Patents

Literature

52 results about "Computer pattern recognition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recognition method of digital music emotion

InactiveCN101599271AImprove recognition efficiencyAdd nonlinearityCharacter and pattern recognitionSpeech recognitionMusic and emotionComputer pattern recognition

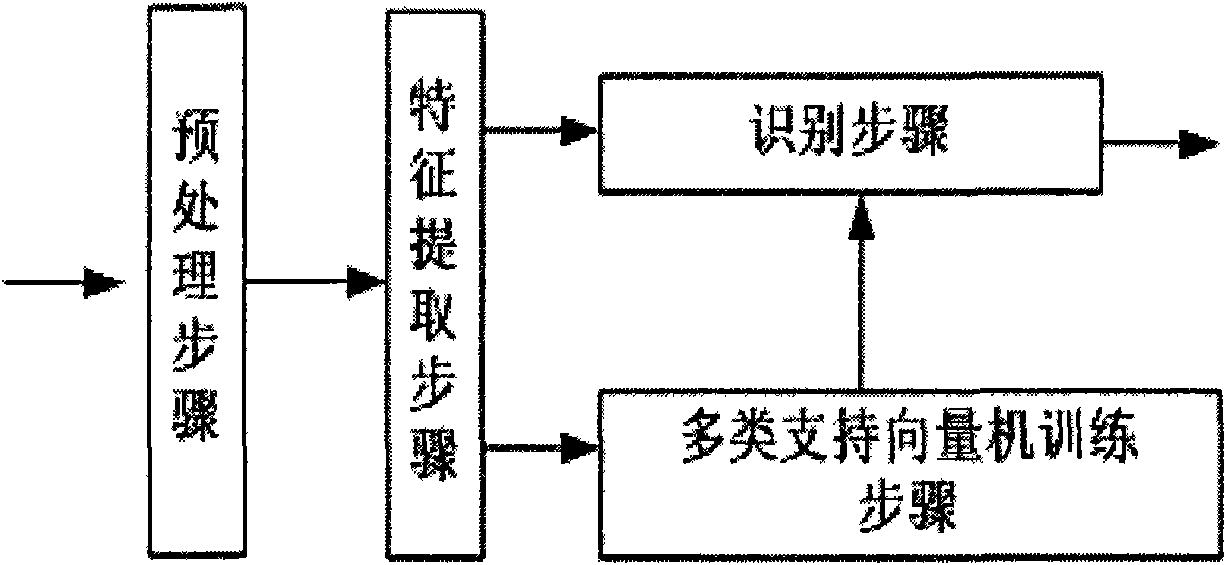

The invention relates to a recognition method of digital music emotion, belonging to the field of computer pattern recognition; the recognition method solves the problem that the existing recognition method of digital music emotion can not recognize sampling-based digital music format, the sorting technology based on a multi-class support vector machine is adopted, acoustic characteristic parameters and music theory characteristic parameters are combined, so as to carry out emotion recognition of digital music; the recognition method comprises the following steps: (1) pretreatment; (2) characteristic extraction; (3) training the multi-class support vector machine; (4) recognition. The music emotion is classified into happiness, impassion, sadness and relaxation, the emotion recognition is carried out based on a sampling-based digital music format file, the common acoustic characteristics in the speech recognition field are not only extracted, and a series of music theory characteristics are extracted according to the theory characteristics of music; meanwhile, the sorting method based on the support vector machine is adopted, the leaning speed is rapid, the sorting precision ratio is high and the recognition efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

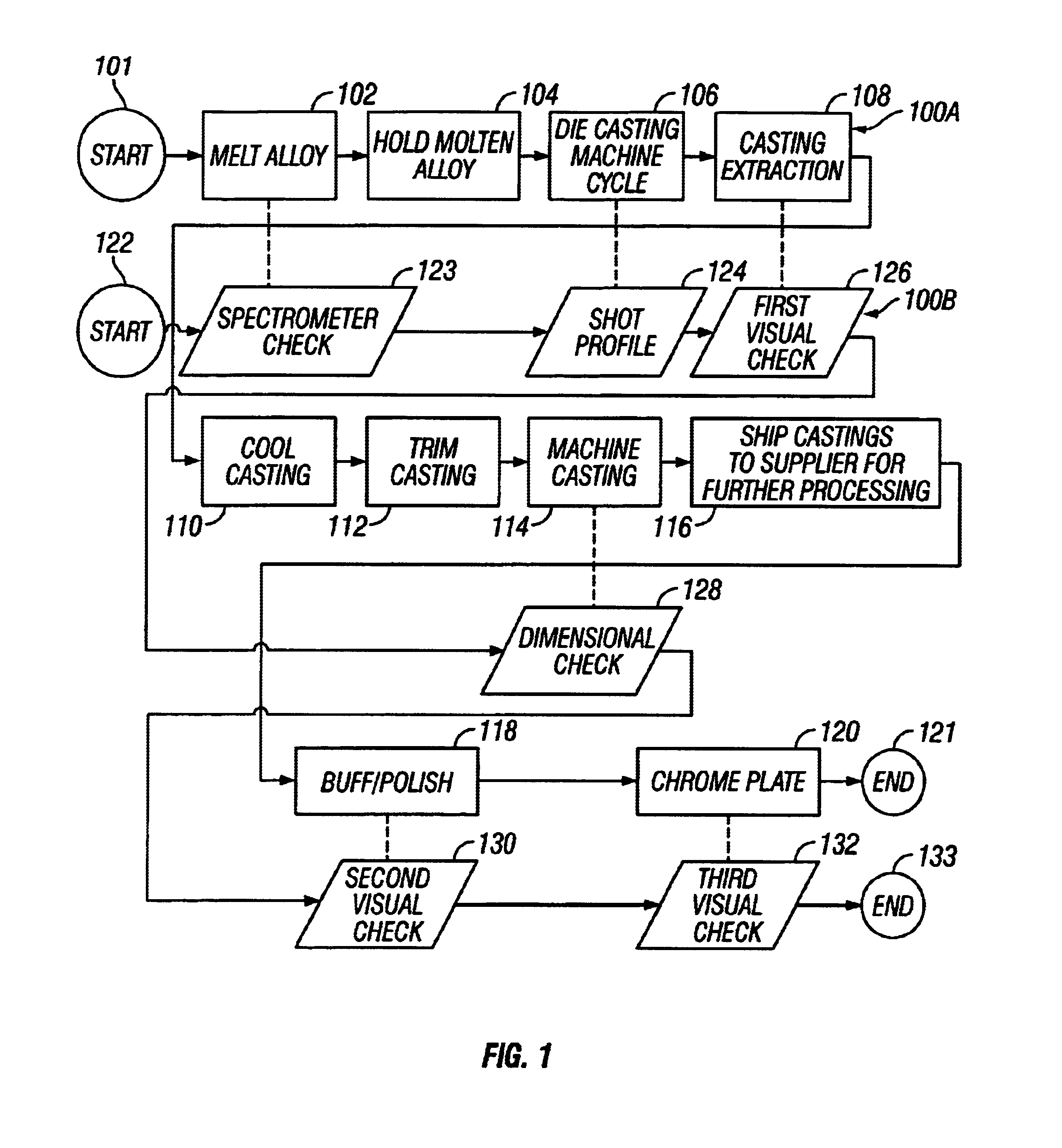

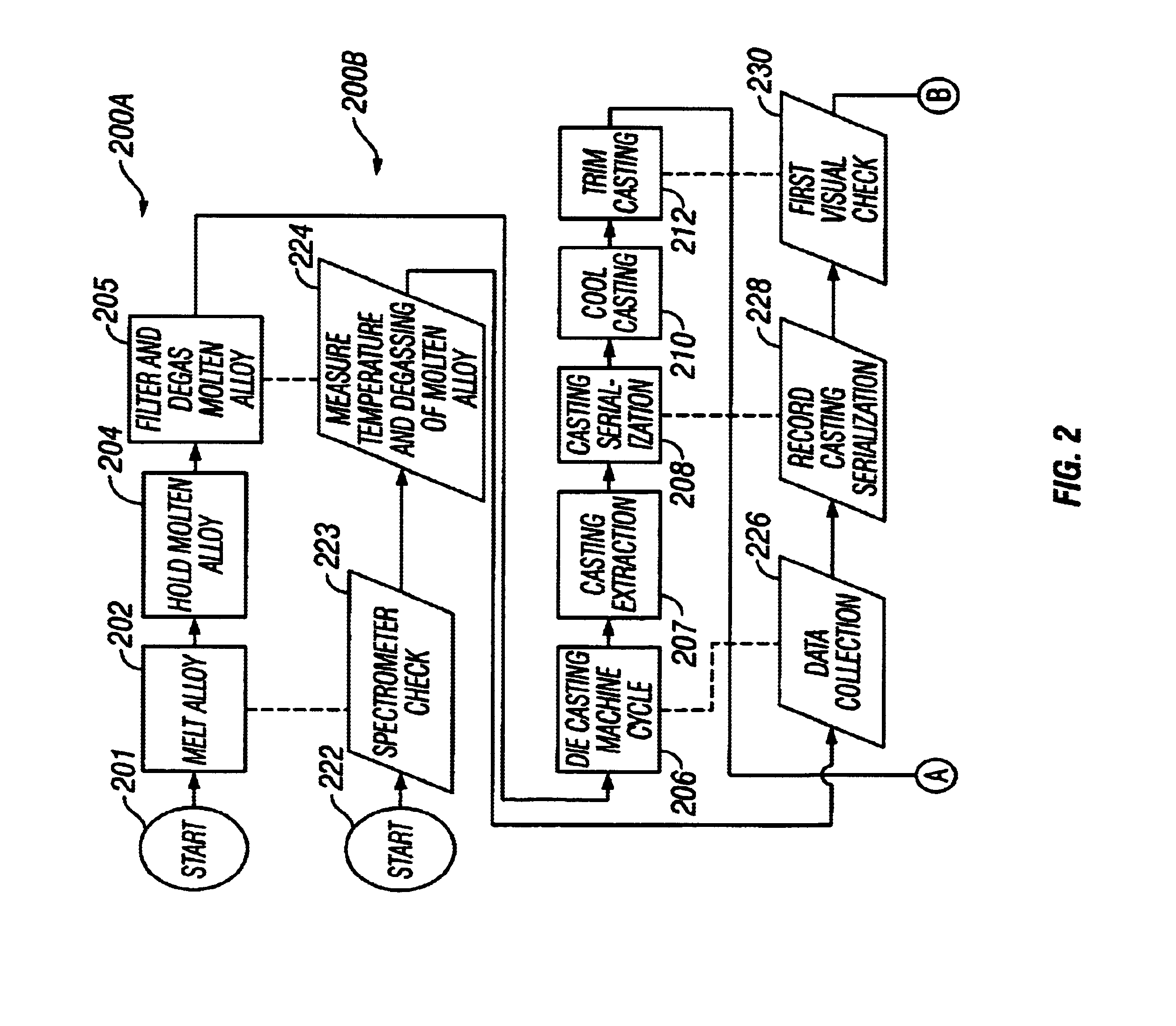

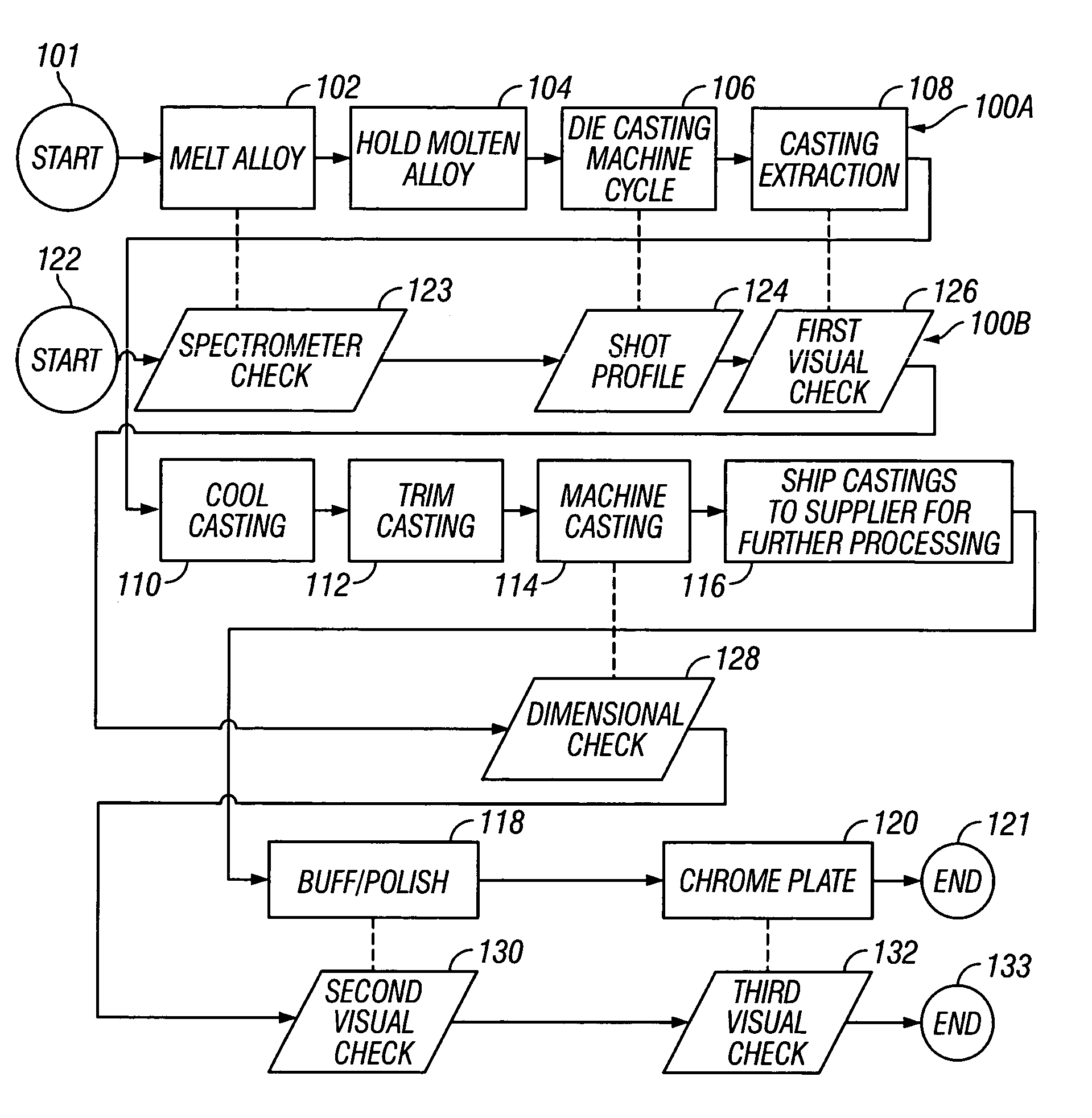

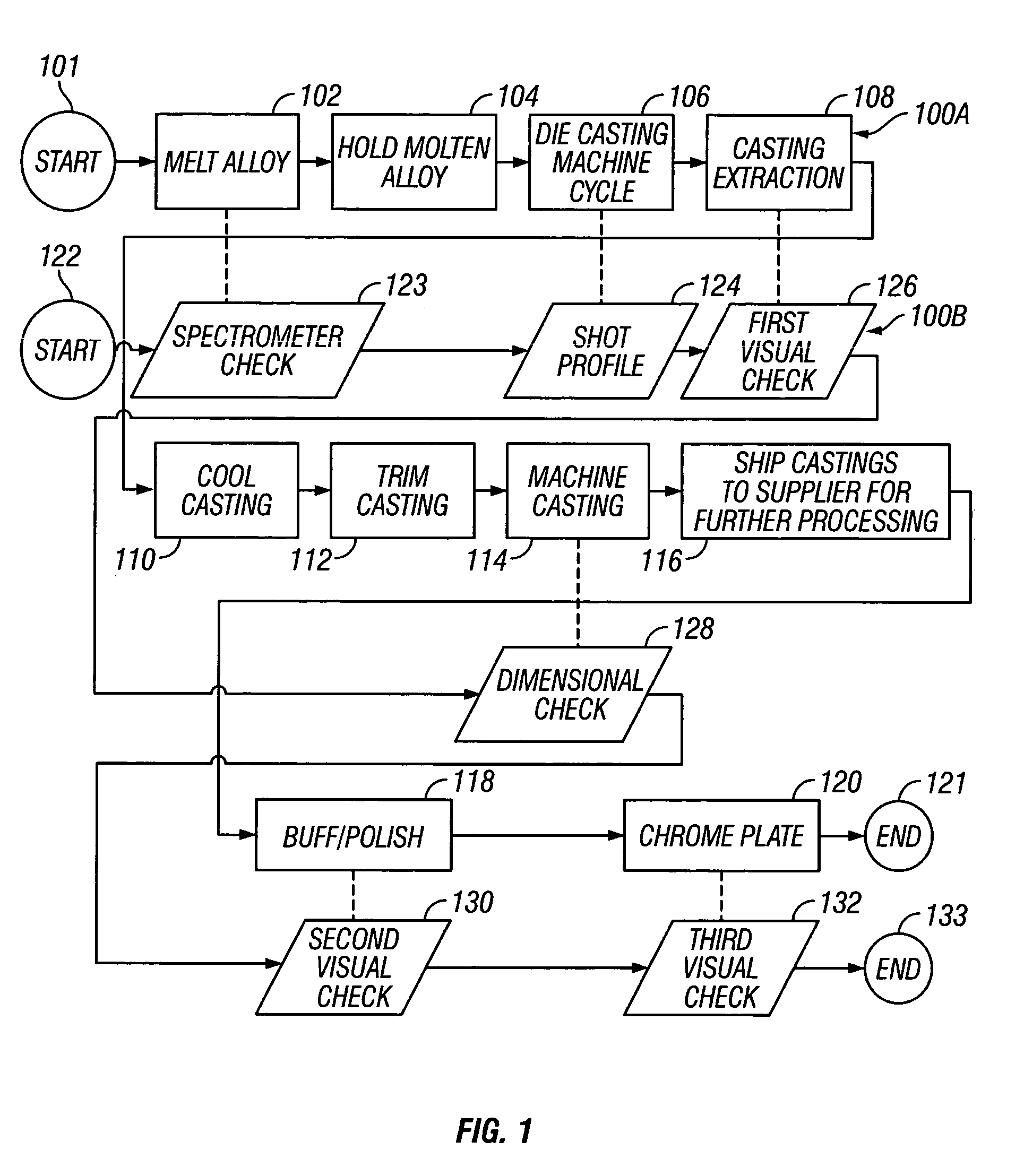

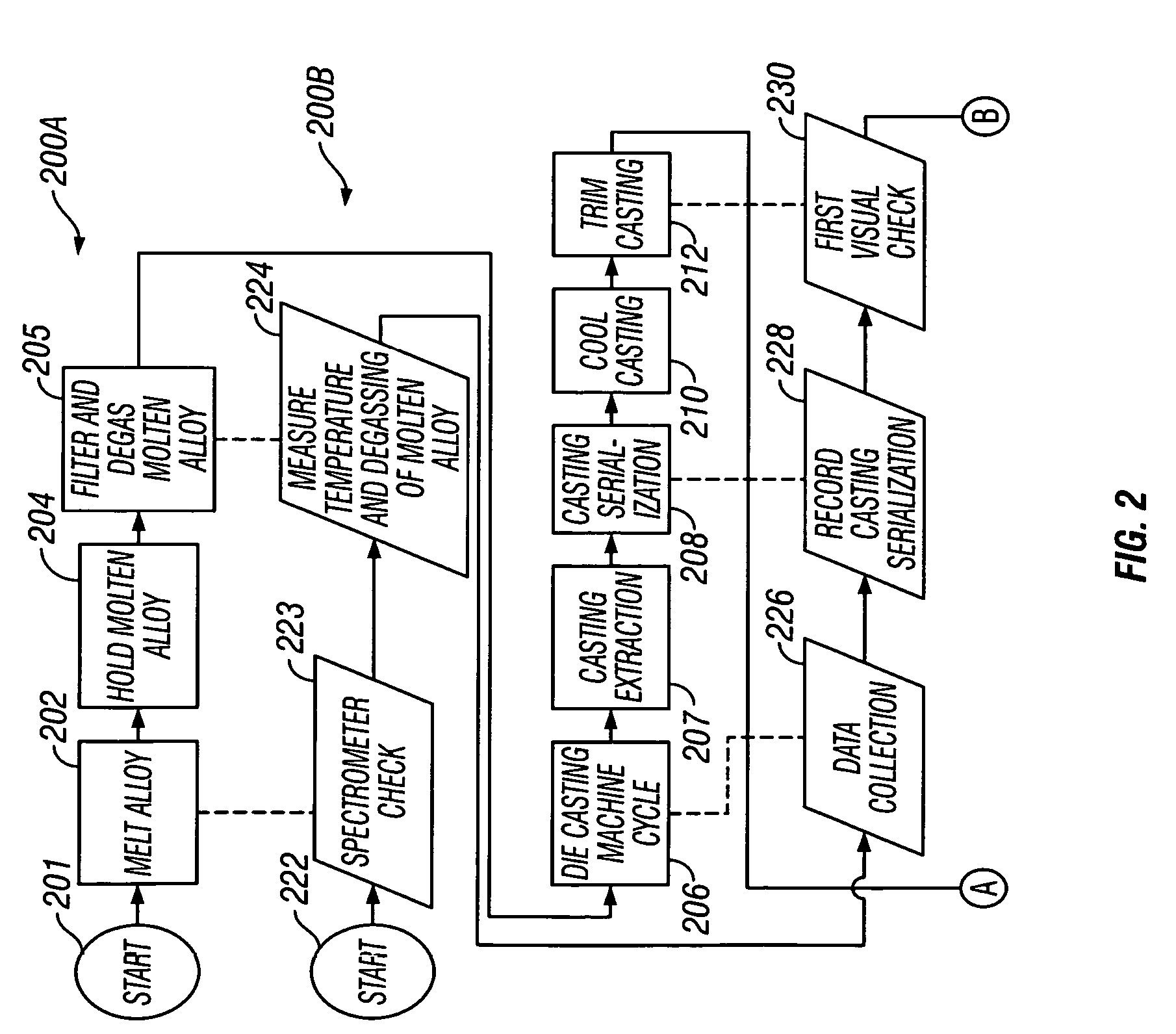

Die casting process incorporating computerized pattern recognition techniques

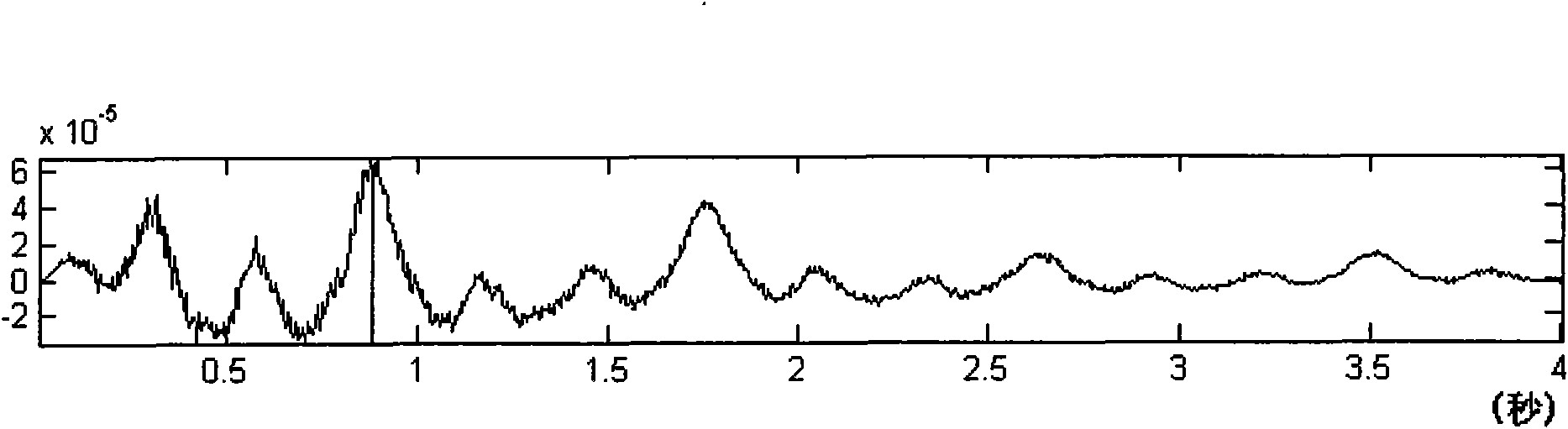

A die casting process using pattern recognition techniques to identify those die castings manufactured under conditions likely to produce a die casting which would subsequently prove unacceptable for use. By promptly identifying such die castings, they may be discarded before being shipped to a remote facility for further processing. As a result, the rejection rate of die castings at the remote facility may be reduced and the raw materials used to form the discarded die castings may be more readily recycled.

Owner:PACE IND LLC A DELAWARE CO

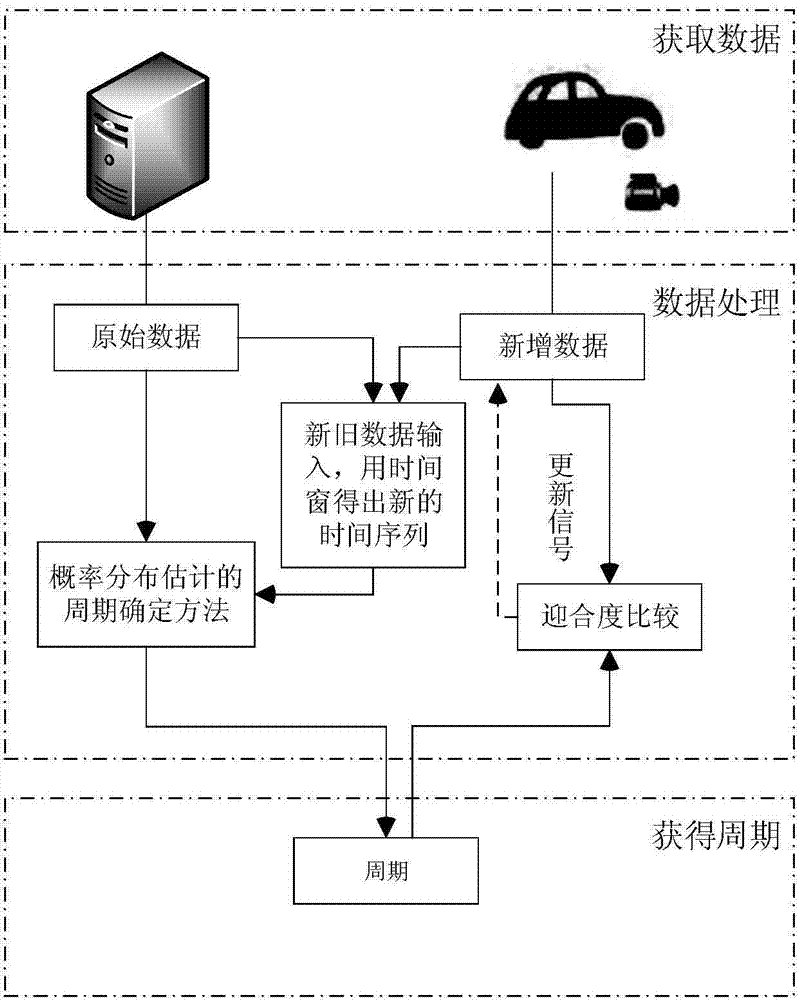

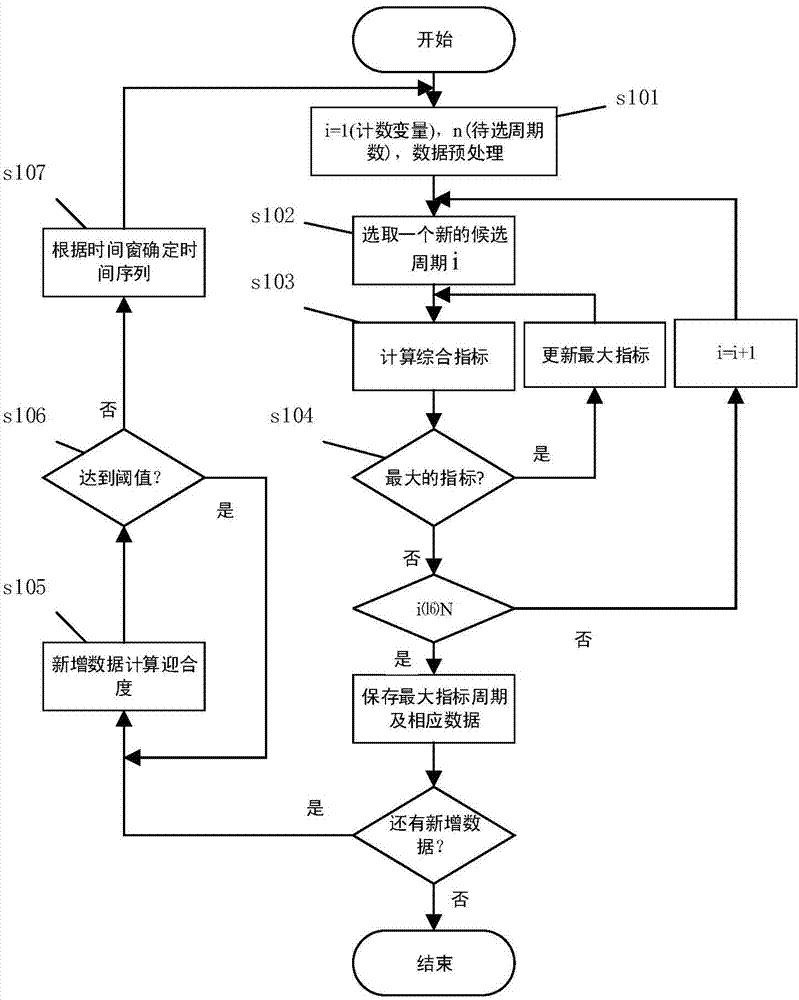

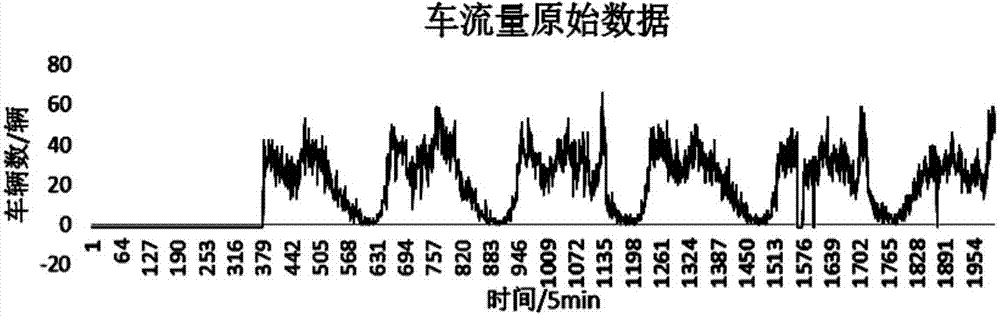

Cycle mining method of time series data

ActiveCN104750830ASolve the problem of uneven observation dataImprove real-time performanceSpecial data processing applicationsData dredgingObservation data

The invention discloses a cycle mining method of time series data and belongs to the technical field of computer mode recognition and data mining. The invention provides the cycle mining method of traffic flow data aiming at overcoming the shortcoming that in the prior art, under the condition that observed data are not even, an accurate cycle cannot be obtained easily. A probability distribution estimation mode is used for carrying out cycle mining, under the condition that the observed data are not even, the accurate cycle can be obtained, an algorithm is simple, and real-time performance is good. On the basis, an on-line incremental updating mode is further used to solve a real-time cycle updating problem, accordingly resources expended on on-line cycle updating are low, and time used on on-line cycle updating is short. The method is especially suitable for cycle mining of a time series where a large amount of data missing exist, such as cycle mining of traffic flow data, hydrology data, climate data and seismological observation data, and a cycle can be obtained quickly and accurately.

Owner:SOUTHEAST UNIV

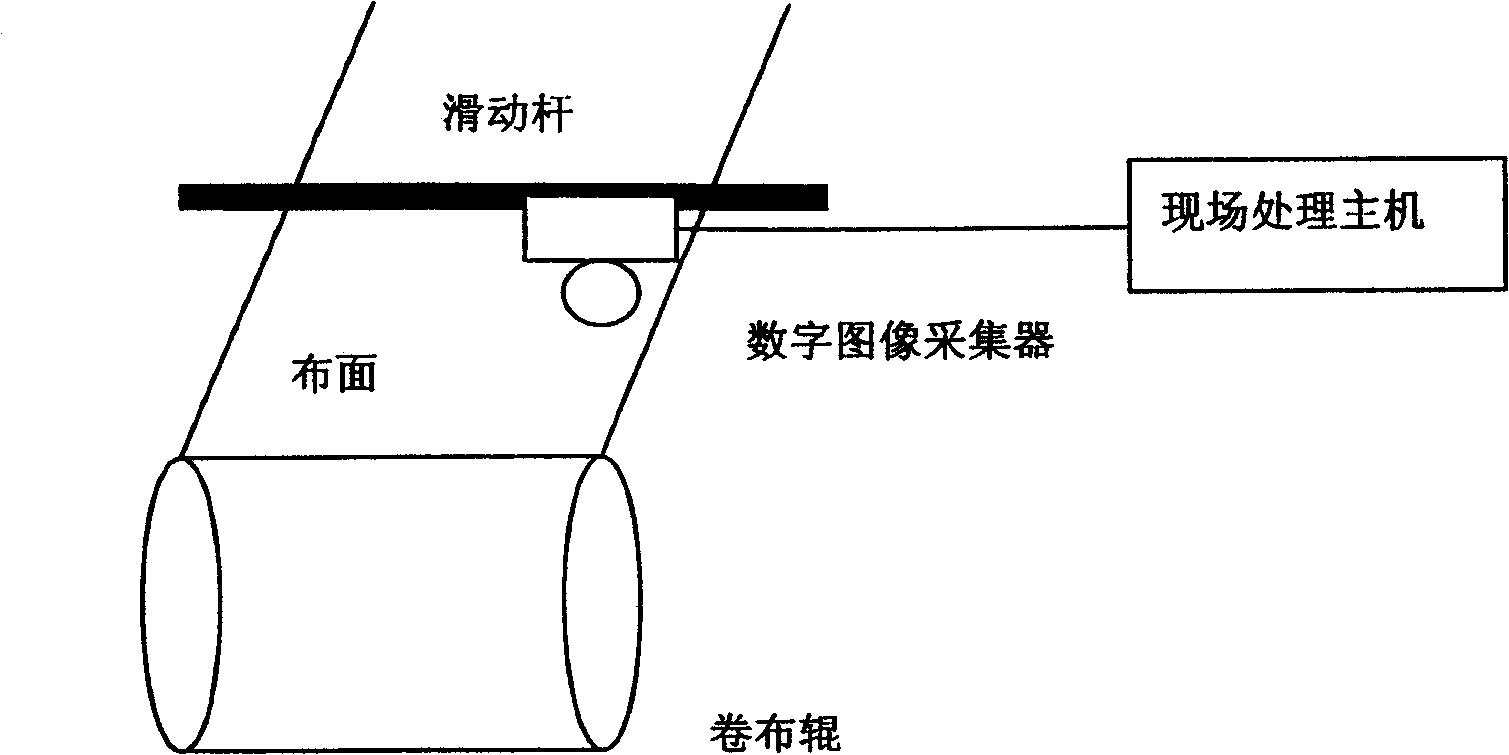

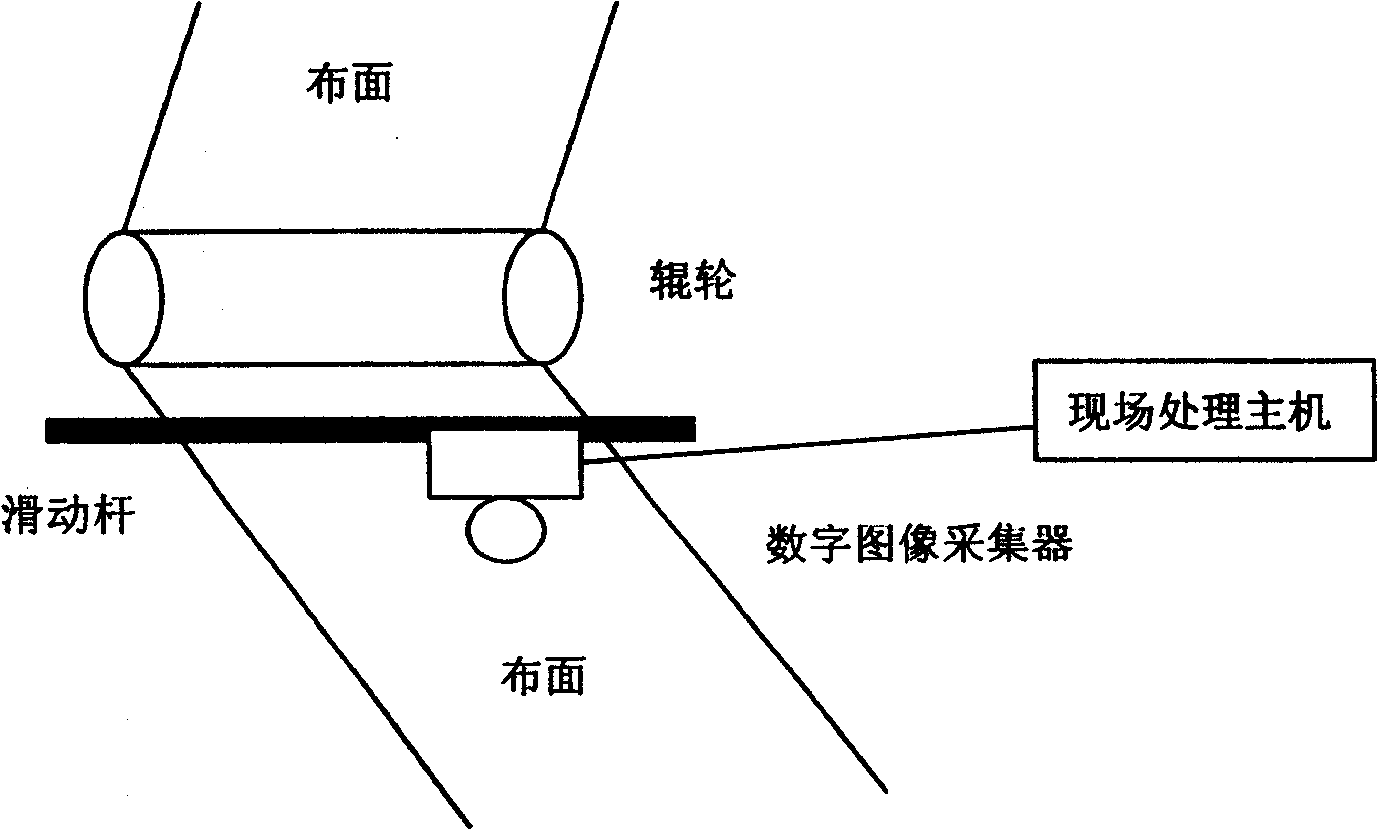

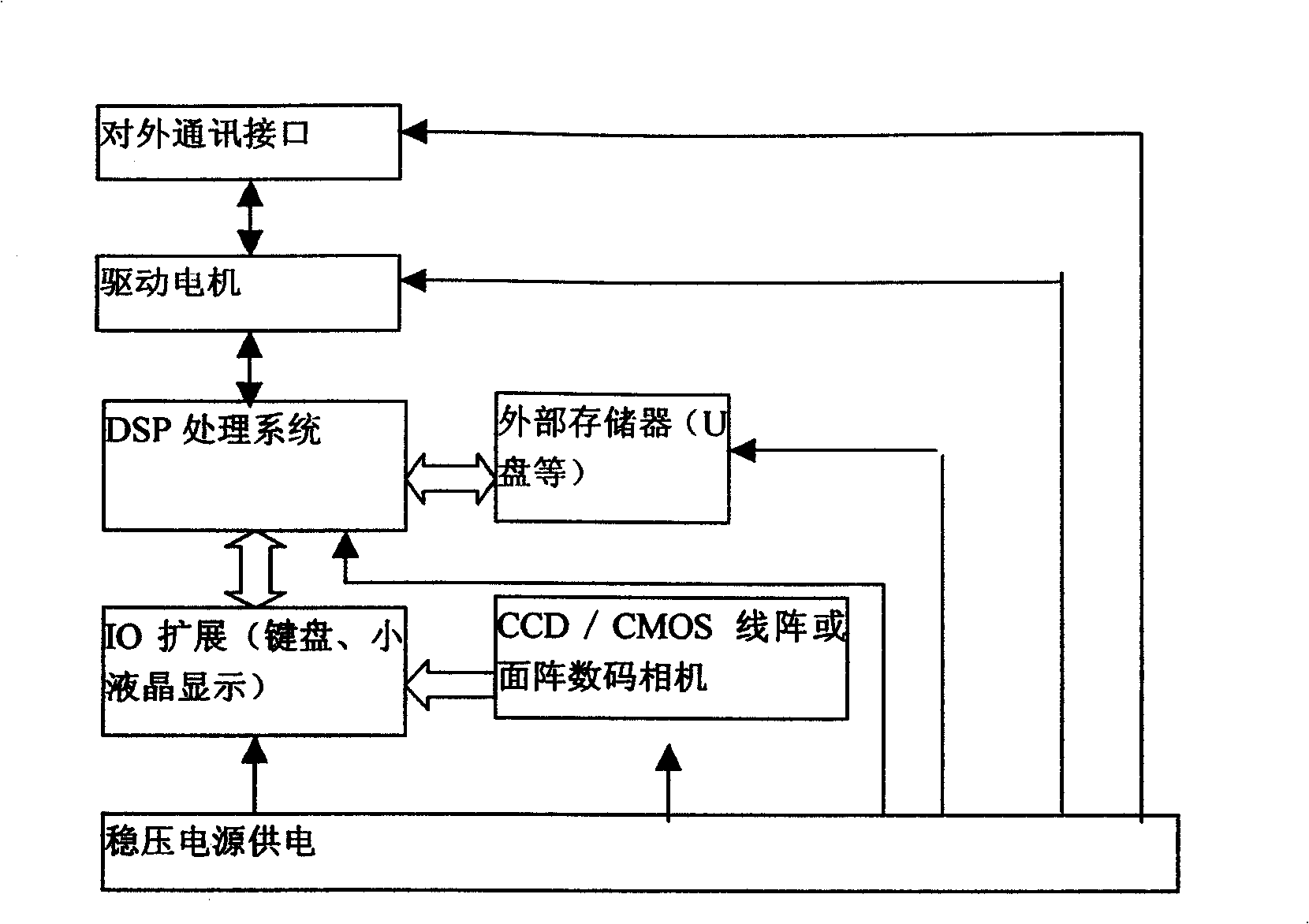

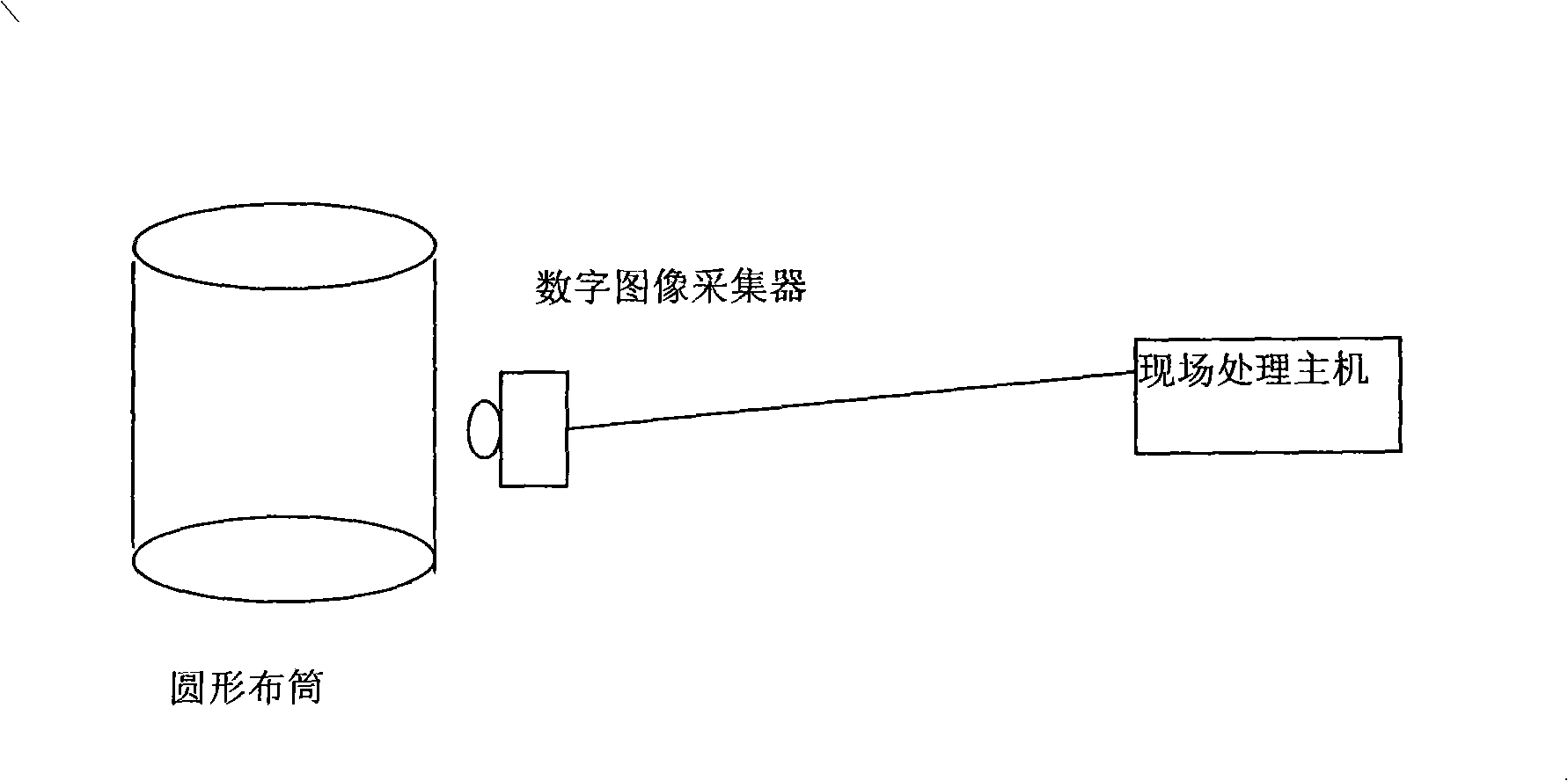

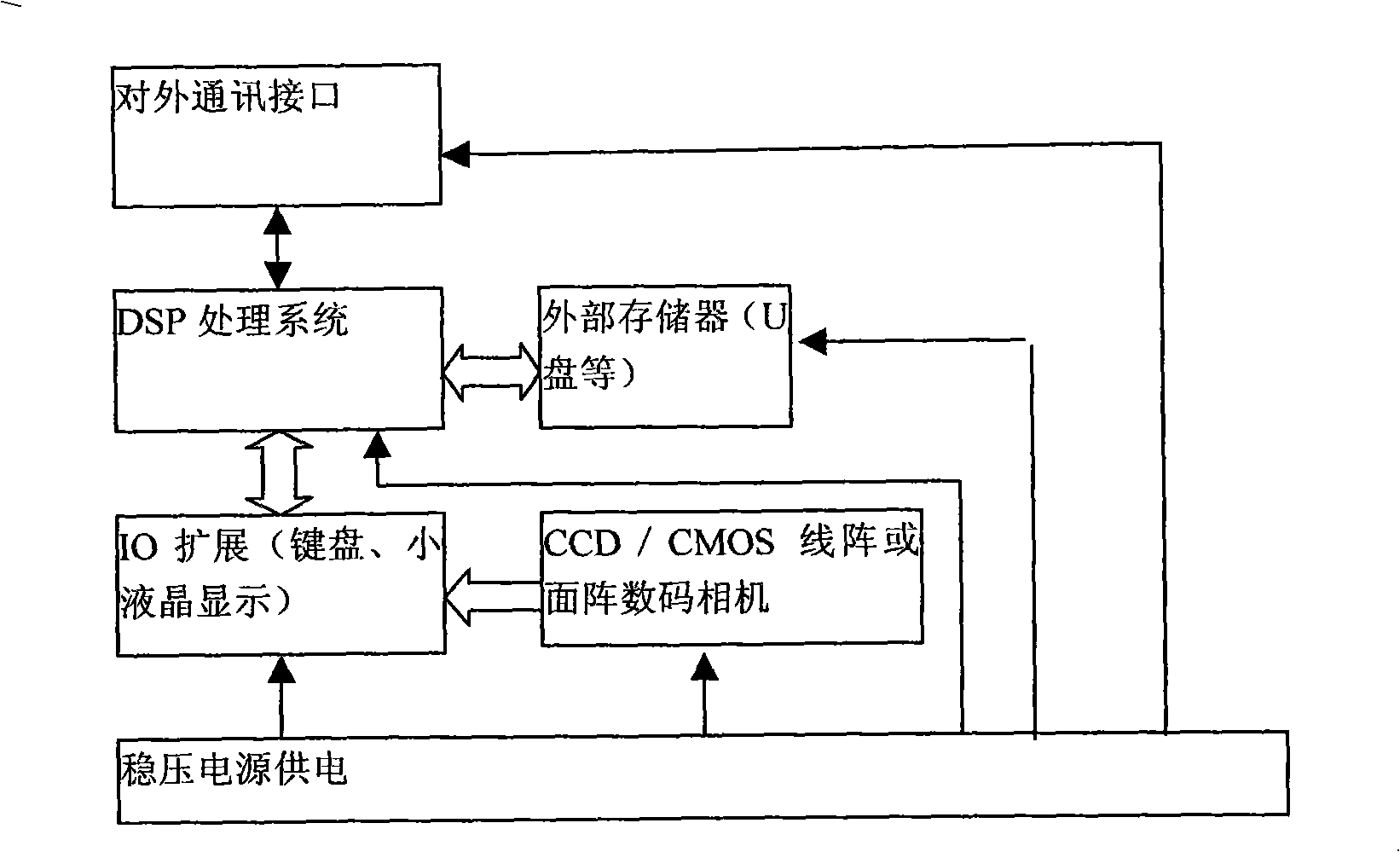

Dyeing and printing products on-line quality monitoring method based on computer pattern recognition principle

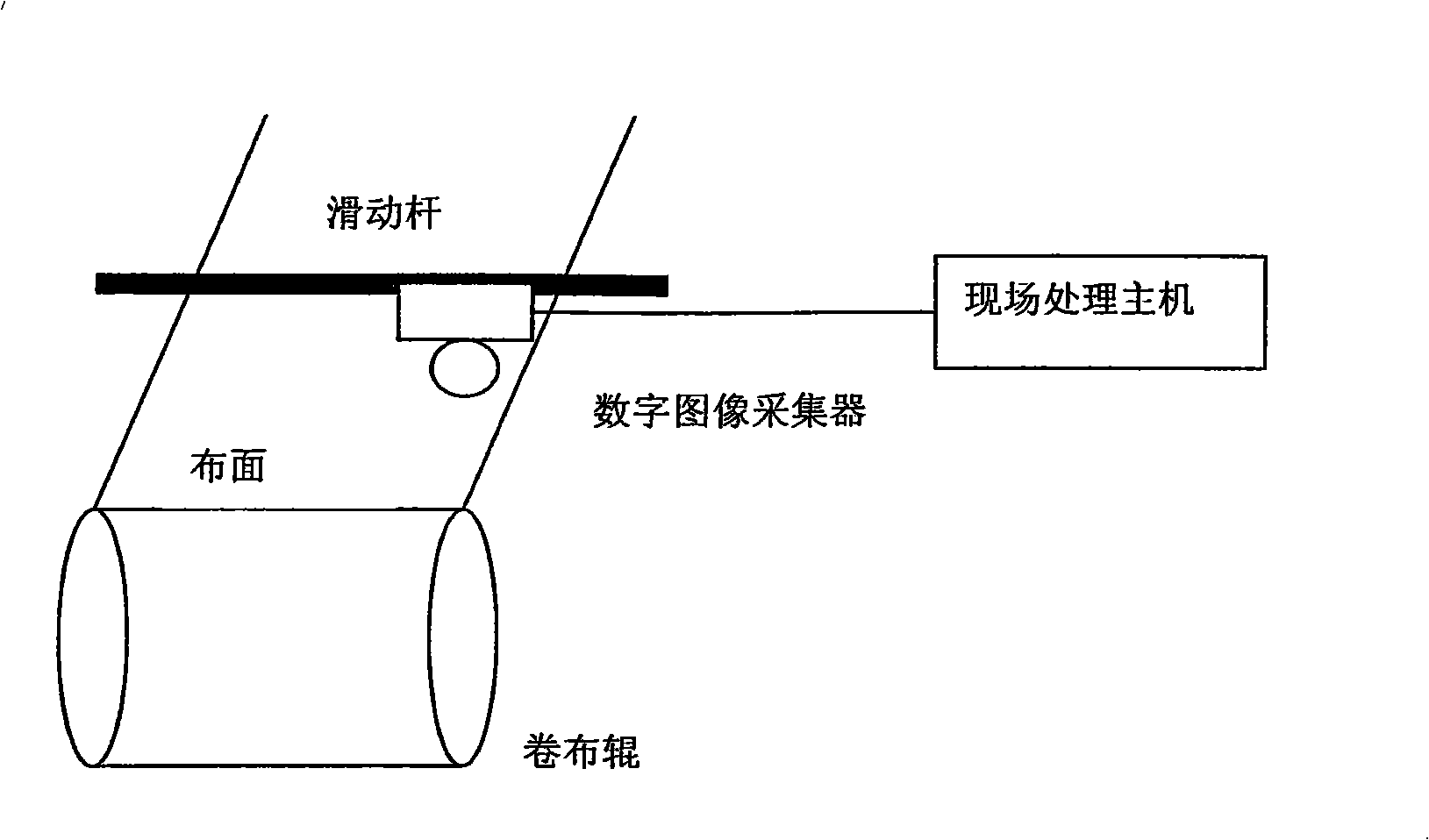

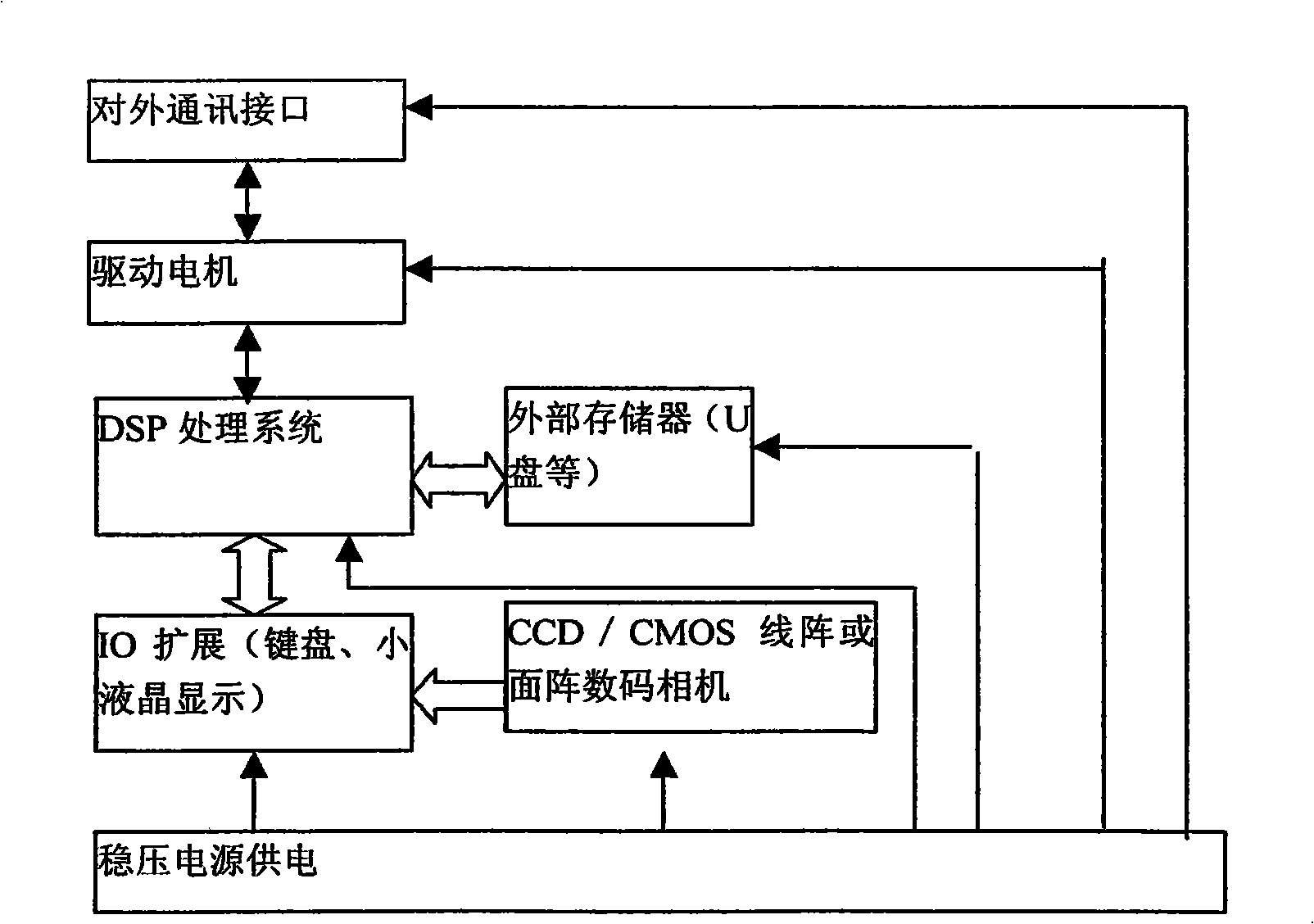

InactiveCN101334367AReduce generationReduce usageInspecting textilesTextile testingSites treatmentReciprocating motion

The invention relates to an online quality monitoring method of dyed products that is based on the computer graphic identification principle, adopts a digital image collector which is arranged and fixed on a slide rod above a rolling wheel or a cloth roller that are related to each technique in the dyeing, a camera shot side of the camera faces to a cloth surface, uninterrupted photographing of the moving cloth surface is implemented according to the set shooting frequency in unit time and repeated motion speed on the slide rod, and collected digital linear array or area array images are transmitted to an in-site processing host in real time; the in-site processing host is internally arranged with a standard cloth sample library and a defect library and implements fabric defect judgment, once a defect is determined, an alarming signal is emitted and leads the machine to halt, defect type on the fabric piece goods is reported, and concrete defect position is computed and indicated. The online quality monitoring method of the invention can implement the uninterrupted quality inspection of the products during the device running process, judge the product defects and indicate the defect type and the defect position.

Owner:何峰

Textile weaving machine on-line quality monitoring method based on computer pattern recognition principle

InactiveCN101308096AReduce generationReduce usageInspecting textilesTextile testingSites treatmentEngineering

The invention relates to a textile machine on-line quality monitoring method based on the computer graphical recognition principle, which adopts a digital image collector fixed on a sliding rod above a textile machine cloth roller, a lens thereof faces a cloth cover to take photographs of moving cloth continuously according to a photographing frequency stated in one unit of time and the reciprocating motion speed on the sliding rod, the collected linear or planar array digital pictures are delivered in real time to a main spot processor which is equipped with a standard fabric library and a defect library for judging defects of textile, one a defect is detected, the main spot processor transmits a warning signal or even stops the machine table, and reports the defect type of the cloth, calculates and indicates the specific location where the defect occurs. The on-line quality monitoring method can be adopted to conduct non-stop inspection of product quality in the running process of equipment, so as to judge defects of products and indicate the defect types and locations of defects.

Owner:何峰

Intelligent control method for visual tracking

InactiveCN1570949AEasy to useReally easy to useImage enhancementCharacter and pattern recognitionActive perceptionComputer pattern recognition

This invention is a vision tracking control method that can realize real time tracking eye's sight point movement by computer pattern identification. This method can realize the tracking of eye's sight point by building view angle boundary proportion model as data imitation sample. By this method, computer can acquire people's command information automatically by actively apperceive mode.

Owner:万众一

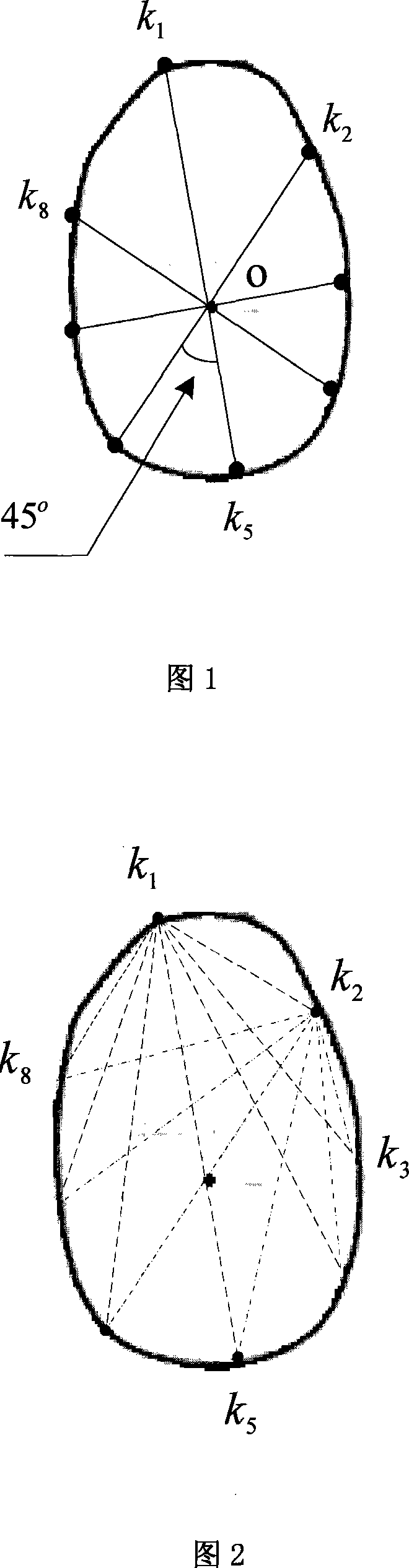

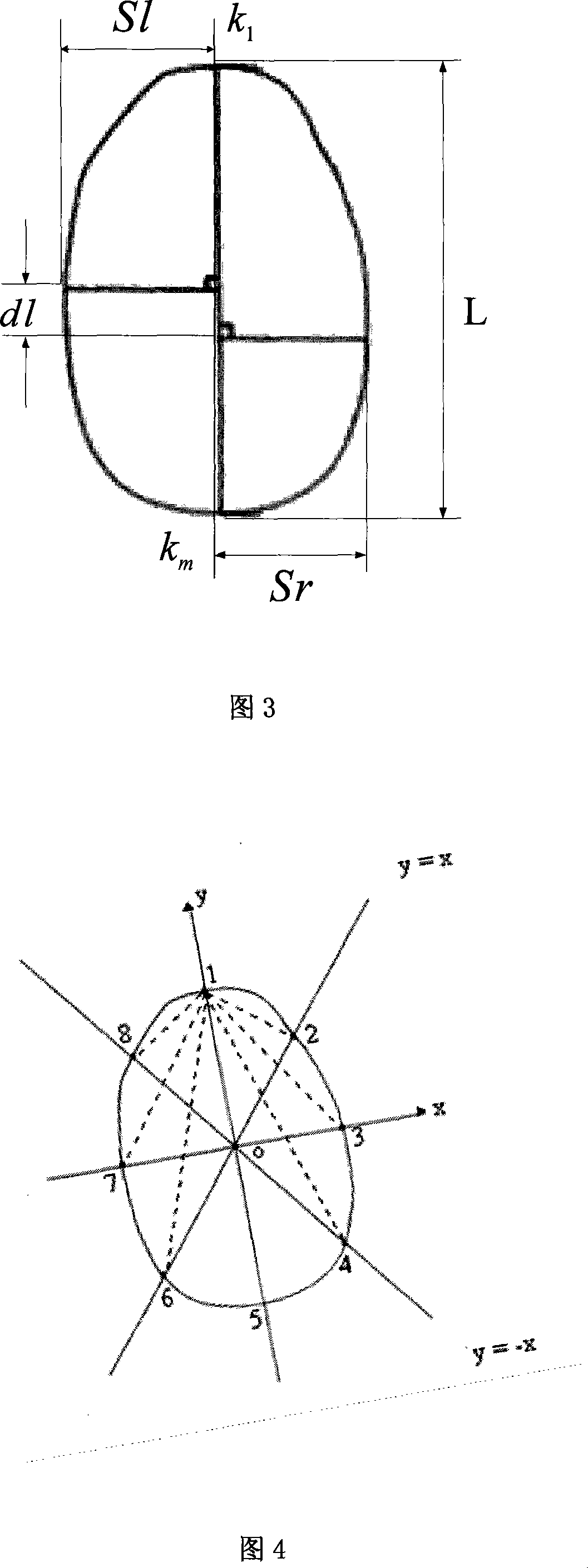

Method for recognizing outline shape of digital image

InactiveCN101093546ARealize sortingImplement testImage analysisCharacter and pattern recognitionComputer pattern recognitionDigital image

A method for identifying outline form of digital image utilizes long axis length, left-short axis length, right-short axis length, distance between left and right short axis as well as absolute value of left-right short axis length difference as five identification feature values of digital image outline form then inputs said identification feature values into computer for finalizing identification of digital image outline form. The method for obtaining said feature values is also disclosed.

Owner:SUZHOU UNIV

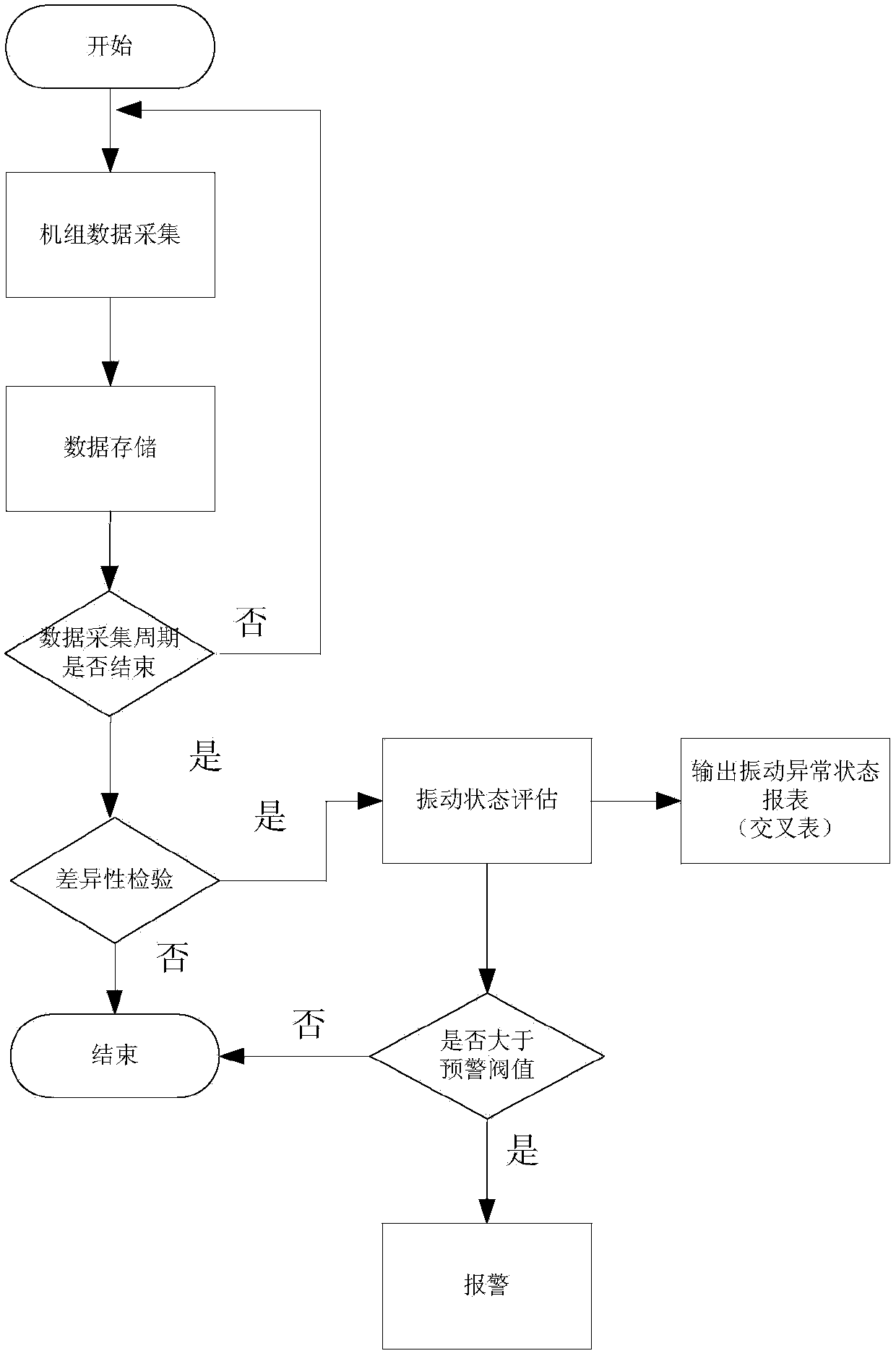

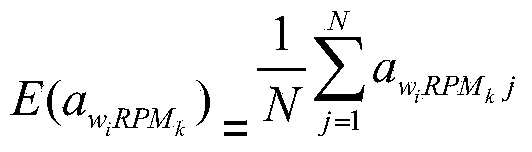

State early warning method and system for abnormal vibration of wind generating set

ActiveCN103674234AImprove robustnessImprove accuracySubsonic/sonic/ultrasonic wave measurementEngine testingEarly warning systemComputer pattern recognition

The invention relates to a state early warning method and system for abnormal vibration of a wind generating set. The method comprises the following steps of: acquiring and storing machine set data; carrying out difference examination, and performing difference comparison on an acquired generator rotating speed transient value of each machine set and the generator rotating speed transient values of other machine sets and / or former records of the machine set; outputting a vibration state, and outputting the vibration state corresponding to the machine set with oversized difference. The system comprises a data acquisition and storage module, a difference examination module and a vibration state output module. Through a way of combining mathematical statistics with computer mode identification, the technical effect of reducing influence from noise data to judgment of the abnormal state is reduced, accordingly, robustness and accuracy of the early warning system are improved, convenience is also brought to customization of an early warning mechanism with better pertinency for fans with different configurations and in different environments, and the state early warning method and system for abnormal vibration of the wind generating set are suitable to be widely generalized and used.

Owner:BEIJING TIANYUAN SCI & TECH CREATION WINDPOWER TECH

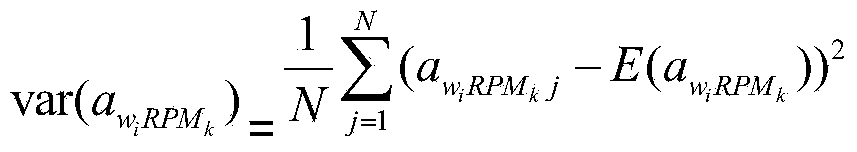

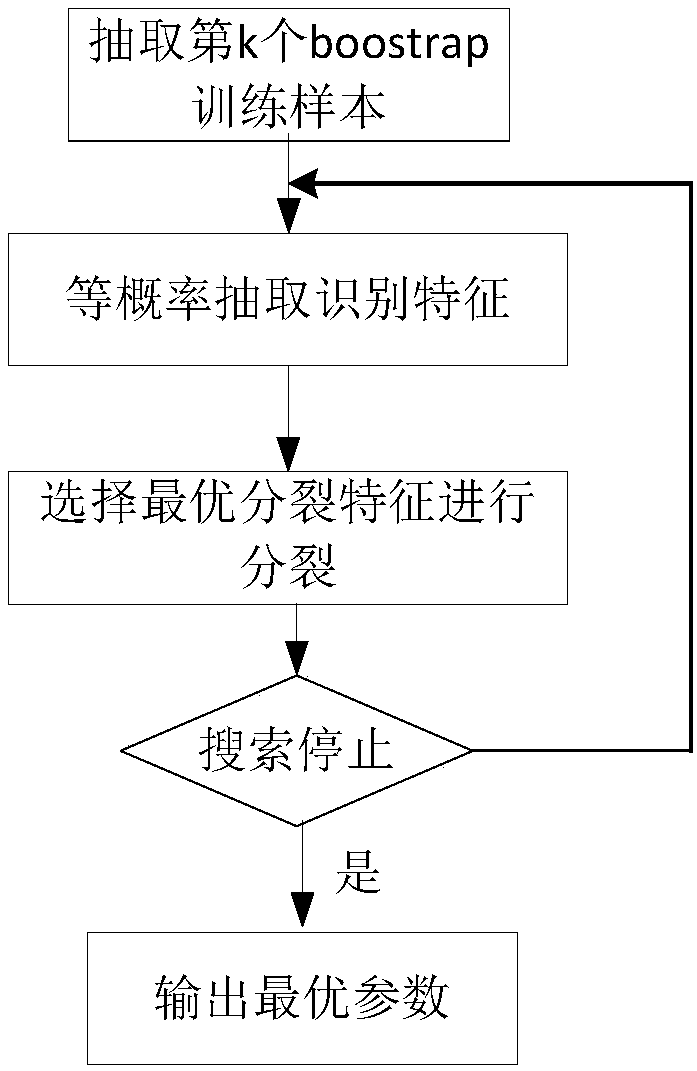

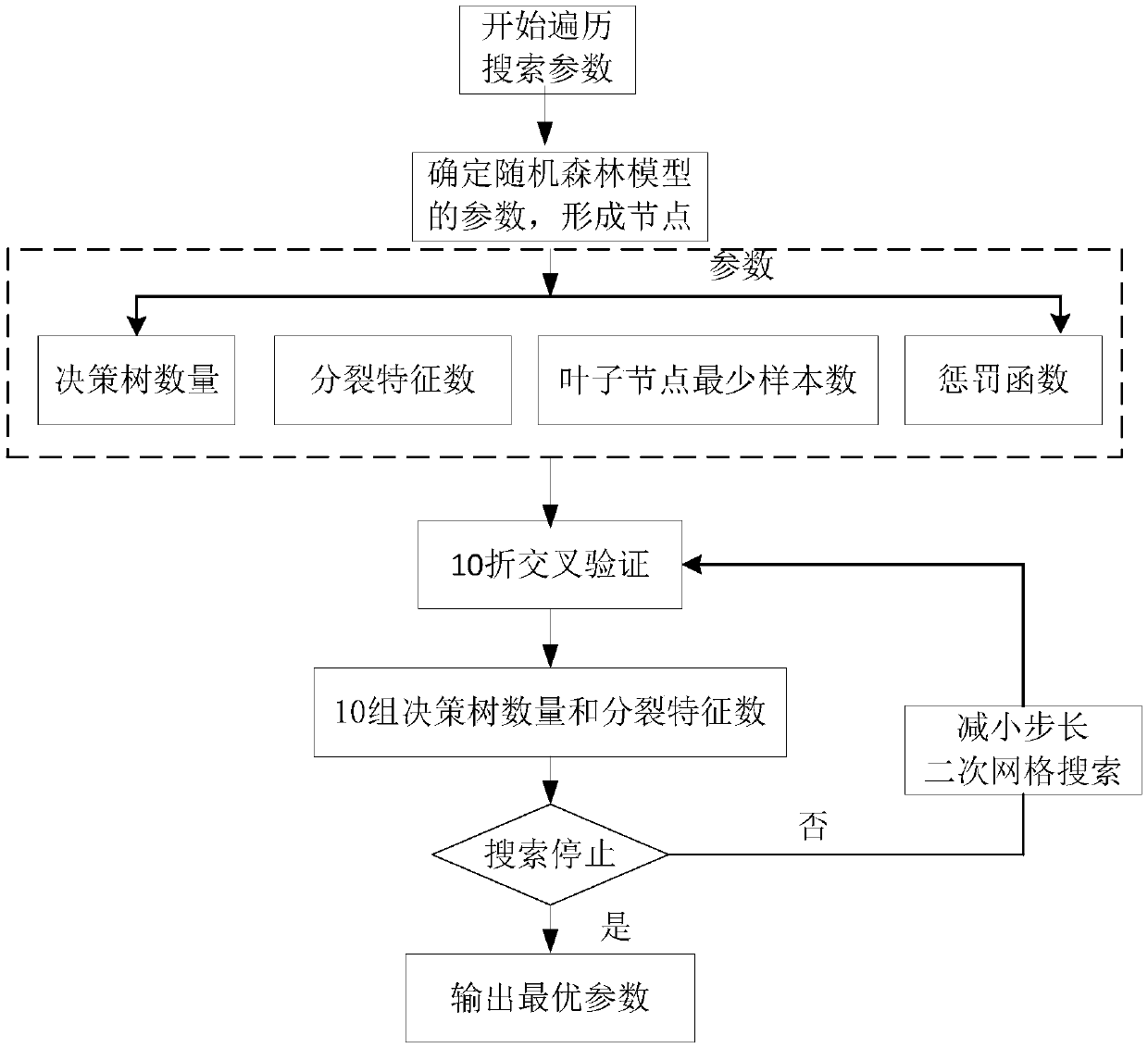

Computer mode recognition method for brain electrical signals of epilepsy patients

ActiveCN109645990AImprove operational efficiencyRealize the function of automatic recognition of EEG signals in patients with epilepsyDiagnostic recording/measuringSensorsDiseaseComputer pattern recognition

The invention discloses a computer mode recognition method for bran electrical signals of epilepsy patients, and relates to the technical field of brain science and epileptic seizure clinical data recognition. The method includes the steps that firstly, a random forest recognition model is constructed and then trained so that the optimal random forest recognition mode can be generated; mode recognition testing of the brain electrical signals of the epilepsy patients with different degrees of disease conditions is conducted on the optimized random forest model on a test set. Through the computer mode recognition method, the function that through a computer, the brain electrical signals of the epilepsy patients are automatically recognized is realized, and technical supports are provided when medical workers consumes time and labor for diagnosis. A grid search optimization method is introduced, a variable step size mode is adopted for repeatedly filtering parameters to accelerate optimalcombining of search parameters, the operation efficiency of the random forest model is improved, the trained random forest recognition model realizes the optimal effect, and the accuracy of mode recognition conducted on three kinds of epilepsy disease conditions can reach 96% or above.

Owner:BEIHANG UNIV

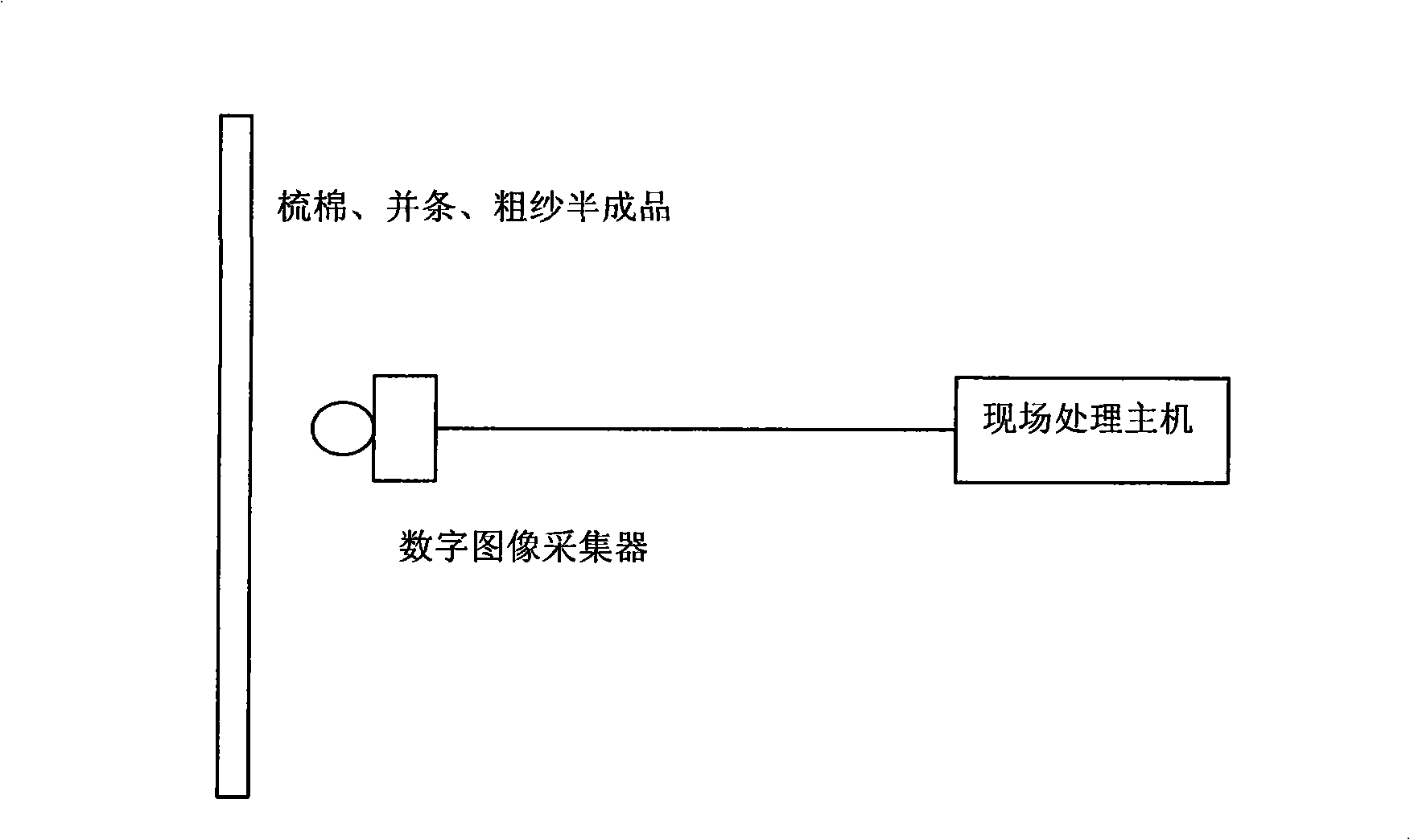

Spinning products on-line quality monitoring method based on computer pattern recognition principle

InactiveCN101308095AReduce generationReduce usageInspecting textilesTextile testingSites treatmentCarding

The invention relates to a spinning product on-line quality monitoring method based on the computer graphical recognition principle, which adopts a digital image collector fixedly arranged at a discharge port of a machine relating to a plurality of processes of cotton carding, drawing and roving in the spinning production process, a lens thereof faces the semi-finished products to take photographs of the semi-finished products during cotton carding, drawing and roving according to a photographing frequency stated in one unit of time, the collected linear or planar array digital pictures are delivered in real time to a main spot processor which is equipped with a standard library and a defect library for judging defects of the semi-finished products, one a defect is detected, the main spot processor transmits a warning signal or even stops the machine station, and reports the defect type, calculates and indicates the specific location where the defect occurs. The on-line quality monitoring method can be adopted to conduct non-stop inspection of the semi-finished products in the running process of equipment, so as to judge defects of products and indicate the defect types and locations of defects.

Owner:何峰

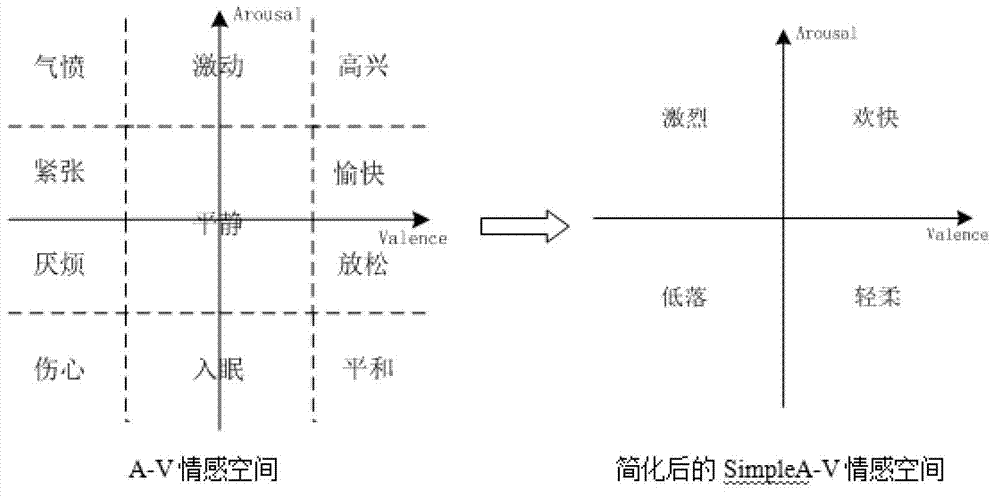

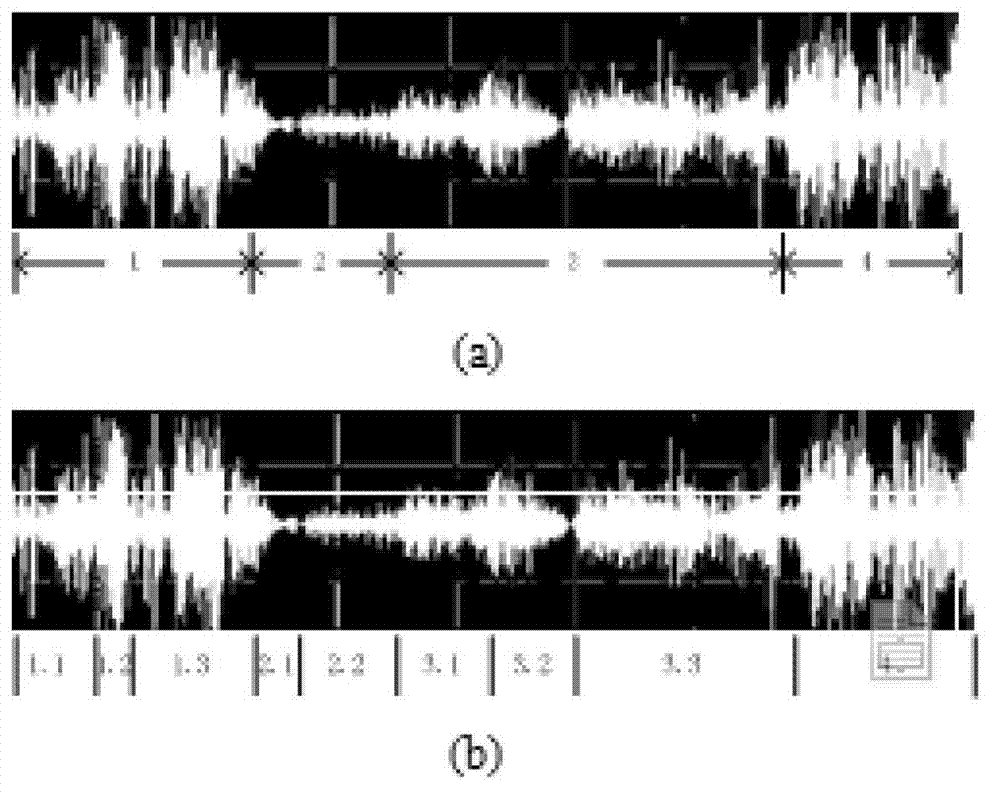

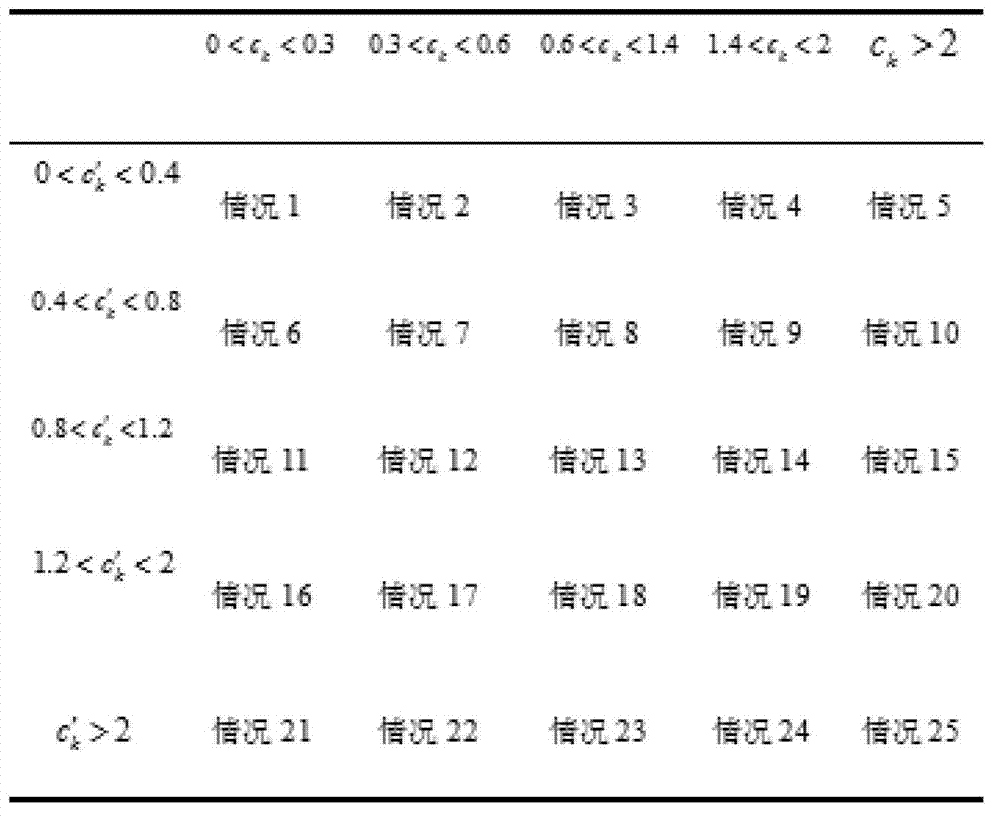

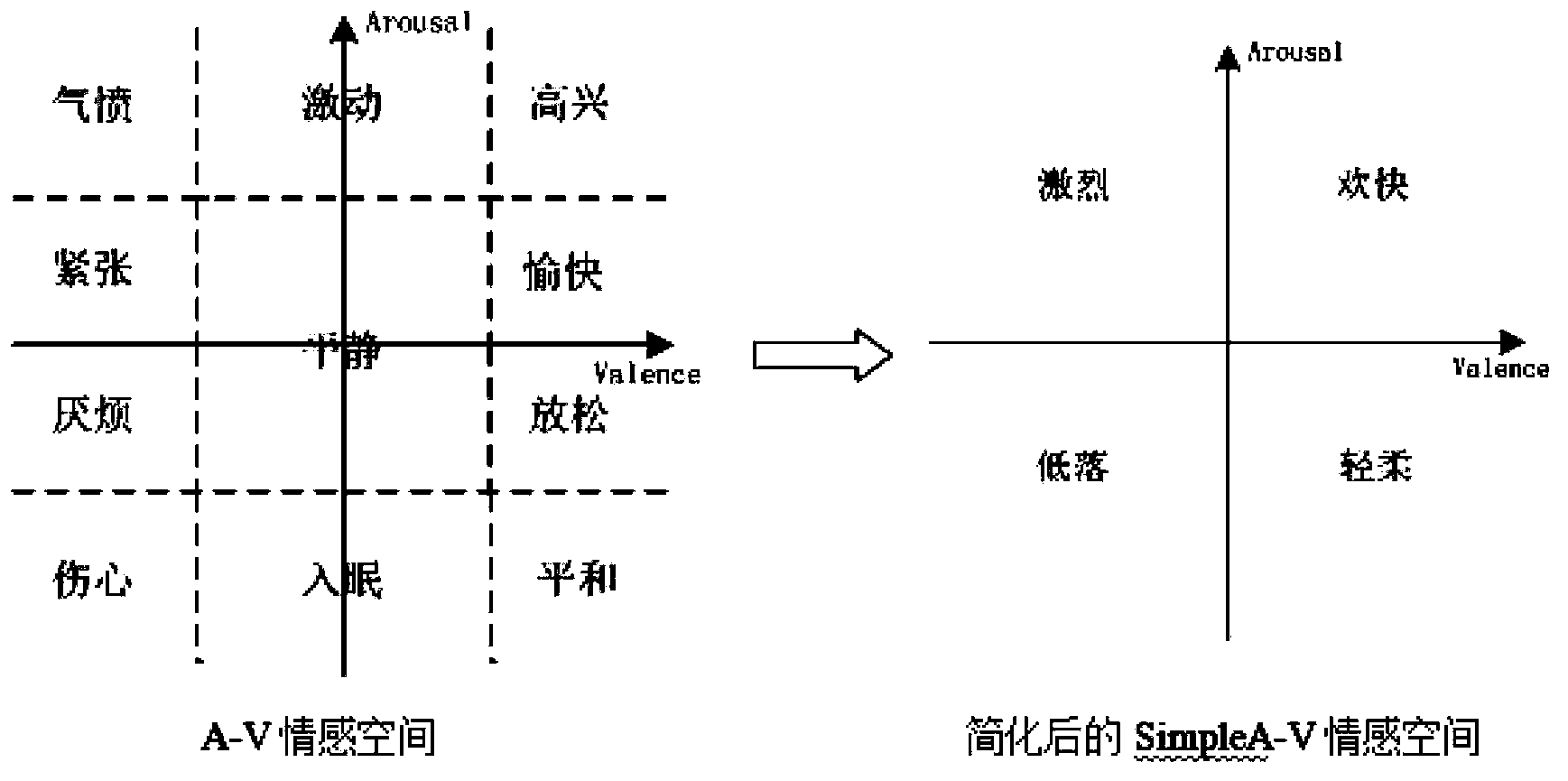

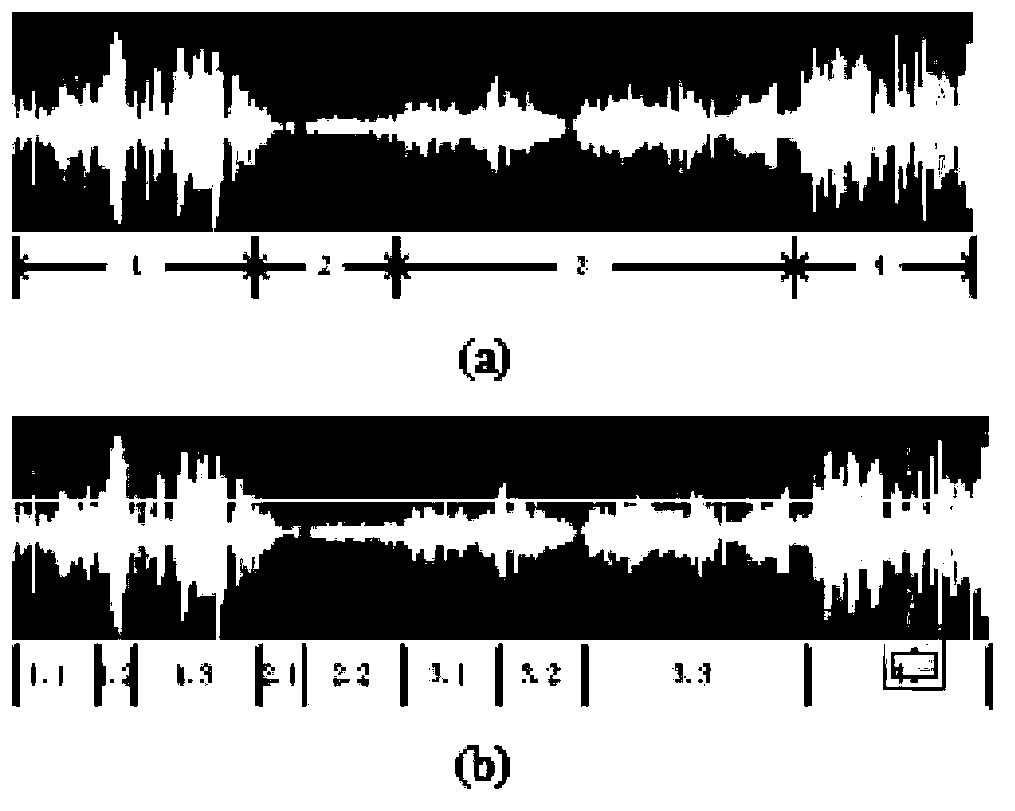

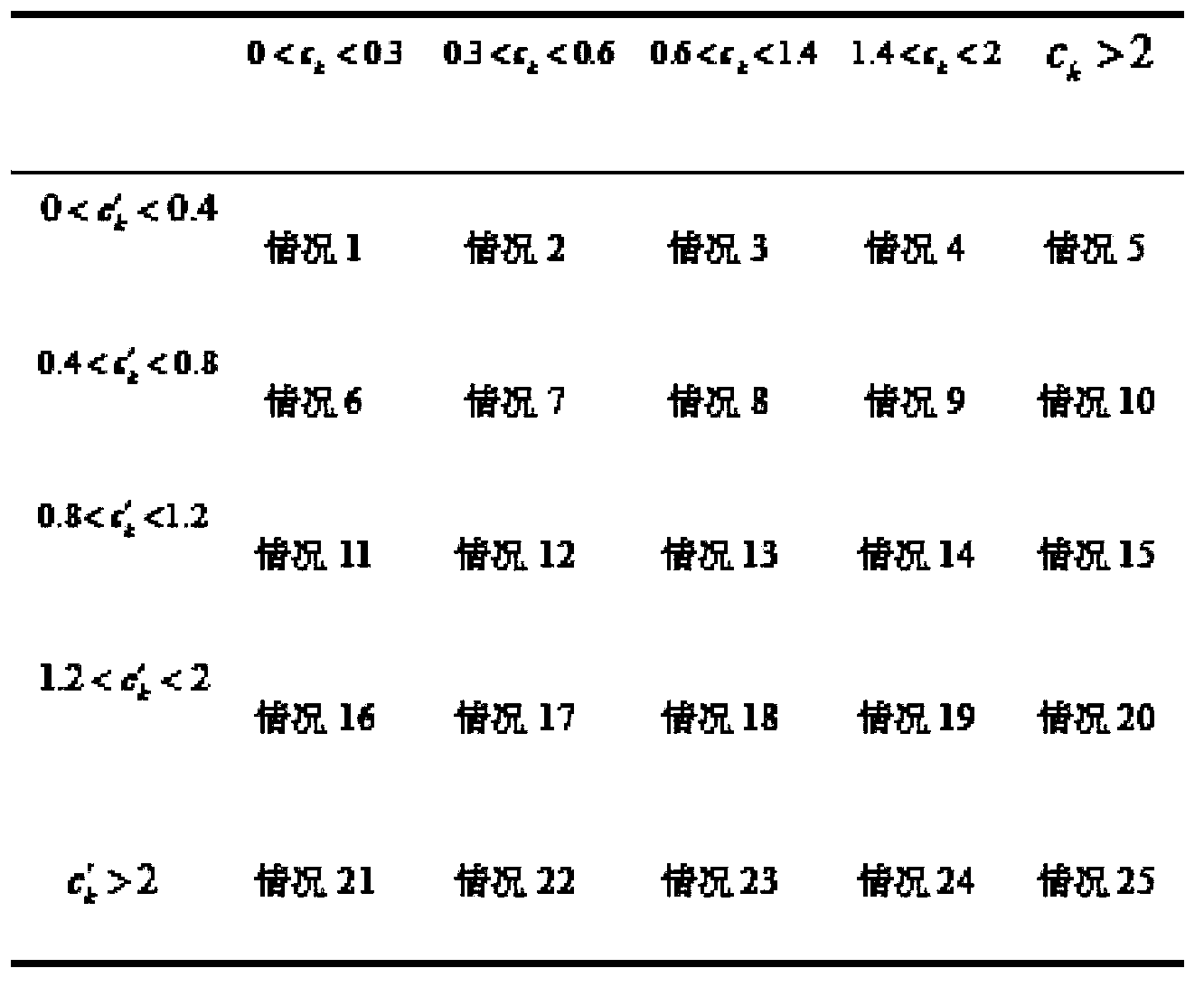

Coarse emotion soft cutting and classification method for waveform music

ActiveCN102930865AImprove universalityAccurate emotional feature recognition resultsSpeech recognitionNODALFeature extraction

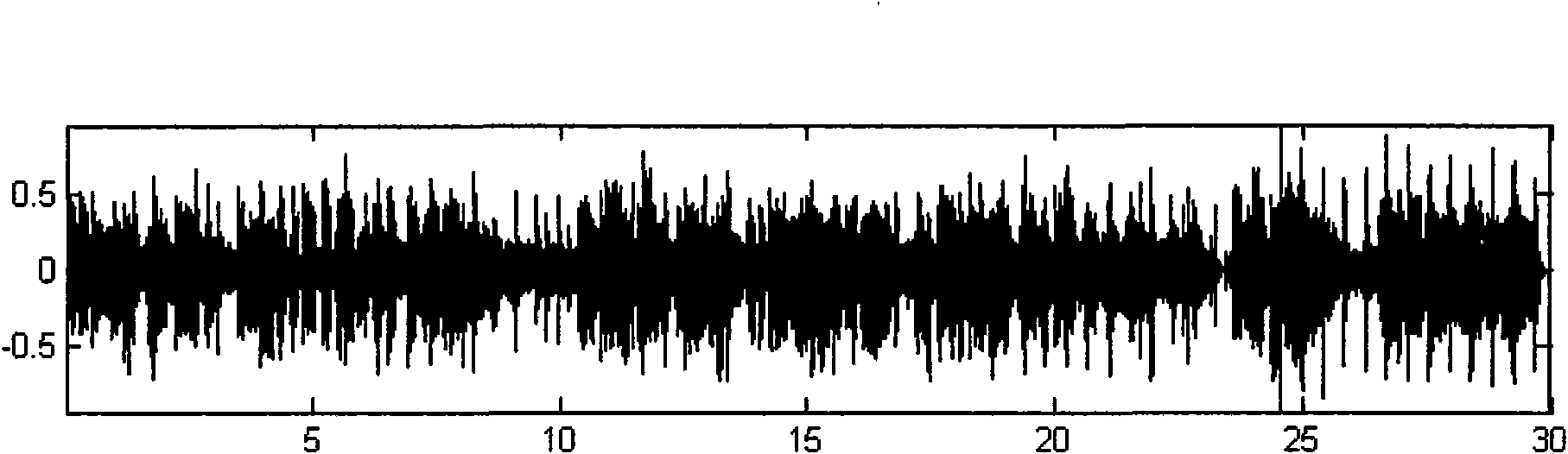

The invention discloses a coarse emotion soft cutting and classification method for waveform music, belonging to the field of pattern recognition of computers. The coarse emotion soft cutting and classification of the waveform music are performed by a Mallat algorithm by aiming at music characteristic parameters, and the problem of accurate capture of waveform music characteristic emotion information used for a control system is solved. The method specifically comprises the following steps of (1) establishing a coarse emotion space domain; (2) pretreating; (3) extracting characteristics; (4) performing soft cutting; and (5) classifying. According to the method, the waveform music is processed by a time-frequency domain analysis method based on the Mallat algorithm, comparison parameter nodes with higher universality can be acquired by a samples training method according to two basic music characteristic quantities (intensity and rhythm), and skip conditions among all the emotion domains are determined according to the experience of experts, and effects of coarse emotion soft cutting and classification on the music are achieved finally.

Owner:黑盒子科技(北京)有限公司

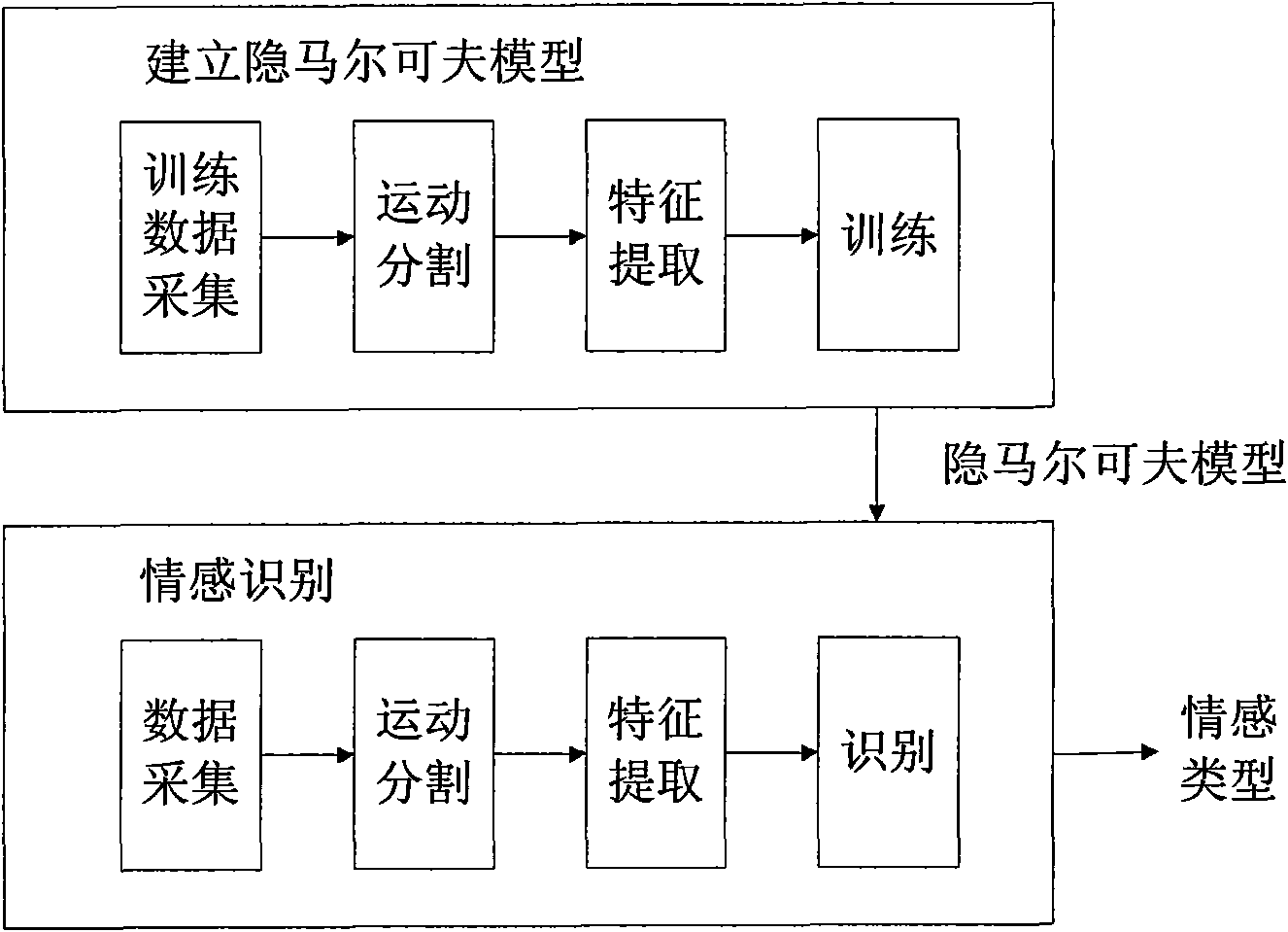

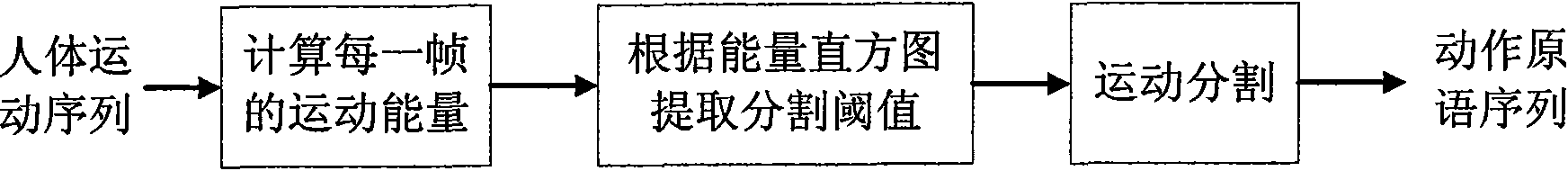

Emotion identification method for human non-programmed motion

InactiveCN101561881AImage analysisCharacter and pattern recognitionFeature extractionHide markov model

The invention relates to an emotion identification method for human non-programmed motion, belongs to the field of computer mode identification, and solves the problems of low learning speed and low identification rate in the prior homogeneous emotion identification method. The method comprises a hidden Markov model establishing step and an emotion identification step, wherein the hidden Markov model establishing step comprises a training data acquisition substep, a motion segmentation substep, a feature extraction substep and a training substep, and establishes a hidden Markov model of various motion types and emotions; and the emotion identification step comprises a data acquisition substep, a motion segmentation substep, a feature extraction substep and an identification substep, and carries out emotion identification and motion type identification for a human motion sequence to be identified through the constructed hidden Markov model. The method can well show the inherent law of the motion, not only can identify the emotion, but also can identify the motion type, and has high identification rate, strong practicability and wide application.

Owner:HUAZHONG UNIV OF SCI & TECH

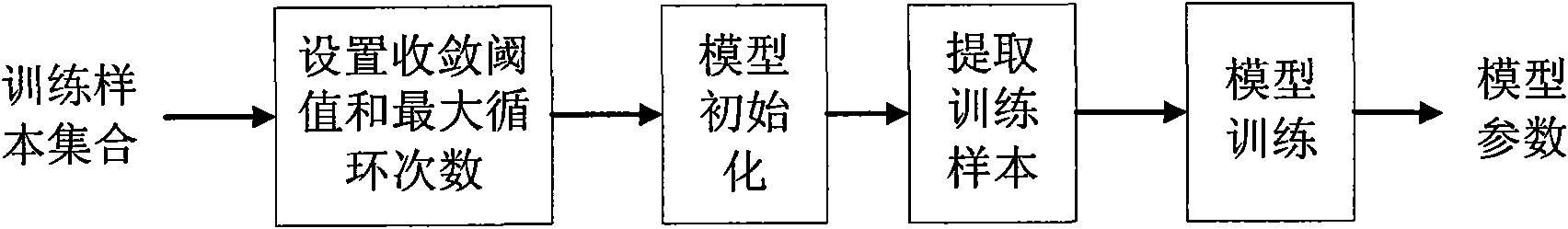

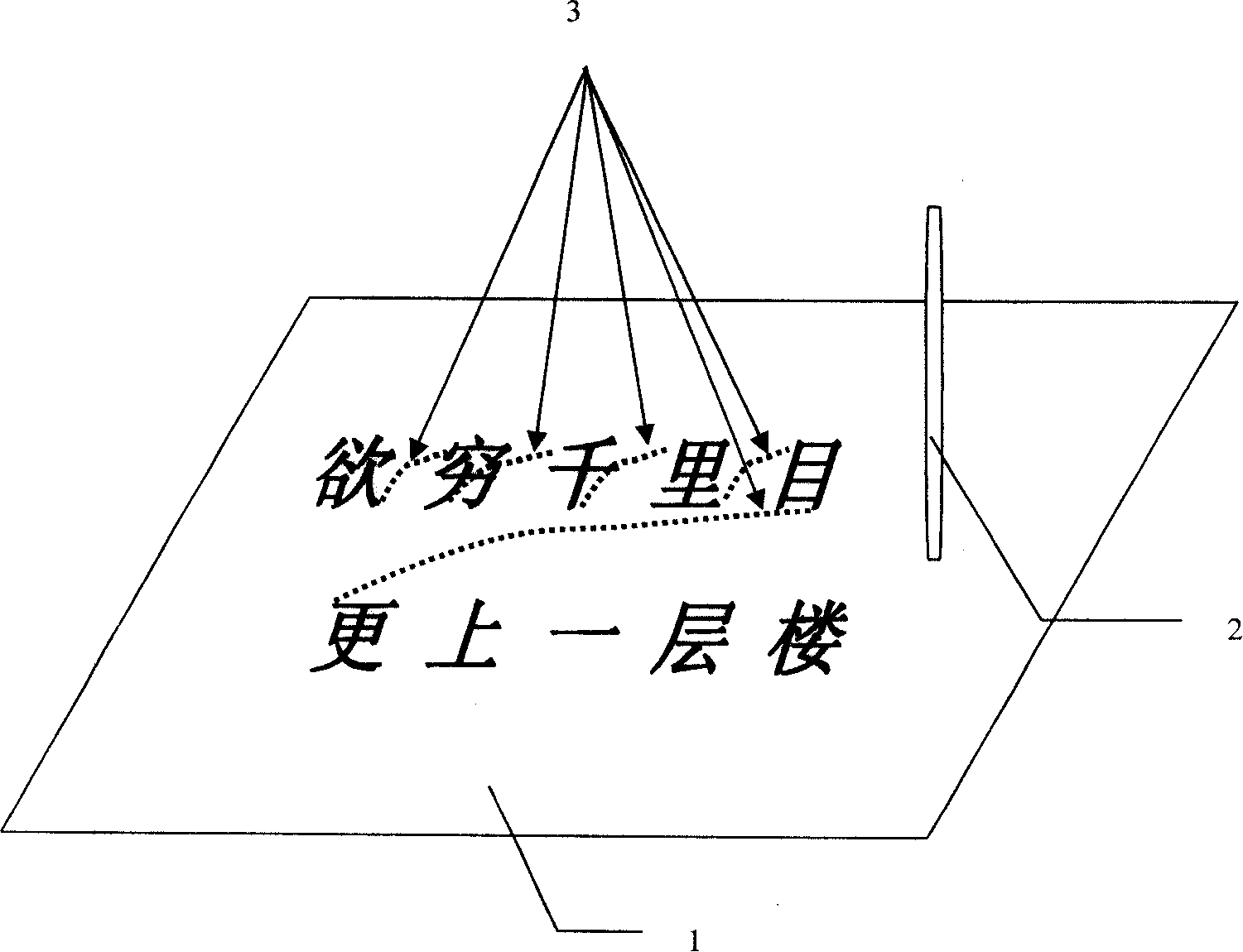

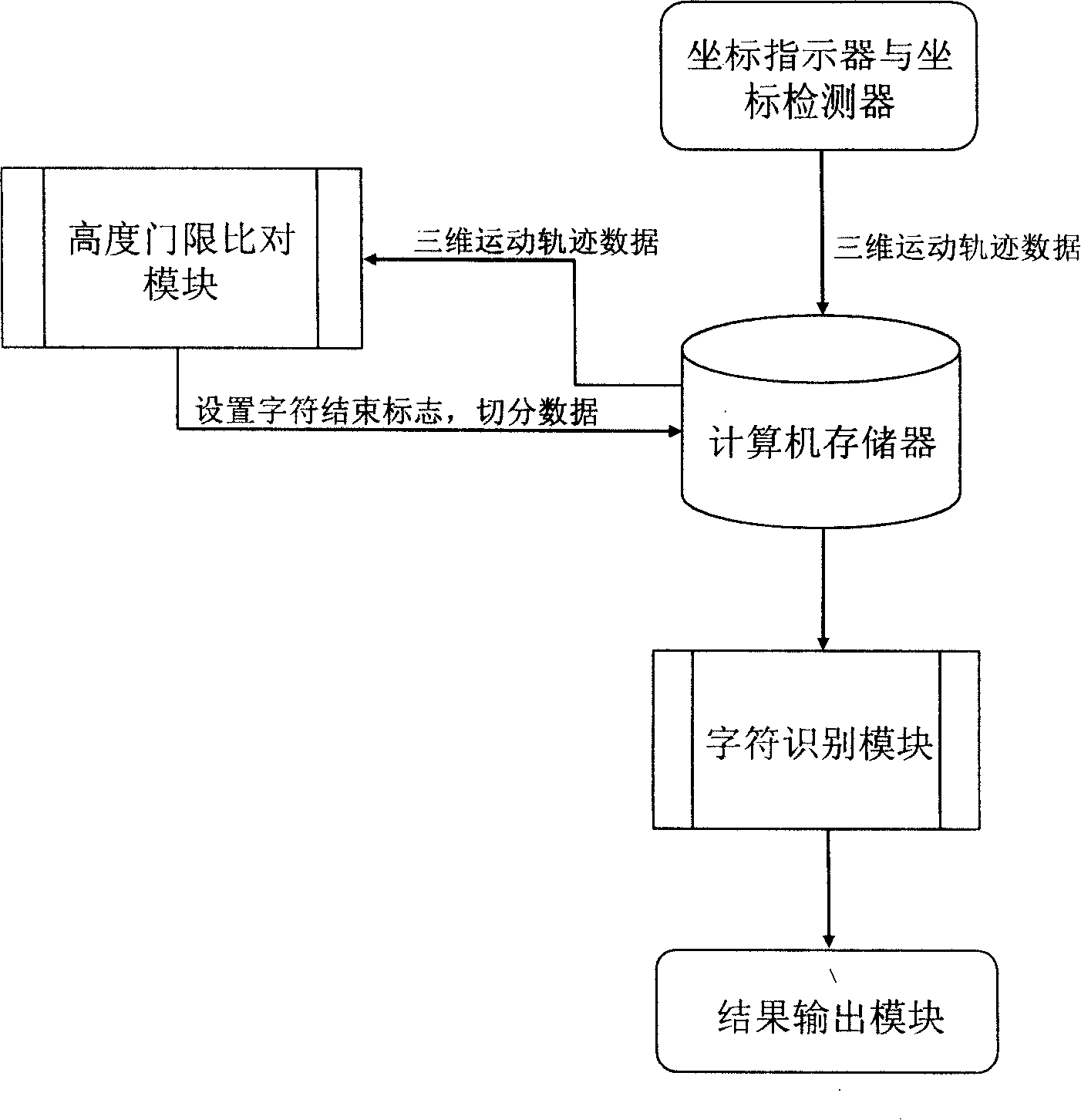

Character cutting method

InactiveCN101178629ALess operating restrictionsOvercome the disadvantages of character segmentationInput/output processes for data processingHandwritingAlgorithm

The invention relates to a character segmentation method, belonging to the technical field of computer pattern reorganization. The invention is characterized in that three-dimensional movement track data produced when the character is input by a coordinate indicator is collected by a coordinate detector; track data information is stored inside a computer memory; the height of the track data is measured to be compared with height threshold data preset in the computer; when the height is higher than the threshold data, the character input can be judged completely by the computer and then a character end symbol is set. The invention has the advantages of overcoming the shortcomings of the existing character segmentation, ensuring the accuracy of character segmentation to be accurate; the method can be widely applied in a handwriting input system, so as to improve the correct rate of handwriting reorganization.

Owner:HANVON CORP

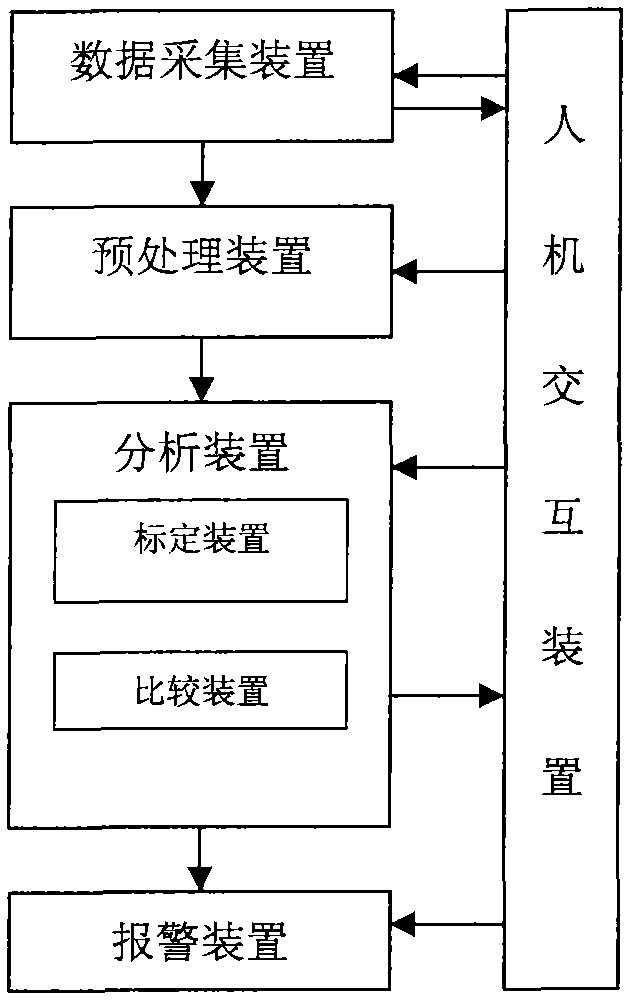

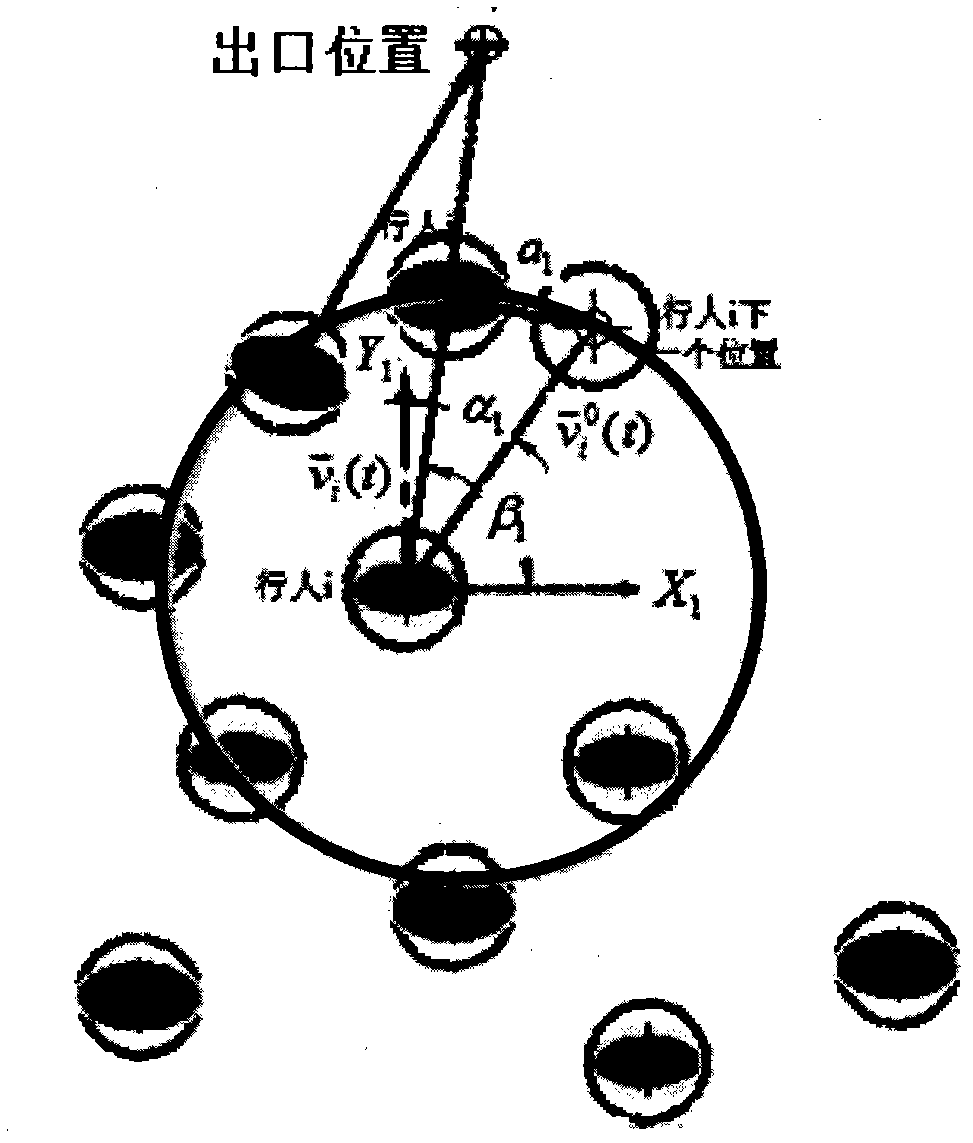

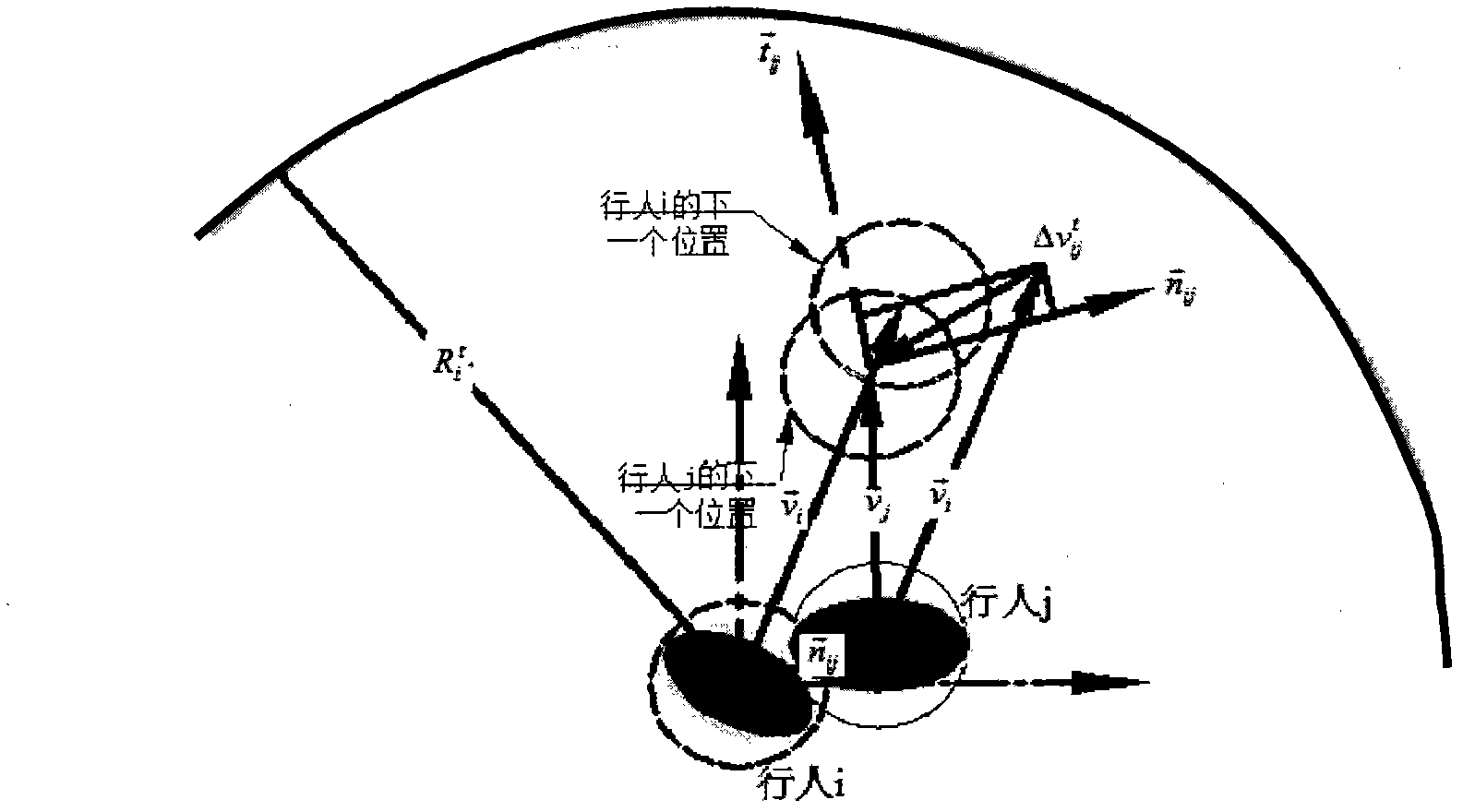

Social-force-model-based monitoring system

InactiveCN102325250AEasy to operateAvoid Social Security IssuesClosed circuit television systemsAlarmsVideo monitoringComputer pattern recognition

The invention discloses a social-force-model-based monitoring system, which comprises a data acquisition device and a preprocessing device, wherein the data acquisition device is used for shooting and identifying the two-dimensional plane position information of pedestrians and fixed objects; and the preprocessing device is used for computing behavioral characteristic values of the pedestrians and rejecting abnormal data. The monitoring system further comprises an analysis device, an alarming device and a human-computer interaction device, wherein the analysis device is used for calibrating contact repelling force strength and contact friction force strength and comparing the contact repelling force strength and the contact friction force strength with preset contact repelling force strength and preset contact friction force strength to determine whether to output an alarming signal or not; the alarming device is used for giving an alarm according to the alarming signal; and the human-computer interaction device is used for interaction between the monitoring system and a worker. The system combines video monitoring and computer mode identification effectively based on a social force model, monitors collective behaviors with simple operations, and maximally solves social security problems caused by abnormal collective behaviors.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

Die casting process incorporating computerized pattern recognition techniques

A die casting process using pattern recognition techniques to identify those die castings manufactured under conditions likely to produce a die casting which would subsequently prove unacceptable for use. By promptly identifying such die castings, they may be discarded before being shipped to a remote facility for further processing. As a result, the rejection rate of die castings at the remote facility may be reduced and the raw materials used to form the discarded die castings may be more readily recycled.

Owner:PACE IND LLC A DELAWARE CO

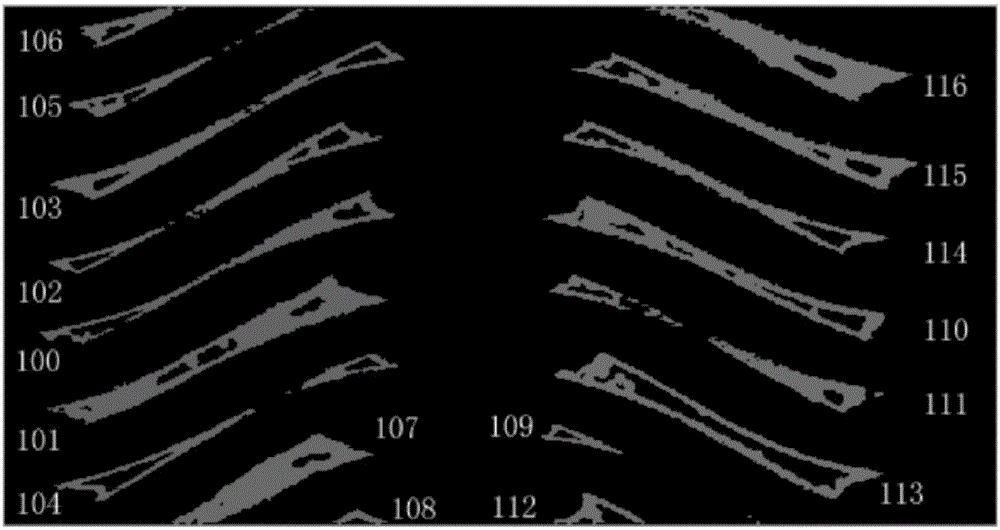

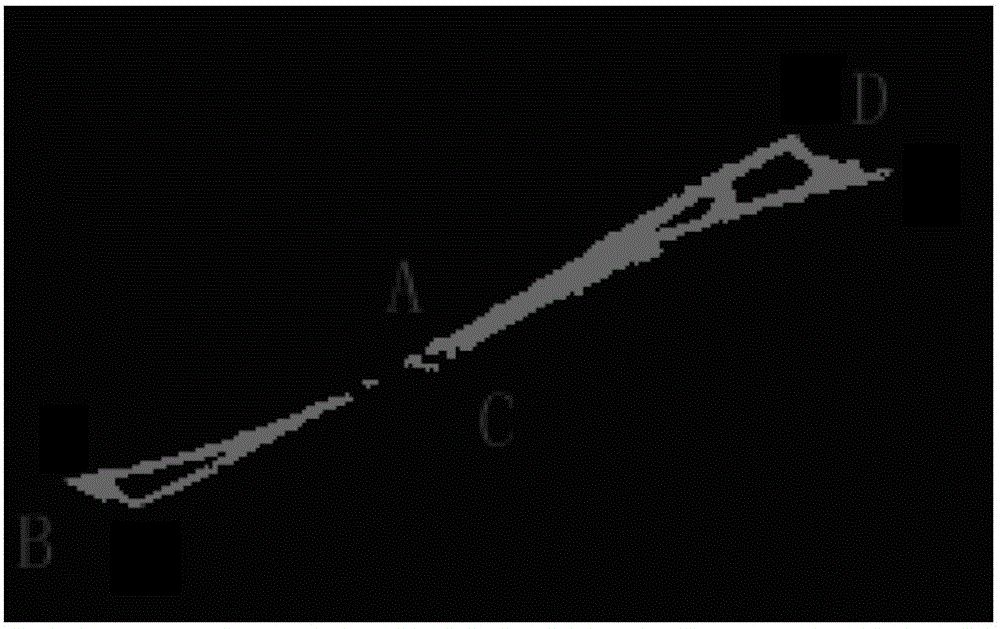

Computer pattern recognition method for composite material microstructure

ActiveCN105803623AOvercome the disadvantage of only being able to build two-dimensional modelsOvercomes the inability to identify components with similar grayscale characteristicsPattern making devicesGraphicsComputer pattern recognition

The invention discloses a computer pattern recognition method for the composite material microstructure. The computer pattern recognition method includes the following steps that pictures of the 2.5-dimensional composite material microstructure are obtained; matrix areas are recognized with the threshold segmentation technology; all the matrix areas serve as twisty quadrilateral structures to be treated, and four boundaries of each matrix area are recognized and marked; the matrix areas matched with the left matrix areas are found; the complete boundaries of warp yarn areas are obtained in a spline fitting mode; in all pairs of symmetrical matrix areas, the areas defined by the boundaries of the left matrix areas, the boundaries of the right matrix areas, upper warp yarn boundary lines and lower warp yarn boundary lines are weft yarn areas, and recognition of components is completed; all the recognized pictures are stacked to build a three-dimensional model of the 2.5-dimensional inside microstructure. According to the computer pattern recognition method, manual intervention is avoided, the three-dimensional model of the composite material microstructure can be built, and warp yarns, weft yarns and matrixes can be automatically recognized by a computer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

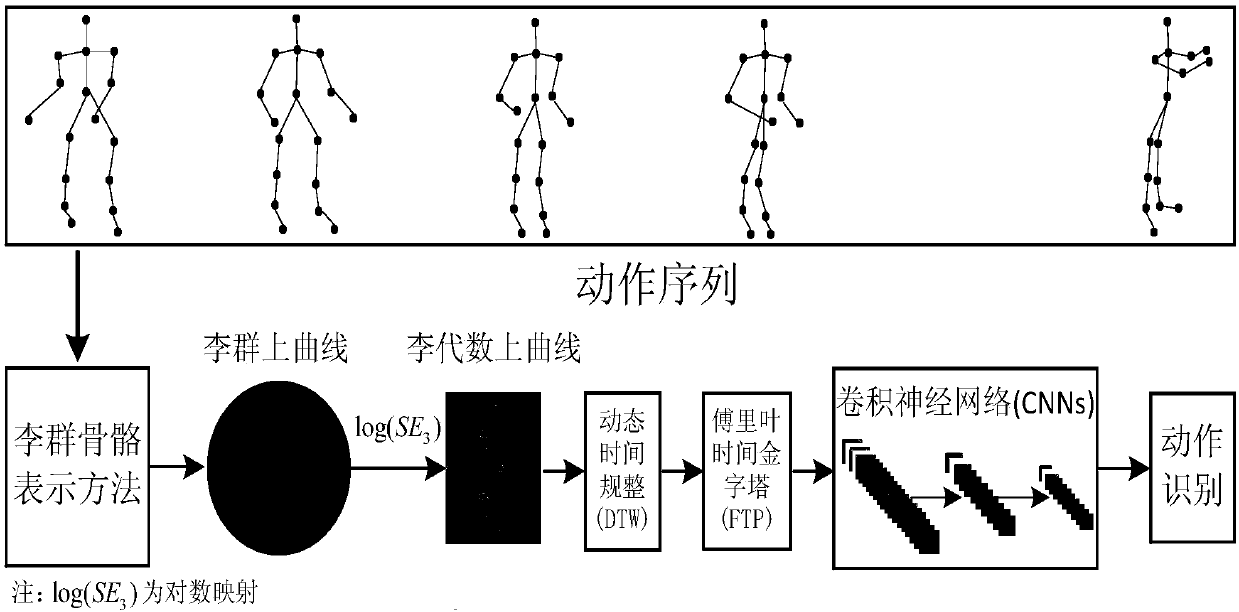

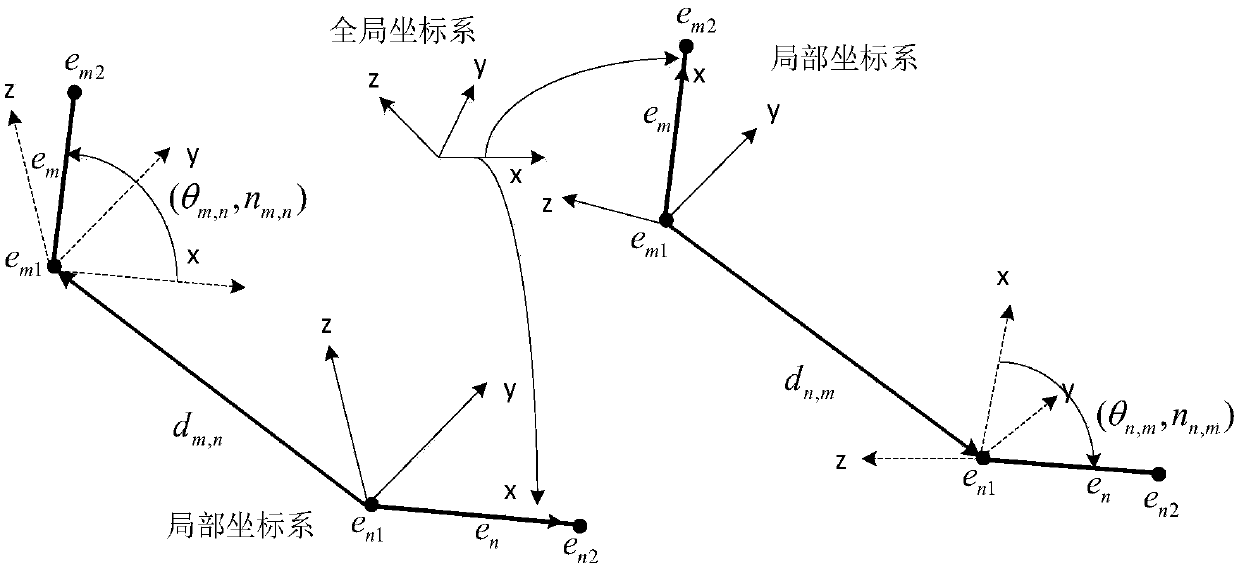

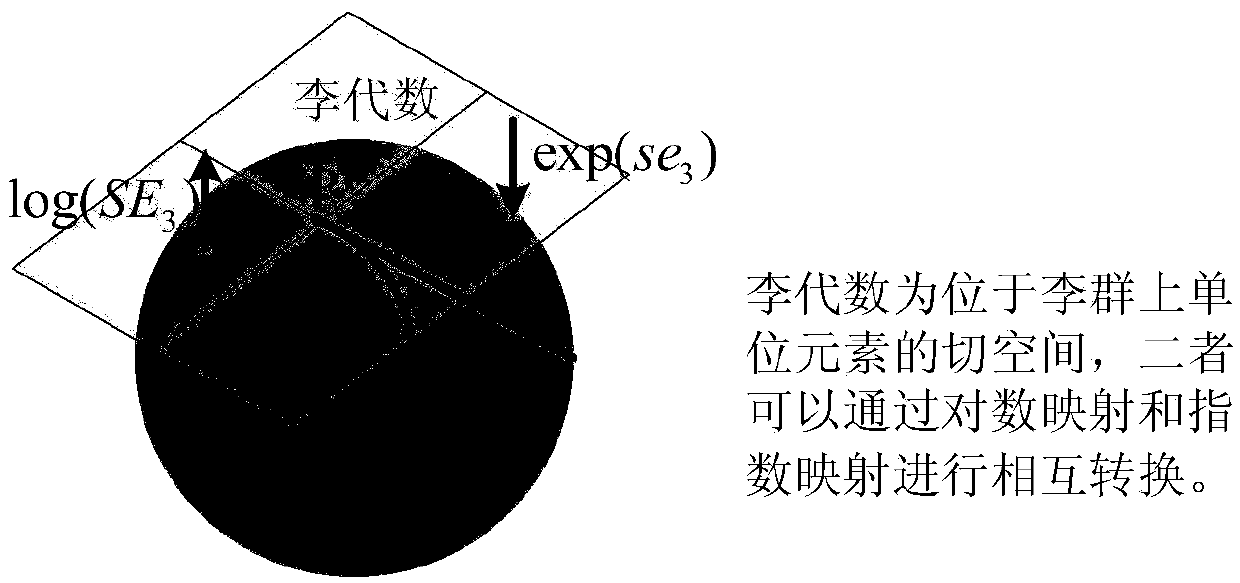

Human motion recognition method based on plum group characteristics and a convolutional neural network

ActiveCN109614899AThe description is accurate and validOvercome the shortcomings of manual feature extractionCharacter and pattern recognitionHuman bodySomatosensory system

The invention relates to a human motion recognition method based on plum group characteristics and a convolutional neural network, and belongs to the field of computer mode recognition. The method comprises the following steps: S1, data acquisition: extracting human skeleton information by utilizing micro soft body sensing equipment Kinect, and acquiring motion information of an experimenter; s2,extracting plum group characteristics, A plum group skeleton representation method for simulating a relative three-dimensional geometrical relationship between limbs of a human body by utilizing rigidlimb transformation is adopted. human body actions are modeled into a series of curves on the plum group, and then the curve based on the plum group space is mapped into a curve based on the plum algebra space through logarithm mapping in combination with the corresponding relation between the plum group and the plum algebra; and S3, feature classification: fusing the plum group features and theconvolutional neural network, training the convolutional neural network by using the plum group features, and enabling the convolutional neural network to learn and classify the plum group features, thereby realizing human body action recognition. According to the invention, a good identification effect can be obtained.

Owner:北京陟锋科技有限公司

Road sign recognition system and method

InactiveCN102156866AMake up for the shortfall caused by the language barrierMake up for deficienciesCharacter and pattern recognitionSpecial data processing applicationsTraffic sign recognitionComputer pattern recognition

The invention discloses a road sign recognition system and method. The road sign recognition system comprises a road sign recognition device and a server, wherein the road sign recognition device comprises a control module, a display module, a human-machine interaction module, a computer mode recognition module, a memory module, an image fusion module and a communication module, wherein the display module, the human-machine interaction module, the computer mode recognition module, the memory module, the image fusion module and the communication module are respectively connected with the control module, and the communication module is connected with the server through a wireless network. When the road sign recognition system and method are adopted, characters in an actual road sign can be translated according to a languish set by a user, the translated characters are fused in an image of the road sign to be displayed, therefore the defect of markup information of the road sign due to languish barrier is overcome.

Owner:SHENZHEN BAVEDA TECH

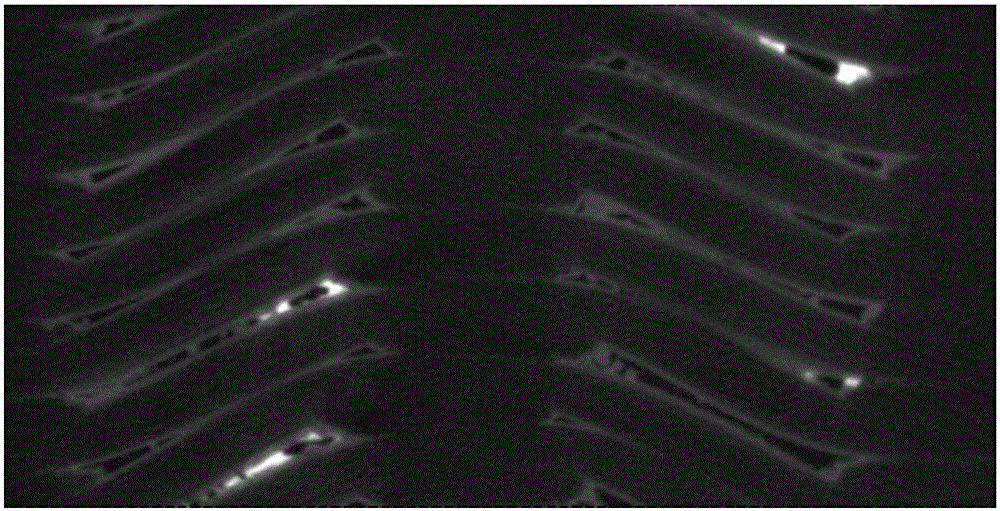

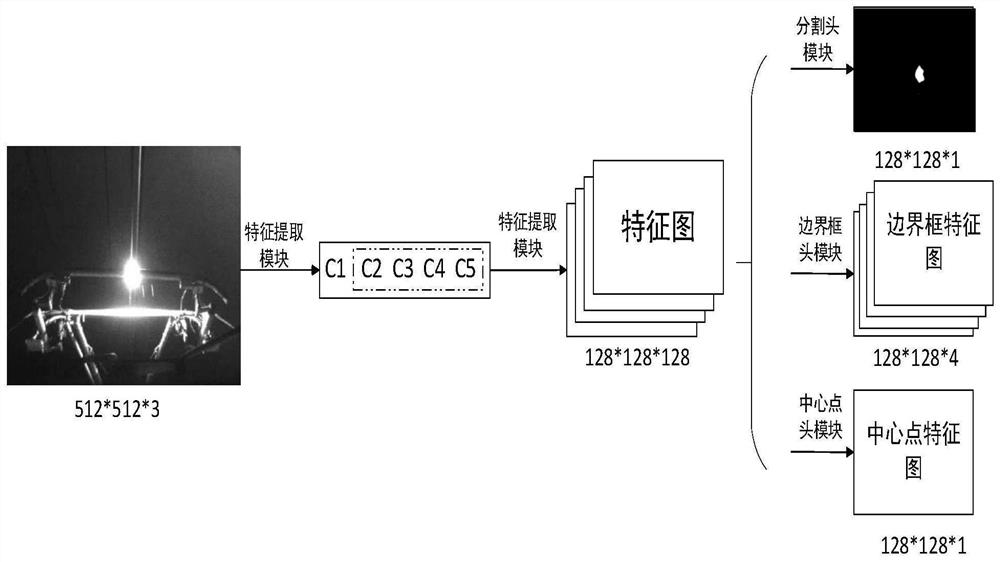

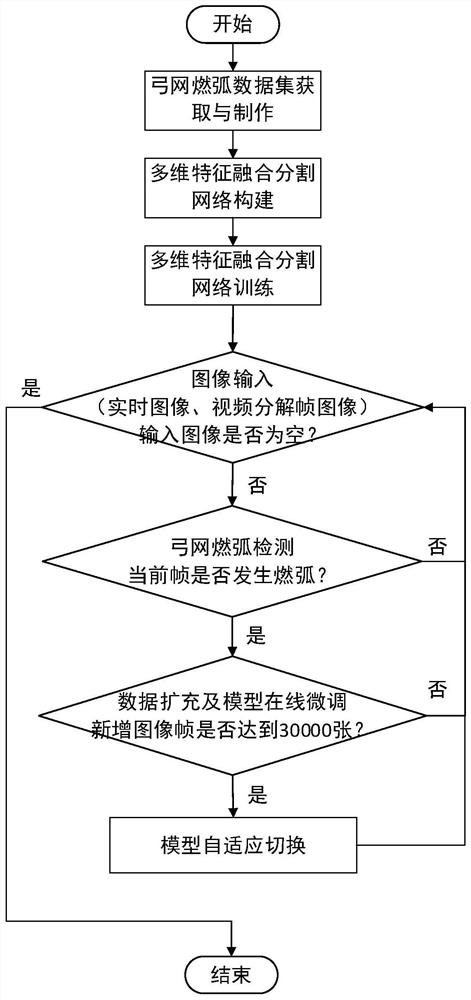

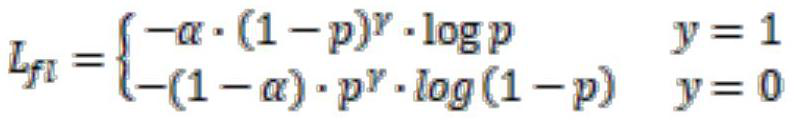

Visual detection method for pantograph-catenary arcing of electrified railway

ActiveCN112766195AGood effectImprove accuracyGeometric image transformationCharacter and pattern recognitionData setComputer pattern recognition

The invention provides a visual detection method for pantograph-catenary arcing of an electrified railway, and relates to the technical field of computer pattern recognition. Firstly, mask labeling is carried out on a pantograph-catenary image with arcing, then a labeled image is used as a data set of a multi-dimensional feature fusion segmentation network to train a network, the segmentation network adopts a deep convolutional network and is composed of a feature extraction module, a multi-dimensional feature fusion module and a head module, forward reasoning is carried out on the pantograph-catenary image through the segmentation network, and a network segmentation head sub-module outputs a feature map obtained after double up-sampling of a result as a segmentation result of the pantograph-catenary image. Deep separable convolution and grouping convolution are added into a multi-dimensional feature fusion module, the network is enabled to pay more attention to arcing region features through the addition of a same-channel attention and space attention mechanism, the network can accurately detect whether an arcing phenomenon occurs in a pantograph-catenary image after training is completed, and the accuracy and robustness of the network can also be improved by performing online learning and adaptive switching on the model.

Owner:SOUTHWEST JIAOTONG UNIV

Insect image detection method and insect classification method

InactiveCN105243390ARealize automatic identificationAccurately reflectCharacter and pattern recognitionSpecial data processing applicationsImage detectionClassification methods

The present invention discloses an insect image detection method and an insect classification method. The method comprises the following steps of: converting frame images in collected video data from colorful images into gray images, and performing partition after performing a difference operation between the gray image and a corresponding modelling background; calculating feature values of image blocks, and normalizing and fusing the feature values; according to an Otsu method, performing adaptive threshold partition on an obtained saliency map with super-pixel precision to obtain a binary image; and generating an image description of the image, performing image matching with each image in a knowledge database, and according to a matching result, determining whether a to-be-classified fruit fly belongs to a known species in the knowledge database. According to the method, automatic identification of insect species is realized by a computer pattern identification technology, and the visual saliency is well combined with phrases, thereby more accurately reflecting a saliency area in a query image and improving identification precision.

Owner:HENAN INST OF SCI & TECH

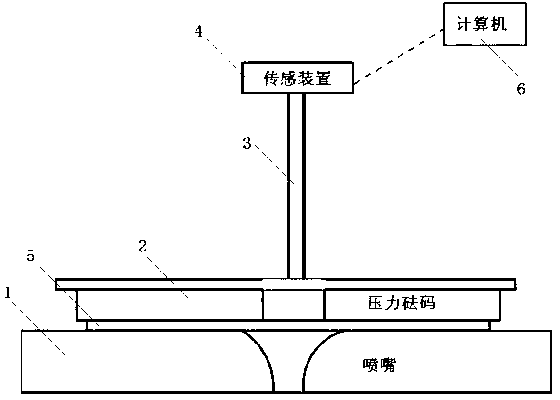

Pattern recognition system and method for evaluating organoleptic performance of fabrics

InactiveCN102354368BMeasuring and evaluating drapabilityMeasuring and evaluating wrinkle recoveryCharacter and pattern recognitionBiotechnologyOriginal data

The invention discloses a pattern recognition system and a pattern recognition method for evaluating the organoleptic performance of fabrics. The system comprises a spray nozzle, wherein the fabrics to be detected are arranged on the spray nozzle; a pressure weight is arranged above the fabrics to be detected; a push rod is connected to the pressure weight; and a sensing device is arranged on thepush rod and is connected with a computer. The method comprises the following steps of: acquiring original data which represents the organoleptic performance from a fabric material, performing feature analysis and extraction on the original data by using a novel computer pattern recognition algorithm, performing physical calibration, and calculating and processing the fabrics by using a result toevaluate the handfeel of the fabrics. The pattern recognition system and the pattern recognition method can be directly used for measuring and evaluating the drapability and crease recovery of the fabrics, and also can be used for tests including paper, leather products and the like.

Owner:SUZHOU FENGBAO NEW MATERIAL SYST TECH

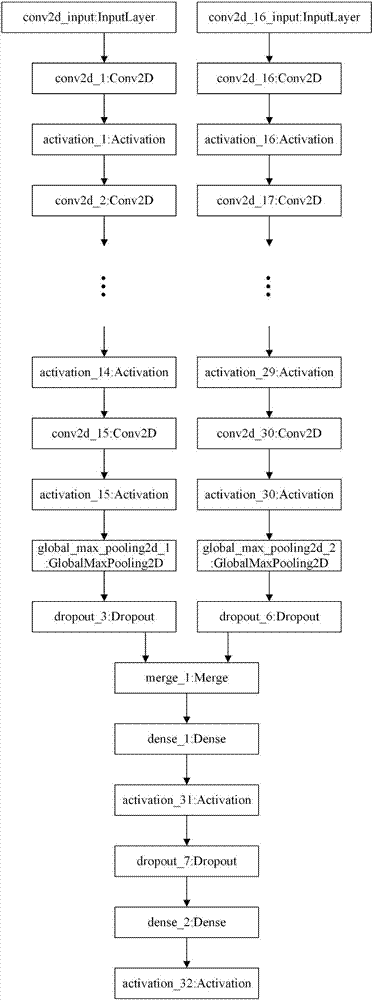

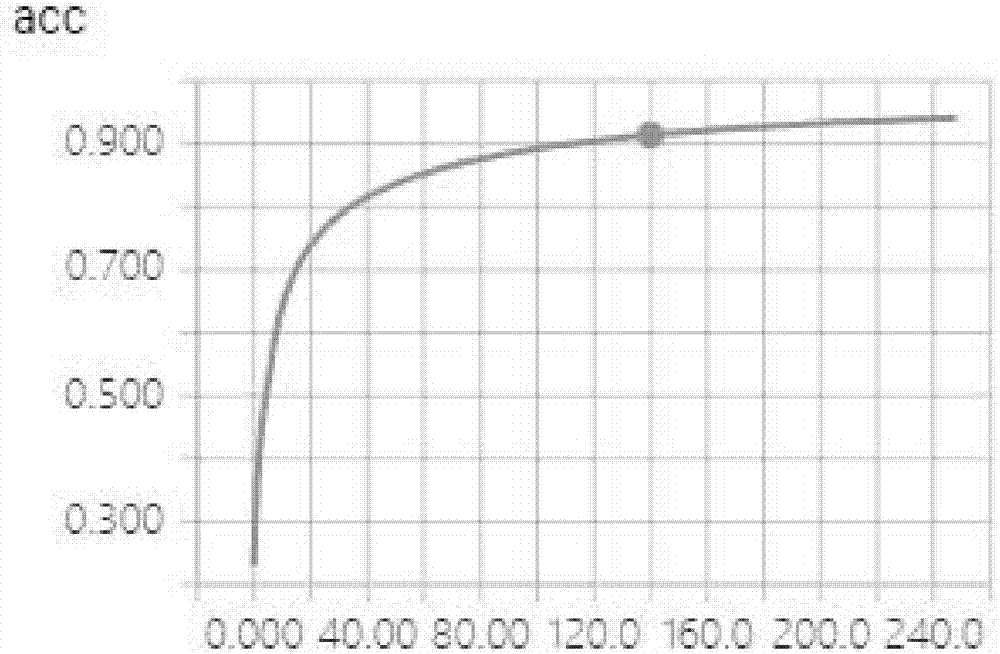

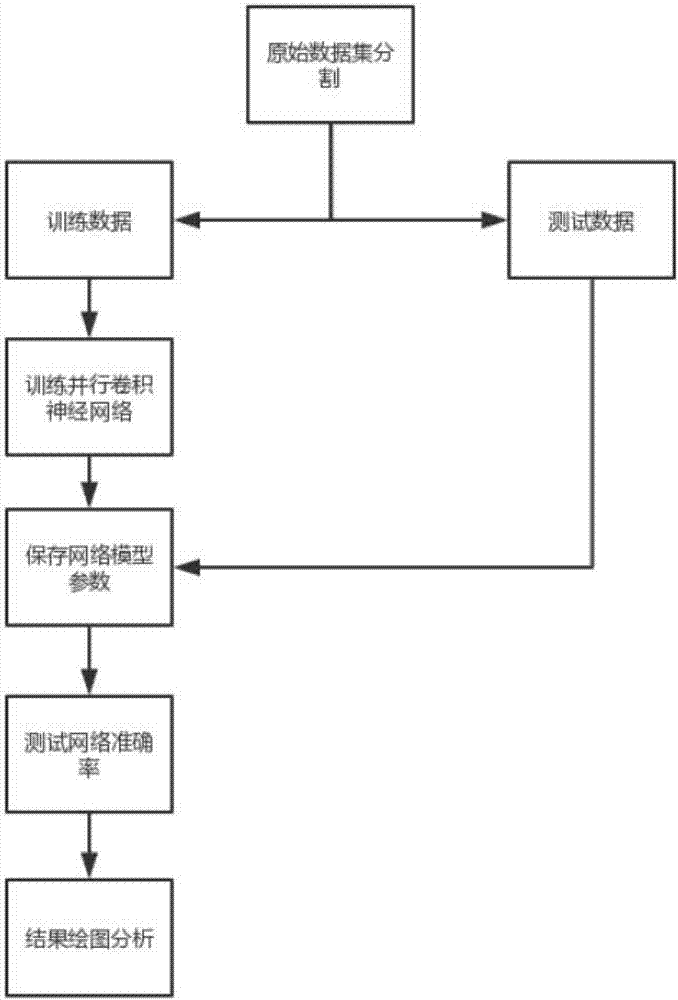

Parallel convolutional neural network method based on computer pattern recognition

InactiveCN107886165AIncrease training speedSave cost resourcesNeural architecturesData setComputer pattern recognition

The invention discloses a parallel convolutional neural network method based on computer pattern recognition. The parallel convolutional neural network method based on computer pattern recognition comprises the following three stages, namely an image classification data collection stage, a parallel convolutional neural network construction stage and a deep convolutional neural network classification stage. The parallel convolutional neural network disclosed by the invention can serve as an actual application platform of a deep learning algorithm for aiding learning; in the current deep learning field, the neural network training speed is improved; and since few hardware cost resources are used in the method disclosed by the invention, the method is easy to implement. The method is composedof an image dataset and a parallel convolutional neural network. The image dataset is composed of various image classification data downloaded from the internet, and the parallel convolutional neuralnetwork is an improved deep convolutional network.

Owner:BEIJING UNIV OF TECH

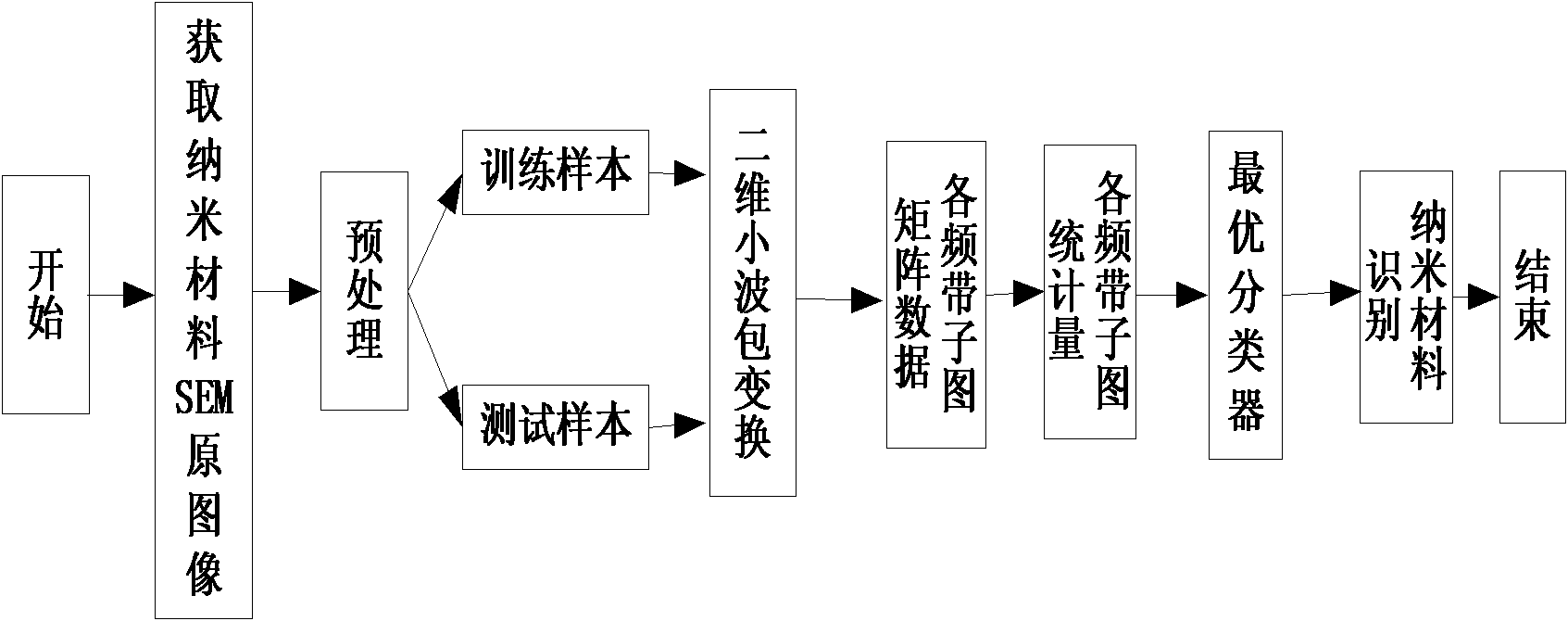

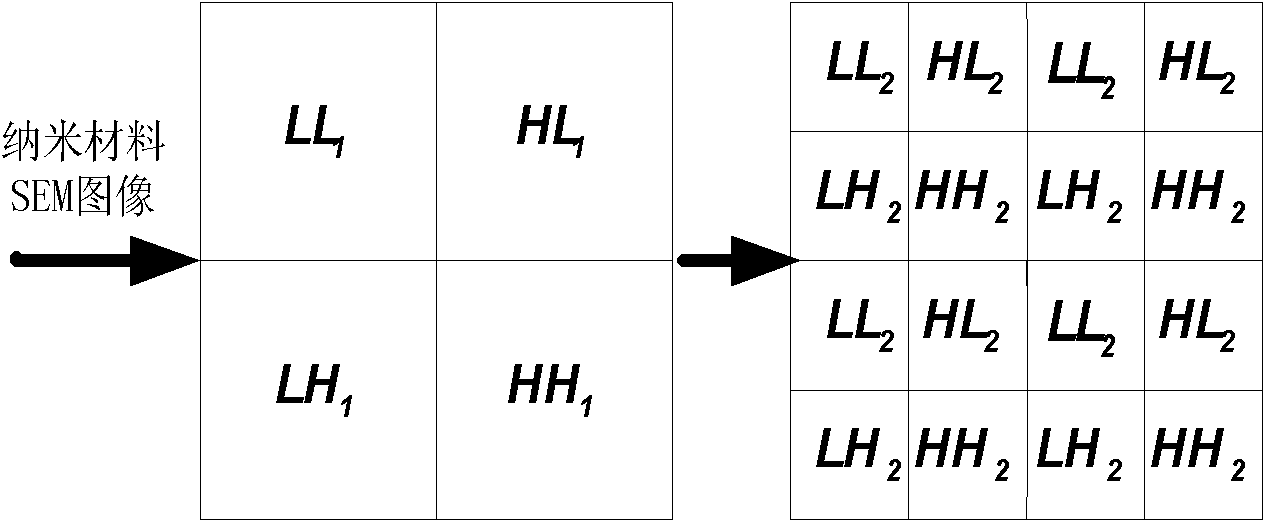

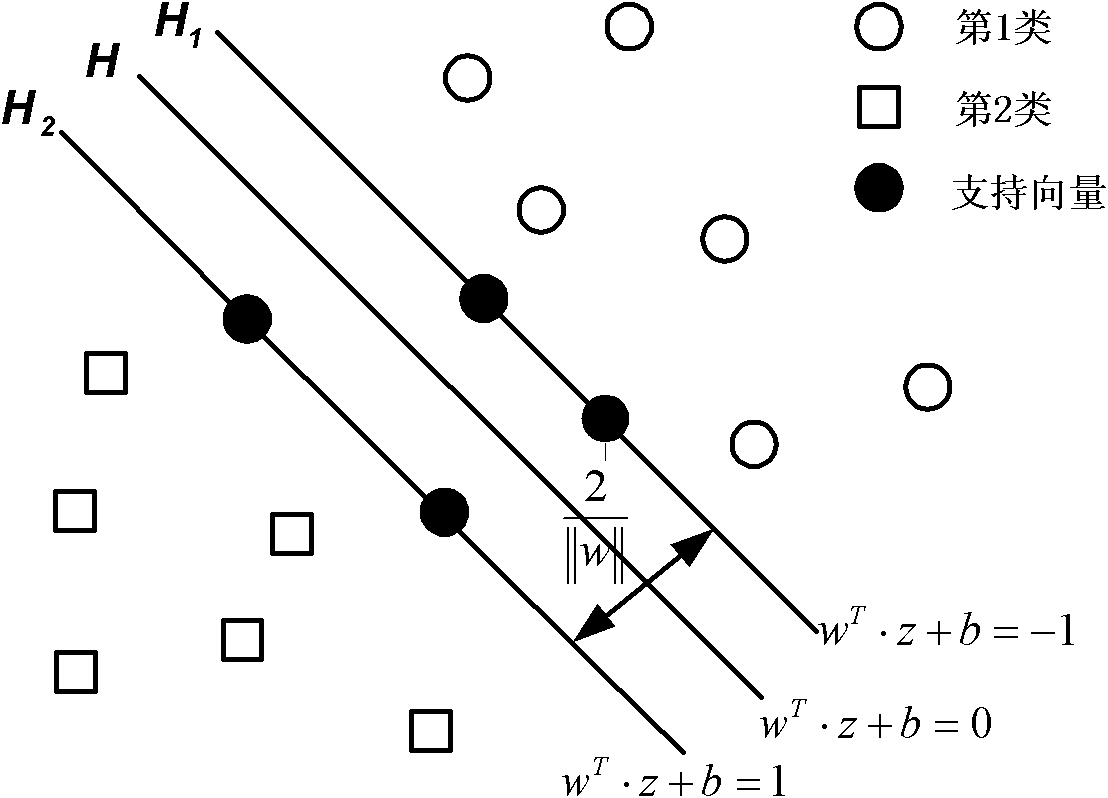

Low-dimensional nano material identification method based on SEM image

ActiveCN102183535ARealize topographical characterizationImplement automatic classificationCharacter and pattern recognitionNanotechnologySupport vector machineGaussian radial basis function

The invention belongs to the crossed technical field of computer mode identification and nano material, and relates to a low-dimensional nano material identification method based on an SEM image. The method comprises the following steps of: (1) preprocessing a known nano material SEM image sample; (2) performing two-dimensional wavelet transformation on the preprocessed image to get sub-image matrixes on different frequency bands; (3) extracting characteristics of the sub-image matrixes on each frequency band, and taking a statistical value of each sub-image matrix as a characteristic value for representing surface texture of the nano material; (4) according to the characteristic value, taking a Gaussian radial basis function as a support vector machine kernel function to find an optimal hyperplane between any two classes, and creating a classification model for different classes of nano materials; (5) extracting a texture characteristic value of the known nano material SEM image sample, and identifying the unknown nano material by voting according to the classification model obtained in the step (4). The low-dimensional nano material identification method based on the SEM image represents and distinguishes different nano material structure types more accurately and effectively, and has the advantages of high accuracy, strong expansibility, high degree of automation and the like.

Owner:NANTONG HUALONG MICROELECTRONICS

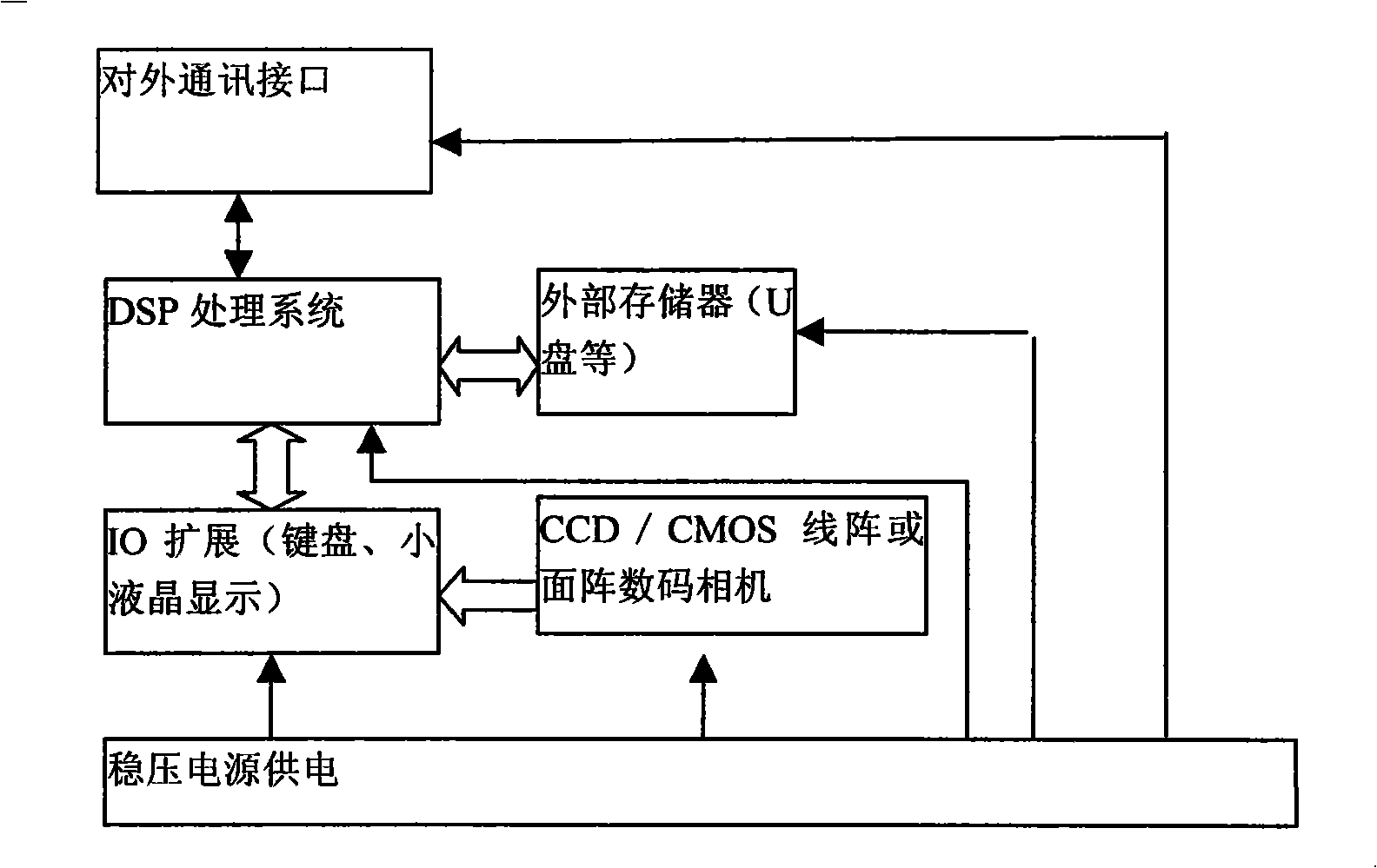

Round knitting machine on-line quality monitoring method based on computer pattern recognition principle

InactiveCN101308097AReduce generationReduce usageInspecting textilesTextile testingSites treatmentEngineering

The invention relates to an on-line quality monitoring method of a circular knitting machine based on the computer graphical recognition principle, which adopts a digital image collector which is fixed at the inner side of a machine table below the circular knitting machine, a lens thereof faces a circular cloth tube of the circular knitting machine to take photographs of moving cloth continuously according to a photographing frequency stated in one unit of time, the collected linear or planar array digital pictures are delivered in real time to a main spot processor which is equipped with a standard cloth sample library and a defect library for judging defects of textile; once a defect is detected, the main spot processor transmits a warning signal or even stops the machine table, and reports the defect type of the cloth, calculates and indicates the specific location where the defect occurs; and the main spot processor is provided with a liquid crystal display and a keyboard, and can be equipped with an external communication interface and an external memory interface. The on-line quality monitoring method can be adopted to conduct non-stop inspection of product quality in the running process of equipment, so as to judge defects of products and indicate the defect types and locations of defects.

Owner:何峰

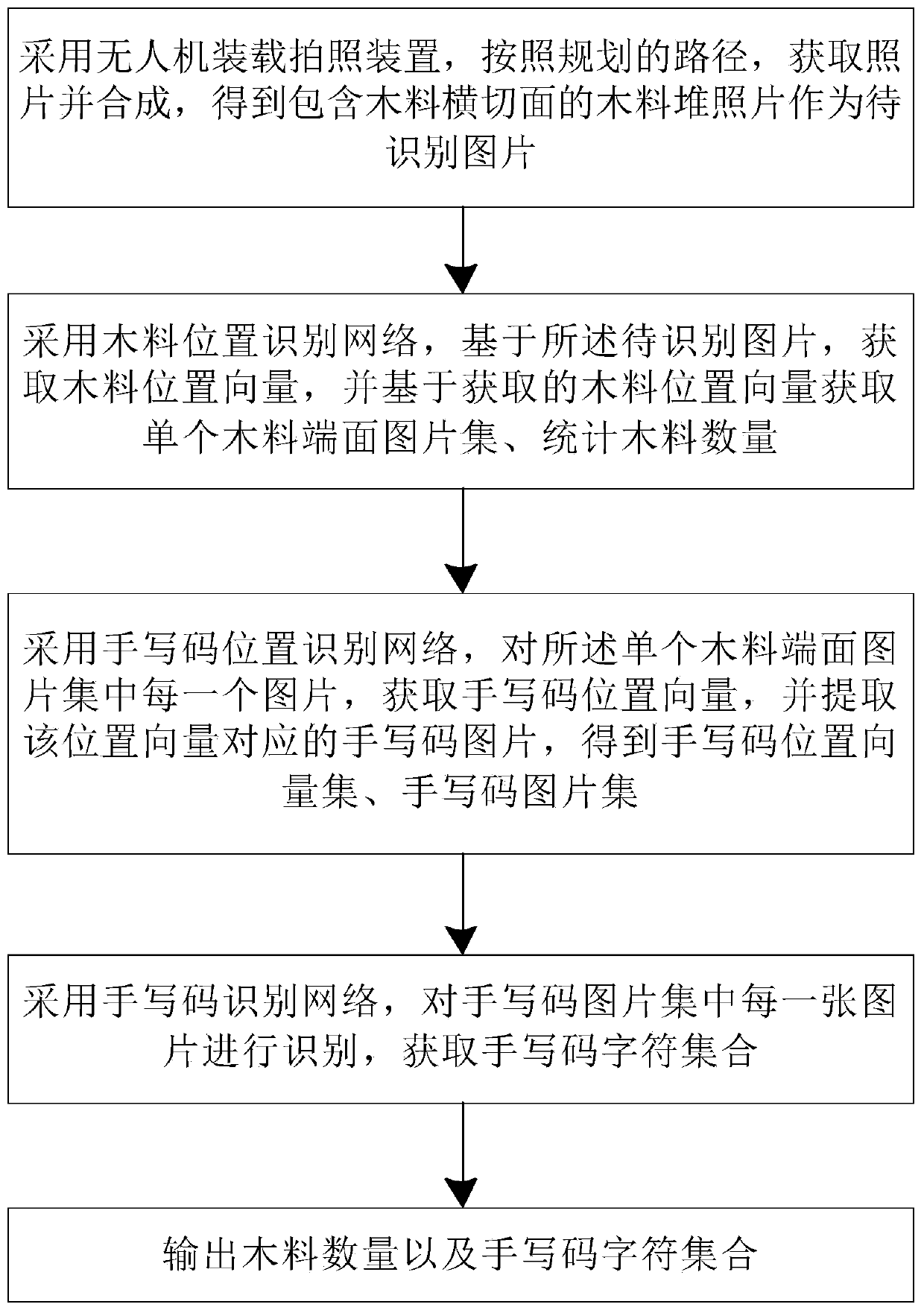

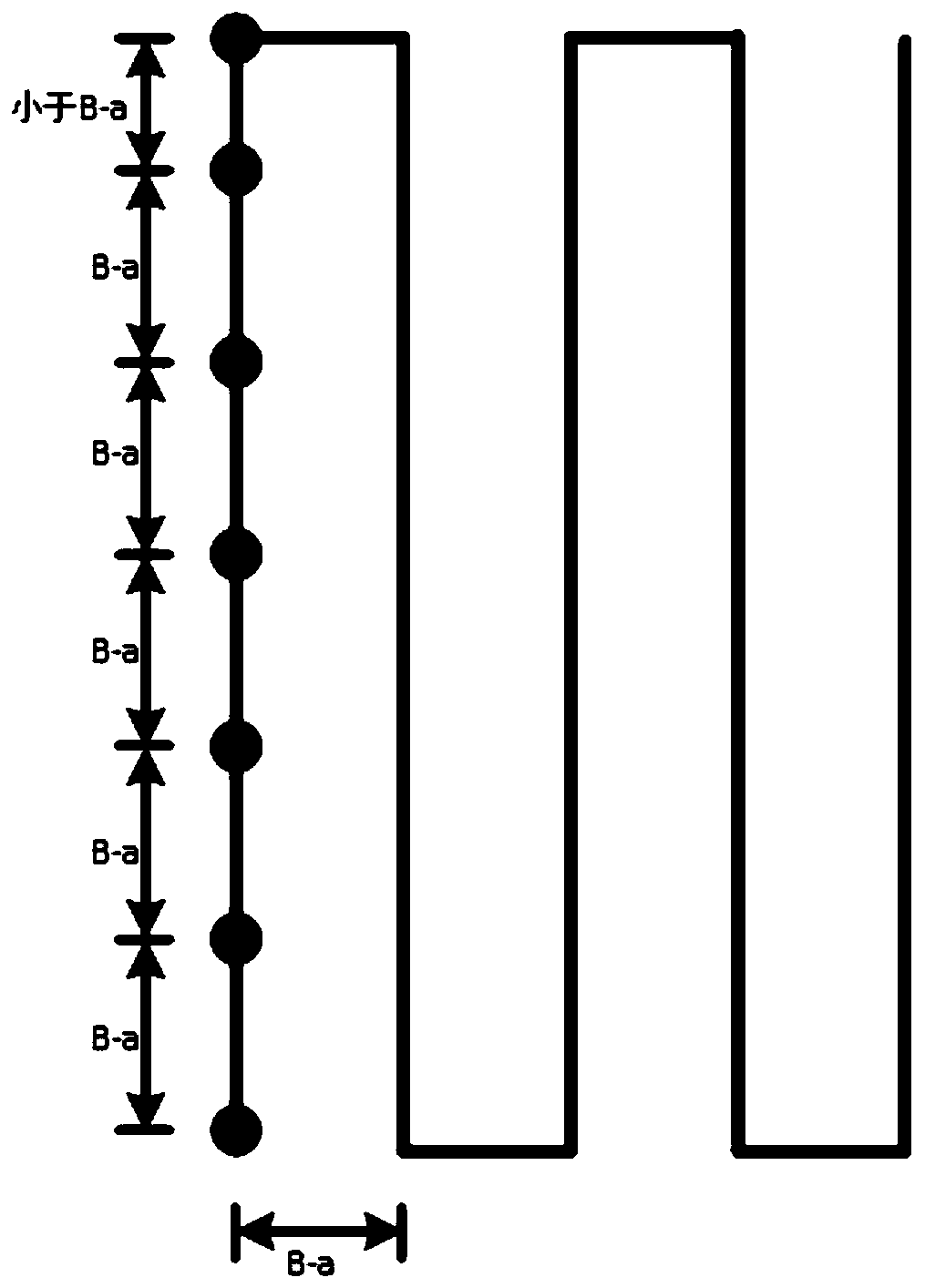

Timber yard wood information acquisition method, system and device based on unmanned aerial vehicle

ActiveCN110084132ARealize image acquisitionRealize acquisitionForecastingScene recognitionInformatizationHandwriting

The invention belongs to the field of unmanned aerial vehicles and computer mode recognition, particularly relates to a timber yard timber information acquisition method, system and device based on anunmanned aerial vehicle, and aims to solve the problem that informatization management of a timber yard is affected due to the fact that timber piles of the timber yard are difficult to take picturescompletely. The method comprises the steps that an unmanned aerial vehicle is adopted to load a photographing device, and pictures are obtained and synthesized according to a planned path; adopting awood position recognition network to obtain a wood position vector and a single wood end face picture set, and counting the number of wood; obtaining a handwritten code position vector set and a handwritten code picture set by adopting a handwritten code position identification network; obtaining a handwritten code character set by adopting a handwritten code recognition network; and outputting the wood quantity and the handwriting code character set. According to the invention, the unmanned aerial vehicle is adopted to load the photographing device to acquire and synthesize pictures, so thatthe overall image acquisition of large objects or densely stacked objects is realized, the automatic information acquisition of special occasions is realized, and the low efficiency and high error rate of a manual intervention process are avoided.

Owner:杭州深数科技有限公司

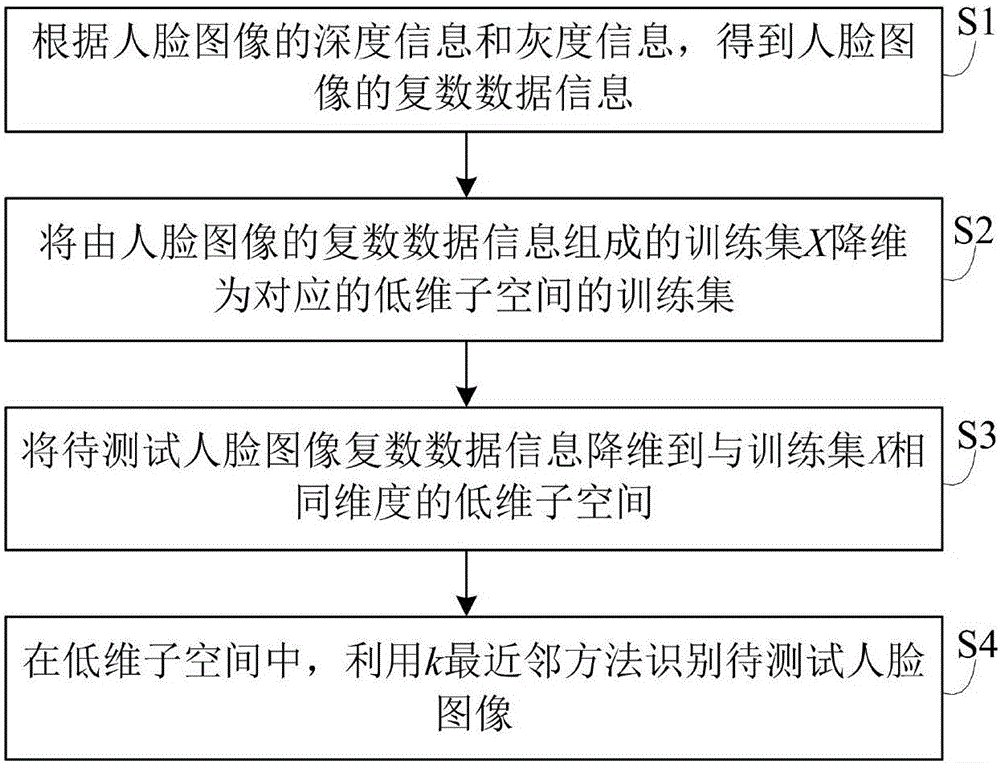

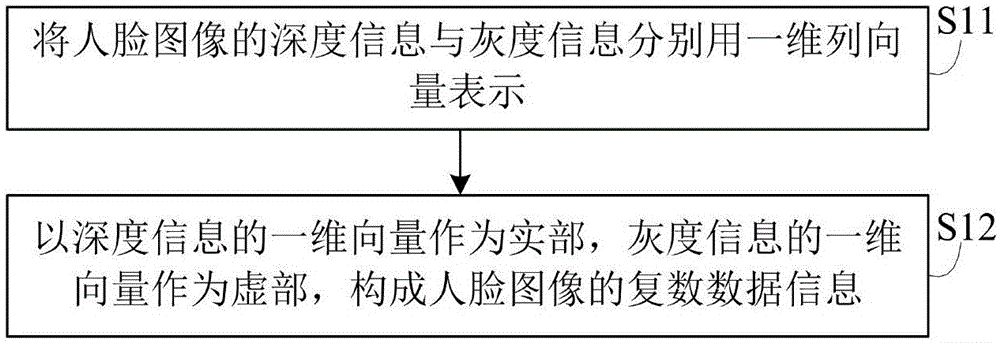

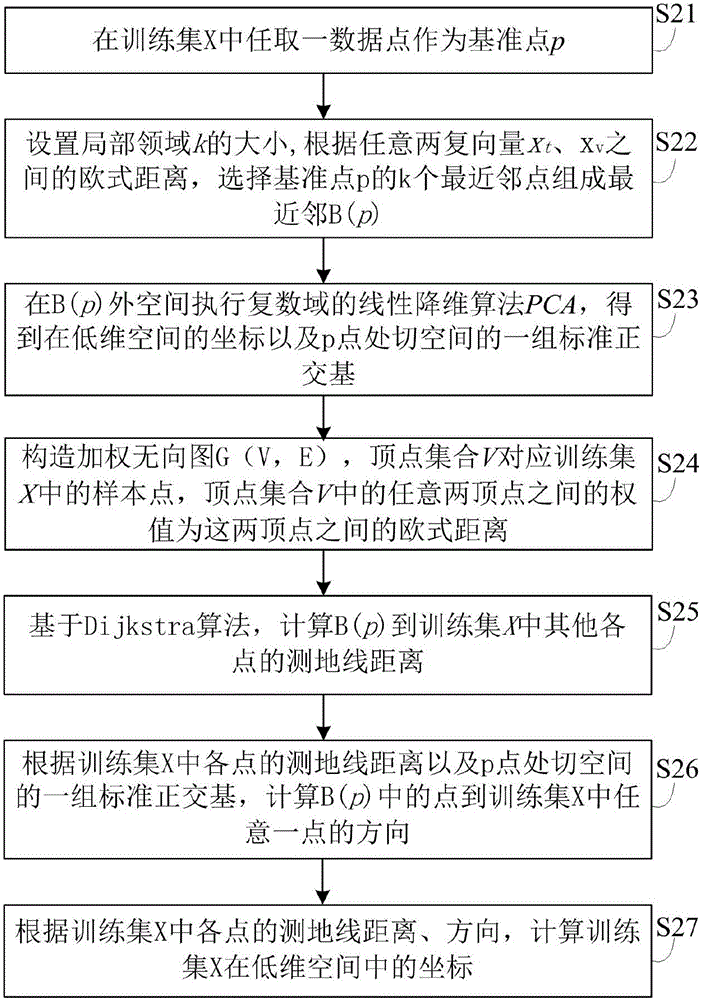

Method for recognizing human faces on basis of information fusion

The invention discloses a method for recognizing human faces on the basis of information fusion, and belongs to the field of technologies for recognizing computer patterns. The method includes acquiring complex data information of human face images according to depth information and gray information of the human face images; representing training sets X in low-dimension subspaces; reducing dimensions for to-be-tested human face images until the to-be-tested human face images are in low-dimension subspaces identical to the low-dimension subspaces of the training sets X and then recognizing the human faces in the low-dimension subspaces by the aid of k nearest neighbor processes. The training sets X comprise the complex data information of the human face images, each training set comprises the corresponding human face images of m persons, and each person has n corresponding human face images. The method has the advantages that the depth information and the gray information of the human face images are fused to obtain the complex data information of the human faces, then the dimensions of the complex data information of the human faces are reduced until the complex data information can be represented in the low-dimension subspaces, the human faces are recognized in the low-dimension subspaces, and accordingly the human face recognition accuracy can be improved.

Owner:ANHUI CREARO TECH

Coarse emotion soft cutting and classification method for waveform music

ActiveCN102930865BImprove universalityAccurate emotional feature recognition resultsSpeech recognitionNODALFeature extraction

The invention discloses a coarse emotion soft cutting and classification method for waveform music, belonging to the field of pattern recognition of computers. The coarse emotion soft cutting and classification of the waveform music are performed by a Mallat algorithm by aiming at music characteristic parameters, and the problem of accurate capture of waveform music characteristic emotion information used for a control system is solved. The method specifically comprises the following steps of (1) establishing a coarse emotion space domain; (2) pretreating; (3) extracting characteristics; (4) performing soft cutting; and (5) classifying. According to the method, the waveform music is processed by a time-frequency domain analysis method based on the Mallat algorithm, comparison parameter nodes with higher universality can be acquired by a samples training method according to two basic music characteristic quantities (intensity and rhythm), and skip conditions among all the emotion domains are determined according to the experience of experts, and effects of coarse emotion soft cutting and classification on the music are achieved finally.

Owner:黑盒子科技(北京)有限公司

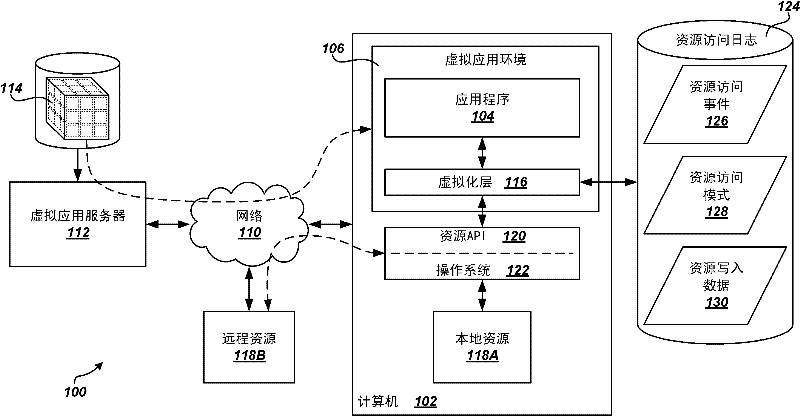

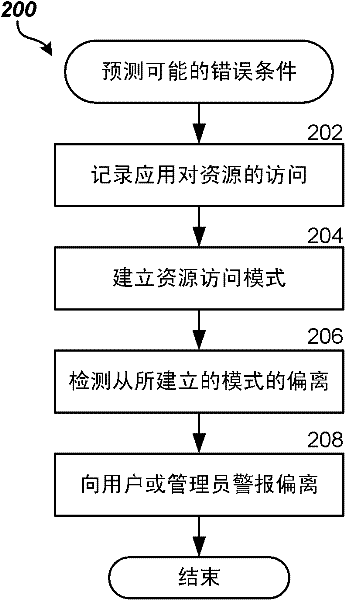

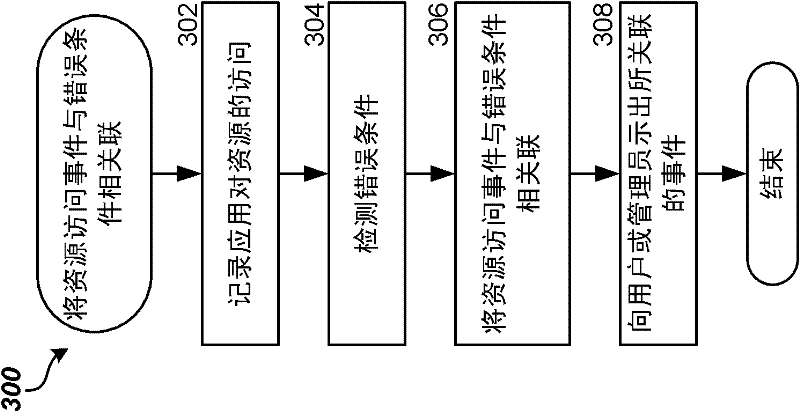

Predicting, diagnosing, and recovering from application failures based on resource access patterns

ActiveCN102567181AAvoid lossRapid diagnosisHardware monitoringReliability/availability analysisComputer pattern recognitionDiagnostic information

The invention relates to predicting, diagnosing, and recovering from application failures based on resource access patterns. Technologies are described herein for differentiating normal operation of an application program from error conditions to predict, diagnose, and recover from application failures. Access to resources by the application program is monitored, and resource access events are logged. Resource access patterns are established from the logged resource access events utilizing computer pattern recognition techniques. If subsequent access to resources by the application program deviates from the established patterns, then a user and / or administrator of the application program is notified of a potential error condition based on the detected deviation. In addition, sequences of resource access events that deviate from the established resources access patterns are correlated with an error condition based on a temporal proximity to the time of occurrence of the error to provide diagnostic information regarding the error.

Owner:MICROSOFT TECH LICENSING LLC

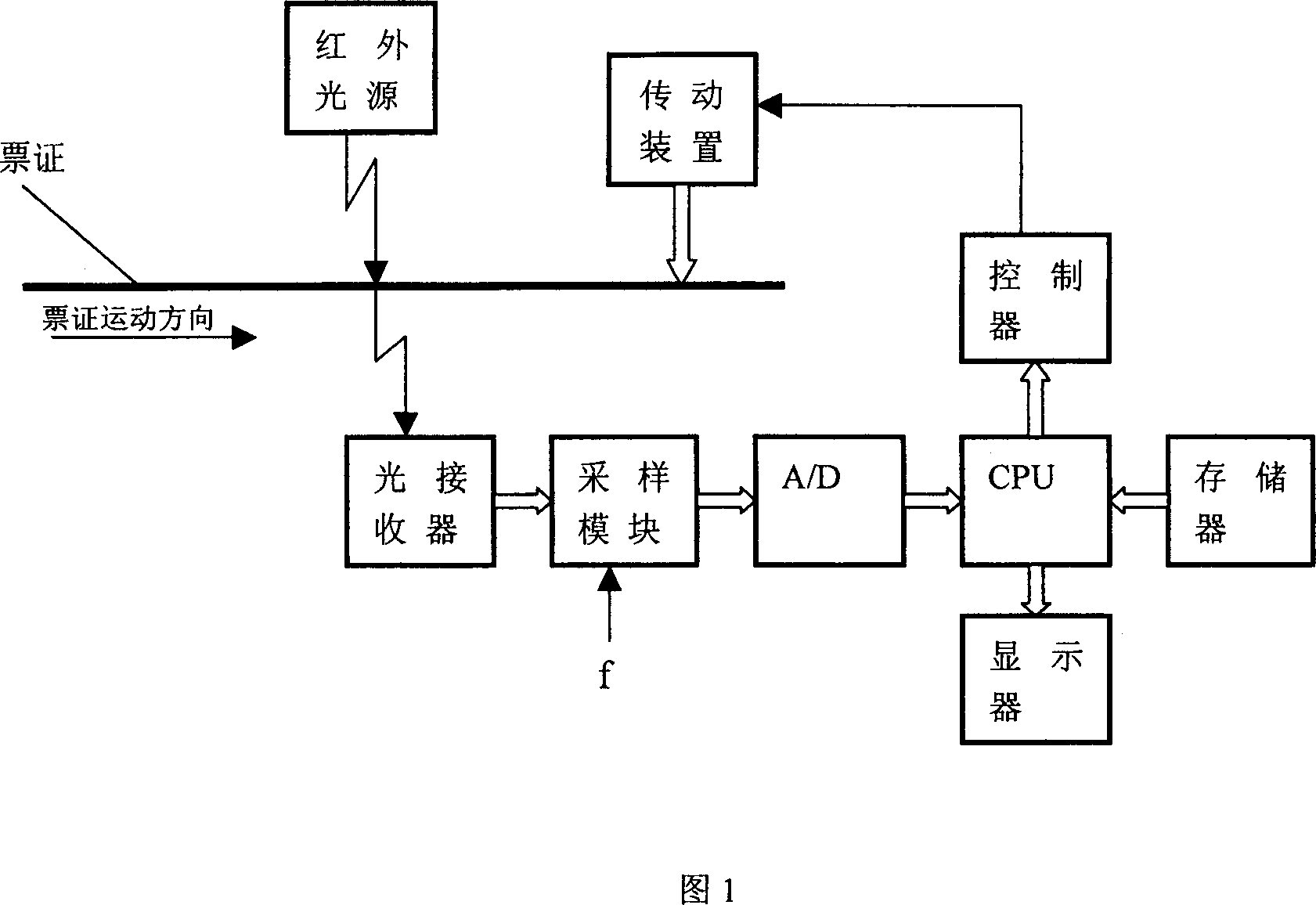

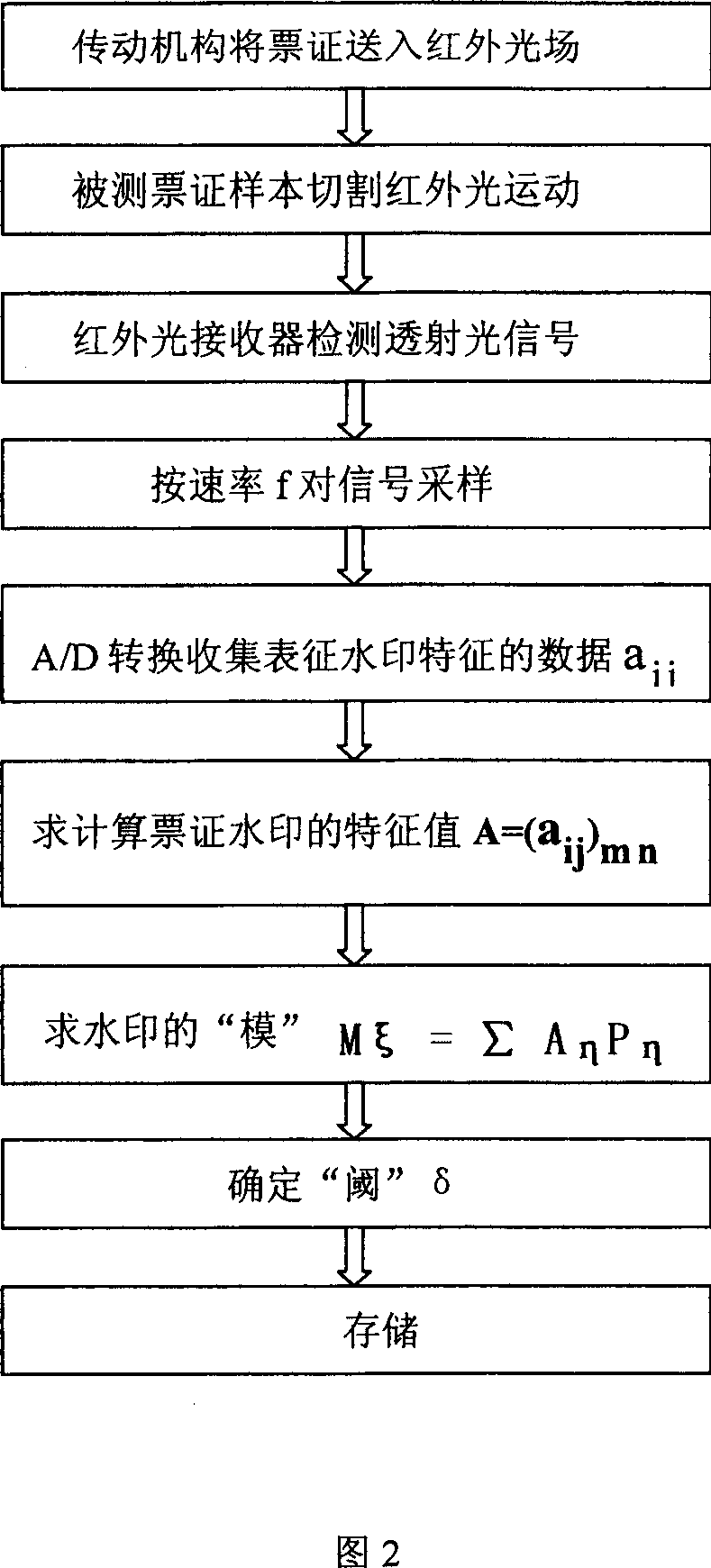

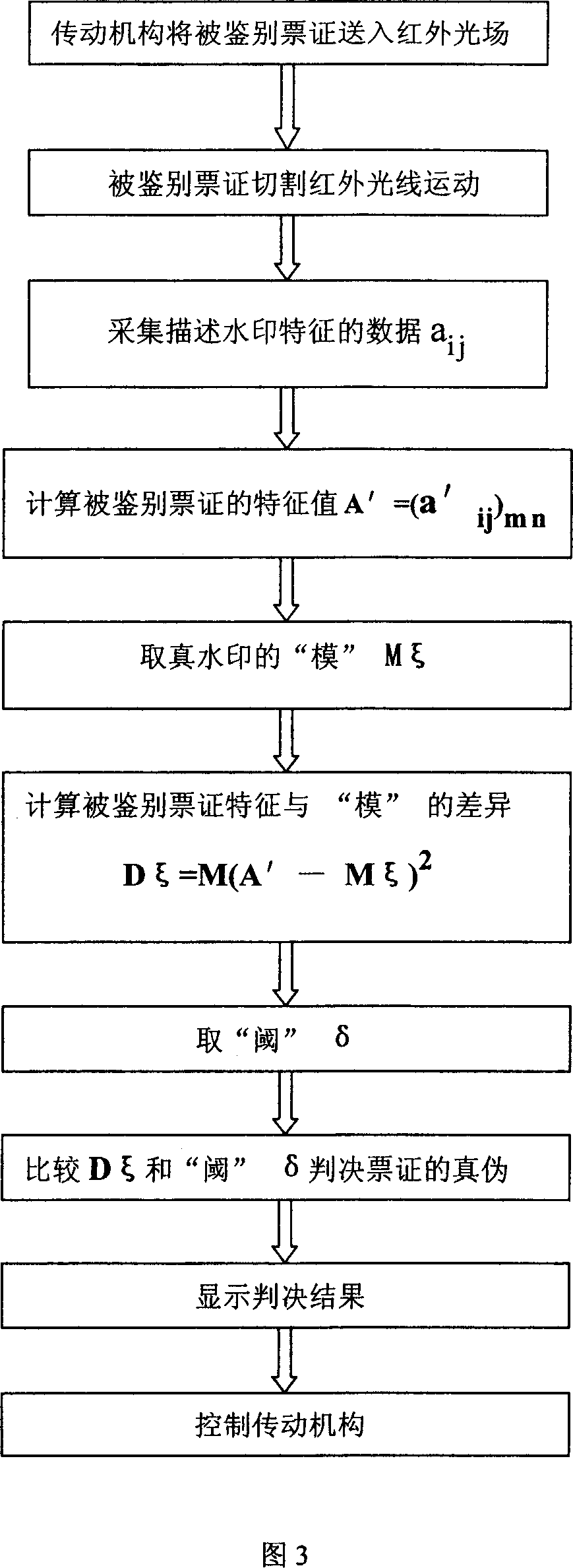

Method and device for true-false identifying of paper ticket based on infrared identifying watermark

InactiveCN1971636AFast identification of authenticityThe identification result is accuratePaper-money testing devicesMathematical modelComputer module

The invention relates to a method and device for discriminating the genuine-fake of paper receipt based on infrared discrimination watermark. The receipt to be detected is through the infrared field via transmission means, the optical receiver covered with watermark pattern detects the transmitted light in the watermark area of receipt in motion procedure, complete the photoelectric signal conversion; output to the sampling module and the digital signal characterized the watermark is obtained by analogue / digital conversion; the analog of watermark which is obtained from the mathematical model complex characterization is as the criterion to discriminate genuine or fake to judge the genuine-fake of the watermark, the central processing unit executes the recognition program of discriminate genuine or fake of watermark, and output the discrimination result. The central processing unit is connected with the controller and memory, the controller is connected with the transmitting means. The invention discriminates genuine or fake by computer module discrimination technique, and the false proof means can be processed by more advanced and accurate device, and make the speed of discrimination technique more fast and the result more accurate.

Owner:南京理工大学科技贸易公司

Method for rapid inspecting animalcule in liquid

InactiveCN101097206AMicrobiological testing/measurementMaterial analysis by optical meansMicroscopic imageImpurity

The invention relates to microbios quick test method in liquid which adopts acid-treatment, centrifugal separation, microscopic imaging, computer pattern recognition technique and programme. The fundamental difference between the invention and other microbios test method is: coloring agent is not used during course of test, without bacterial cultivation, liquid sample book detected is acidified and centrifuge treated. The create mode of execution is: firstly liquid sample book detected is acidified, so protein can be denaturation processed; thereinto the liquid sample book is centrifugal separated to clear protein, fat and impurity; then the liquid sample book is imaged using optical microscopic imaging system; and adopting computer pattern recognition technique to process the microscopic image of microbios, so purpose of detecting quantity of microbios within 2-3 minutes without coloring agent and train can be realized.

Owner:赵化平 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com