Double-template discharge device of puffing machine

A discharge device and double template technology, applied in feed, food forming, food science, etc., can solve the problems of slow peripheral flow, fast flow in the middle of the forming template, uneven product particle size, etc., to achieve uniform flow rate and increase production , good puffing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

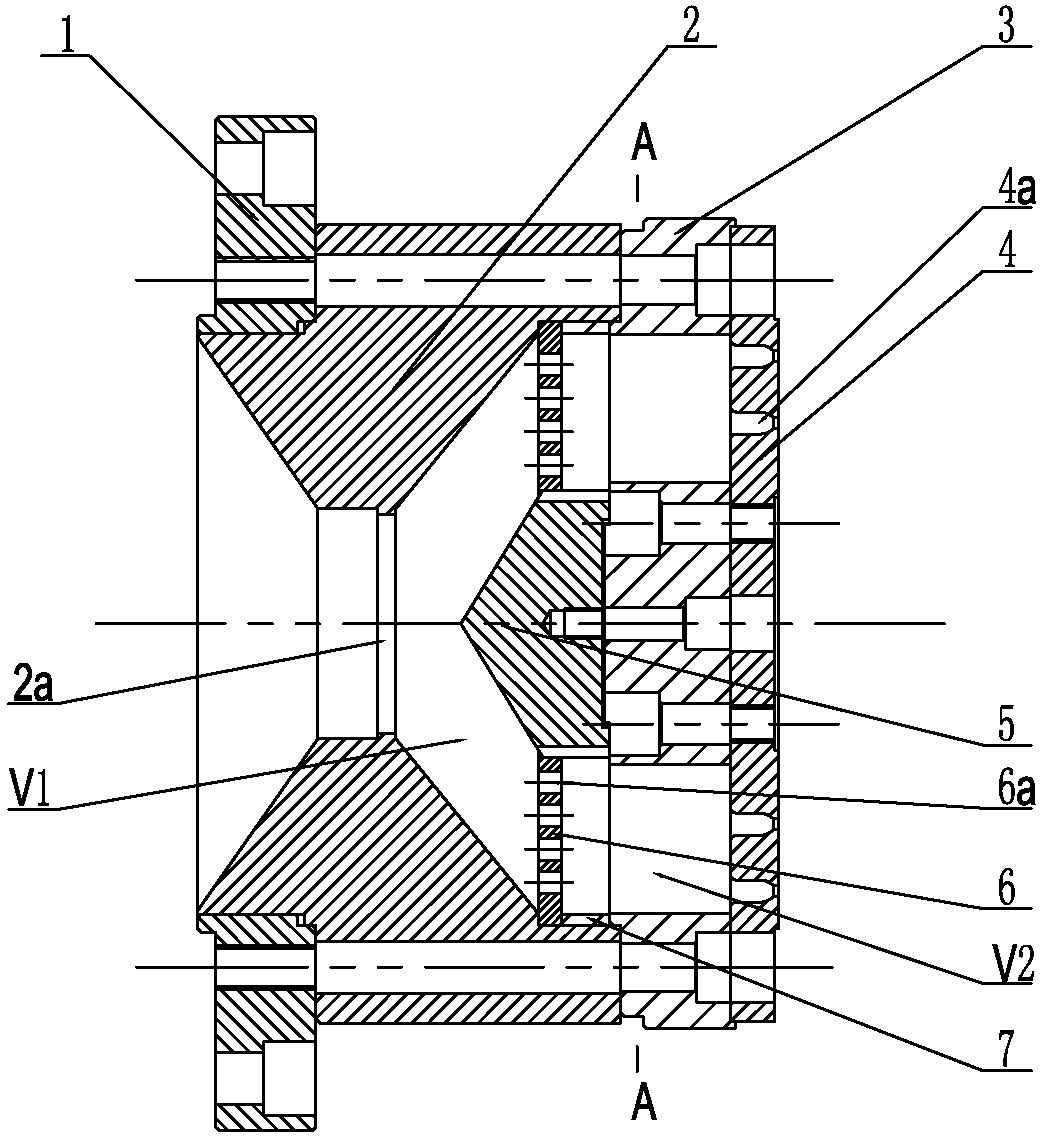

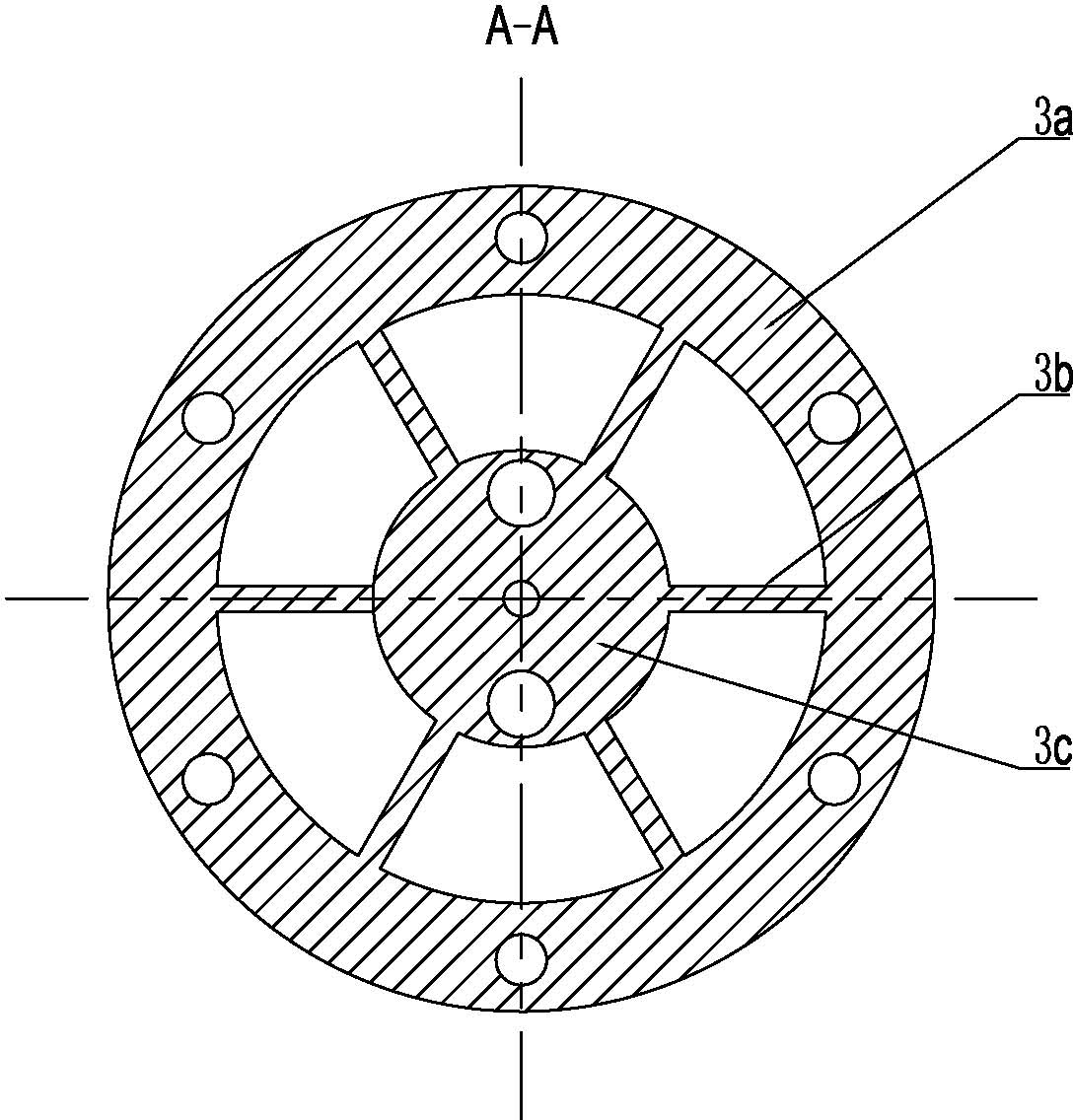

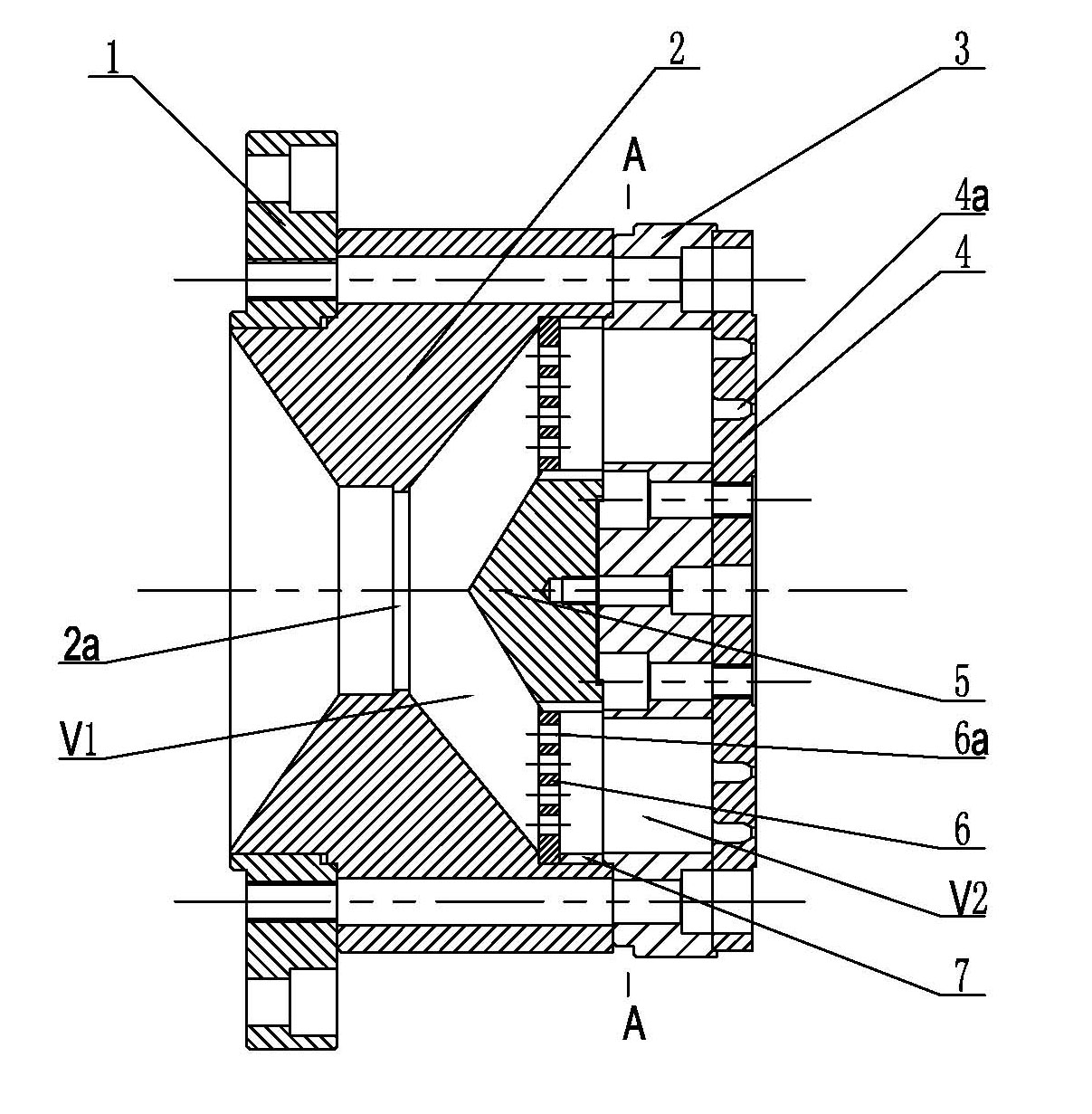

[0022] As shown in the figure, it is a double-platen discharge device for an extruder. Its structure mainly includes a fixed frame 1, a venturi 2, a diversion cone 5 and a forming plate 4. The forming plate 4 is provided with a number of die holes, and the fixed frame 1 Set on one side of Venturi 2, formwork frame 3 is arranged between Venturi 2 and forming template 4, diversion cone 5 is fixed on the center position of the side of Venturi 2 on the formwork frame 3, Venturi 2 and formwork frame 3 There is a pressure-regulating template 6 between them, and the center of the pressure-regulating template 6 is set on the root of the diversion cone 5. The pressure-regulating template 6 is provided with a number of flow holes 6a, and the flow holes 6a can be several round holes or other Form holes, such as tapered holes, strip holes, elliptical holes, fan-shaped holes, etc.; the sum of the flow areas of the flow holes 6a is greater than the sum of the flow areas of the die holes 4a; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com