Self-cleaning sieve plate

A self-cleaning, sieve plate technology, applied in the direction of sieve, solid separation, grid, etc., can solve the problems of reduced screening efficiency, easy occurrence of paste holes, sticky materials, etc., to achieve good screening stability and improve screening. Effect, the effect of not easy to block holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

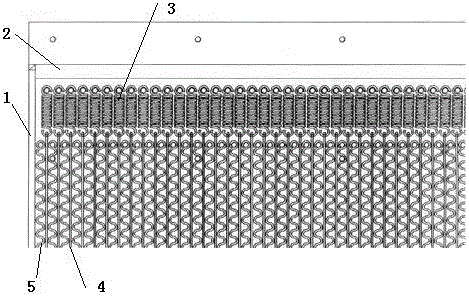

[0007] The embodiment is described in detail in conjunction with the accompanying drawings. The embodiment of the present invention is a self-cleaning sieve plate, which includes a sieve plate body 1, fixed frames 2 are arranged on both sides of the sieve plate body, and linear sieve bars are arranged on the sieve plate body 4 and wavy sieve bars 5, straight line sieve bars and wavy sieve bars are alternately arranged, and the two ends of the straight line sieve bars of the sieve bars are respectively connected with extension springs 3, and the extension springs are fixedly connected with the fixed frame.

[0008] When the present invention utilizes the vibration of the sieve plate body, secondary vibration will be generated to the straight line screen bar fixed by the tension spring. Wet and sticky materials get rid of the adhesion, which can ensure that the wet and sticky materials are not easy to block holes. This kind of sieve plate has a higher opening rate and is easier t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com