Coal gasification system and coal gasification method

A technology of coal gasification and gas, applied in the field of coal gasification system, can solve the problems of pyrolysis gasification reaction furnace not working normally, tar blockage, etc., and achieve the effect of improving the temperature reduction in the furnace and realizing miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

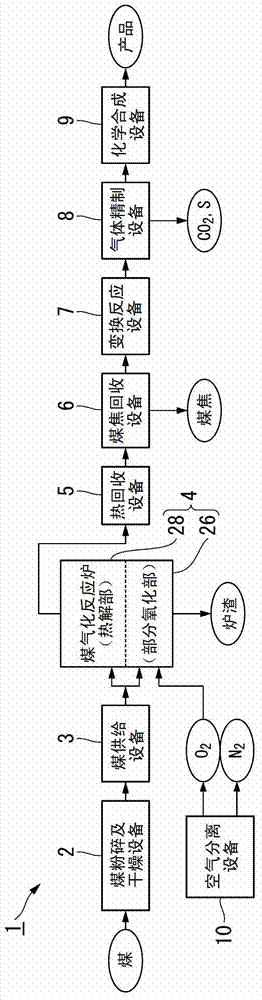

[0047] Below, refer to Figure 1 to Figure 5 The first embodiment of the coal gasification system of the present invention will be described. Such as figure 1 As shown, the coal gasification system 1 is a complete set of equipment that uses coal as a raw material to synthesize a synthetic gas mainly composed of hydrogen and carbon monoxide gas, and finally produces products such as methane, methanol, and ammonia from the synthetic gas. As the coal used in the coal gasification system 1 of the present embodiment, sub-bituminous coal or lignite that contains 20% or more moisture by weight can be used.

[0048] The coal gasification system 1 is equipped with coal drying and crushing equipment (drying device) 2, coal supply equipment 3, coal gasification reactor 4, heat recovery equipment 5, coal char recovery equipment 6, shift reaction equipment 7, gas purification equipment 8, chemical synthesis Equipment 9 and air separation equipment 10.

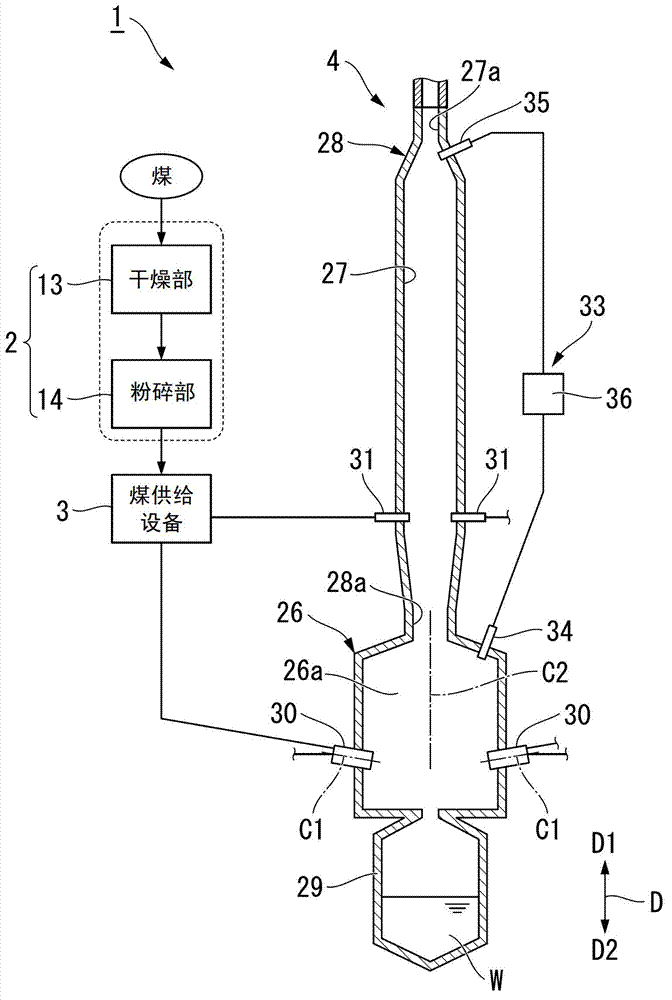

[0049] Such as figure 2 As shown, the ...

no. 2 Embodiment approach

[0114] Next, the second embodiment of the present invention will be described. The same parts as those in the first embodiment described above are given the same reference numerals and their descriptions are omitted, and only the points different from the first embodiment will be described.

[0115] Such as Image 6 As shown, the coal gasification system 41 of the present embodiment includes, in addition to the various components of the coal gasification system 1 of the first embodiment, a device for adjusting the amount of moisture in the coal based on the pressure difference measured by the pressure measuring device 33 Control unit 42.

[0116] The control unit 42 includes a memory and an arithmetic unit not shown. The control unit 42 is electrically connected to the temperature sensors of the pressure measuring device 33, the drying unit 13 and the crushing unit 14. Stored in memory Figure 4 The relationship between the temperature of the temperature sensor of the crushing un...

Embodiment 1

[0129] Using the coal gasification system 1 described above, the temperature in the partial oxidation section 26 is set to 1300°C, and the moisture content supplied from the gasification burner 30 to the partial oxidation section 26 is 18%. The flow rate of oxygen in the example is 650 (kg / h), 345 (Nm 3 / h). Water vapor is not supplied to the partial oxidation part 26.

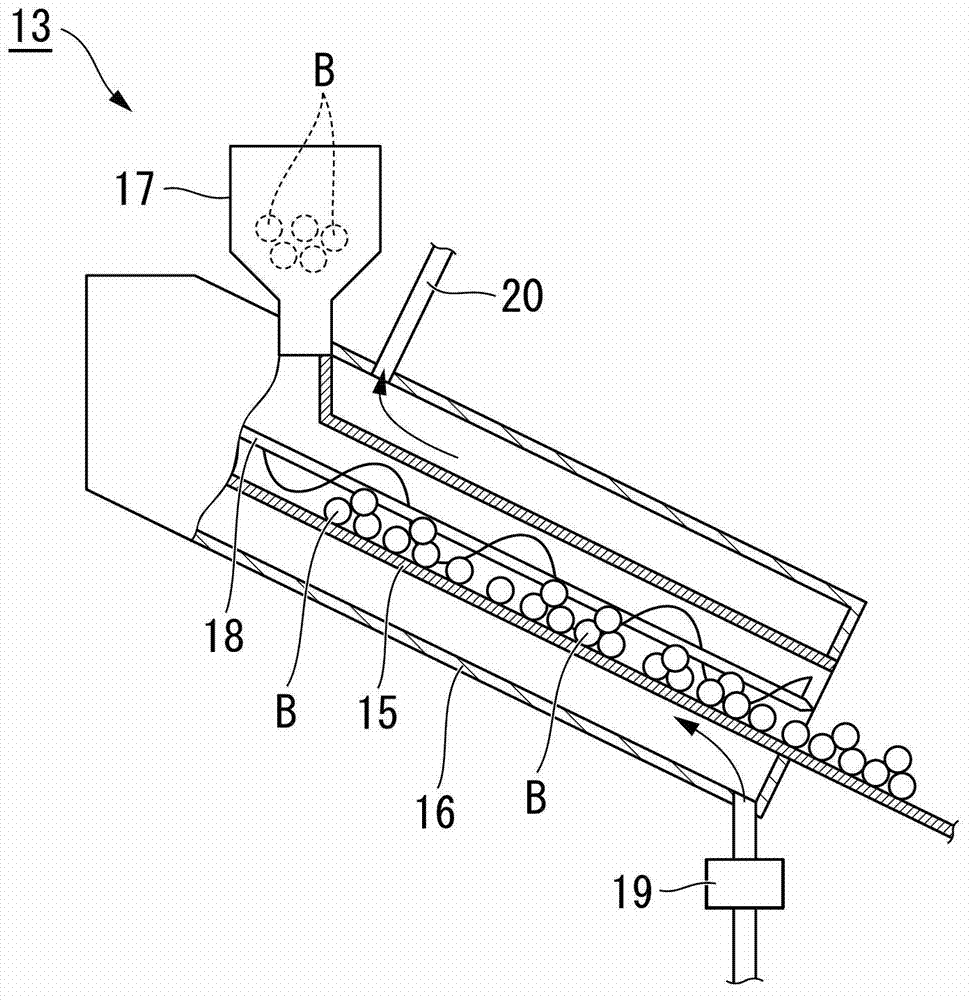

[0130] In addition, the drying device uses image 3 The illustrated device doubles as a pulverizer, and the coal is dried and pulverized to a granular shape of 10 μm or more and 100 μm or less.

[0131] It can be seen that under this condition, when the moisture-regulated coal 150 (kg / h) with a moisture content of 18% is supplied from the nozzle section 31 to the pyrolysis section 28 and steam is not supplied, tar does not adhere to the through hole 27.

[0132] In this way, in the coal gasification system 1 of the embodiment of the present invention, even if devices such as steam nozzles and steam supply pumps are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com