Reducing environmental pollution and fouling when burning coal

A clean coal, coal-fired technology, applied in [0017] field, can solve problems such as low heat exchange efficiency and increased operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

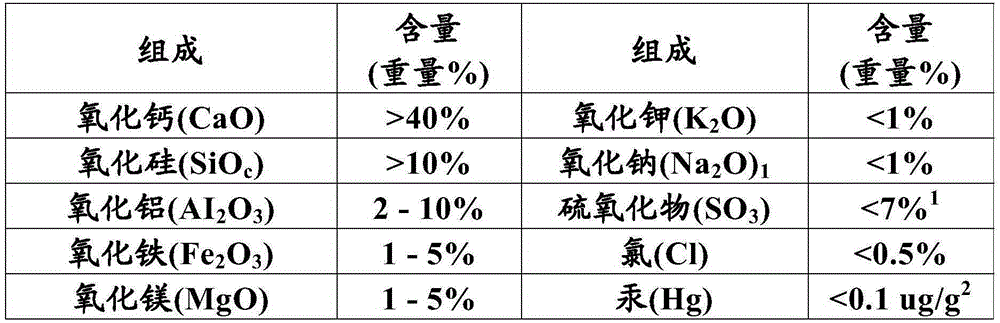

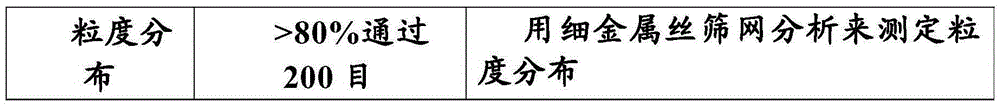

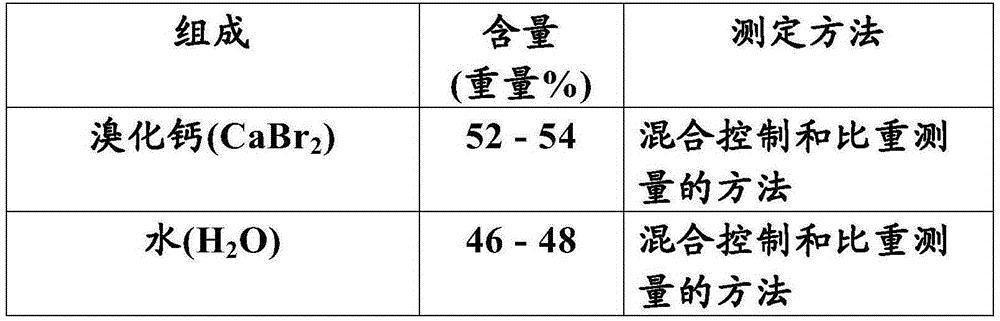

[0124] Below are the required specifications for powder sorbents and halide sorbents for making clean coal from sub-bituminous coal.

[0125] Powder adsorbent:

[0126]

[0127]

[0128] 1. except 7% SO 3 Outside the hard limits, CaO and SO 3 The ratio between should not be lower than 6:1, and preferably should remain greater than 8:1. This ensures enough CaO to absorb the added sulfur.

[0129] 2. In practice, the mercury content in the powder sorbent should be kept less than or equal to the mercury content of the coal being treated.

[0130] Acceptable test methods for oxide analysis are:

[0131] ASTMD3682 Standard Test Method for Major and Minor Elements in Combustion Residues from Coal Utilization Processes

[0132] ASTMC114 Standard Test Methods for Chemical Analysis of Hydraulic Cement

[0133] Acceptable test methods for mercury content are:

[0134] ASTM D6414 Standard Test Method for Total Mercury in Coal and Coal Combustion Residues by Acid Extraction...

Embodiment 2

[0140] A series of experiments were conducted at the Energy and Environmental Research Center's (EERC's) Combustion Test Facility (CTF) to measure NO during the combustion of sorbents for Powder River Basin (PRB) sub-bituminous coal x and Hg emissions. Tests were conducted in support of confirmation that the applied process produced "clean coal," as defined in Section 45 of the Internal Revenue Code. Clean coal as defined in section 45(C)(7)(A) includes fuel that 1) is a solid fuel derived from coal and 2) sold by a taxpayer with a reasonable expectation that the fuel is used for the purpose of generating steam, And 3) the fuel is certified by the taxpayer as producing (when used to generate steam) a "qualified emission reduction".

[0141] Section 45(C)(7)(B) defines the term "qualified emission reduction" to mean at least a 20% reduction in NOx emissions from the combustion of said clean coal compared to the emissions SO 2 Or the emission of Hg is reduced by at least 40%....

Embodiment 2a

[0162]

[0163] *not suitable

[0164] The mercury concentration in the ash of raw coal was 0.558 μg / g and the mercury concentration in the ash of clean coal was 0.833 μg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com