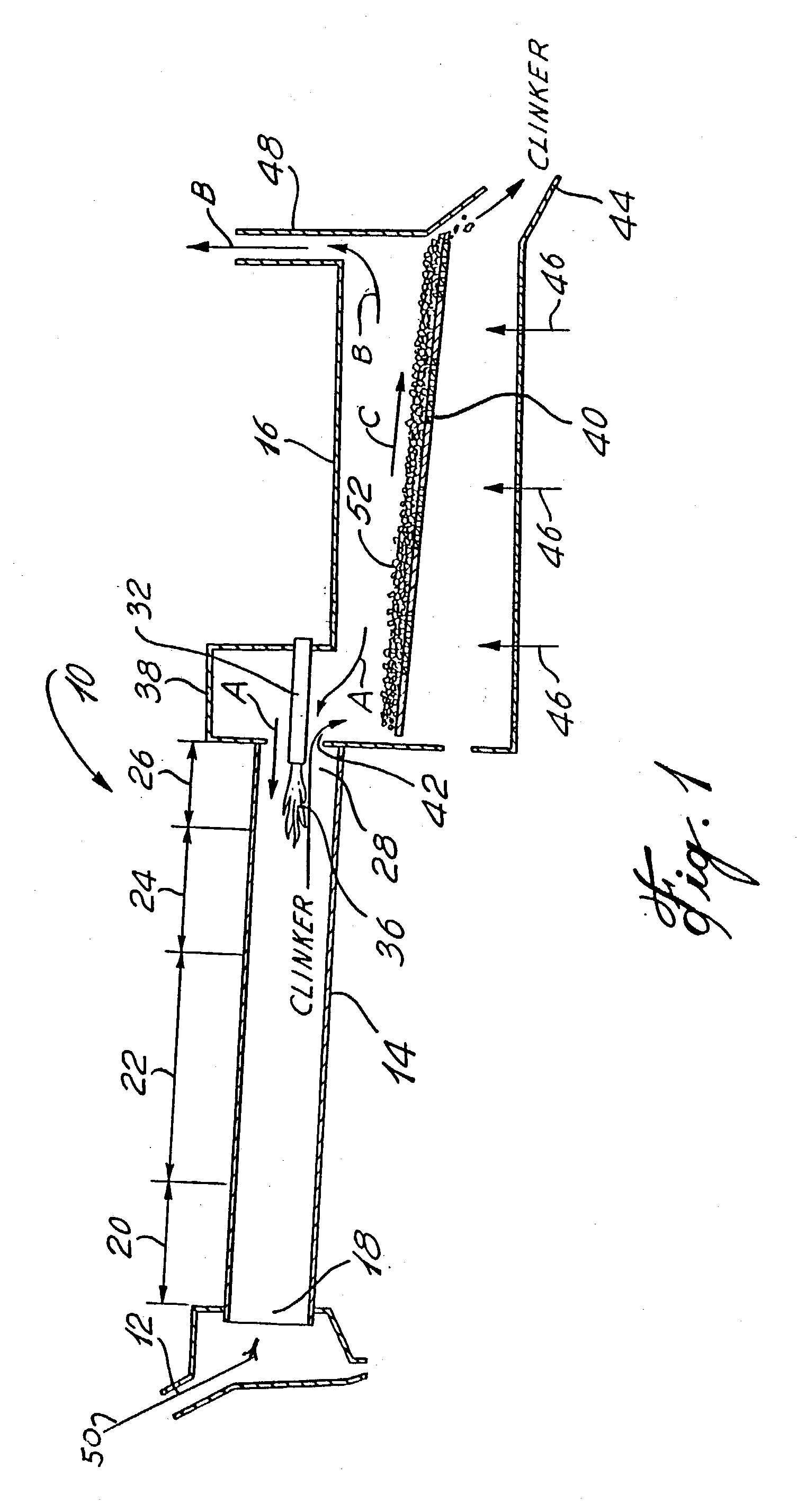

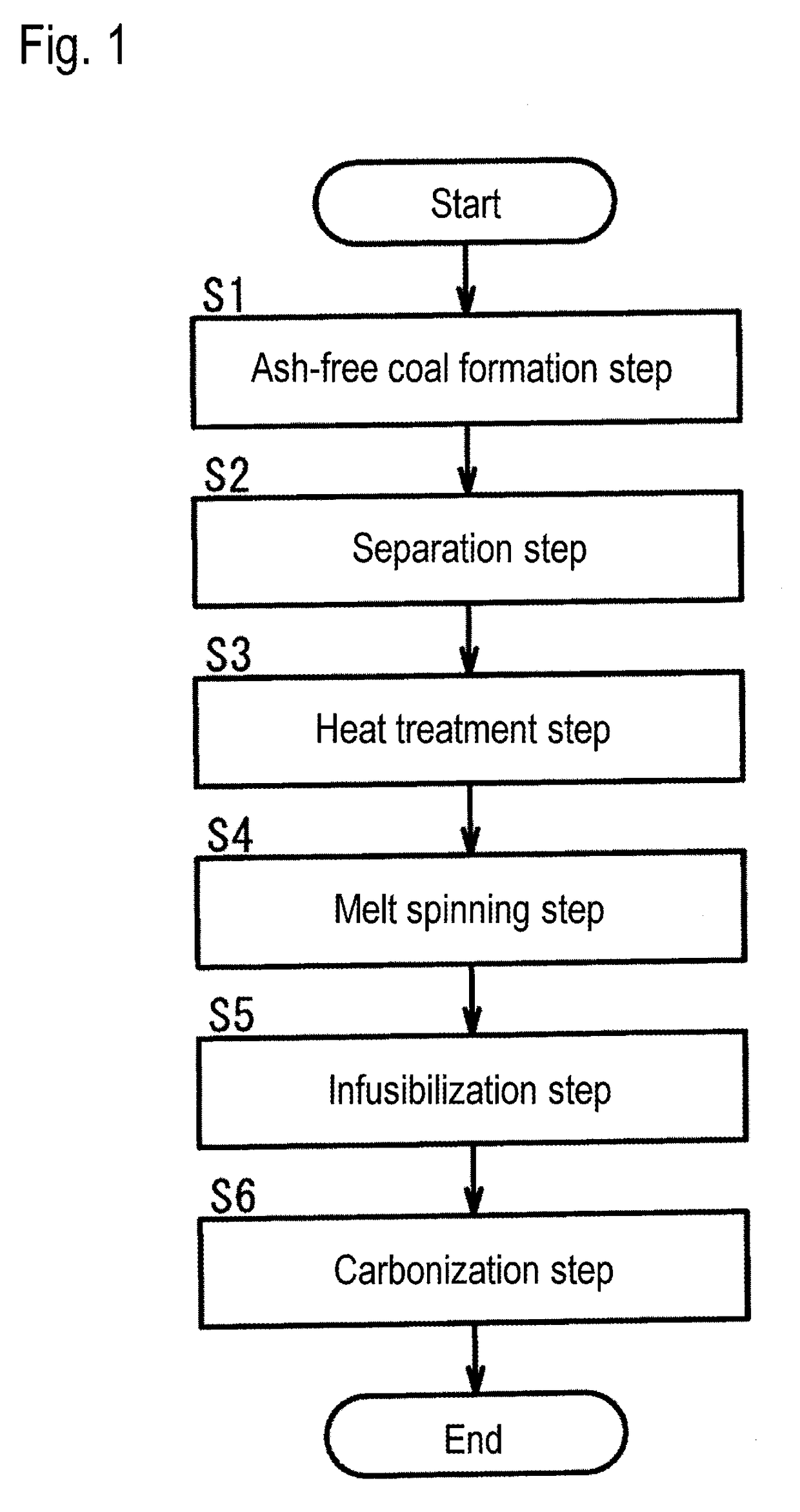

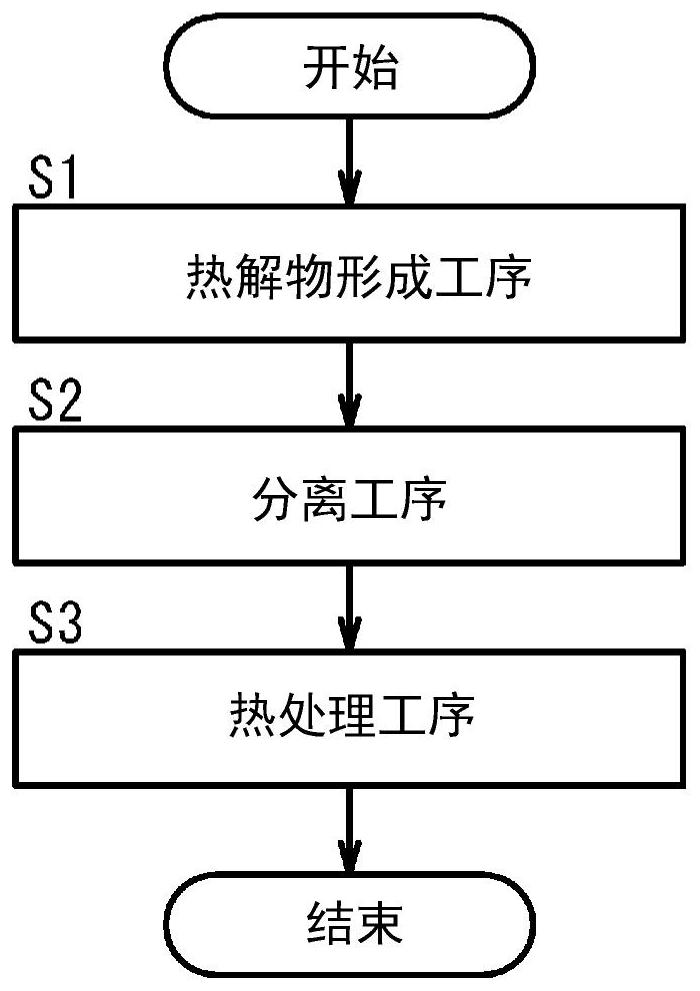

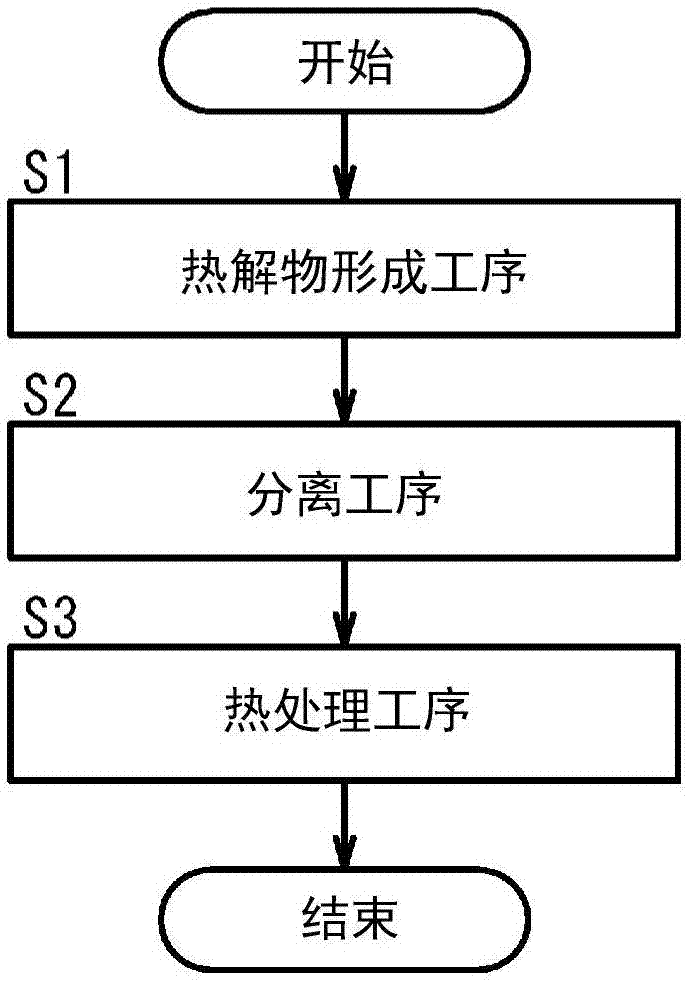

Method for producing carbon fibers

ActiveCN107407012AImprove qualityReduce contentArtificial filament heat treatmentLiquid hydrocarbon mixture productionCarbon fibersSolvent

This method for manufacturing carbon fibers is provided with: a step for separating ashless coal obtained from bituminous coal or sub-bituminous coal into soluble components and insoluble components using a solvent extraction process; a step for heat-treating the soluble components; a step for melt-spinning the heat-treated soluble components; a step for infusibilizing the strands obtained by melt-spinning; and a step for carbonizing the infusibilized strands.

Owner:KOBE STEEL LTD +1

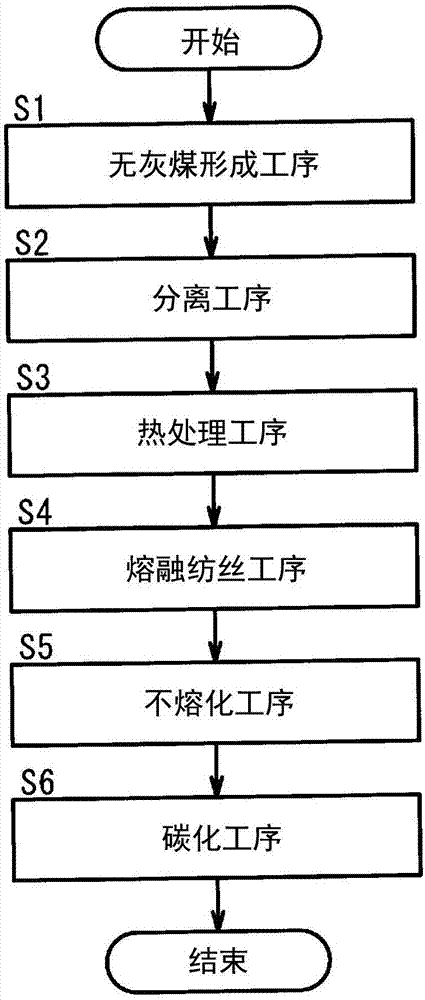

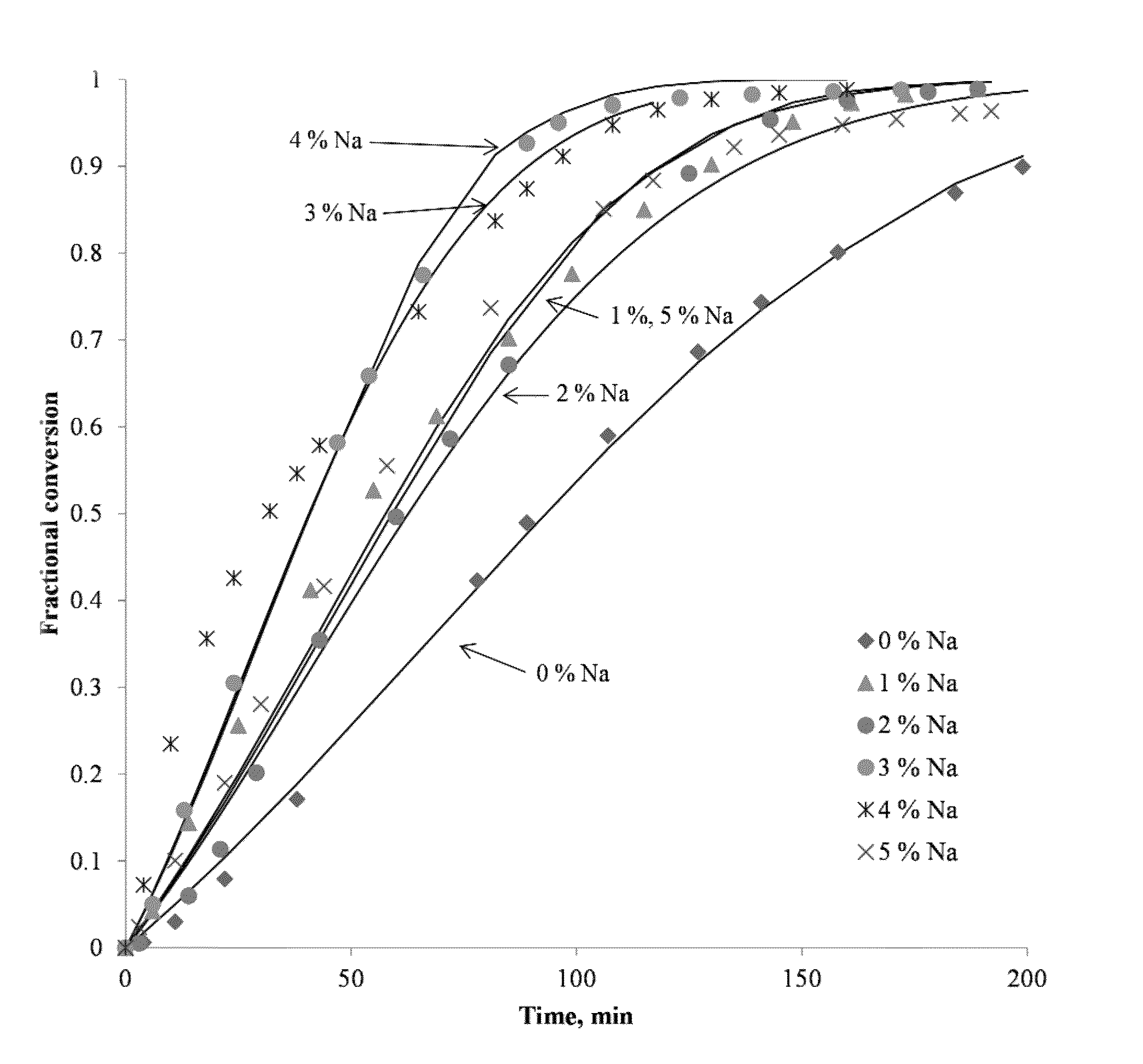

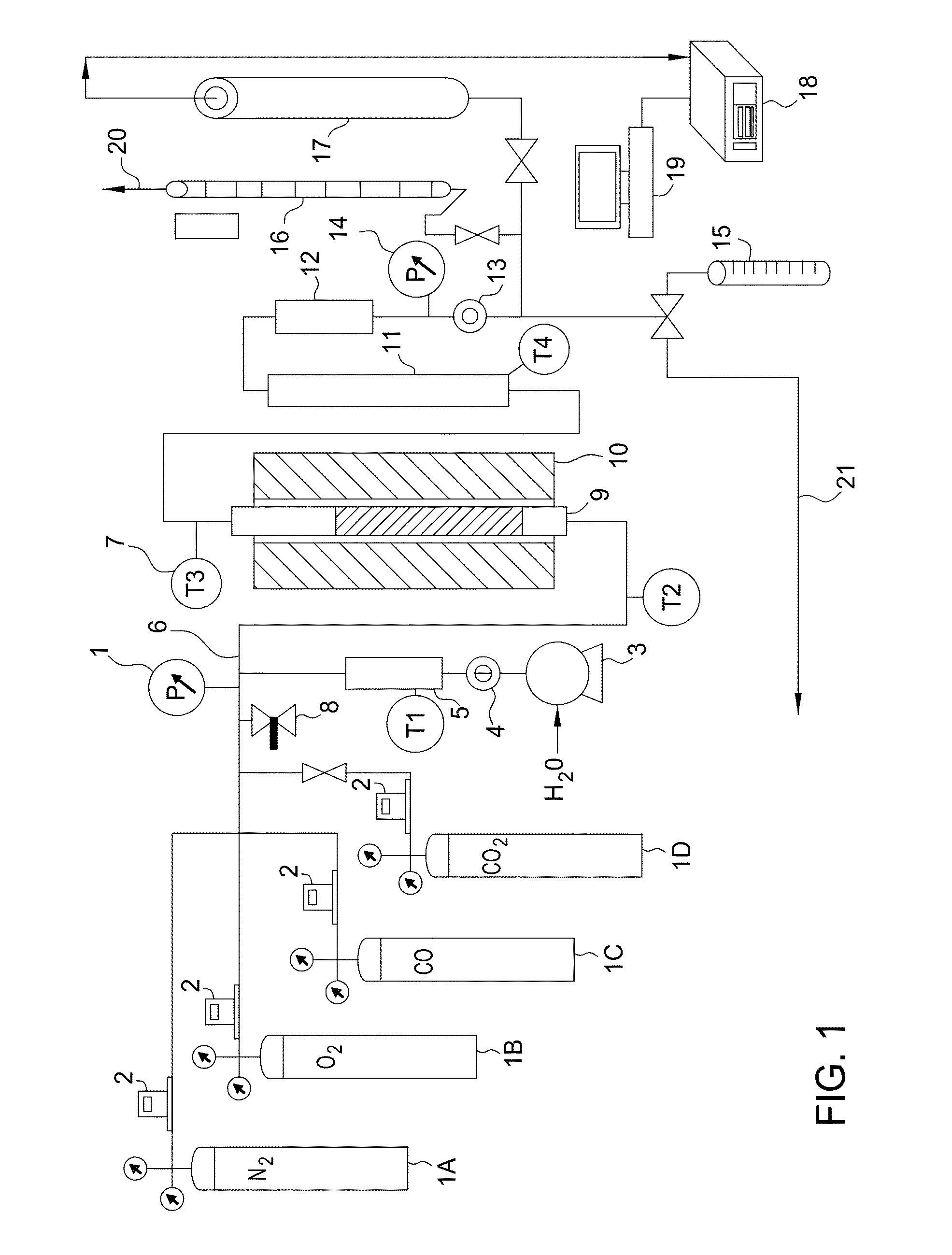

Cost-effective catalyst for gasification of powder river basin coal

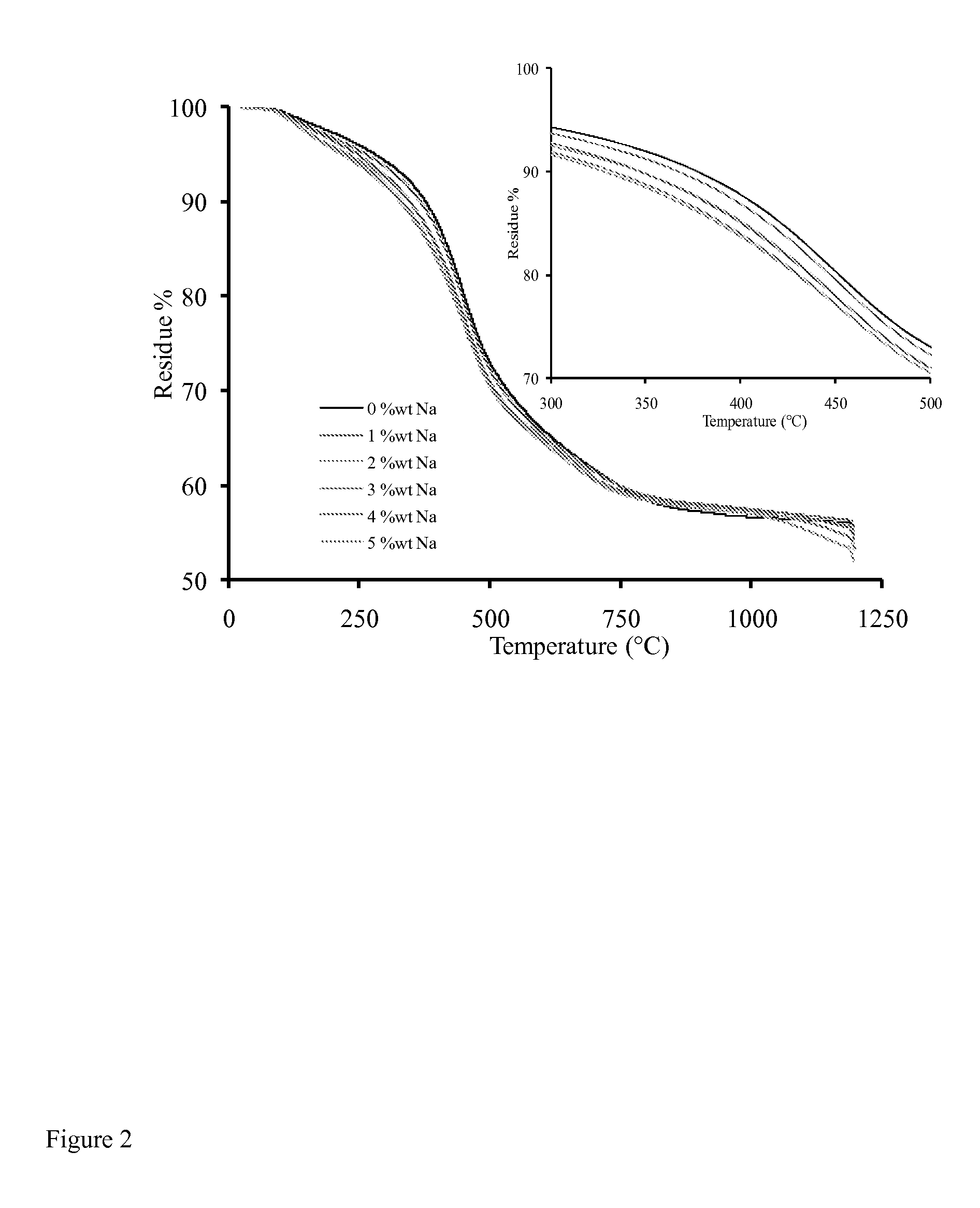

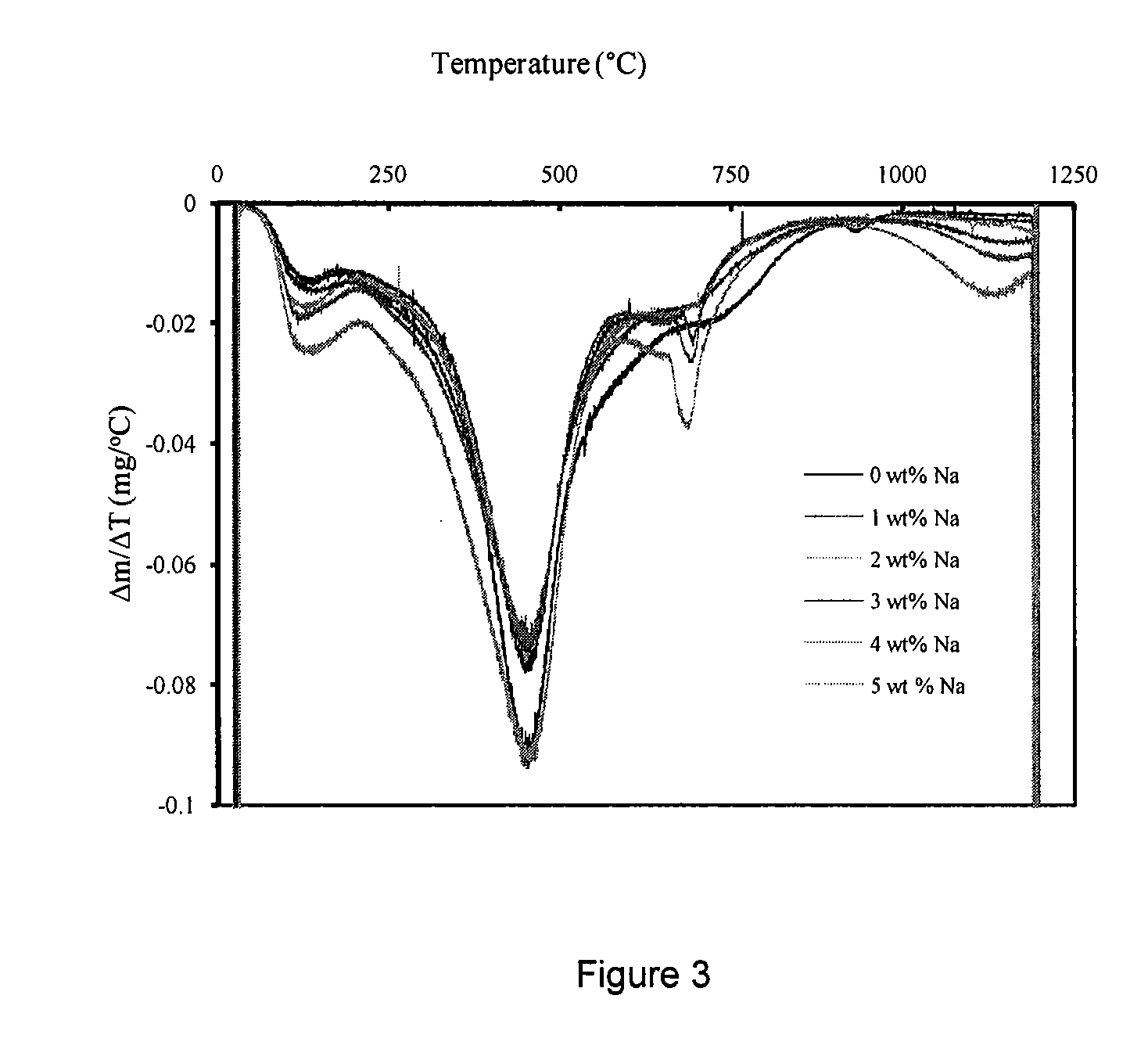

ActiveUS20130032761A1Reduce lossesImprove fitOther chemical processesGasification processes detailsReaction temperatureIncipient wetness impregnation

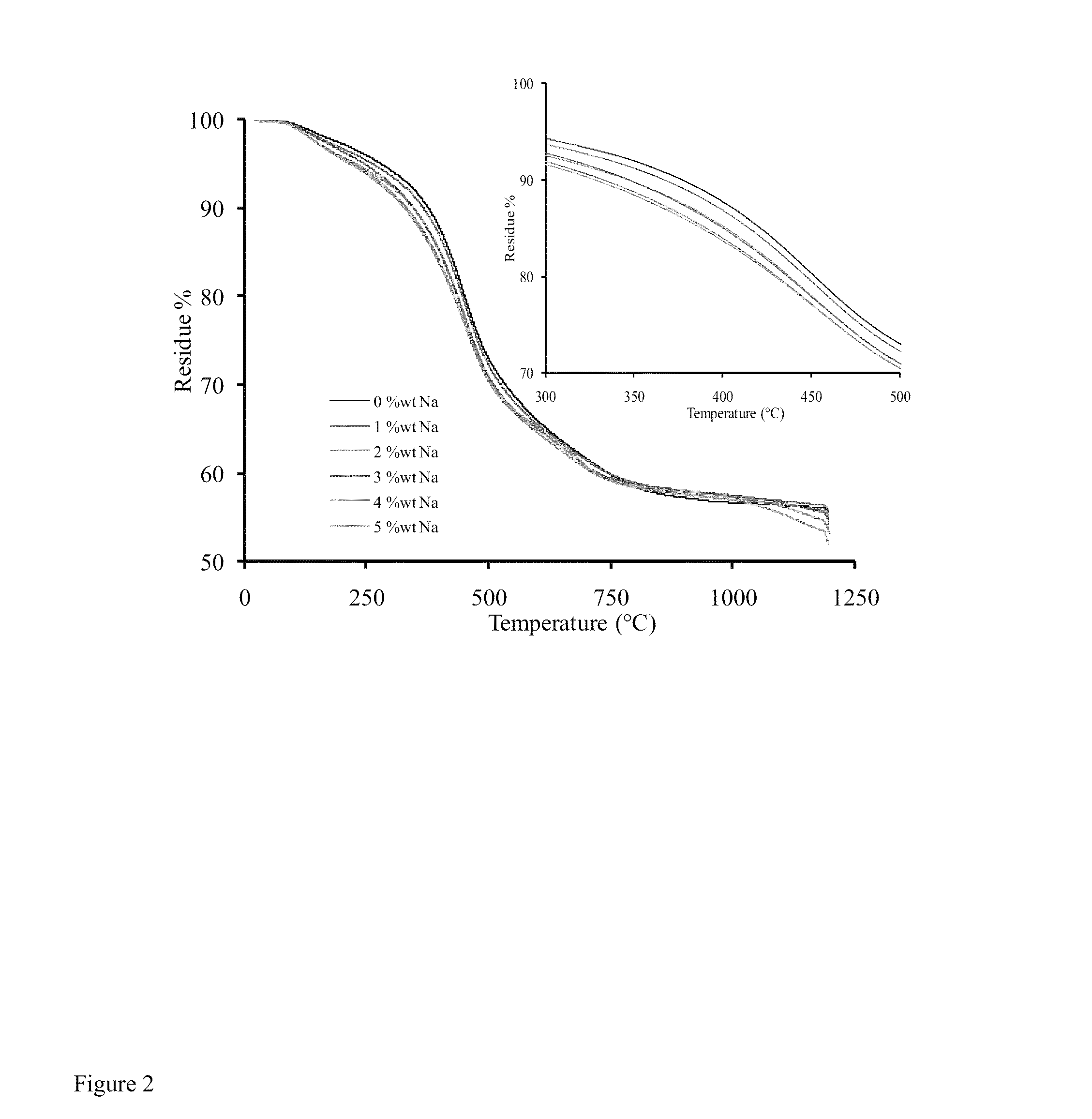

The present invention generally relates to a catalytic gasification of coal. Catalytic gasification of a Wyodak low-sulfur sub-bituminous coal from the Powder River Basin of Wyoming was investigated using an inexpensive sodium carbonate catalyst applied via incipient wetness impregnation. Experiments in an atmospheric pressure fixed-bed laboratory gasifier were performed to evaluate the effects of reaction temperature, feed gas steam content, and Na2CO3 loading on the catalytic gasification of the Wyodak coal. The temperature range investigated (700-900° C.) was selected with consideration of the Na2CO3 melting point (850° C.) to reduce the loss by volatilization of sodium. Sodium was found to be active during both pyrolysis and gasification steps. The catalyst was most cost-effective at addition levels of approximately 3 wt %. The random pore model provided a good fit to the conversion versus time data collected under both the catalytic and the uncatalytic conditions.

Owner:FAN MAOHONG +2

Flue gas hydrargyrum-removing method by catalytic oxidation

InactiveCN1331571CLittle matrix damageReduce pollutionDispersed particle separationPtru catalystSorbent

Owner:SHANGHAI JIAO TONG UNIV

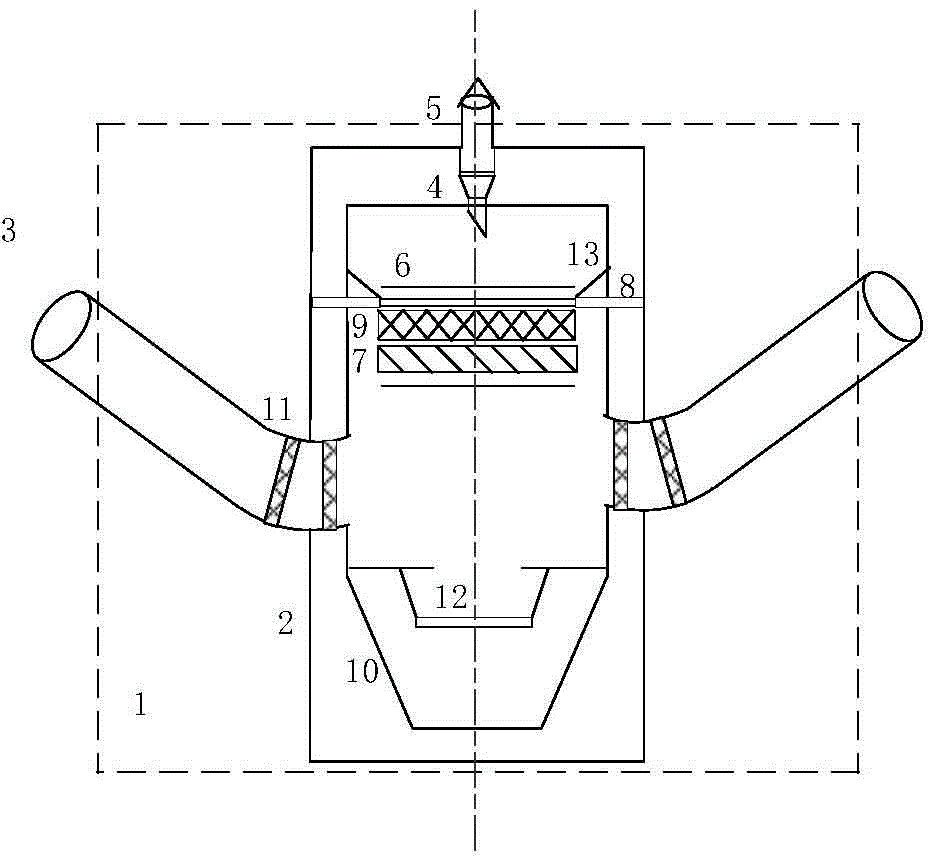

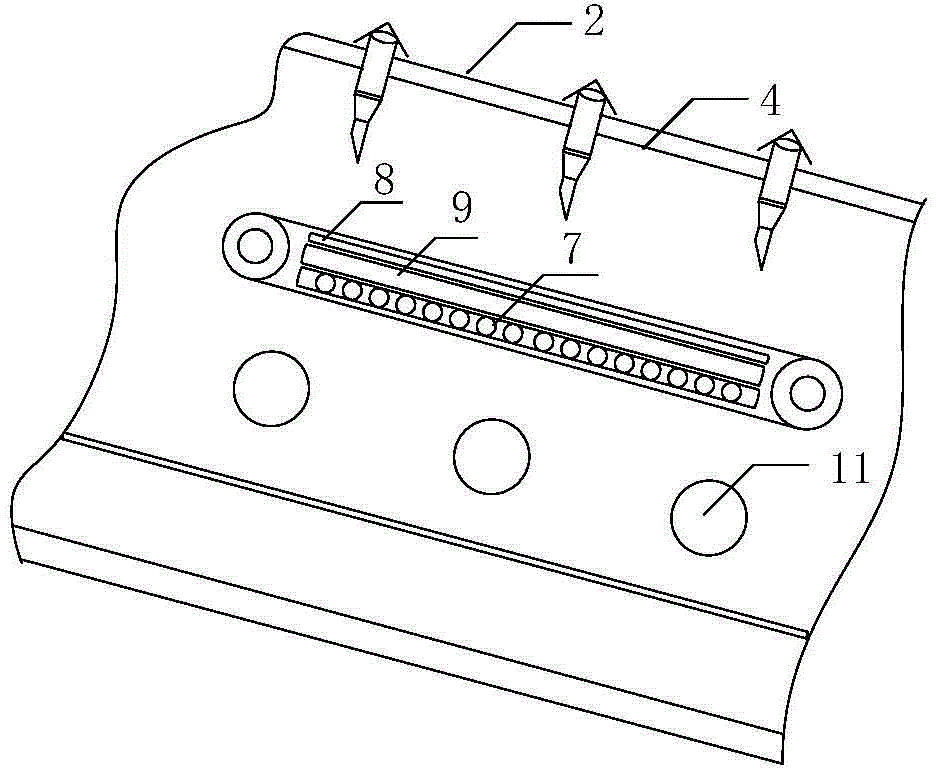

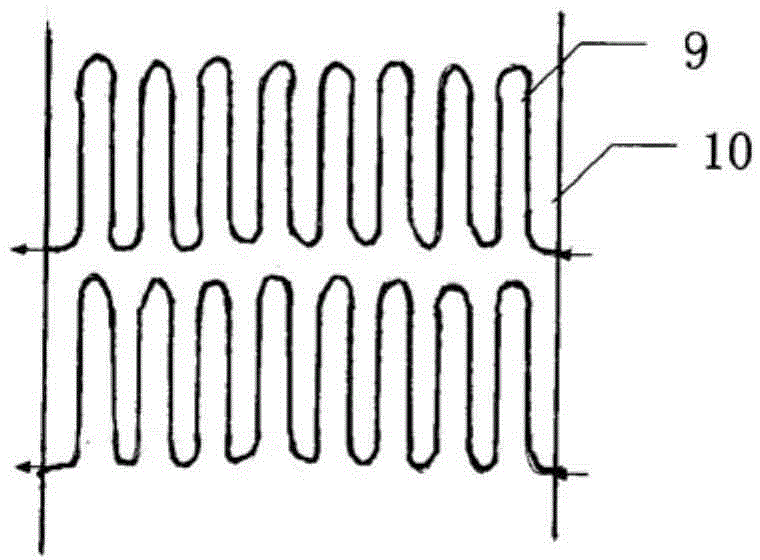

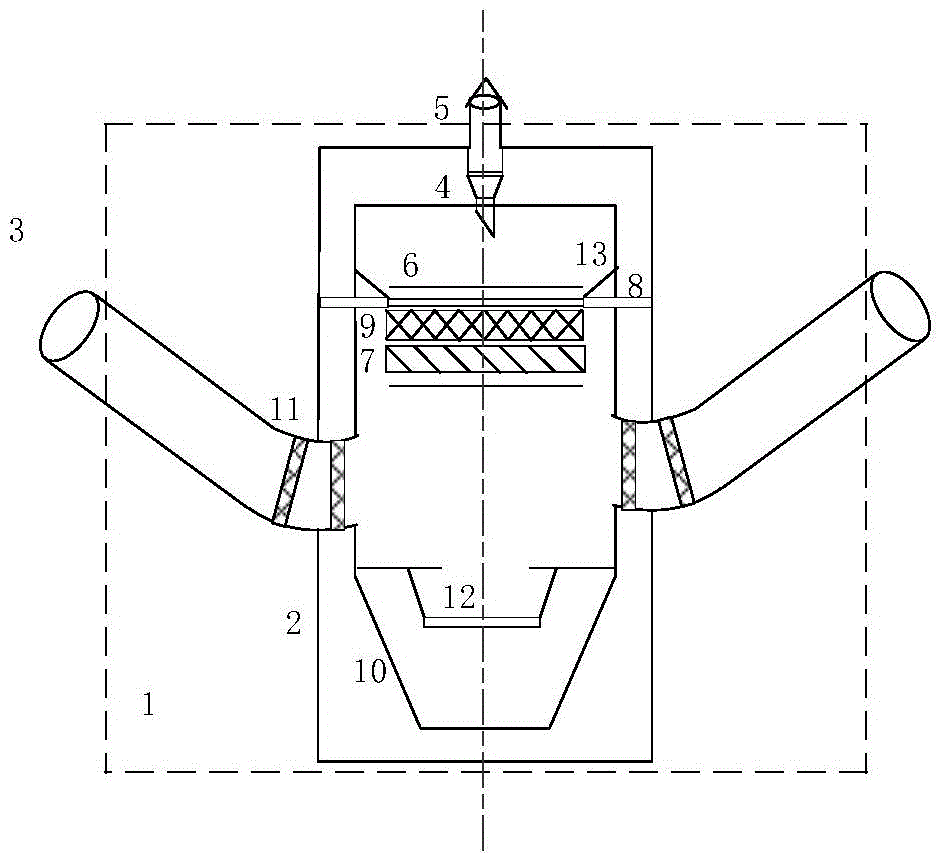

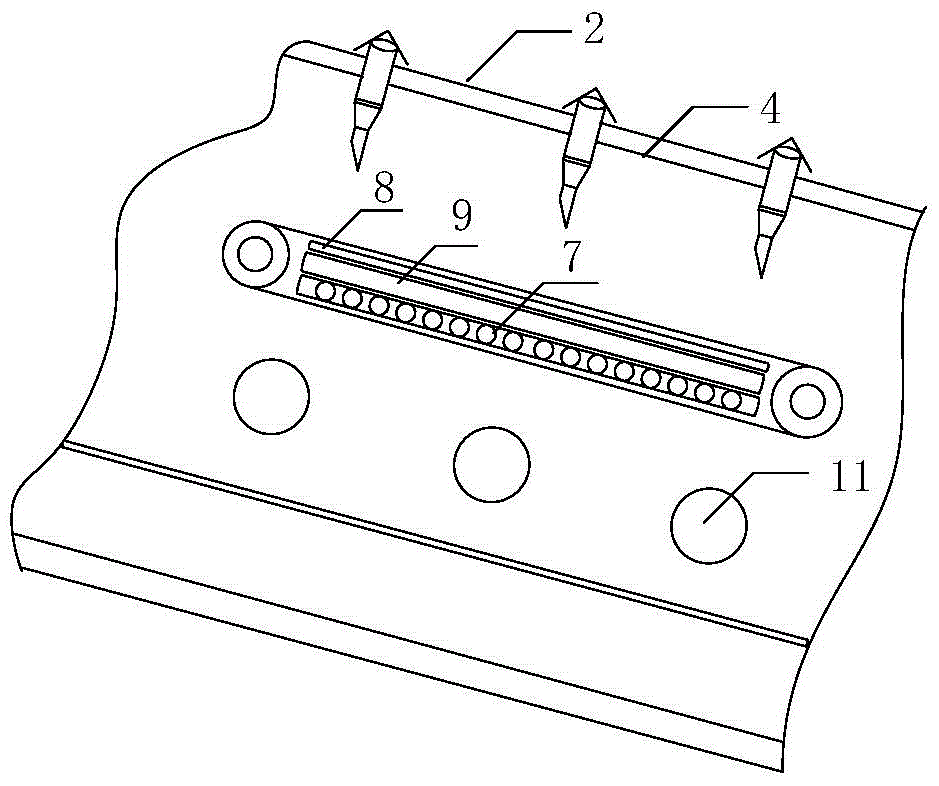

Low-temperature drying and coal conveying integrated equipment for raw coal

ActiveCN104566431AImprove utilization efficiencyImprove power generation efficiencyDrying gas arrangementsDrying machines with progressive movementsAtmospheric airBunker

The invention discloses low-temperature drying and coal conveying integrated equipment for raw coal and belongs to the field of raw coal drying equipment. In a coal conveying room, a double-layer closed space is formed by an equipment outer shell and an equipment inner shell, air introduction pipelines are connected with the drying equipment inner shell, first water medium heaters are arranged at junctions of the air introduction pipelines and the drying equipment inner shell, a supporting structure, a second water medium heater and a rotating shaft are sequentially arranged inside a crawler from top to bottom, and thus, the low-temperature drying and coal conveying integrated equipment for the raw coal is formed; an outlet of the low-temperature drying and coal conveying integrated equipment is connected with a coal bunker, and external moisture drying for lignite, sub-bituminous coal and bituminous coal is completed while coal granules are conveyed; air drying tail gas is conveyed to chimneys with baffles through an air pipeline and then is exhausted into the atmosphere. According to the low-temperature drying and coal conveying integrated equipment for the raw coal, disclosed by the invention, the external moisture drying for the raw coal (lignite, sub-bituminous coal and bituminous coal) can be completed by using low-temperature drying heat sources of different types while the coal granules are conveyed, so that the efficiency of an electric power plant is increased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for producing carbon fibers

InactiveUS20180051397A1Reduce contentImprove spinning efficiencyArtificial filament heat treatmentLiquid hydrocarbon mixture productionCarbon fibersCarbonization

A method for producing a carbon fiber includes a separation step of separating an ash-free coal obtained from a bituminous coal or a sub-bituminous coal, into a soluble component(s) and an insoluble component(s) by a solvent extraction treatment, a heat treatment step of heat-treating the soluble component(s), a melt spinning step of melt-spinning the soluble component(s) subjected to the heat treatment, an infusibilization step of infusibilizing a filament body obtained by the melt spinning, and a carbonization step of carbonizing the filament body subjected to the infusibilization.

Owner:KOBE STEEL LTD +1

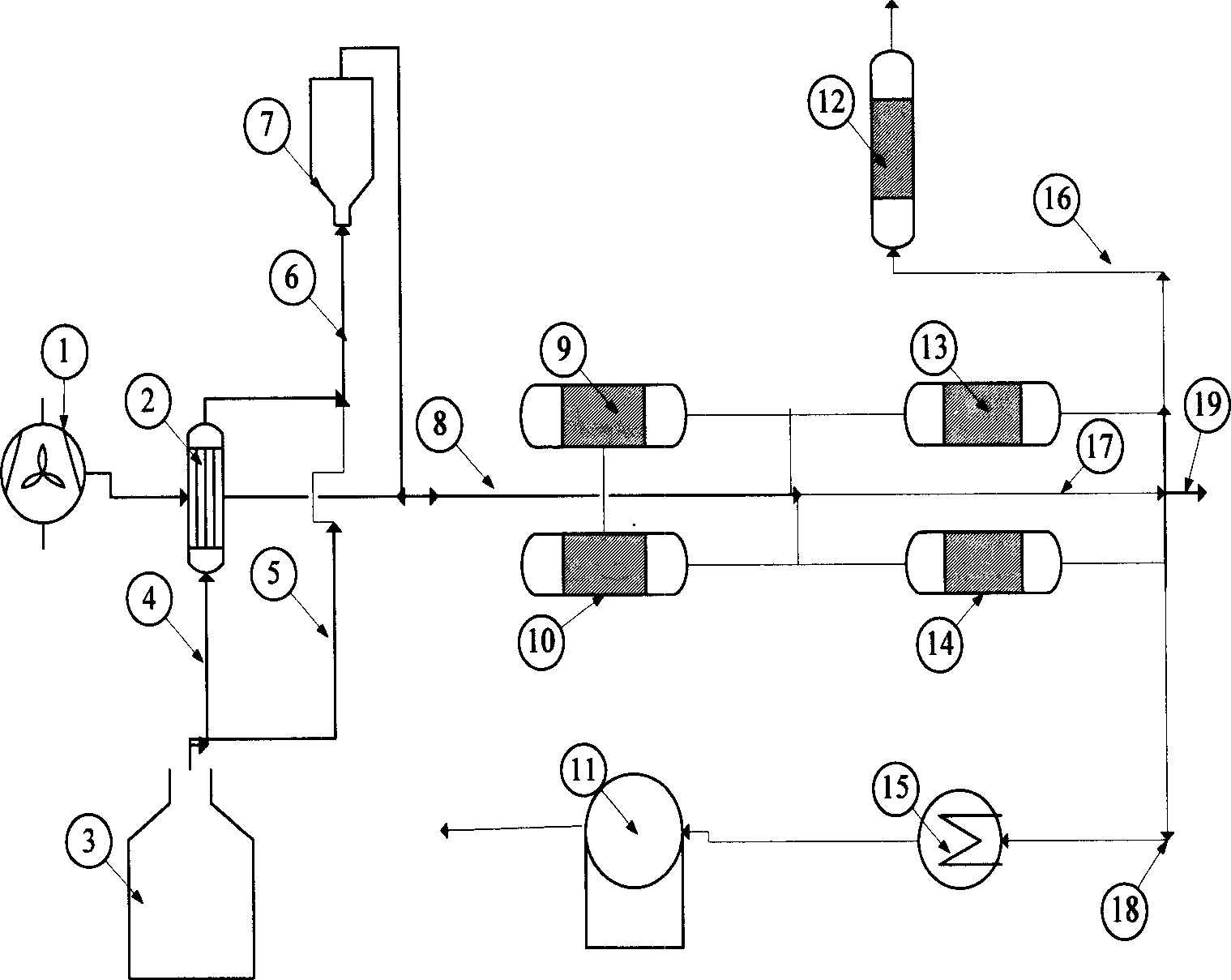

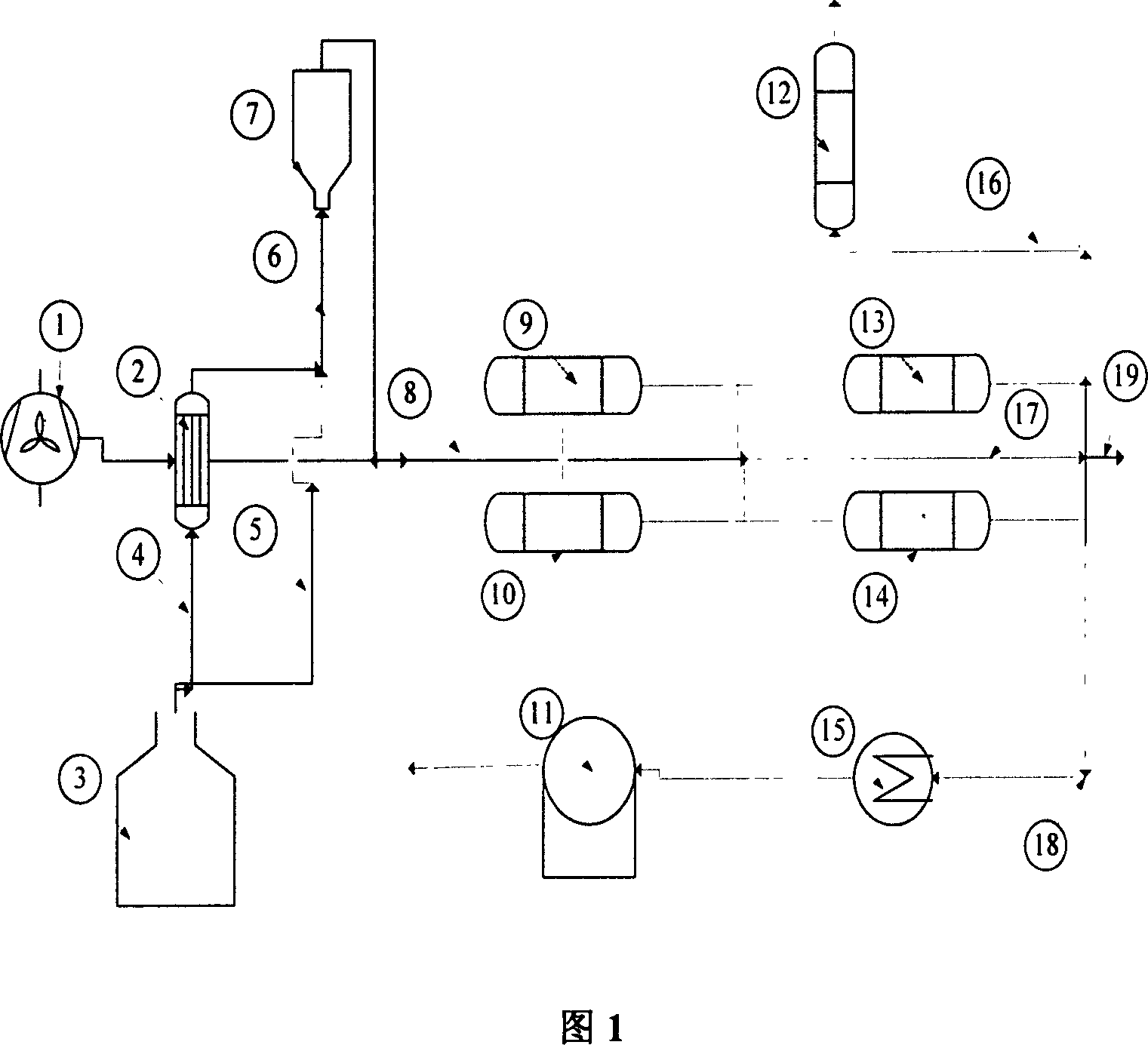

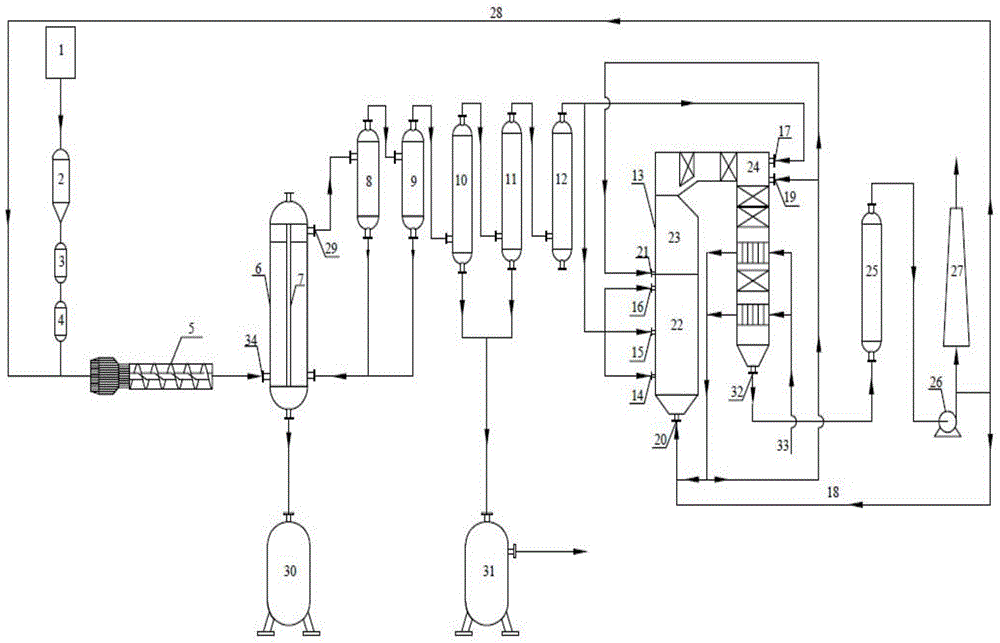

Poly-generation apparatus and method using low nitrogen oxides in coal gas for combustion power generation

ActiveCN104864391AIncrease added valueEfficient cleaningCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow nitrogenCadmium Cation

The invention provides a poly-generation apparatus and method using low nitrogen oxides in coal gas for combustion power generation. According to the invention, one or more low rank coal selected from the group consisting of brown coal, long flame coal, sub-bituminous coal and soft coal are added into a fine coal upgrading conversion reactor for rapid conversion, crude coal gas produced after conversion undergoes dedusting and purifying, oil-gas separation, and desulphurization and purification; and purified coal gas is successively injected into a boiler for combustion through graded combustion nozzles. Compared with the prior art, the invention has the following advantages: a desired air excess coefficient is small, combustion temperature is lower than a typical temperature--1400 DEG C at which a great amount of thermal NOx is produced, so production of thermal NOx in the process of combustion is radically inhibited and production of fuel NOx and rapid NOx is avoided; the concentration of respirable particulates like SO2, PM2.5 and PM10 in combustion flue gas is extremely low, and ultra-low concentration discharge of SO2 and NOx can be realized; and the combustion flue gas is almost free of heavy metals like lead, chromium, cadmium, arsenic and mercury.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Briquetting process

ActiveUS20090025285A1Reducing pressure buildupLower the volumeBiofuelsSolid fuelsParticulatesWater vapor

A process and system is provided for briquetting particulate matter such as moisture-containing bituminous and sub-bituminous coal. This process includes partially drying the particulate matter and feeding, the partially dried particulate matter to a briquetting apparatus under conditions such that water vapor is released from the particulate matter during feeding. The particulate matter is passed through briquette forming rollers to form briquettes. The released water vapor substantially displaces or prevents the ingress of a large proportion of other gaseous components from the atmosphere surrounding an / or intermixed with the particulate matter. The particulate matter that is fed to the briquetting apparatus is surrounded by and intermixed with a gaseous component containing 70% to 100% by volume of water vapor at the point where it enters the briquette-forming part of the briquetting apparatus, such that when the particulate matter is compressed during briquette formation, the water vapor liquefies and the pressure buildup of gaseous material in the thus-formed briquettes is minimised. This reduction in the pressure buildup of gaseous components also acts to reduce blow-back of gases as the coal fines are being formed into briquettes.

Owner:COMMONWEALTH SCI & IND RES ORG +3

Reducing environmental pollution and fouling when burning coal

InactiveCN105339070AEmission reductionReduce foulingSolid fuel pretreatmentEmission preventionBrown coalHalogen

Owner:NOX II LTD

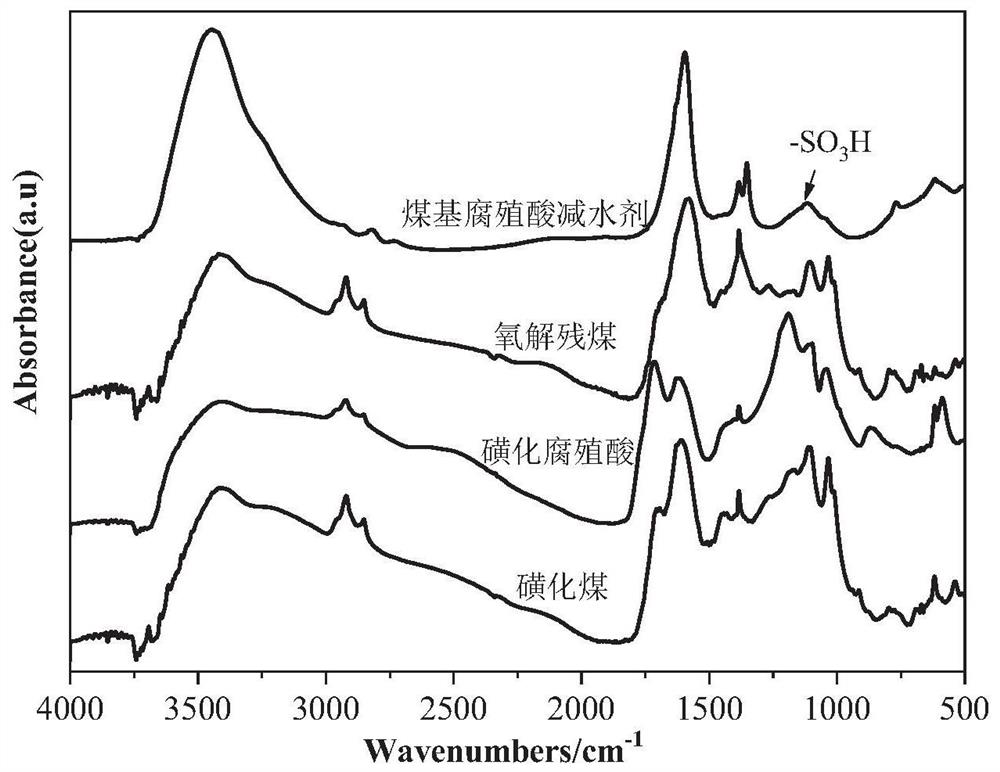

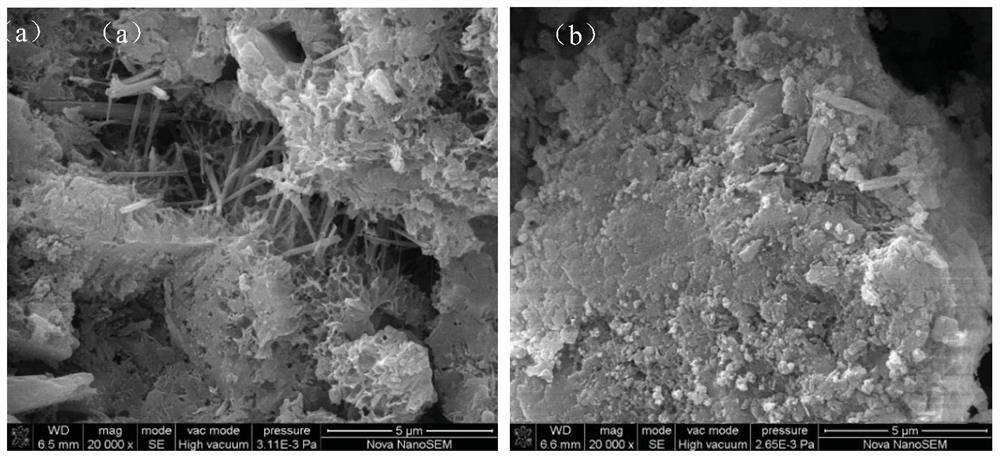

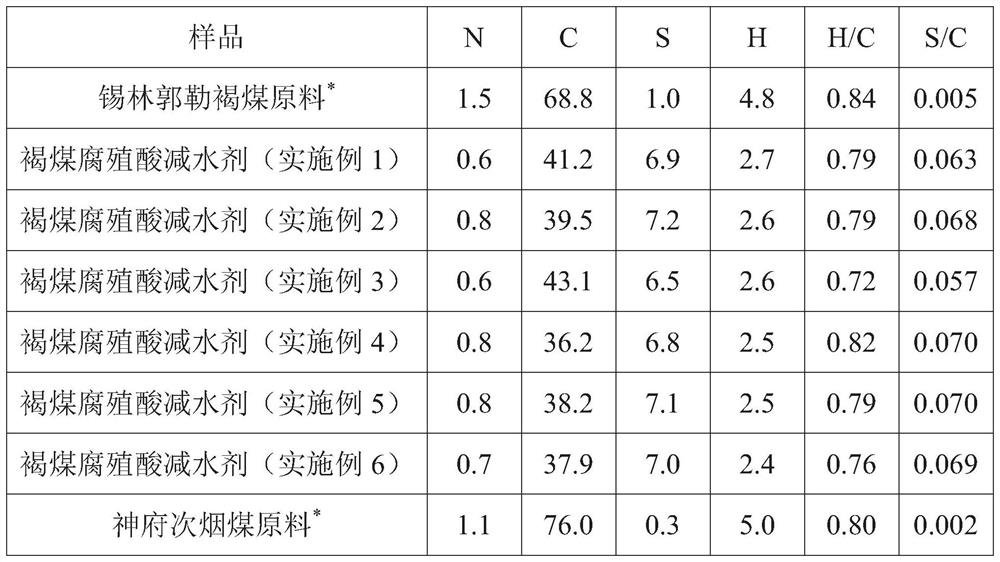

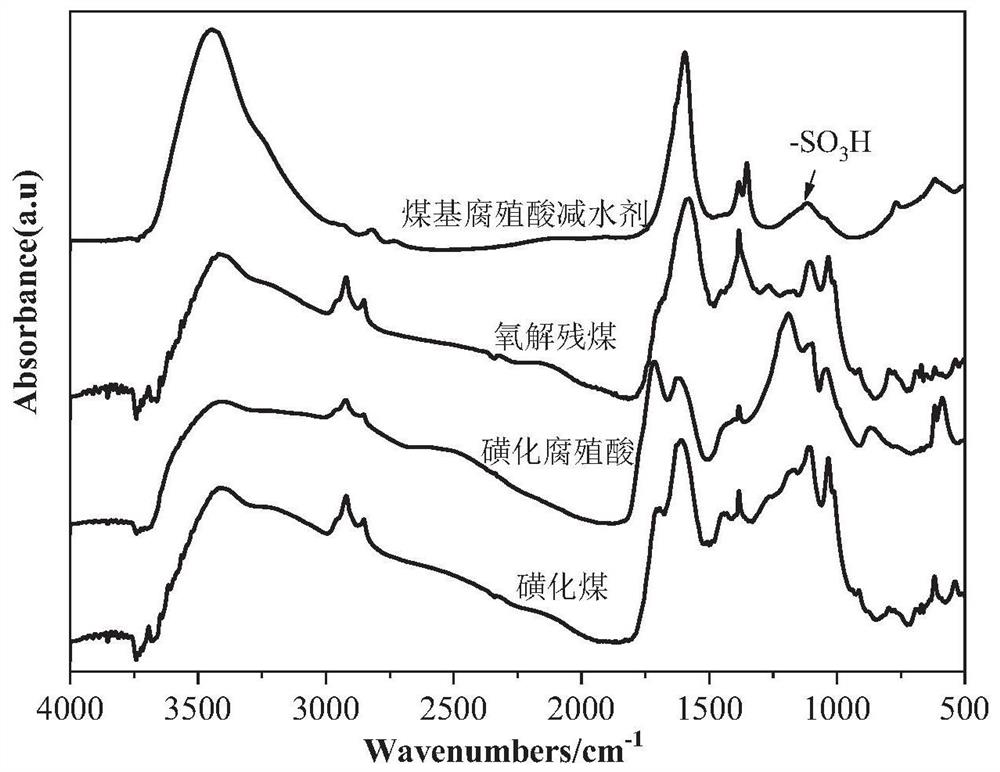

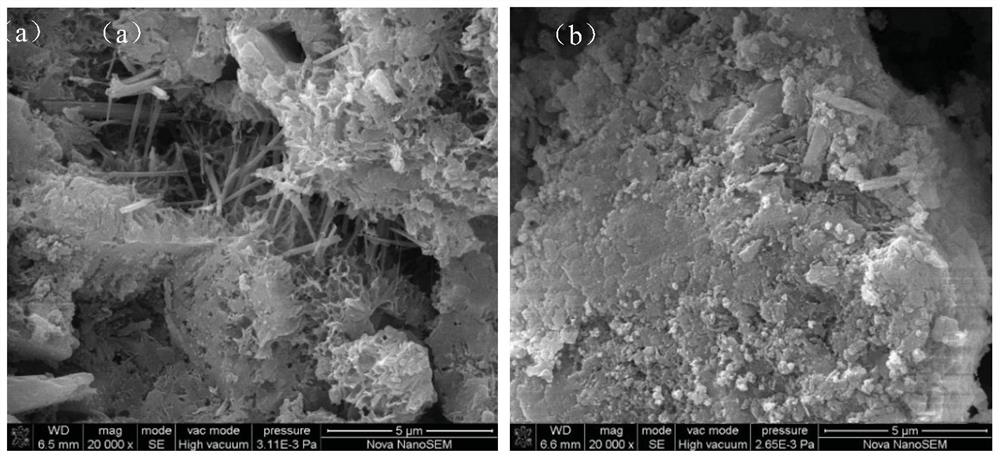

Preparation method of low-rank coal-based superplasticizer

ActiveCN112661976AHigh degree of sulfonationMild reaction conditionsSolid waste managementSuperplasticizerWater reducer

The invention discloses a preparation method of a low-rank coal-based superplasticizer, and belongs to the technical field of low-rank coal resource utilization and fine chemical engineering. Low-rank coal such as lignite and sub-bituminous coal is used as raw materials, sulfonated coal is obtained through sulfite sulfonation, sulfonated coal-based humic acid is obtained through sulfonated coal liquid-phase oxidative cracking, and finally the obtained sulfonated coal-based humic acid is subjected to formaldehyde polycondensation to synthesize the coal-based humic acid high-efficiency water reducing agent. The method for synthesizing the high-efficiency water reducing agent by taking the low-rank coal such as the lignite and the sub-bituminous coal as the raw materials has the characteristics of high yield of sulfonated coal-based humic acid and the water reducing agent, low cost, clean process and the like, the synthesized coal-based humic acid water reducing agent has good dispersing, water reducing and slump retaining properties, and the water reducing effect is superior to that of a commercially available naphthalene high-efficiency water reducing agent. Under the condition that the mixing amount is 0.4%, the highest water reducing rate can reach 24.5%, the initial cement paste fluidity is 162 mm, the mortar fluidity is 305 mm, and the mortar fluidity loss rate within 2 h is 6.9%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

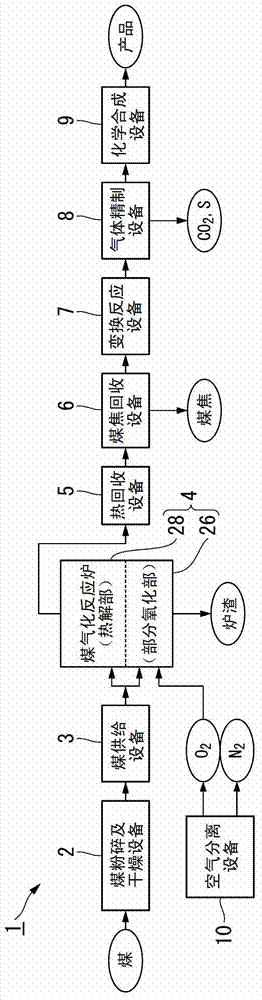

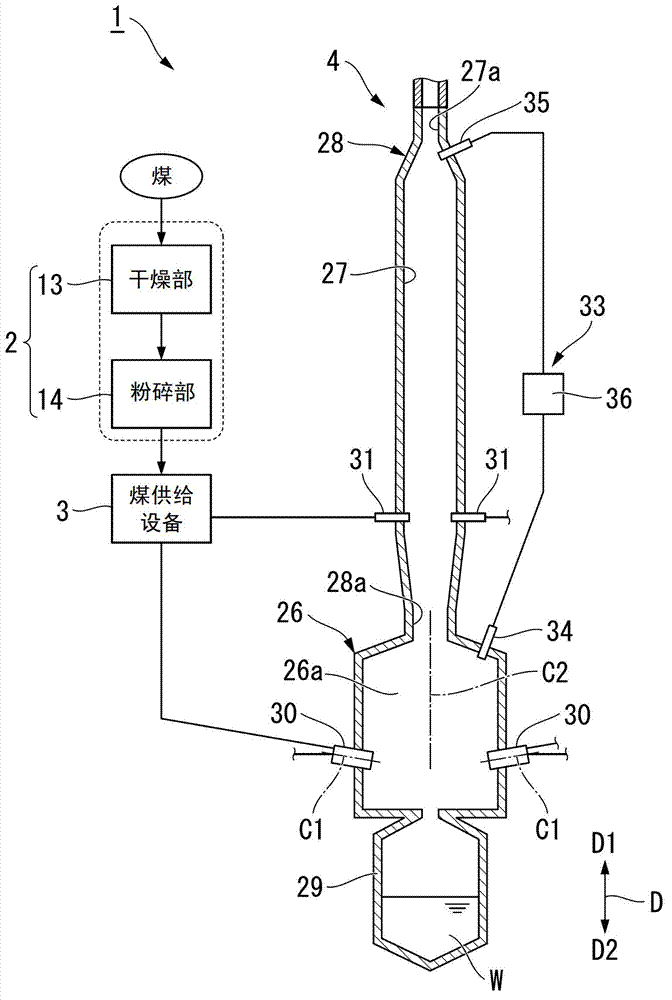

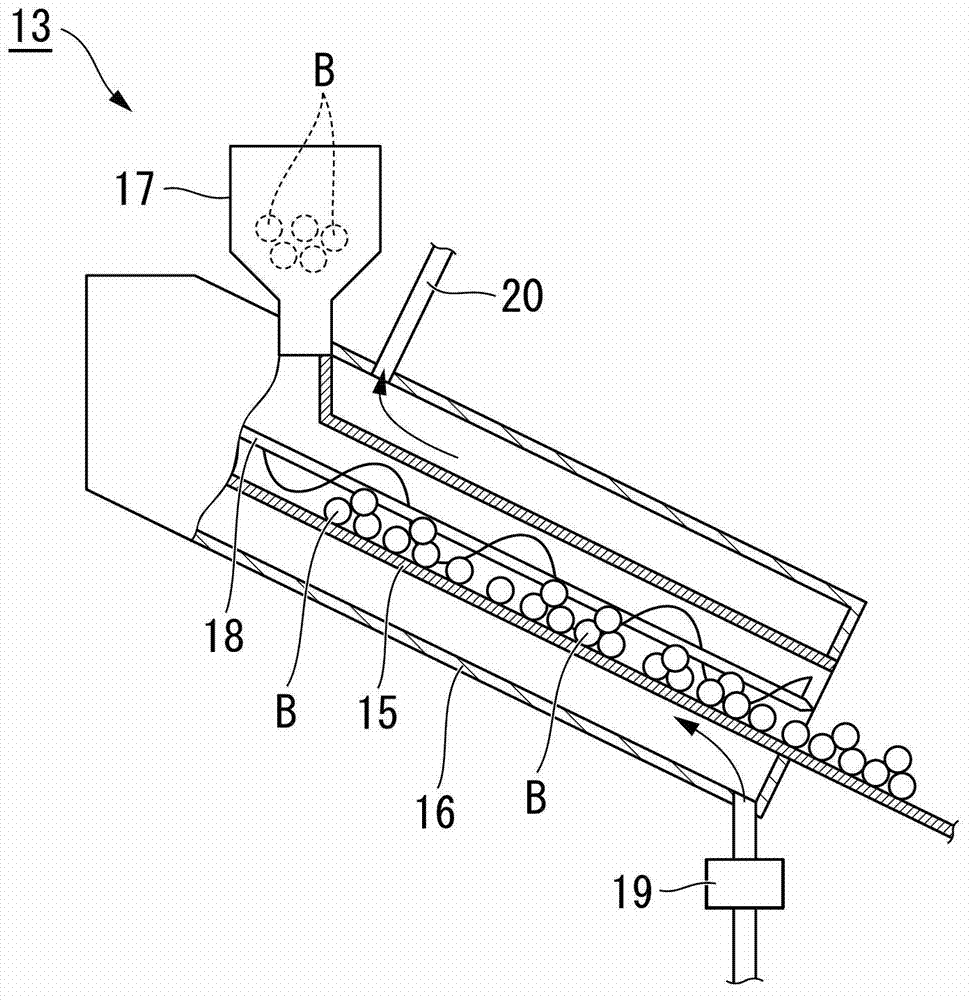

Coal gasification system and coal gasification method

ActiveCN102892869AAdjustable steam volumeCombustible gas catalytic treatmentGasification processes detailsHydrogenChemical reaction

Disclosed are a coal gasification system and a coal gasification method, comprising a drying apparatus which turns subbituminous coal or brown coal into moisture-regulated coal by drying until same contain a specified moisture content; and a coal gasification reaction furnace which produces at least hydrogen gas and carbon monoxide gas by burning the moisture-regulated coal. The specified moisture content is set to a quantity such that when the moisture vapour emitted from the moisture-regulated coal and tar are chemically reacted, the tar does not stick inside through holes.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD

Process for the preparation of blue-flourescence emitting carbon dots (CDTS) from sub-bituminous tertiary high sulfur Indian coals

ActiveUS10655061B2Minimize uncontrollable eventsHigh quantum yieldGraphiteLuminescent paintsBituminous coalUltrasound assisted

The present invention relates to a process for the preparation of blue-fluorescence emitting carbon dots (CDTs) from sub-bituminous tertiary high sulfur Indian coals. More particularly, the present invention relates to the production of characteristics carbon dots from low-quality Indian coals by an ultrasonic-assisted wet-chemical method. Also, the present invention provides a simple and environmentally benign method for fabrication of characteristics and size-controlled carbon dots.

Owner:COUNCIL OF SCI & IND RES

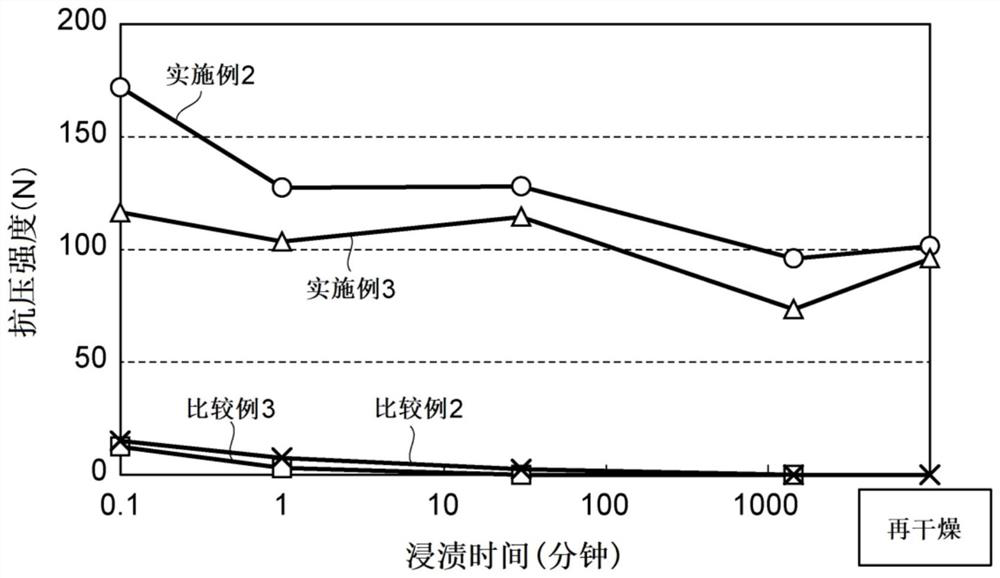

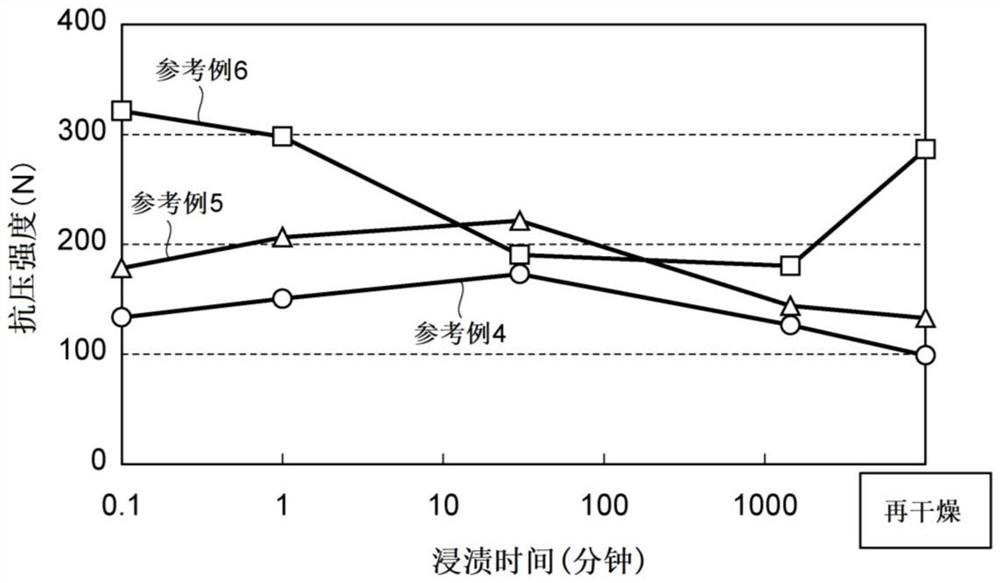

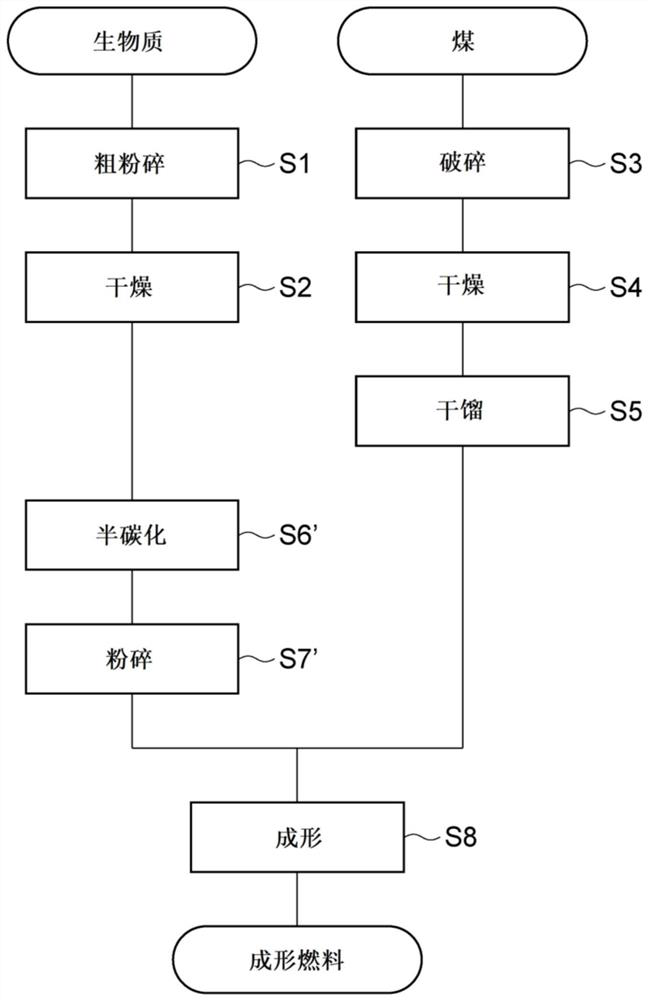

Production method for briquette

Provided is a production method that is for a briquette and that comprises a step for obtaining a briquette having a water content of 5 wt% or less by molding a molding raw material containing a powder carbonized coal and a binder and drying the same at 60-100 DEG C. The binder contains an aqueous solution of a polyvinyl alcohol having a saponification degree of more than 99.3 mol% and a polymerization degree of 1700 or more. The powder carbonized coal is a pulverized coal obtained by drying and carbonizing a coal including brown coal and / or subbituminous coal.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD

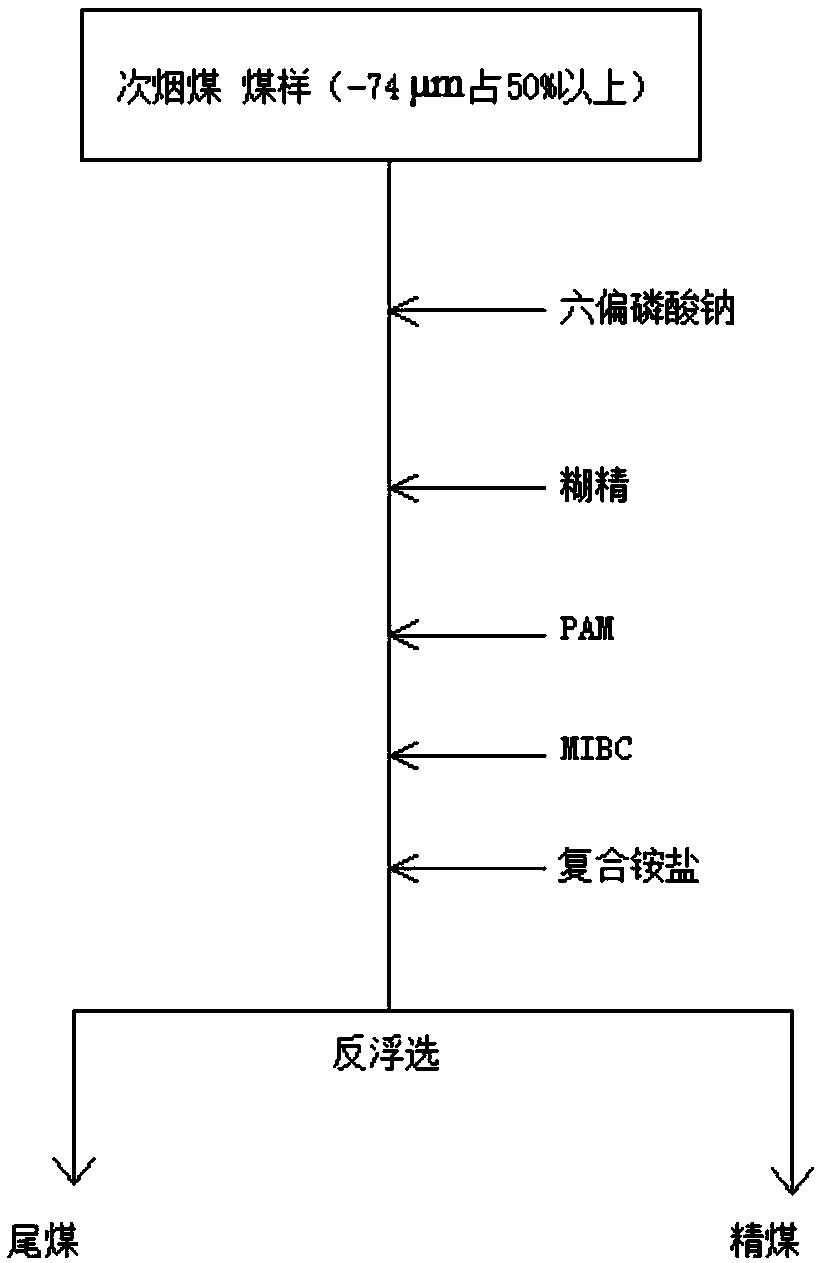

A Method of Selective Flocculation-Reverse Flotation for Ash Reduction of Ultrafine Subbituminous Coal

InactiveCN107442293BEnhanced inhibitory effectIncrease apparent particle sizeDifferential sedimentationFlotationMethyl isobutyl carbinolSub-bituminous coal

Owner:CHINA UNIV OF MINING & TECH

Earth cementation agent in use for roadway construction

InactiveCN100434383CImprove responseGood water hardnessSolid waste managementOrganic fertilisersRoad surfaceAlunite

In the invention, two kinds of waste material dry dust discharging coal ash and desulfurize gyp produced by power plant burning sub-bituminous coal or lignitous coal are used as main composition, shell and or cement, calcined gypsum and aluminum sulfate or alunite are used as secondary composition, they are prepared to dry powder soil curing agent by weighing, matching, forced stirring and mixing. The soil can be concreted by mixing a proper quantity of curing agent into the soil and processes of stirring, compacting, soaking and maintaining.

Owner:徐尔昌

A kind of preparation method of highly adsorptive coal-based briquette activated carbon

ActiveCN105858656BImprove adsorption capacityHigh yieldCarbon compoundsActivated carbonCoal blending

The invention discloses a preparation method of high-adsorptivity coal-base pressed block activated carbon. The preparation method comprises the following steps: carrying out coal blending on 60-80 wt% of main coal, 10-20 wt% of sub-bituminous coal and 10-20 wt% of gas-fat coal, and pulverizing to obtain raw material coal, wherein the main coal is non-caking coal and / or jet coal; and carrying out pressure molding and granulation on the obtained raw material coal, and carrying out oxidation treatment, carbonizing treatment and activating treatment, thereby obtaining the activated carbon. The activated carbon, which is prepared by carrying out coal blending on certain amounts of the main coal, sub-bituminous coal and gas-fat coal, well combines the properties and interactions of the coals. Compared with the traditional coal-base activated carbon, the adsorptivity of the high-adsorptivity coal-base pressed block activated carbon is obviously enhanced, thereby solving the common problem of poor adsorptivity in the traditional coal-base pressed block activated carbon production process.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A kind of preparation method of low-rank coal-based superplasticizer

ActiveCN112661976BHigh degree of sulfonationMild reaction conditionsSolid waste managementSulfite saltSuperplasticizer

The invention discloses a preparation method of a low-rank coal-based high-efficiency water reducer, which belongs to the technical field of low-rank coal resource utilization and fine chemical industry. The present invention uses low-rank coal such as lignite and sub-bituminous coal as raw materials, obtains sulfonated coal through sulfite sulfonation, then obtains sulfonated coal-based humic acid through liquid-phase oxidative cracking of sulfonated coal, and finally sulfonated coal-based humic acid is obtained. The humic acid is polycondensed by formaldehyde into coal-based humic acid superplasticizer. The method for synthesizing high-efficiency water-reducing agent using low-rank coal such as lignite and sub-bituminous coal as raw materials provided by the invention has the characteristics of high yield of sulfonated coal-based humic acid and water-reducing agent, low cost, clean process, and the like. The coal-based humic acid water-reducing agent has good dispersion, water-reducing and slump-preserving properties, and the water-reducing effect is better than the commercially available naphthalene-based superplasticizer. Under the condition of the dosage of 0.4%, the water reduction rate can reach up to 24.5%, the initial cement slurry fluidity is 162mm, the mortar fluidity is 305mm, and the 2h mortar fluidity loss rate is 6.9%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Cost-effective catalyst for gasification of powder river basin coal

ActiveUS8926931B2Reduce lossesCost-effectiveOther chemical processesHydrazoic-acids/azides/halogen-azidesIncipient wetness impregnationFixed bed

The present invention generally relates to a catalytic gasification of coal. Catalytic gasification of a Wyodak low-sulfur sub-bituminous coal from the Powder River Basin of Wyoming was investigated using an inexpensive sodium carbonate catalyst applied via incipient wetness impregnation. Experiments in an atmospheric pressure fixed-bed laboratory gasifier were performed to evaluate the effects of reaction temperature, feed gas steam content, and Na2CO3 loading on the catalytic gasification of the Wyodak coal. The temperature range investigated (700-900° C.) was selected with consideration of the Na2CO3 melting point (850° C.) to reduce the loss by volatilization of sodium. Sodium was found to be active during both pyrolysis and gasification steps. The catalyst was most cost-effective at addition levels of approximately 3 wt %. The random pore model provided a good fit to the conversion versus time data collected under both the catalytic and the uncatalytic conditions.

Owner:FAN MAOHONG +2

Preparation method of high-adsorptivity coal-base pressed block activated carbon

ActiveCN105858656AImprove adsorption capacityHigh yieldCarbon compoundsActivated carbonBituminous coal

The invention discloses a preparation method of high-adsorptivity coal-base pressed block activated carbon. The preparation method comprises the following steps: carrying out coal blending on 60-80 wt% of main coal, 10-20 wt% of sub-bituminous coal and 10-20 wt% of gas-fat coal, and pulverizing to obtain raw material coal, wherein the main coal is non-caking coal and / or jet coal; and carrying out pressure molding and granulation on the obtained raw material coal, and carrying out oxidation treatment, carbonizing treatment and activating treatment, thereby obtaining the activated carbon. The activated carbon, which is prepared by carrying out coal blending on certain amounts of the main coal, sub-bituminous coal and gas-fat coal, well combines the properties and interactions of the coals. Compared with the traditional coal-base activated carbon, the adsorptivity of the high-adsorptivity coal-base pressed block activated carbon is obviously enhanced, thereby solving the common problem of poor adsorptivity in the traditional coal-base pressed block activated carbon production process.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Molasses-based explosion-proof dust suppressant and preparation method thereof

InactiveCN113444491AWith bondingMoisturizingOther chemical processesDust removalCoal dustEnvironmental engineering

The invention relates to an explosion-proof dust suppressant for coal dust and a preparation method thereof. The dust suppressant is prepared from the following raw materials in percentage by mass: 10 to 30 percent of molasses, 0.1 to 0.5 percent of a nonionic surfactant, and 5 to 10 percent of starch-based super absorbent resin (SAP), with the balance being water and a trace pH neutralizer Ca(OH)2. More than 99.5% of the components of the dust suppressant are environment-friendly degradable materials,and the molasses is a byproduct in the sugar industry and is a main material of the dust suppressant, so the dust suppressant has the characteristics of low price, environment friendliness and degradability. The dust suppressant has the functions of wetting, bonding, moisturizing and explosion suppression on coal dust. On-site actual measurement shows that the inhibition rate of the dust suppressant on deposited coal dust in an underground return airway is not lower than 62.86% within three days; and the inhibition rates of the dust suppressant on the explosion indexes of sub-bituminous coal, bituminous coal and anthracite coal dust are 57.45%, 51.47% and 76.98% respectively.

Owner:UNIV OF SCI & TECH BEIJING

A raw coal low-temperature drying and coal transportation integrated equipment

ActiveCN104566431BImprove utilization efficiencyImprove power generation efficiencyDrying gas arrangementsDrying machines with progressive movementsEngineeringDry heat

The invention discloses low-temperature drying and coal conveying integrated equipment for raw coal and belongs to the field of raw coal drying equipment. In a coal conveying room, a double-layer closed space is formed by an equipment outer shell and an equipment inner shell, air introduction pipelines are connected with the drying equipment inner shell, first water medium heaters are arranged at junctions of the air introduction pipelines and the drying equipment inner shell, a supporting structure, a second water medium heater and a rotating shaft are sequentially arranged inside a crawler from top to bottom, and thus, the low-temperature drying and coal conveying integrated equipment for the raw coal is formed; an outlet of the low-temperature drying and coal conveying integrated equipment is connected with a coal bunker, and external moisture drying for lignite, sub-bituminous coal and bituminous coal is completed while coal granules are conveyed; air drying tail gas is conveyed to chimneys with baffles through an air pipeline and then is exhausted into the atmosphere. According to the low-temperature drying and coal conveying integrated equipment for the raw coal, disclosed by the invention, the external moisture drying for the raw coal (lignite, sub-bituminous coal and bituminous coal) can be completed by using low-temperature drying heat sources of different types while the coal granules are conveyed, so that the efficiency of an electric power plant is increased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

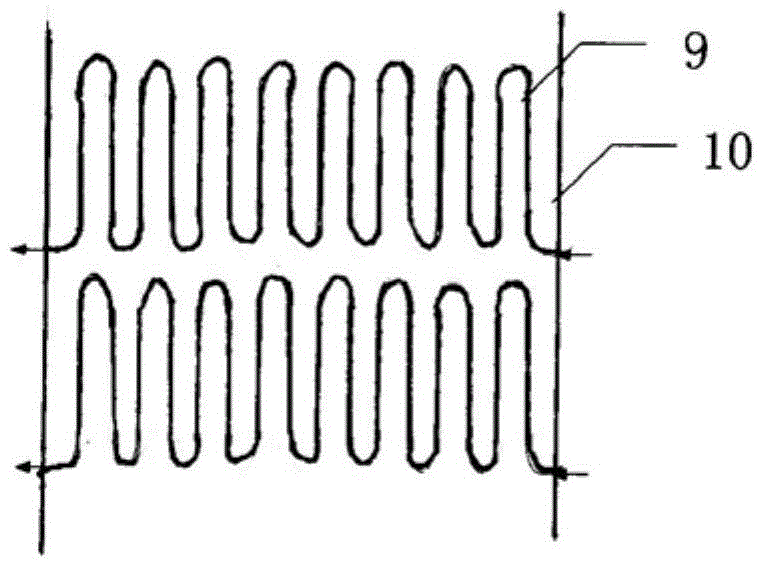

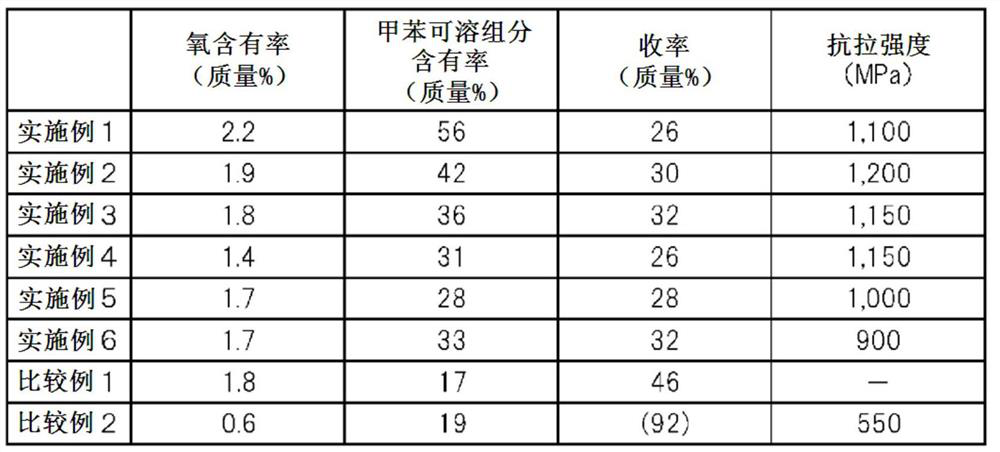

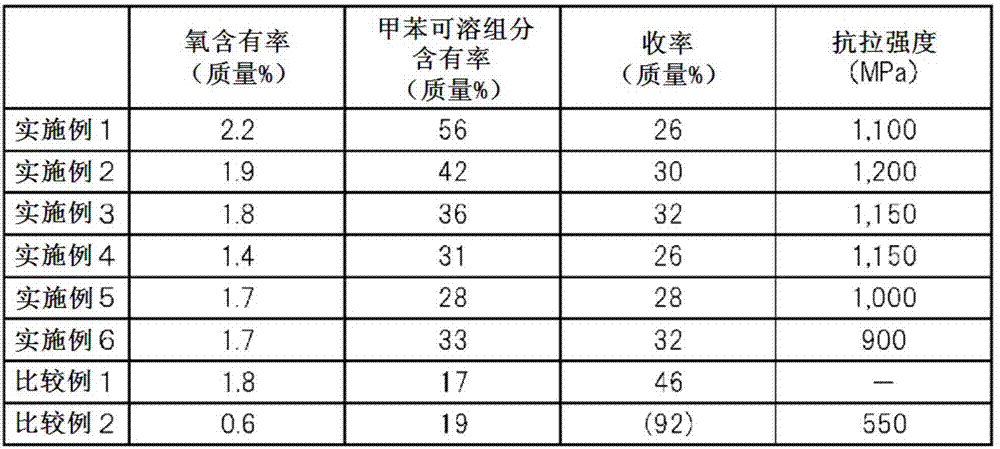

Raw material pitch for carbon fiber manufacturing

ActiveCN107532086BCheap manufacturingWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCarbon fibersToluene

An object of the present invention is to provide a raw material pitch for carbon fiber production that can produce carbon fibers excellent in tensile strength at relatively low cost. The raw material pitch for carbon fiber production of the present invention is obtained from coal and is used for producing carbon fibers by melt spinning, and is characterized in that the content of oxygen is 1.0% by mass or more, and the content of toluene-soluble components is 20% Mass% or more. The above-mentioned coal may be bituminous coal or sub-bituminous coal. The raw material pitch for carbon fiber production can be obtained by performing a solvent extraction treatment at a temperature lower than 300°C from a pyrolyzed product of coal in a solvent, and heat-treating the soluble component thus separated at a temperature of 150°C or higher. obtained substance.

Owner:KOBE STEEL LTD +1

Raw material pitch for carbon fiber production

ActiveCN107532086ACheap manufacturingWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCarbon fibersOxygen

The present invention addresses the problem of providing a raw material pitch for carbon fiber production with which it possible to produce carbon fibers having excellent tensile strength relatively inexpensively. This raw material pitch for carbon fiber production is a pitch obtained from coal for producing carbon fibers by melt spinning, the raw material pitch for carbon fiber production characterized in that the content of oxygen is 1.0 mass% or higher, and the content of toluene solubles is 20 mass% or higher. The coal may be bituminous or sub-bituminous coal. The raw material pitch for carbon fiber production may be obtained by heat treatment of a soluble component separated from a thermal decomposition product of coal in a solvent by solvent extraction treatment at a temperature of less than 300C, at a temperature of 150C or higher.

Owner:KOBE STEEL LTD +1

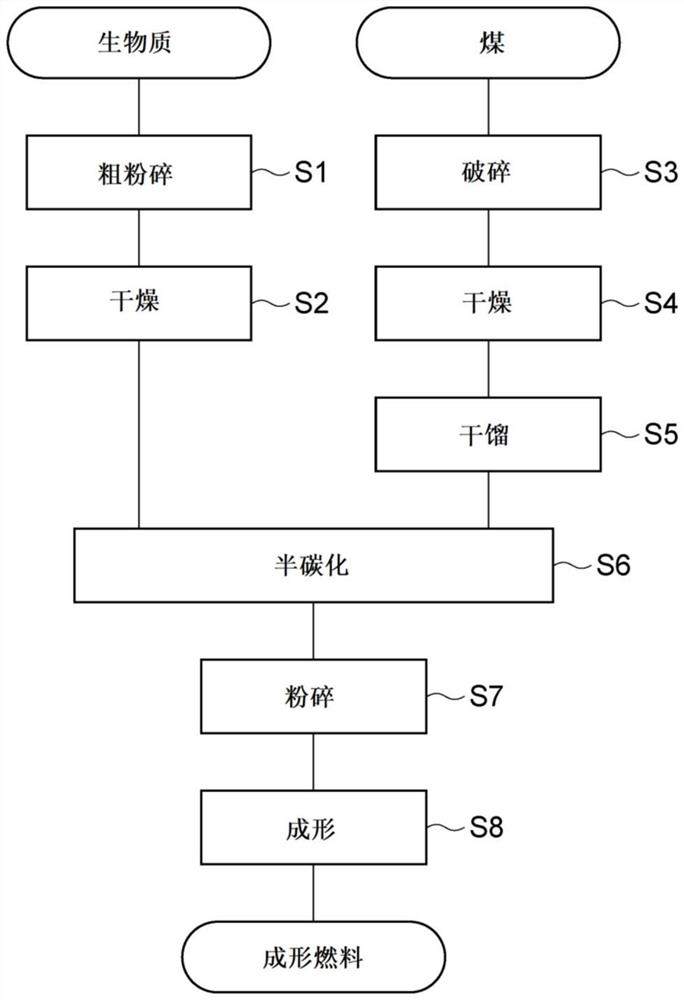

Molded fuel and method for producing same

Provided is a method for producing a molded fuel. The method comprises a carbonization step of carbonizing a coal containing at least one of brown coal and subbituminous coal to produce a carbonized coal; and a molding step of molding a mixture containing the carbonized coal and a biomass semi-carbide produced by the semi-carbonization of a biomass to produce the molded fuel. Also provided is a molded fuel comprising a carbonized coal produced from a coal containing at least one of brown coal and subbituminous coal; and a biomass semi-carbide.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com