Recycled brick aggregate permeable concrete and preparation method thereof

A technology of permeable concrete and recycled bricks, applied in the field of building materials, can solve the problems of polluting the environment, occupying land resources, urban environmental protection and adverse effects of construction, etc., achieving good effects, improving the density of the slurry, and improving the water storage capacity. Effects of Water Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

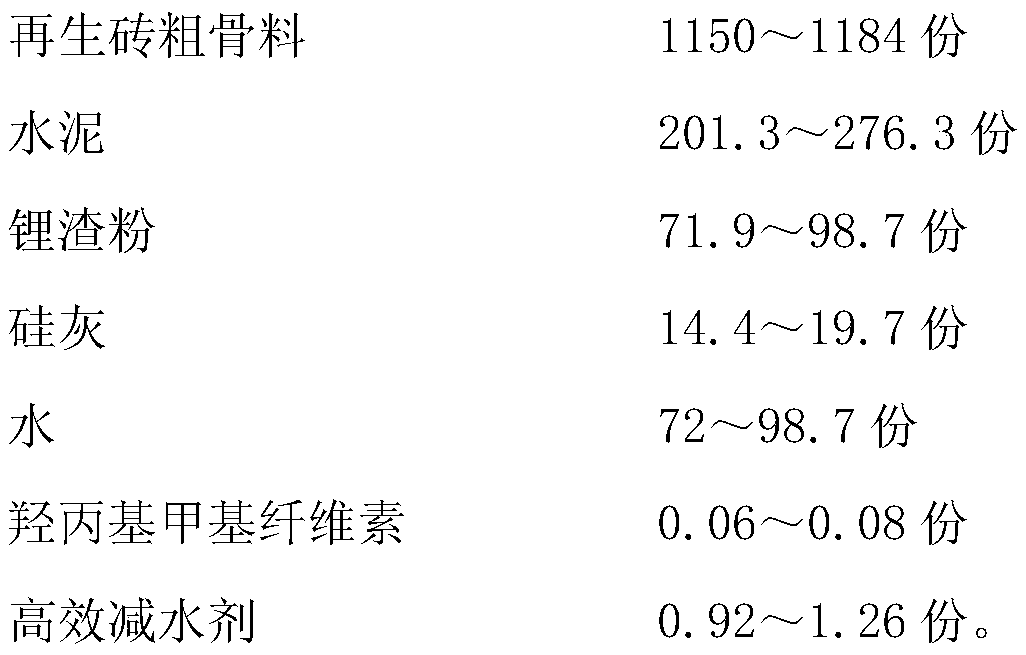

[0032] A recycled brick aggregate water-permeable concrete, the proportion of recycled brick-aggregate water-permeable concrete in terms of mass includes:

[0033]

[0034] The preparation process of the recycled brick aggregate permeable concrete is as follows:

[0035] According to the saturated water absorption rate of the recycled brick aggregate, the recycled brick aggregate is pre-wet 20h in advance, and then placed in a mixer. The cement, lithium slag powder and silica fume are weighed in proportion and added to the forced mixer at a rate of 30r / min. Stir for 60s under the conditions, then add the recycled brick aggregate weighed in proportion and continue to stir for 90s, add water, polycarboxylic acid high-performance water reducing agent, and hydroxypropyl methylcellulose to the mixer at the same time and stir for 120s. Recycled brick aggregate permeable concrete.

example 2

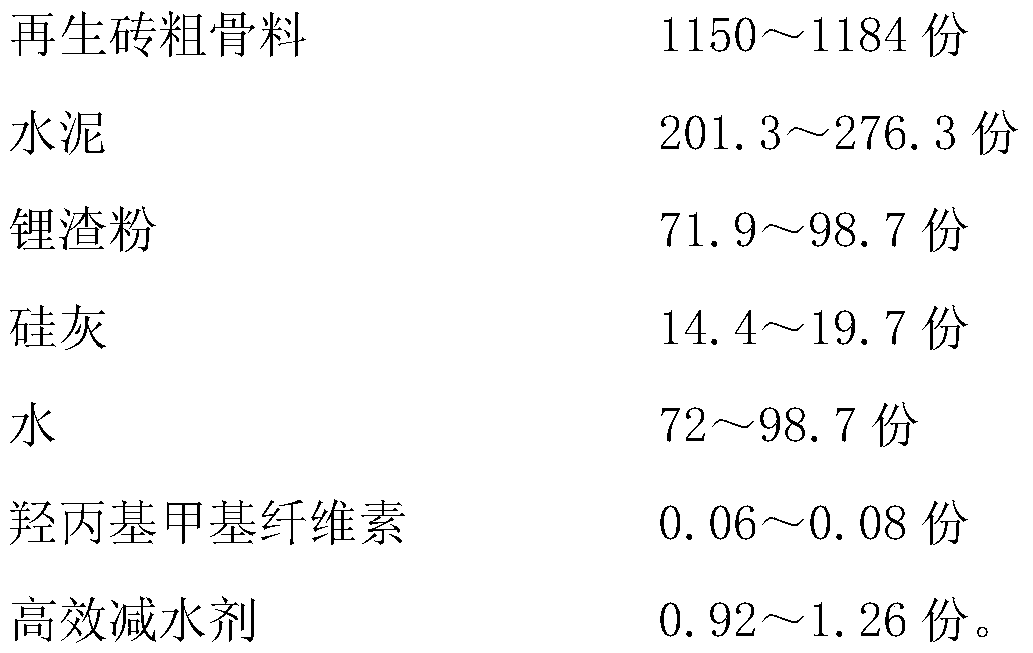

[0037] A recycled brick aggregate concrete. The ratio of recycled brick aggregate concrete by mass includes:

[0038]

[0039]

[0040] The preparation process of the recycled brick aggregate concrete is as follows:

[0041] According to the saturated water absorption rate of the recycled brick aggregate, the recycled brick aggregate is pre-wet 24h in advance, and then placed in the mixer. The cement, lithium slag powder and silica fume are weighed in proportion and added to the forced mixer at a rate of 30r / min. Stir for 30s under the conditions, then add the recycled brick aggregate weighed in proportion and continue to stir for 60s. Add water, polycarboxylic acid high-performance water reducing agent, and hydroxypropyl methylcellulose into the mixer at the same time and stir for 150s. Recycled brick aggregate permeable concrete.

example 3

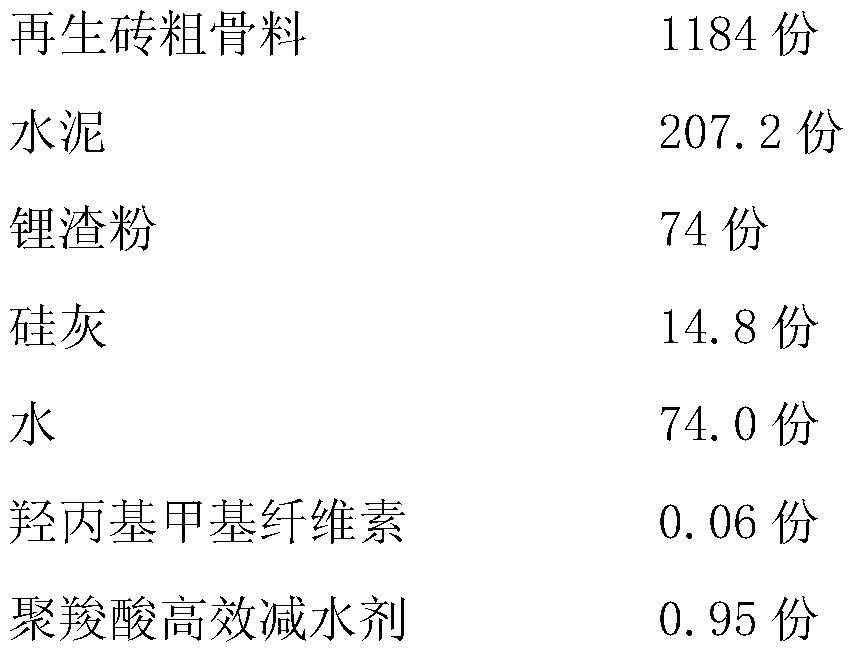

[0043] A recycled brick aggregate water-permeable concrete, the proportion of recycled brick-aggregate water-permeable concrete in terms of mass includes:

[0044]

[0045] The preparation process of the recycled brick aggregate concrete is as follows:

[0046] According to the saturated water absorption rate of the recycled brick aggregate, the recycled brick aggregate is pre-wet 30h in advance, and then placed in a mixer. The cement, lithium slag powder and silica fume are weighed in proportion and added to the forced mixer at a rate of 30r / min. Stir for 30s under the conditions, then add the recycled brick aggregate weighed in proportion and continue to stir for 90s, add water, polycarboxylic acid high-performance water reducing agent, and hydroxypropyl methylcellulose into the mixer at the same time and stir for 150s. Recycled brick aggregate permeable concrete.

[0047] Implementation Effect:

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com