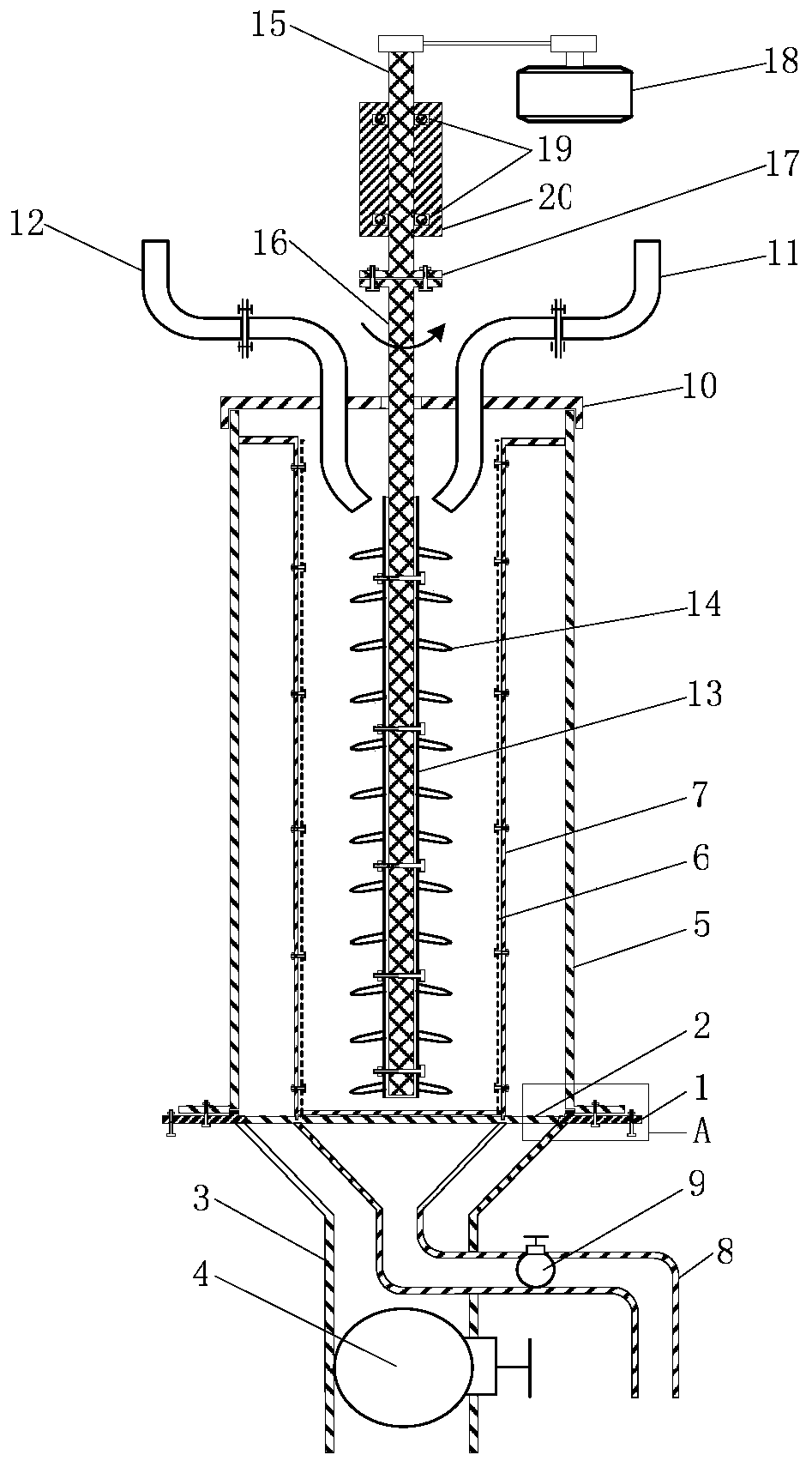

Cyclone Classification Column and Its Method for Classifying Ore Pulp Coarse and Fine Particles

A swirl classification and coarse particle technology, applied in swirl classification column and its application to classify coarse and fine particles of pulp, non-ferrous metal mine concentrator classification operation field, can solve the problem of strict use conditions, easy blockage of grit nozzle, low classification accuracy, etc. problems, to achieve the effect of small footprint, not easy to block holes, and high grading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

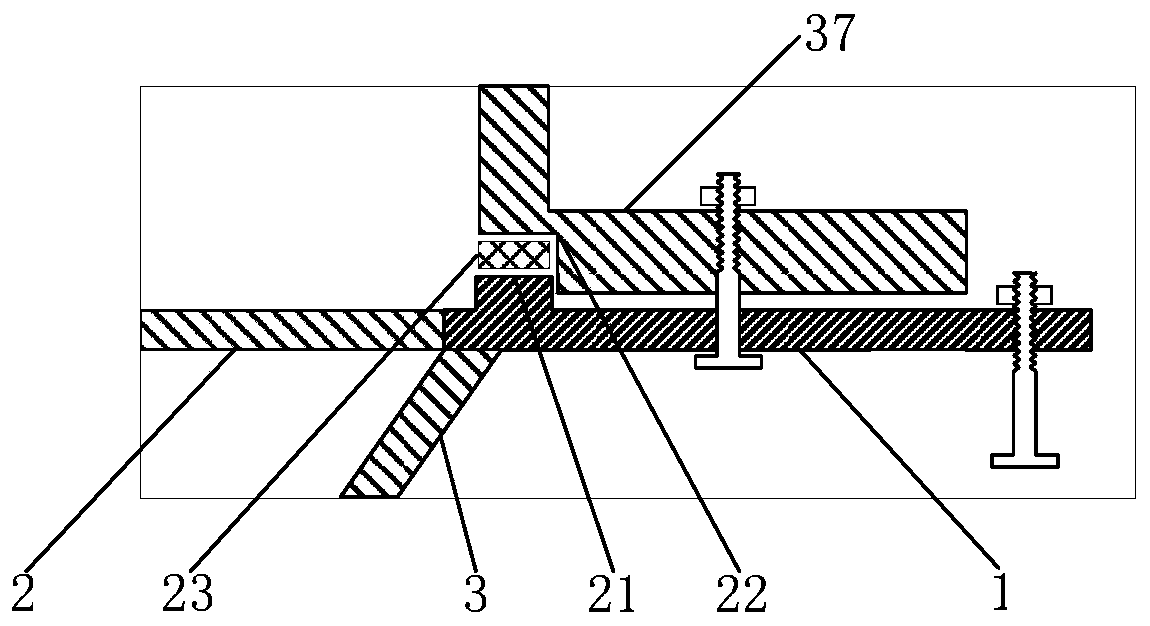

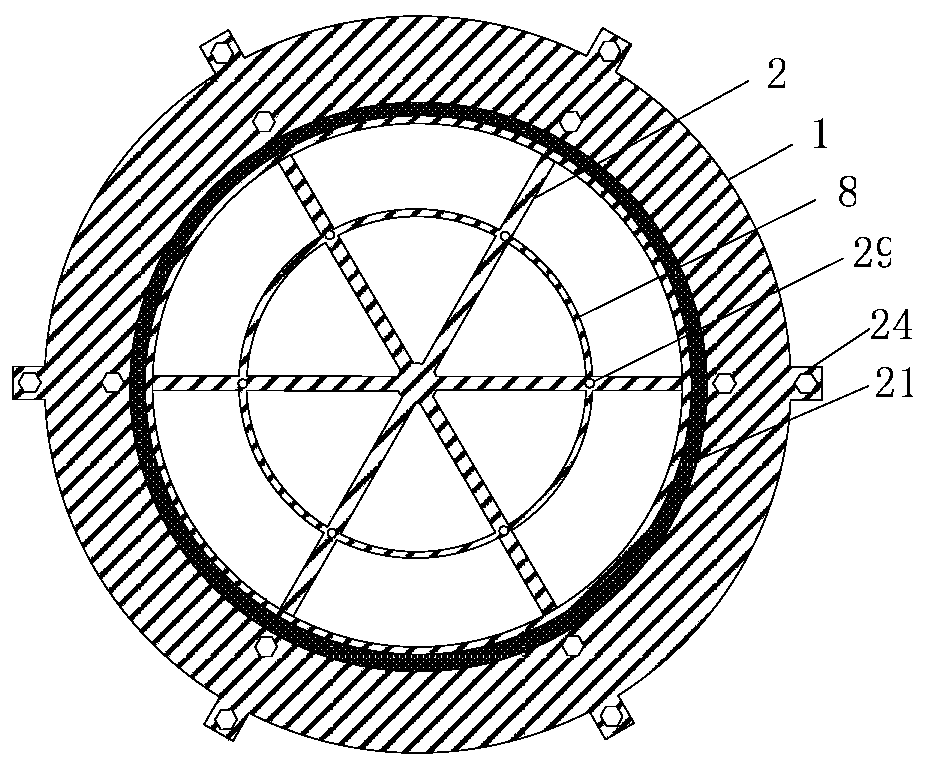

Method used

Image

Examples

Embodiment 1

[0051] The device and method of the present invention are used to classify the overflow product (the raw ore of this embodiment) of the hydrocyclone of a large-scale state-owned enterprise in Jiangxi Province, a copper mine dressing plant. The useful minerals composed of raw ore are mainly chalcopyrite and pyrite, and the gangue minerals are mainly quartz, calcite magnetite and hematite. The raw ore density is 3.25g / cm3, and the raw ore particle size composition is shown in Table 1.

[0052] Table 1:

[0053] Grain fraction / mm Yield / % Cumulative yield under sieve / % -0.833+0.351 10.98 100.00 -0.351+0.147 13.04 89.02 -0.147+0.074 17.70 75.98 -0.074 58.28 58.28 total 100.00

[0054] Adopt device of the present invention, the operation step of classification is as follows:

[0055] According to step A: keep the water level 10cm lower than the upper end of the cylindrical screen, and keep the water in and out in balance;

[0056]...

Embodiment 2

[0066] The raw ore of present embodiment is with embodiment 1.

[0067] Adopt device of the present invention, the operation step of classification is as follows:

[0068] A step is with embodiment 1;

[0069] According to step B: adjust the rotational speed of the central shaft to 1000r / min;

[0070] According to step C: add ore pulp (mass concentration is 35%, and the addition speed is 4kg / min measured by dry ore) from the ore feeding pipe, and the continuous addition time of ore pulp is 30min;

[0071] D step and E step are with embodiment 1.

[0072] The calculation results of Example 2 are shown in Table 3.

[0073] table 3:

[0074] Grain fraction / mm Raw ore yield / % Fine particle product / % Coarse particle product / % E quality efficiency / % E volume efficiency / % -0.351 89.02 100.00 50.42 87.45 87.45 -0.147 75.98 85.69 38.65 42.22 89.50 -0.074 58.28 68.95 19.25 34.46 92.91

[0075] According to Table 3, the classificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com