Method for recycling hydrogen peroxide oxidized tail gas

A technology for oxidizing tail gas and hydrogen peroxide, applied in chemical instruments and methods, dispersed particle separation, fractional distillation, etc., can solve the problems of high operation and maintenance costs, easy to exceed the content of aromatics, and large fluctuations in the content of aromatics, reducing the degree of automation and reducing steam Dosage and the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the present invention will be further described in conjunction with the embodiments, but the scope of protection claimed by the present invention is not limited to the scope expressed by the embodiments.

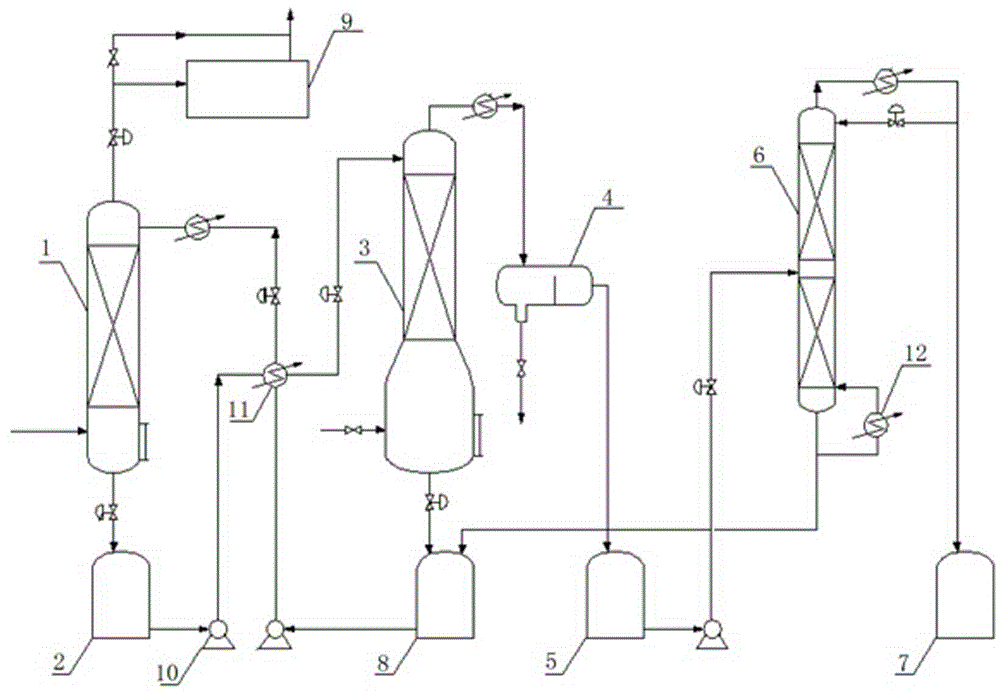

[0018] A hydrogen peroxide oxidation tail gas recovery and utilization device, which is characterized in that it comprises an absorption tower 1, a rich liquid tank 2, a stripping tower 3, a separator 4, a recovery tank 5, a rectification tower 6 and a refining tank 7 which are sequentially connected by pipelines; The device is also provided with a lean liquid tank 8, the discharge port of which is connected to the absorption tower 1, the stripping tower 3 and the rectification tower 6 are equipped with pipes connected to the feed port of the lean liquid tank 8, and the top of the absorption tower is provided with a drain Empty pipe.

[0019] An adsorption tank 9 is provided on the top of the absorption tower 1, and the adsorption tank 9 is filled with carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com