Method for producing carbon fibers

A manufacturing method and technology of carbon fiber, which is applied in the field of carbon fiber manufacturing, can solve the problems of increasing the manufacturing cost of carbon fiber, and achieve the effect of high spinning efficiency and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

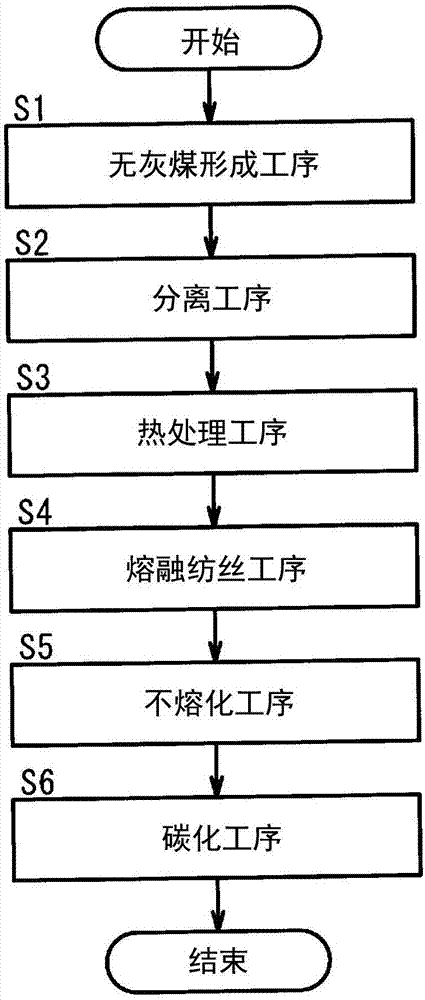

Image

Examples

Embodiment approach

[0073] The above-mentioned embodiments do not limit the configuration of the present invention. Therefore, in the above-mentioned embodiment, omission, substitution, or addition of constituent elements of each part of the above-mentioned embodiment may be made based on the description in this specification and technical common sense, and it should be construed that all of these belong to the scope of the present invention.

[0074] The method for producing carbon fibers of the present invention does not necessarily require the production of ash-free coal from bituminous coal or sub-bituminous coal. That is, in the method for producing a carbon material of the present invention, ash-free coal produced by a third party may be used as a raw material.

[0075] In this method of producing carbon fibers, after the carbonization step, the carbon fibers may be further graphitized by heating in a non-oxidizing atmosphere to a temperature higher than that of the carbonization step.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com