Graphite filter plate

A filter plate and graphite technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of waste material, incomplete filtration, heavy filter screen load, etc., to reduce production cost, improve production efficiency, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

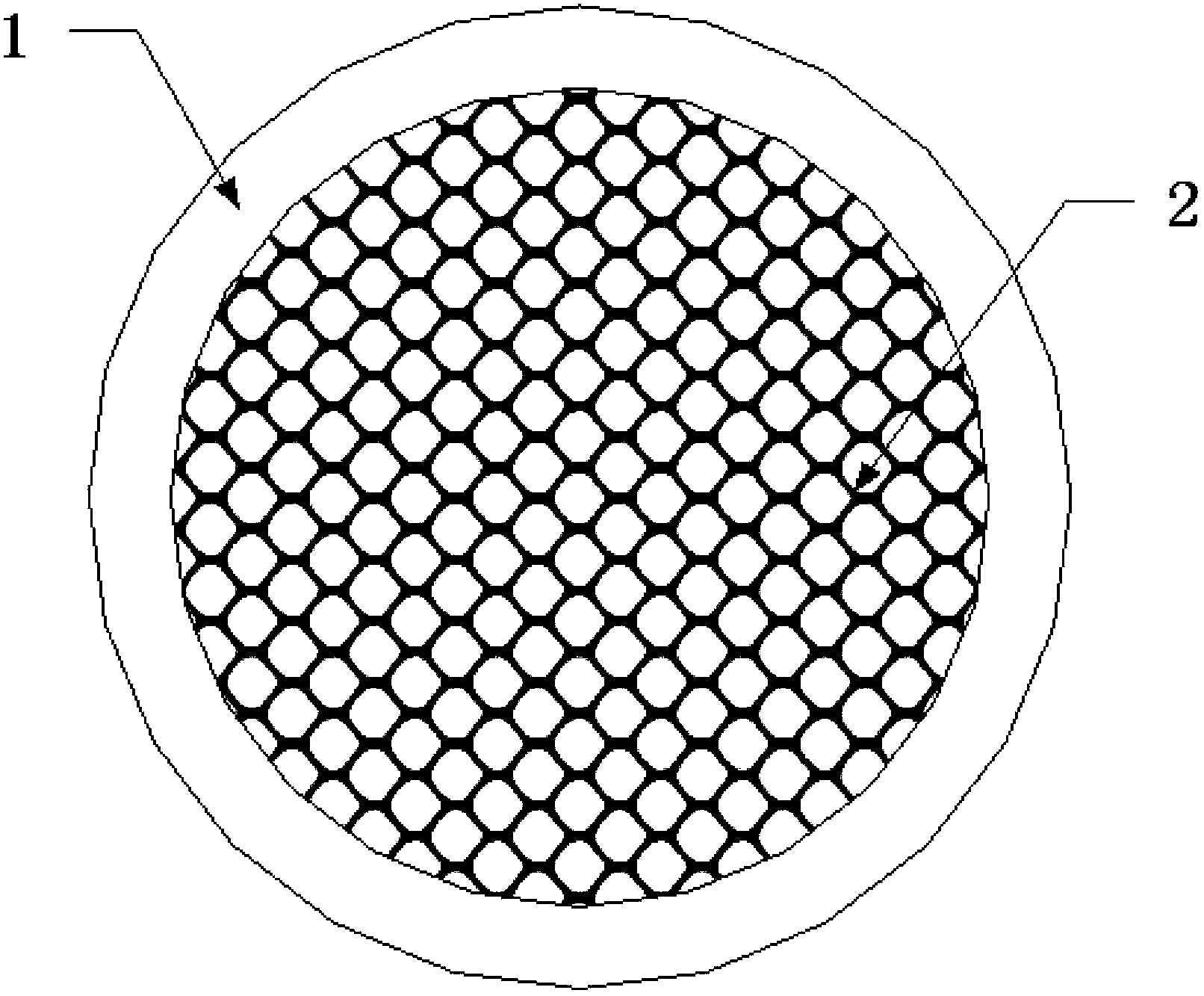

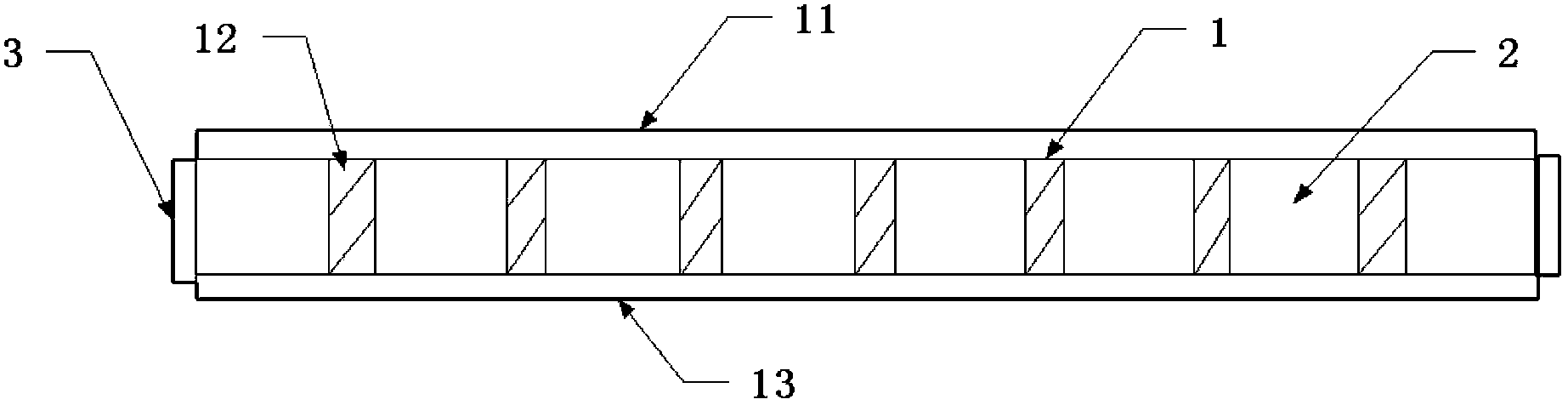

[0011] Such as figure 1 , figure 2 As shown, a graphite filter plate of the present invention comprises a filter plate body 1 and evenly arranged filter holes 2 arranged on the filter plate body 1, and the filter plate body 1 comprises an upper filter cloth 11, a middle graphite filter plate 12 And lower layer filter cloth 13, upper layer filter cloth 11 and lower layer filter cloth 13 are fixed on the middle layer graphite filter plate 12 by the fixed ring 3 that is arranged on the middle layer graphite filter plate 12 surroundings.

[0012] An embodiment of the present invention has been described in detail above, but the content described is only a preferred embodiment of the present invention, and cannot be considered as limiting the implementation scope of the present invention. All equivalent changes and improvements made according to the application scope of the present invention shall still belong to the scope covered by the patent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com