Precise metal mask and etching laser composite manufacturing method thereof

A metal mask and precision technology, which is used in laser welding equipment, metal processing equipment, metal material coating technology, etc., can solve the problem of poor stability of the cusp, poor hole size accuracy, and the accuracy is difficult to reach the accuracy of the laser fabrication method. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

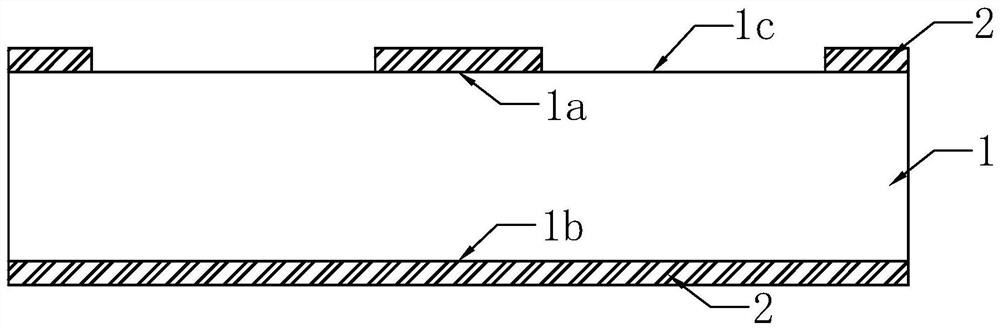

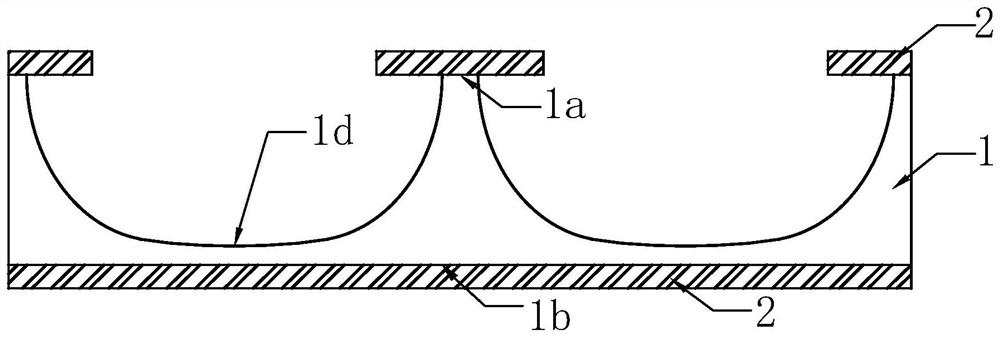

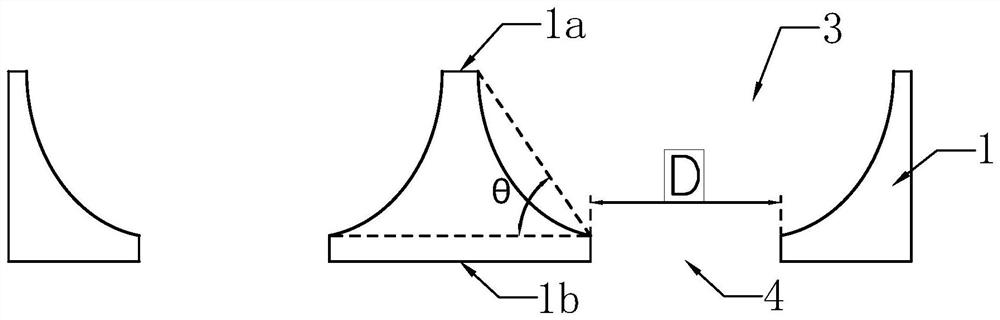

[0026] like image 3 As shown, the precision metal mask includes a metal substrate 1, one side of the metal substrate 1 is the first main surface 1a, and the other side is the second main surface 1b, and several exposure holes are opened on the metal substrate 1 to expose The hole is located on the first main surface 1a and the etching hole 3 is set, and the exposure hole is located on the second main surface 1b to set the laser hole 4. The etching hole 3 and the laser hole 4 overlapping in the center are in a connected state, and the outer opening of the etching hole 3 is large. The inner opening is small, the outer opening and the inner opening are transitioned through the concave arc hole wall, the inclined angle between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com