Anti-blocking corrugated plate for screening wet coal slime

A corrugated plate and screening technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of affecting the screening efficiency of vibrating screen, unfavorable wet coal slime screening, wet coal slime screening difficulty, etc., and achieves the goal of using Good effect, not easy to block holes, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Embodiment is described in detail in conjunction with accompanying drawing,

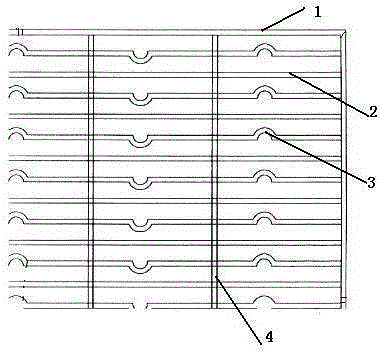

[0008] A specific embodiment of the present invention is an anti-blocking corrugated plate for wet coal slime screening, which includes a sieve plate body 4, the outer frame 1 of the sieve plate is edged by polyurethane, and the horizontal sieve bars on the sieve plate body are corrugated sieves. Bar 3 and linear screen bar 2 are arranged at intervals to form screen holes; the protruding directions of adjacent corrugations on the same corrugated screen bar in this embodiment are opposite.

[0009] Because the sieve plate of the present invention adopts corrugated sieve bars, the sieve hole will form a circular arc transition at the corrugated place, and the wet coal slime around the circular arc hole and the wet coal slime at the ordinary long sieve hole have different movement trends. Under the action of the exciting force, the wet coal slime has a unique running speed and acceleration around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com