Spinning products on-line quality monitoring method based on computer pattern recognition principle

A technology of computer graphics and principles, applied in the field of textile machinery, can solve the problems of unguaranteed missing inspection, heavy workload, high labor intensity, etc., and achieve the effect of reducing the generation of defective products, reducing the amount of use, and improving labor production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

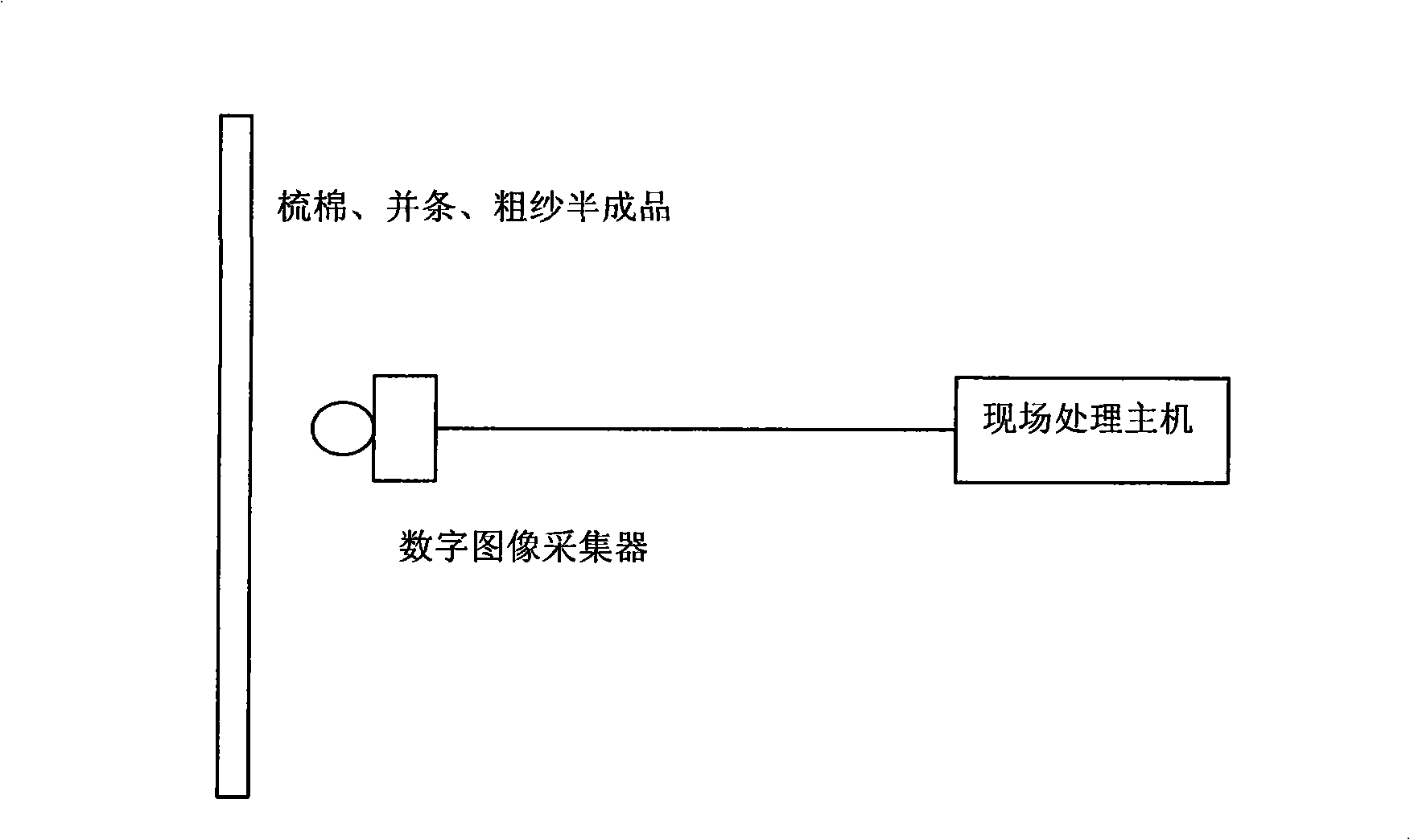

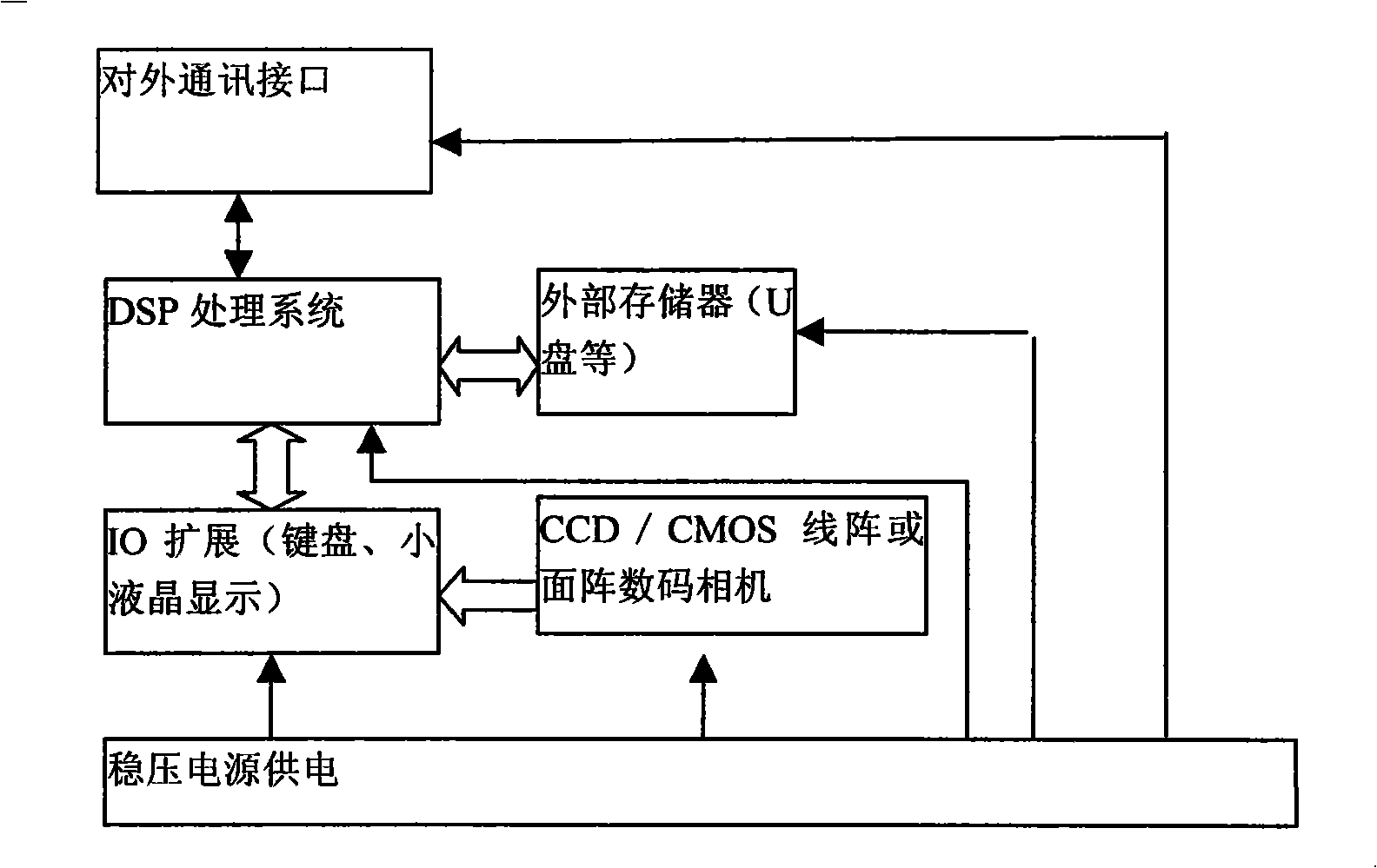

[0012] The on-line quality monitoring method of carding, drawing, and roving semi-finished products in spinning production based on the principle of computer graphic recognition involved in the present invention adopts a digital image collector, and the digital image collector adopts a linear array CCD or CMOS sensor, or Area array CCD or CMOS sensor is adopted, and the digital image collector is installed and fixed at the outlet of the machines involved in the processes of carding, drawing, and roving in the spinning production process. It is a fixed structure and does not generate movement at all times. . Described digital image acquisition device camera lens faces carding, drawing frame, roving semi-finished product, and digital image acquisition device lens is apart from carding, drawing frame, roving semi-finished product certain distance (the distance of specific distance, according to the focal length of the camera lens on the digital image acquisition device adjusted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com