A method and device for concentrating a large graphene oxide solution

A technology of stone oxide and graphene, which is applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of long centrifugation time and poor centrifugation effect, and achieve the effect of not easy to block holes and beneficial to centrifugation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

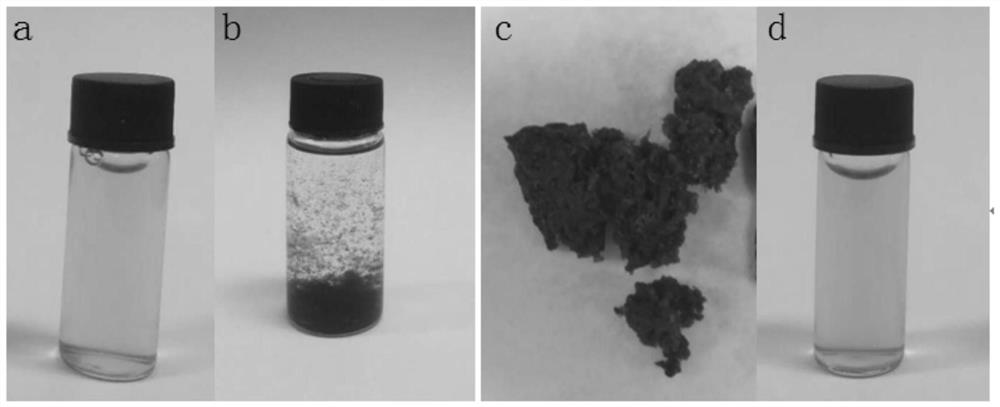

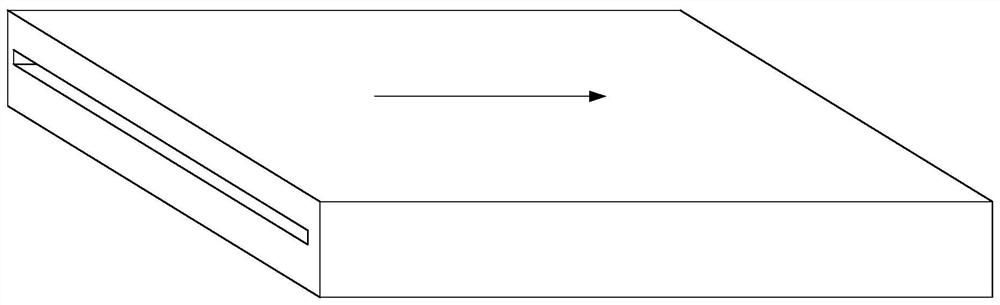

[0015] (1) Inject 4mg / mL large-scale graphene oxide aqueous solution at 20m / s into such as figure 2 Among the slits of the shearing device shown, the height of the slit is 1um, and the shearing time is 2min. After shearing, graphene oxide coagulates, such as figure 1 As shown in b, it can be seen that the graphene oxide aggregates have millimeter-scale diameters.

[0016] (2) After dehydration with bag centrifuge (centrifugal force 6000xG) then, obtain the graphene oxide concentrated solution that concentration is 60mg / mL, as figure 1 as shown in c;

[0017] After the above-mentioned graphene oxide concentrate is redispersed in water, the highly dispersed state of the original graphene oxide is maintained, such as figure 1 shown in d.

Embodiment 2

[0019] (1) Inject 3mg / mL large-scale graphene oxide aqueous solution at 100m / s into such as figure 2 Among the slits of the shearing device shown, the height of the slit is 10um, and the shearing time is 2min. After shearing, the graphene oxide coagulates, and the graphene oxide aggregates have millimeter-scale diameters.

[0020] (2) After dehydration with a bag centrifuge (centrifugal force 17000xG) then, the graphene oxide concentrate obtained with a concentration of 100mg / mL;

[0021] After the graphene oxide concentrate is redispersed in water, the original highly dispersed state of graphene oxide is maintained.

Embodiment 3

[0023] (1) 5mg / mL large-scale graphene oxide aqueous solution is injected into such as 40m / s figure 2 Among the slits of the shearing device shown, the height of the slit is 4um, and the shearing time is 1.5min. After shearing, the graphene oxide coagulates, and the graphene oxide aggregates have millimeter-scale diameters.

[0024] (2) After dehydration with a bag centrifuge (centrifugal force 12000xG) then, the graphene oxide concentrate obtained with a concentration of 80mg / mL;

[0025] After the graphene oxide concentrate is redispersed in water, the original highly dispersed state of graphene oxide is maintained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com