Dyeing and printing products on-line quality monitoring method based on computer pattern recognition principle

A technology of computer graphics and principles, applied in textile testing, material inspection products, textiles and papermaking, etc., can solve the problems of high labor intensity, heavy workload, and inability to guarantee missed inspections, so as to reduce the generation of defective products and reduce the use of Quantity, the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

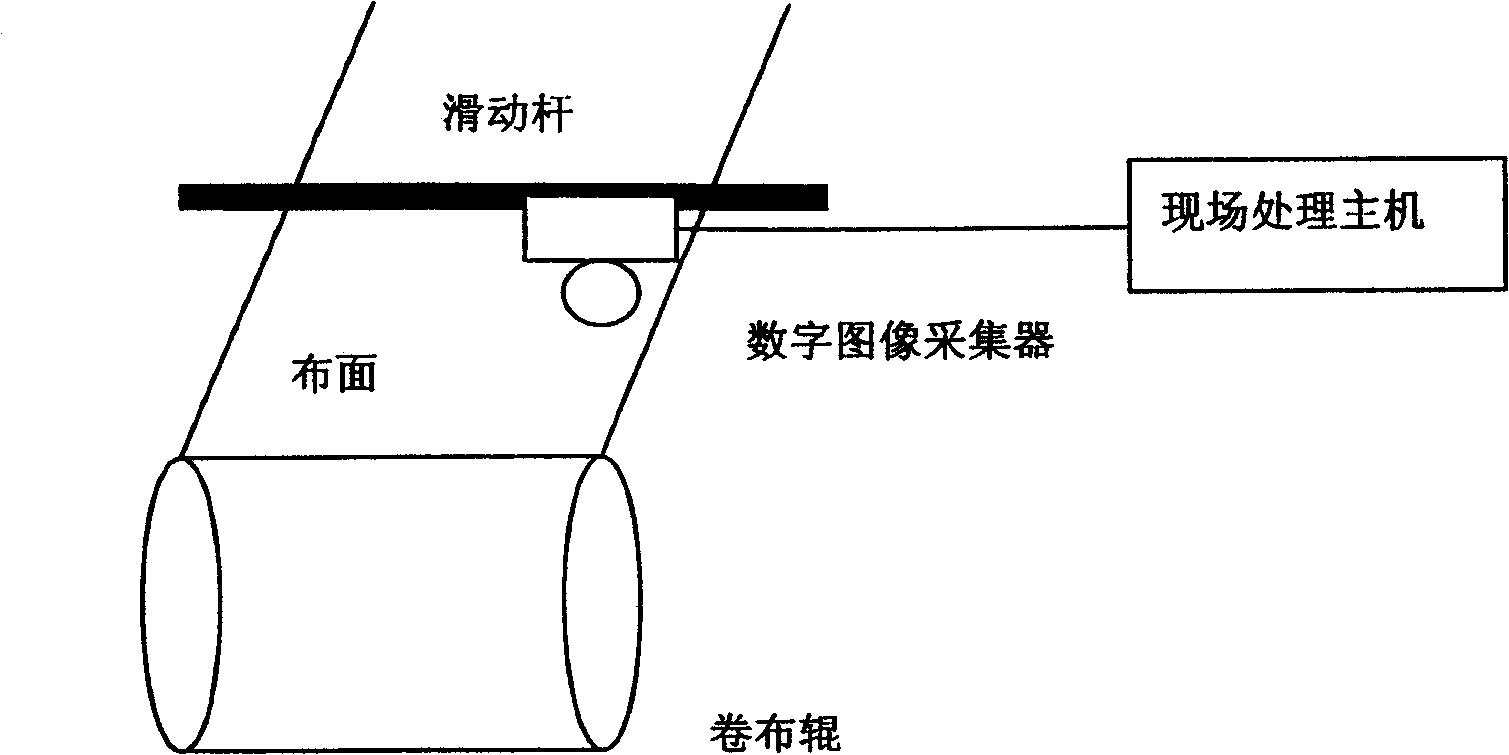

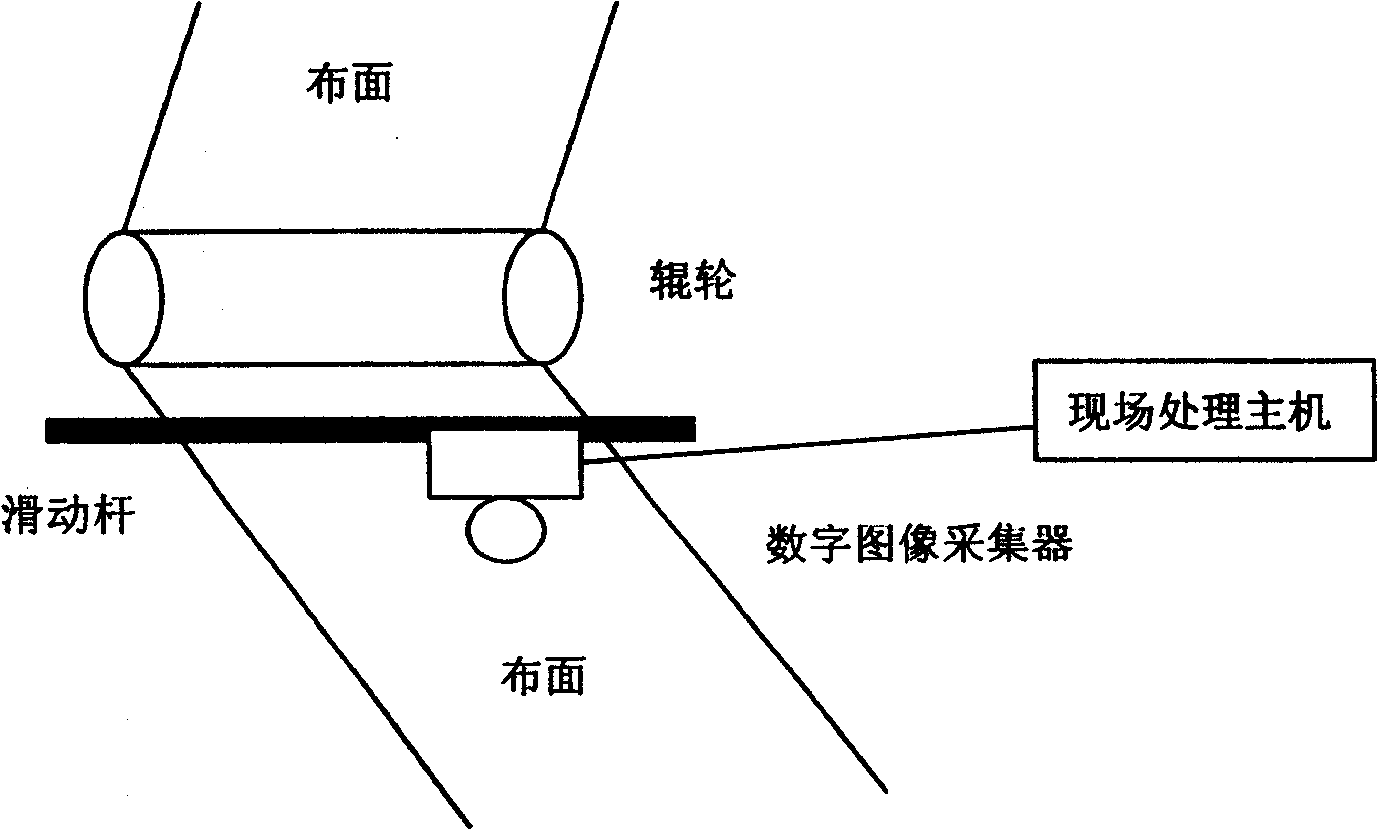

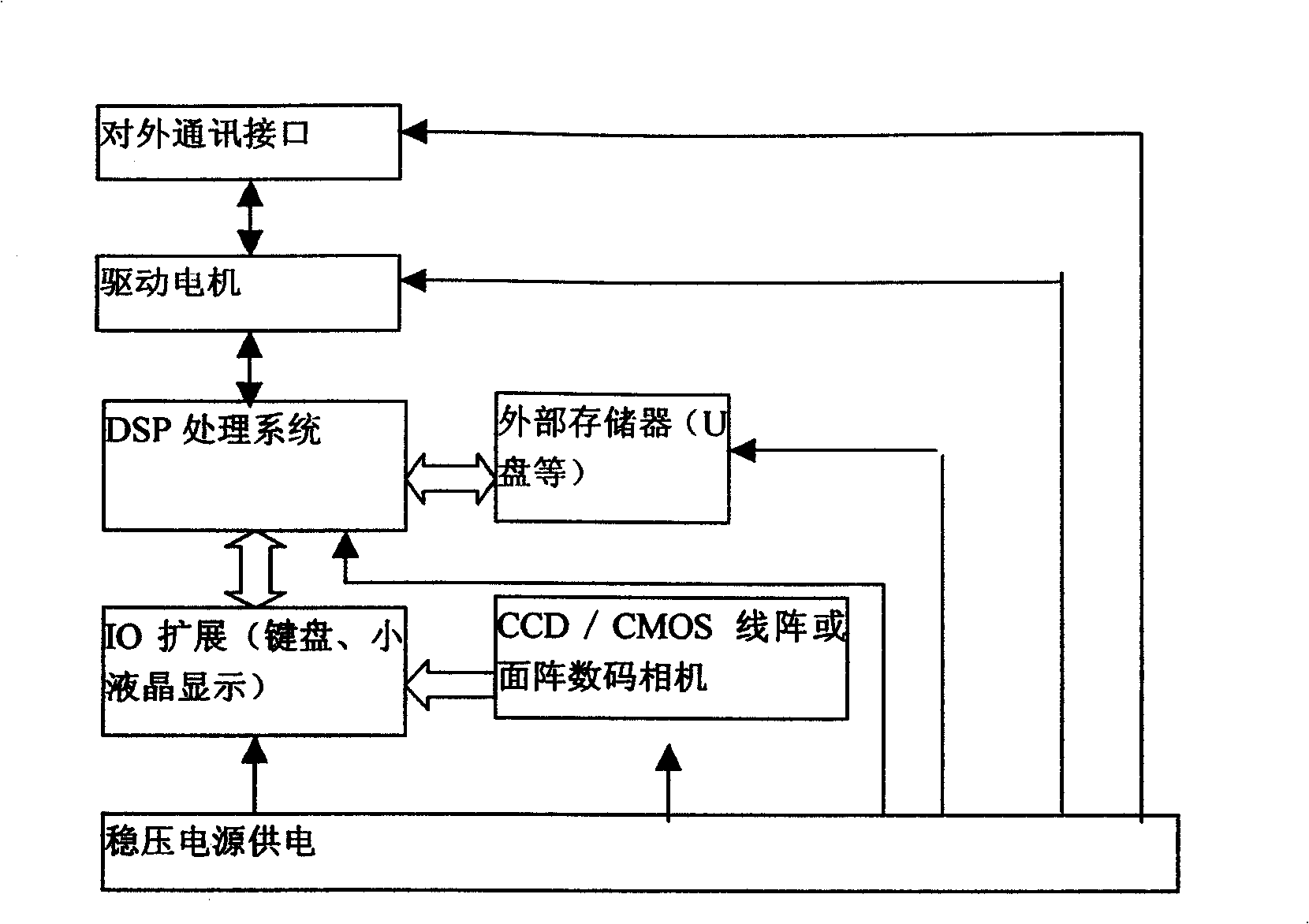

[0012] The online quality monitoring method of printing and dyeing products based on the principle of computer graphic recognition involved in the present invention adopts a digital image collector, and the digital image collector adopts a linear array CCD or CMOS sensor, or adopts an area array CCD or CMOS sensor. The digital image collector is installed and fixed on a sliding rod above the rollers or cloth rolling rollers in each process of printing and dyeing. The digital image collector can be driven by a motor according to the setting of the program and slide back and forth on the sliding rod. The camera lens of the digital image collector faces the cloth surface of the front end of the roller or the cloth rolling roller, and the lens of the digital image collector is at a certain distance from the roller wheel or the cloth surface of the cloth rolling roller (the distance of the specific distance depends on the distance of the lens on the digital image collector. focus an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com