Rotary gravel vibrating screen for construction

A technology for building construction and rotary vibrating screen, applied in the direction of filter screen, mixer with rotary stirring device, grille, etc., can solve the problems of reduced work efficiency, unreasonable structure design, poor screening effect, etc. Service life, avoid the decline of the screening rate, and improve the effect of screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

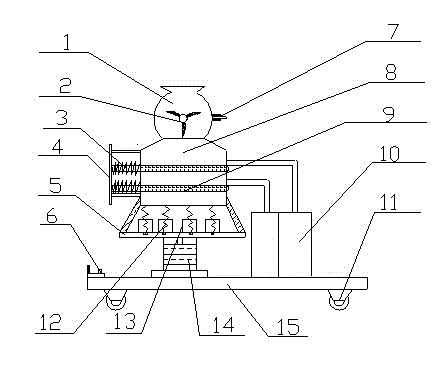

[0011] Such as figure 1 As shown, a sand-gravel rotary vibrating screen for building construction includes a base 15 and a sieve chamber 8 arranged on the base 15, and it also includes a mixing chamber 1, the cross section of the mixing chamber 1 is a circular open opening Structure, the stirring chamber 1 is provided with a feed inlet at the upper end, a stirring impeller 2 is provided in the center of the interior of the stirring chamber 1, and the input end of the stirring impeller 2 is connected to a driving motor. The sand and gravel particles are stirred and separated to facilitate the next step of screening; the lower end of the stirring chamber 1 is connected to the sieve chamber 8, and the sieve chamber 8 is provided with two layers of filter screens 9 in parallel. The mesh of 9 decreases from top to bottom. One side extension of the filter screen 9 is connected to the compression spring 3. The compression spring is provided so that the filter screen can move back and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com