Preparation method of high-density nickel-cobalt-manganese hydroxide

A hydroxide, nickel-cobalt-manganese technology, applied in nickel compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of inability to eliminate small and micro particles, high content of impurities in sodium and sulfur, poor morphology consistency, etc. The effect of slow crystallization, low sodium sulfur content and high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

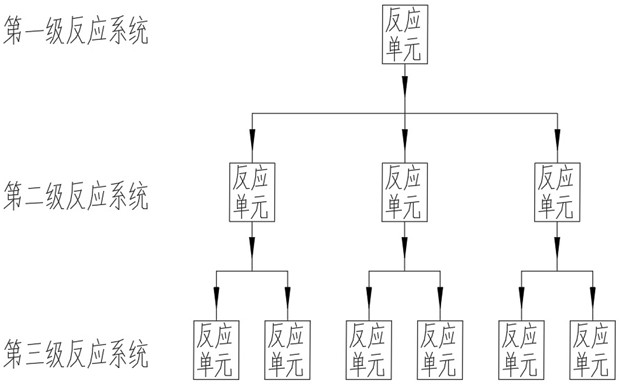

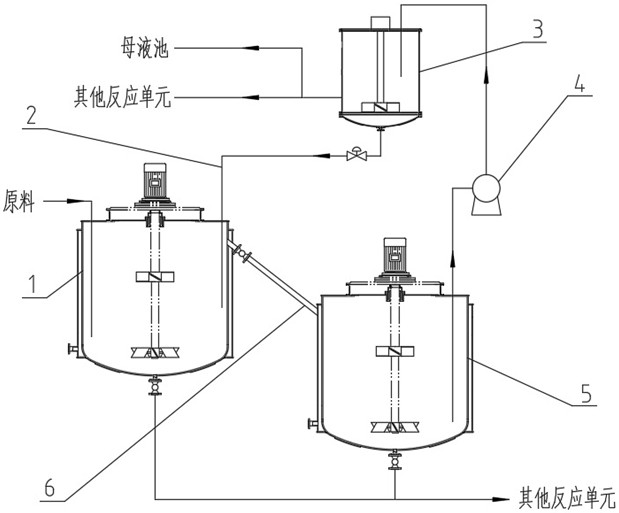

[0049] A method for preparing high-density nickel-cobalt-manganese hydroxide, including a three-stage reaction system, each reaction system includes one or more reaction units, and the number of reaction units in the third-stage reaction system is greater than that of the second-stage reaction The number of reaction units of the system, the number of reaction units of the second-level reaction system is greater than the number of reaction units of the first-level reaction system; each reaction unit includes successively connected reaction kettle 1, overflow pipe 6, intermediate Tank 5, diaphragm pump 4, concentrator 3, return pipe 2, the upper part of the reaction kettle is provided with an overflow port, which is connected to the middle tank through the overflow pipe, and the lower part of the concentrator has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com