Sieve plate made of graphite

A sieve plate and graphite technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of poor cold resistance, temperature resistance and processing performance, corrosion resistance, poor wear resistance, short service life, etc., to achieve The fineness is not easy to block holes, the fineness is accurate, and the service life is long

Inactive Publication Date: 2012-03-14

NANTONG WULIAN BRAND PLANNING

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most of the sieve plates used for material screening are metal sieve plates. Due to the inherent defects of metal materials, these metal sieve plates have poor corrosion resistance and wear resistance, and their service life is short.

In order to solve this problem, for example, the patent application No. 200920102045.4 relates to a wear-resistant rubber sieve plate. The wear-resistant rubber sieve plate has good wear resistance, but poor cold resistance, temperature resistance and processability, and high cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

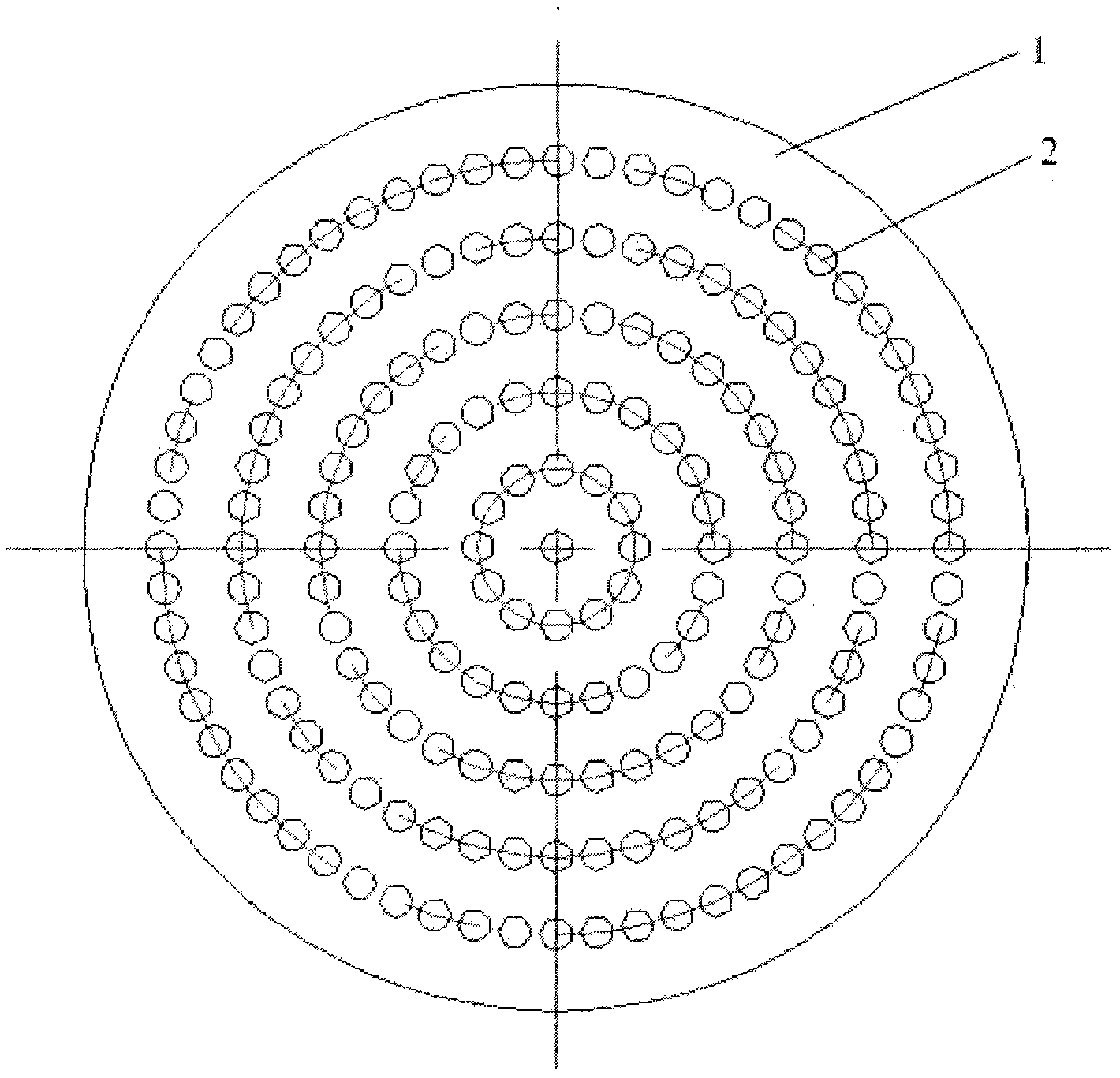

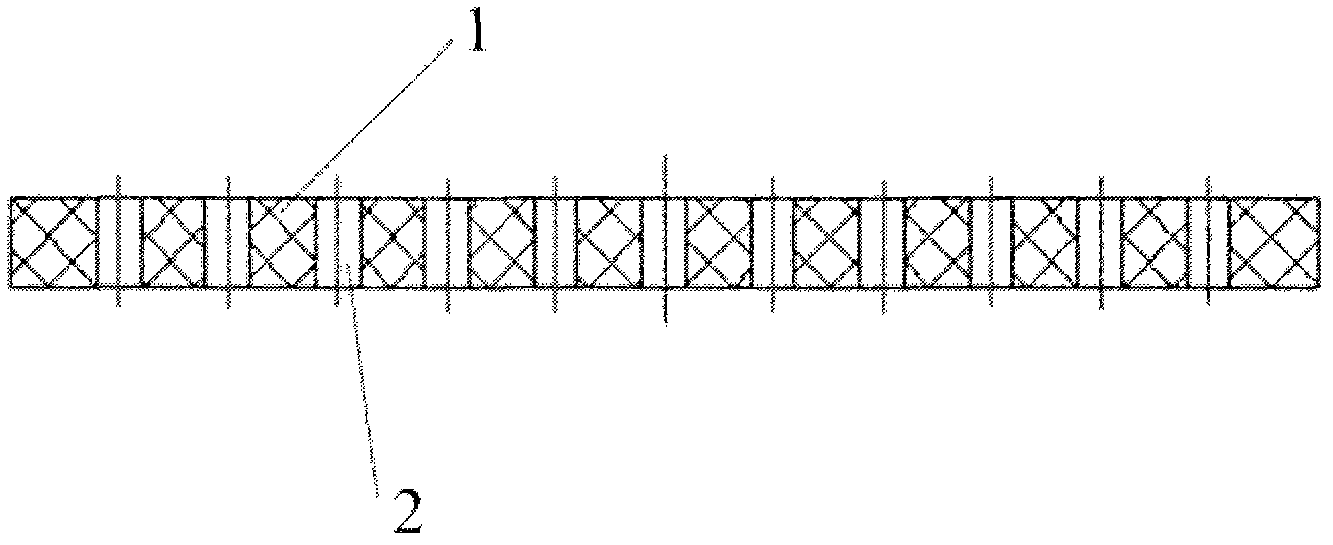

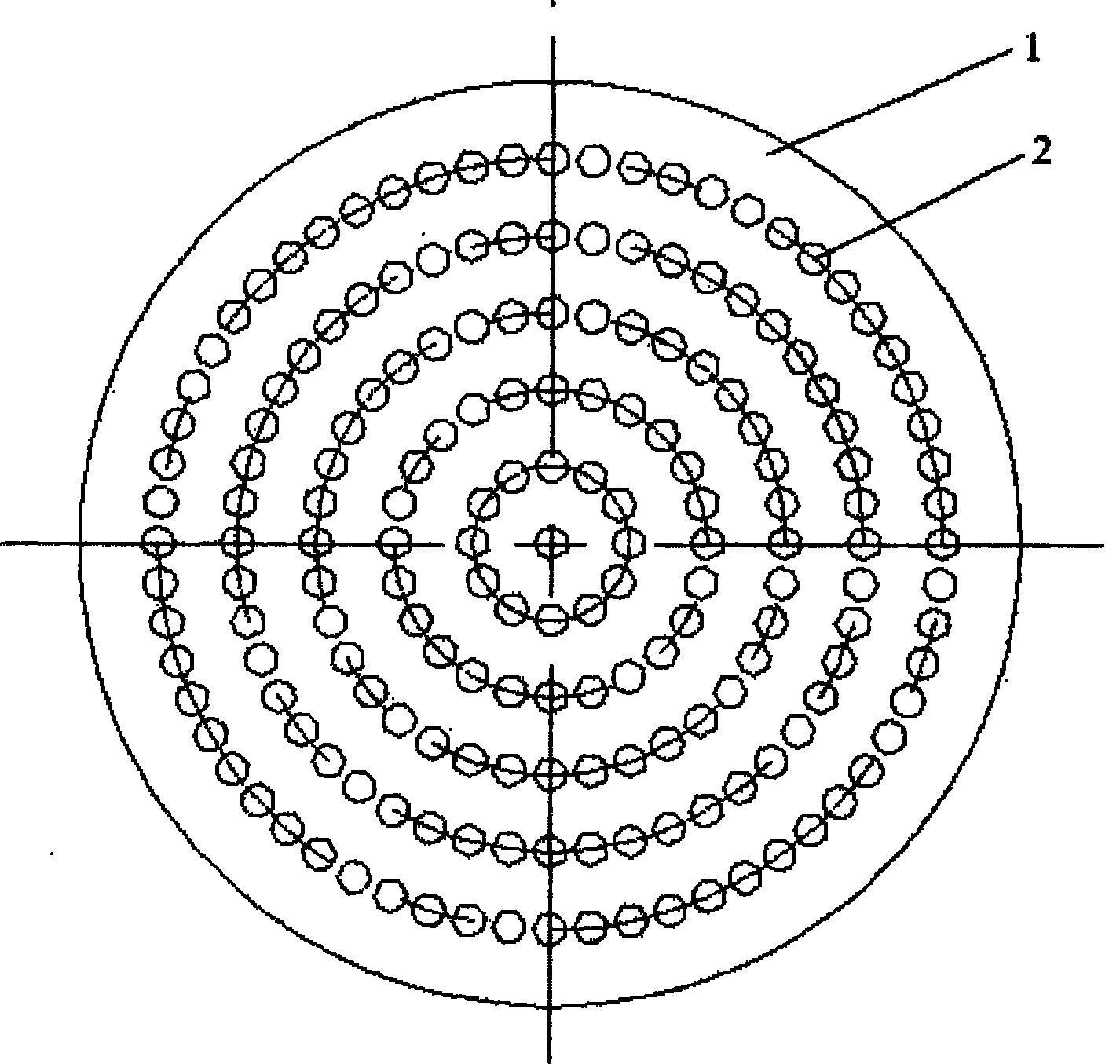

[0010] Such as figure 1 , figure 2 Shown is a circular graphite sieve plate comprising a graphite sieve plate body 1 on which are provided sieve holes 2 of equal diameter, said sieve holes 2 being circumferentially distributed on the sieve plate On the body 1, the circle formed by the sieve holes 2 forms five concentric circles.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a sieve plate made of graphite. The sieve plate comprises a sieve plate body, the sieve plate body is provided with sieve pores, the sieve pores are circumferentially distributed in the sieve plate body, and the circumferences formed by connecting the sieve pores form concentric circles. The sieve plate made of the graphite has the properties of high strength, temperature resistance, corrosion resistance, accurate fineness, pore blockage resistance and the like; meanwhile, the material adopted in the sieve plate has high abrasion resistance, and the screen is unloaded, so that the sieve plate has long service life, the frequency of changing the sieve surface is reduced, the production cost of an enterprise is reduced, and the production efficiency can be effectively improved.

Description

technical field [0001] The invention relates to chemical equipment, in particular to a graphite sieve plate. Background technique [0002] Graphite sieve plate is often used to screen out solid impurities from materials on the side of the equipment head. When the particle size of impurities is small, filter cloth can be added to the sieve plate. Another function of the sieve plate is to evenly distribute the material, so as to prevent the material from only passing through part of the channel of the equipment, resulting in incomplete utilization of the equipment and failing to meet the process requirements. At present, most of the sieve plates used for material screening are metal sieve plates. Due to the inherent defects of metal materials, these metal sieve plates have poor corrosion resistance and wear resistance, and their service life is short. In order to solve this problem, for example, the patent application No. 200920102045.4 relates to a wear-resistant rubber siev...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B07B1/46

Inventor 袁春梅

Owner NANTONG WULIAN BRAND PLANNING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com