Horizontal type extrusion casting machine

A squeeze casting machine and horizontal technology, applied in the field of squeeze casting machines, can solve problems such as high technical requirements for operators, difficult promotion of squeeze casting technology, and difficulty in squeeze casting advantages, and achieve mold clamping speed and The effect of small shaking and fast clamping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

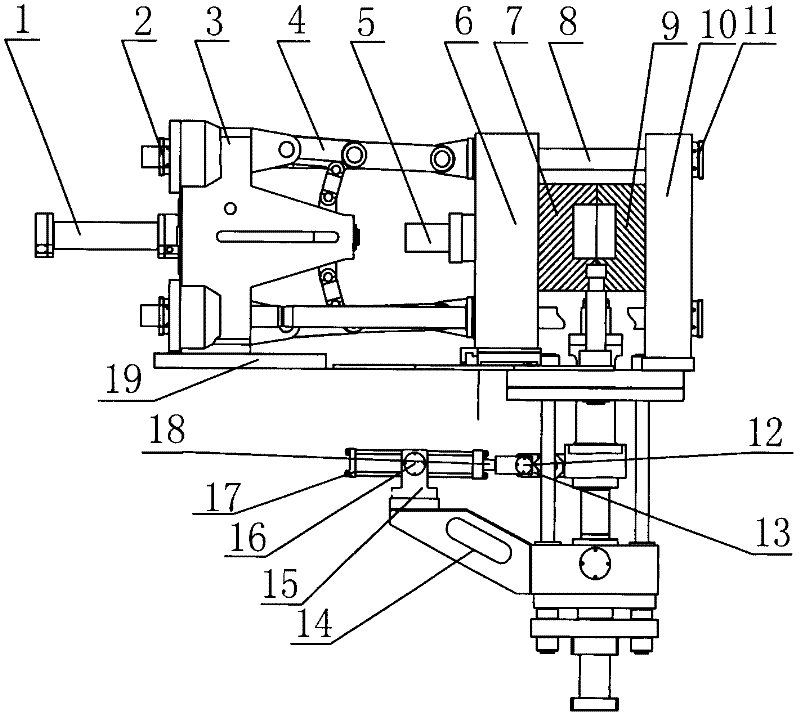

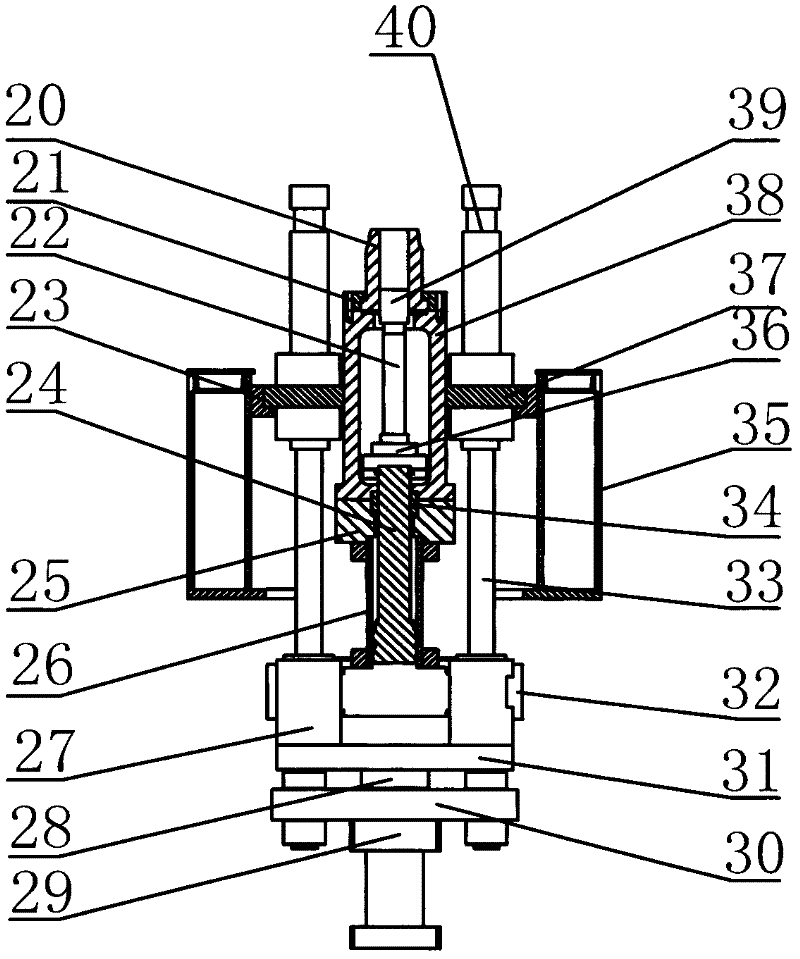

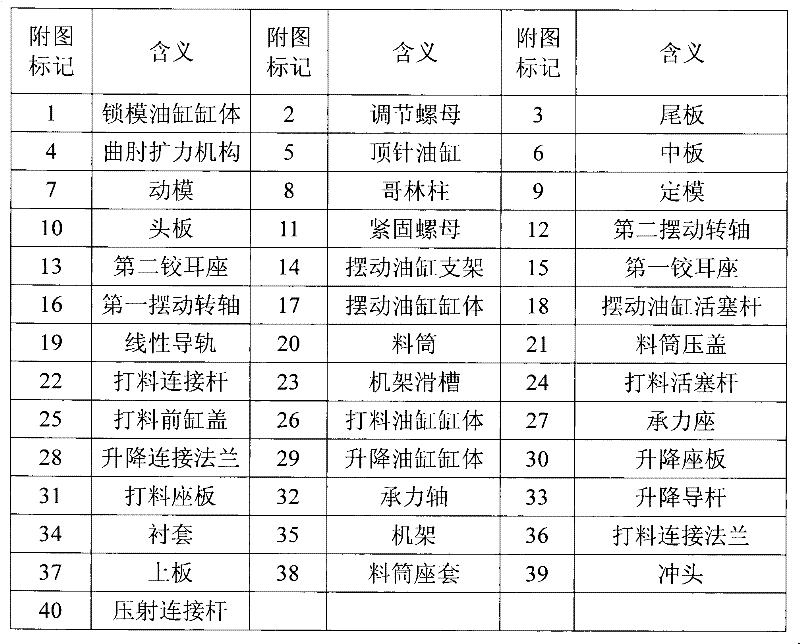

[0015] Such as figure 1 , figure 2 As shown, a horizontal squeeze casting machine includes a frame 35, and the upper end of the frame 35 is horizontally provided with a parallel head plate 10, a middle plate 6 and a tail plate 3, and the head plate 10, the middle plate 6 and the tail plate 3 are respectively It is penetrated by the Corinthian column 8, the toggle expansion mechanism 4 is set between the middle plate 6 and the tail plate 3, the mold locking cylinder 1 is set on the side of the tail plate 3, and the mold locking cylinder in the mold locking cylinder 1 The piston rod is connected with the toggle mechanism 4, the lower end of the tail plate 3 is provided with a linear guide rail 19, the inner wall of the middle plate 6 is provided with a movable die 7, the outer wall of the middle plate 6 is provided with a thimble cylinder 5, and the inner wall of the head plate 10 directly opposite the movable die 7 Fixed mold 9 is provided, and frame 35 is provided with frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com