Production method for briquette

A manufacturing method and briquette technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of dust generation, and achieve the effect of excellent safety and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0056]

[0057] Prepare the following 12 binders.

[0058] (1) Aqueous solution of polyvinyl alcohol (polymerization degree: 1700, saponification degree: 99.7 mol%) (polyvinyl alcohol content: 10% by weight)

[0059] (2) Alpha starch (from corn)

[0060] (3) Alpha starch (from tapioca)

[0061] (4) Straight run asphalt

[0062] (5) Soft asphalt (SOP)

[0063] (6) Asphalt A

[0064] (7) Asphalt B

[0065] (8) Vinyl acetate emulsion

[0066] (9) Molasses A (no added slaked lime)

[0067] (10) Molasses B (add slaked lime)

[0068] (11) pulp waste liquid

[0069] (12) Alkaline aqueous solution of humic acid

[0070] (13) Bentonite

[0071] The carbonized coal obtained by carbonization was sieved with a 1 mm sieve, and the above-mentioned binders (1) to (13) were kneaded separately to obtain molding raw materials. Binders (1) and (8) to (13) can be kneaded at room temperature to prepare molding raw materials. On the other hand, the binders (4) to (7) were difficult to...

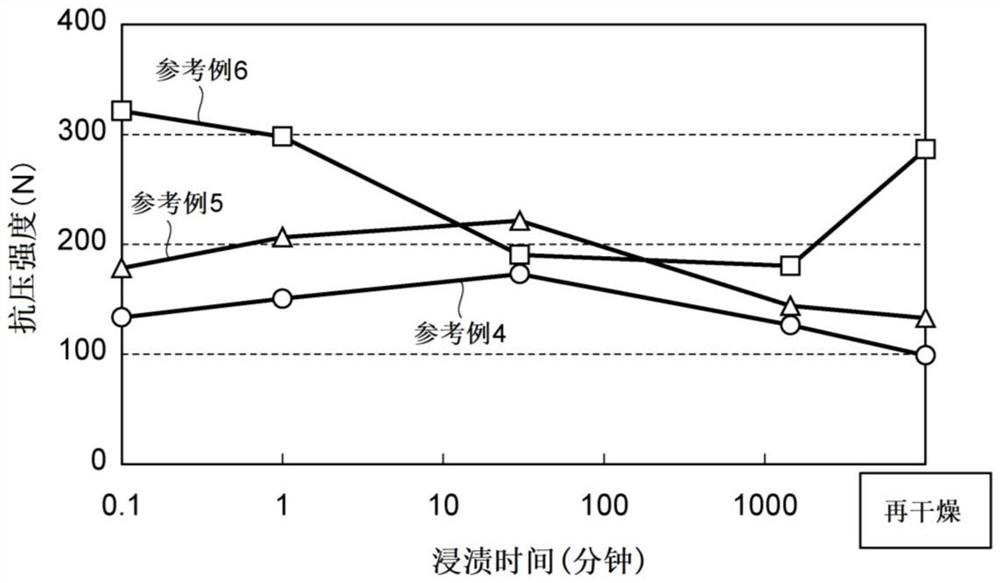

Embodiment 2

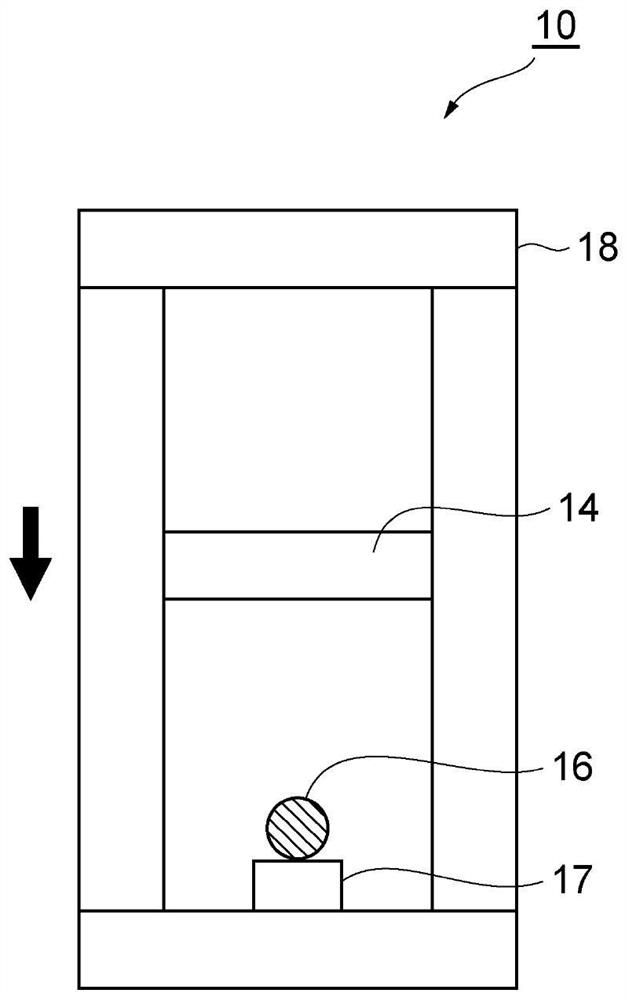

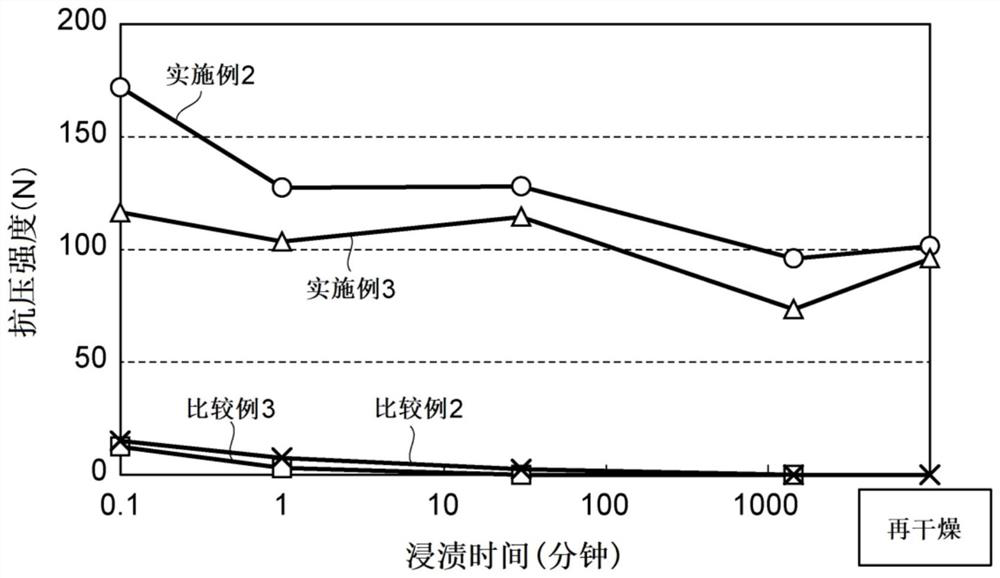

[0081] An aqueous solution (aqueous binder solution) containing polyvinyl alcohol at a concentration of 10% by weight (saponification degree: >99.85 mol%, polymerization degree: 1700), water, and pyrolysis coal used in Example 1 were mixed to obtain a mixture. The compounding ratio based on weight at this time was 30 parts by weight of the binder aqueous solution and 10 parts by weight of water with respect to 100 parts by weight of pyrolysis coal. The mixture was molded using a single-screw press molding machine (molding pressure: 283 MPa) to produce a plurality of coal briquettes (before drying). The water content of this briquette was 27.6% by weight, and the compressive strength (average value of n=2) was 66N. compressive strength use figure 1 measuring device for the measurement.

[0082] Dry the produced briquettes in the air at 80°C for 15 hours. The moisture and compressive strength of the dried briquettes are shown in Table 2. The moisture content of the coal briq...

Embodiment 3

[0089] Except having used polyvinyl alcohol (saponification degree: >99.3 mol%, polymerization degree: 1700) instead of the polyvinyl alcohol used in Example 2, briquette was produced similarly to Example 2, and it measured. The results are shown in Table 3.

[0090] [table 3]

[0091]

[0092] As shown in Table 3, the briquetting coal of Example 3 maintained a compressive strength of 70N or higher even after 24 hours. Example 2 having a high degree of saponification has higher compressive strength than Example 3, and is also excellent in water resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com