Distributed driven type rocking sieve

A driving type and drive shaft technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems that affect the running stability of the relaxation screen, the processing technology of the drive shaft is complex, and it is difficult to overcome the inertial force of the screen box. Low mechanical stress, high screening efficiency, and the effect of preventing axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

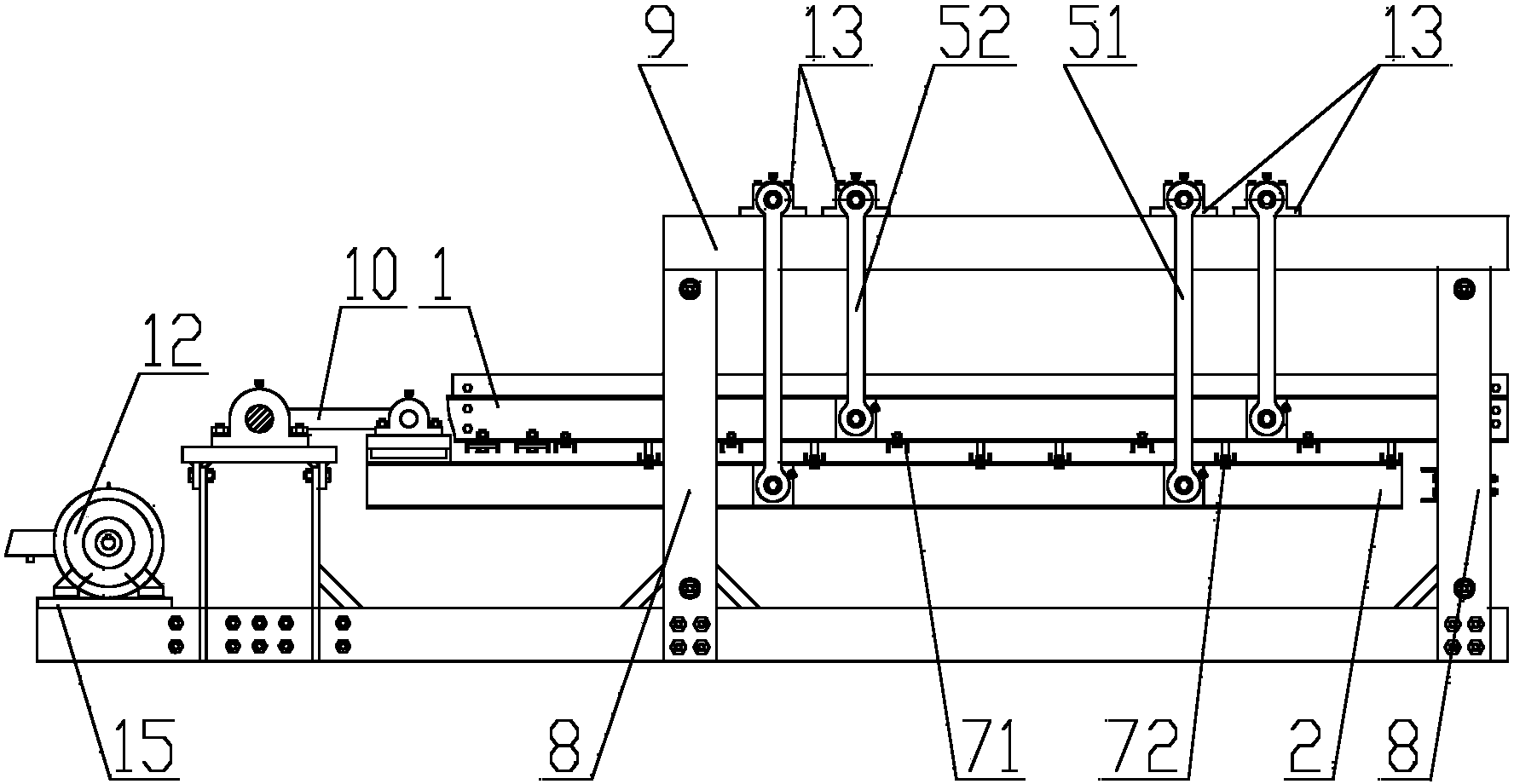

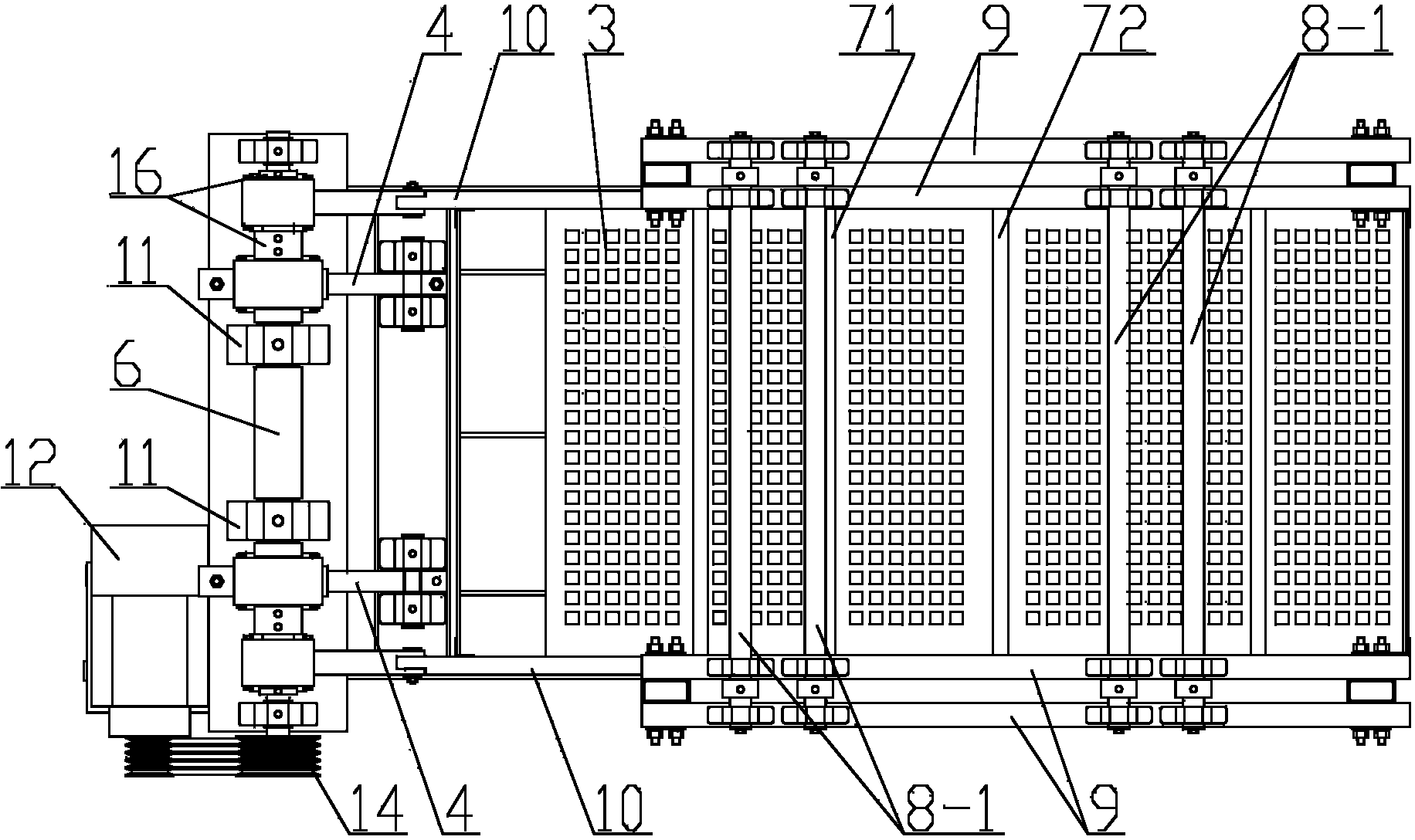

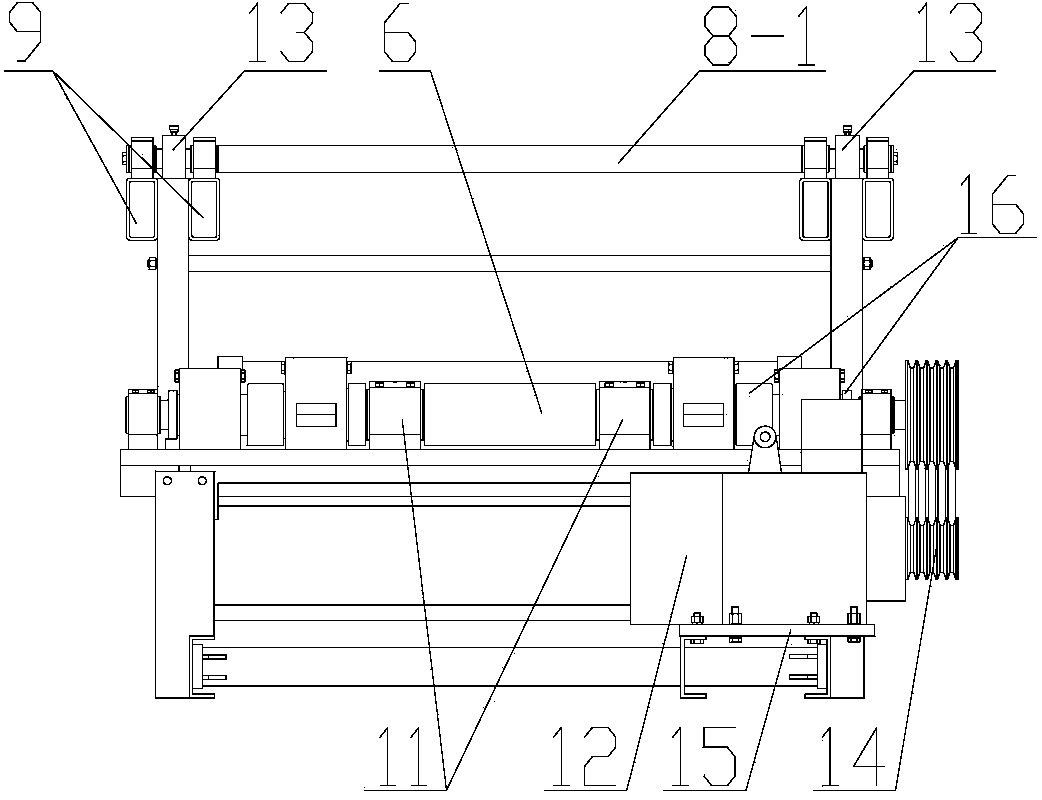

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] like figure 1 , figure 2 , image 3 Shown is a distributed drive swinging screen, including a base, a motor 12, a drive shaft 6, a first crank linkage mechanism 4, a second crank linkage mechanism 10, an inner screen box 1, an outer screen box 2, a first Suspension rod 51, second suspension rod 52 and frame 8, the weight of described inner screen box 1 and outer screen box 2 are equal; Below just each part is described in detail.

[0034] The base and the frame 8 maintain a fixed position, and a bearing seat 11 is fixedly installed on the base; the motor 12 is installed on the base through an adjustable motor base 15, and the motor 12 is driven by a belt transmission mechanism 14 The shaft 6 is connected; as shown in the figure, the connecting section 6-1 of the drive shaft 6 is connected with the pulley of the belt transmission mechanism 14, wherein the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com